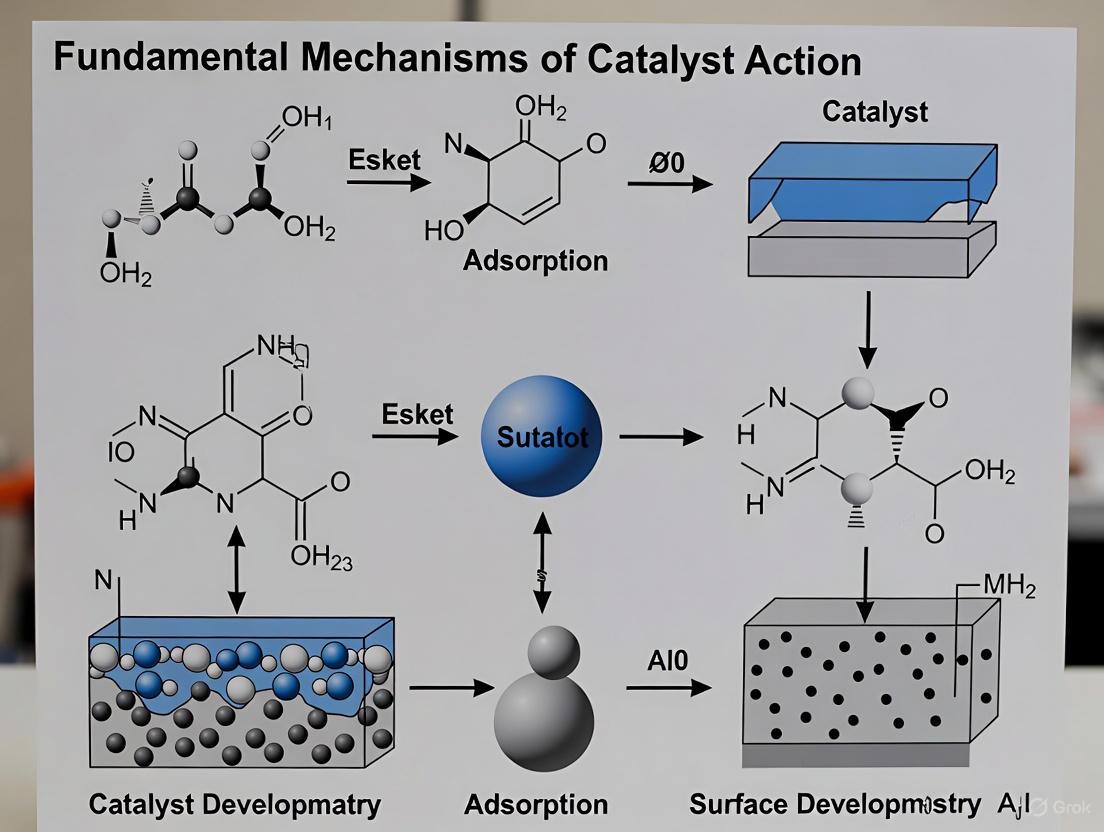

Fundamental Mechanisms of Catalyst Action and Adsorption: From Molecular Principles to Biomedical Applications

This article provides a comprehensive examination of the fundamental mechanisms governing catalyst action and adsorption processes, tailored for researchers and drug development professionals.

Fundamental Mechanisms of Catalyst Action and Adsorption: From Molecular Principles to Biomedical Applications

Abstract

This article provides a comprehensive examination of the fundamental mechanisms governing catalyst action and adsorption processes, tailored for researchers and drug development professionals. It explores the core principles of surface interactions, including key mechanisms like Langmuir-Hinshelwood and Eley-Rideal, and investigates the structure-activity relationships in diverse catalytic systems from single-atom catalysts to metal-organic frameworks. The content delves into advanced methodological approaches for studying adsorption and activation, discusses strategic optimization to combat catalyst deactivation, and presents rigorous validation through computational and comparative performance analyses. By synthesizing foundational knowledge with cutting-edge applications, this review aims to bridge theoretical understanding with practical implementation in biomedical and clinical research, offering insights for developing next-generation catalytic solutions in drug development and therapeutic applications.

Core Principles of Catalytic Action and Adsorption Mechanisms

The design of efficient catalytic processes hinges on a fundamental understanding of how reactions proceed at the molecular level on solid surfaces. Among the classical frameworks explaining these pathways, three mechanisms are paramount: Langmuir-Hinshelwood (L-H), Eley-Rideal (E-R), and Mars-van Krevelen (MvK). These models describe the sequence of elementary steps—including adsorption, surface reaction, and desorption—that lead from reactants to products. The precise mechanism governing a reaction influences kinetic models, catalyst selection, and operational conditions. This guide provides an in-depth technical examination of these core pathways, framed within modern catalytic research and development. It details their theoretical foundations, kinetic formulations, methodologies for experimental discrimination, and their application in contemporary chemical processes, providing researchers with a comprehensive resource for understanding catalyst action and adsorption research.

Theoretical Foundations and Kinetic Models

Langmuir-Hinshelwood (L-H) Mechanism

The Langmuir-Hinshelwood mechanism proposes that a catalytic reaction occurs between two or more reactants that are both chemisorbed on the catalyst surface. The reaction proceeds through the formation of a surface intermediate, and the defining characteristic is that the surface reaction between adjacent adsorbed species is the rate-determining step.

- Elementary Steps: The mechanism involves multiple steps:

- Adsorption of reactant A onto an active site : A + * ⇌ A

- Adsorption of reactant B onto a separate active site: B + * ⇌ B

- Surface reaction between the adsorbed species: A + B* → AB

- Desorption of the product: AB → AB + *

Kinetic Formulation: The rate expression is derived by assuming that the surface reaction (step 3) is the slow, rate-determining step, while the adsorption and desorption steps are in equilibrium. For a bimolecular reaction A + B → C on a surface with a fixed number of sites, the rate equation is often expressed as:

$$ r = k \thetaA \thetaB $$

where $\thetaA$ and $\thetaB$ are the fractional surface coverages of A and B, given by the Langmuir isotherm. For instance, if A and B adsorb on the same sites without dissociation and compete for adsorption, $\thetaA = \frac{KA PA}{1 + KA PA + KB PB}$ and $\thetaB = \frac{KB PB}{1 + KA PA + KB PB}$. This leads to the common rate law:

$$ r = \frac{k KA KB PA PB}{(1 + KA PA + KB PB)^2} $$

Characteristics and Requirements: A key requirement for the L-H mechanism is that the reactants must have sufficient surface mobility to encounter each other, or the sites must be adjacent. The rate often exhibits a maximum as a function of reactant partial pressure, as high coverages of one reactant can block the adsorption of the other (competitive adsorption).

Eley-Rideal (E-R) Mechanism

In contrast to the L-H mechanism, the Eley-Rideal mechanism involves a reaction between a chemisorbed reactant and another species that is in the gas phase or only physisorbed.

- Elementary Steps: The process is typically simpler:

- Adsorption of reactant A onto an active site: A + * ⇌ A

- Reaction of the adsorbed A with a gas-phase molecule B: A* + B(g) → AB

- Desorption of the product: AB → AB + *

Kinetic Formulation: Assuming the surface reaction (step 2) is the rate-determining step and the adsorption of A is in equilibrium, the rate is proportional to the surface coverage of A and the partial pressure (or concentration) of B in the gas phase.

$$ r = k \thetaA PB $$

Substituting the Langmuir isotherm for $\theta_A$ yields:

$$ r = \frac{k KA PA PB}{1 + KA P_A} $$

Characteristics and Applications: This mechanism is less common than L-H but is invoked in specific systems. A prominent example is the heterogeneous catalytic carbamate formation in CO₂ absorption with primary and secondary amines, where an amine molecule adsorbed on a solid alkaline carbonate surface reacts with gaseous CO₂ [1]. Other applications include mercury oxidation in flue gas, where adsorbed HCl or NOx species react with gaseous Hg⁰ [2], and certain cases of CO oxidation and NH₃-SCR reactions [2].

Mars-van Krevelen (MvK) Mechanism

The Mars-van Krevelen mechanism is distinct in that the catalyst itself, typically a metal oxide, is directly involved as a reactant by providing its lattice oxygen. The catalyst is consumed and then regenerated in a redox cycle.

Elementary Steps: The mechanism is characterized by two main steps:

Reduction Half-Cycle: A reactant molecule reacts with lattice oxygen ($O_{latt}$), incorporating it into the product and creating an oxygen vacancy ($\square$) on the catalyst surface.

$$ \text{Rad} + O_{latt} \rightarrow \text{RO} + \square $$

Oxidation Half-Cycle: The oxygen vacancy is subsequently replenished by an oxidant (typically O₂) from the gas phase, restoring the catalyst.

$$ \frac{1}{2} O2 + \square \rightarrow O{latt} $$

Kinetic Formulation: The overall rate depends on the kinetics of both the reduction and oxidation steps. A key feature is that the reaction rate can be limited by either step, depending on the conditions. The catalyst's oxidation state and vacancy concentration are dynamic and reach a steady state under reaction conditions [3].

- Characteristics and Applications: This mechanism is fundamental for oxidation reactions on reducible oxide catalysts. A classic example is CO oxidation on Au/TiO₂ at temperatures above 80°C, which proceeds via a Au-assisted MvK mechanism where CO adsorbed on Au nanoparticles reacts with lattice oxygen from the TiO₂ support at the perimeter interface [3]. Other examples include selective oxidations, such as the oxidation of SO₂ to SO₃ on V₂O₅ catalysts.

Table 1: Comparative Summary of Fundamental Adsorption Mechanisms

| Feature | Langmuir-Hinshelwood (L-H) | Eley-Rideal (E-R) | Mars-van Krevelen (MvK) |

|---|---|---|---|

| Core Principle | Reaction between adsorbed species | Reaction between an adsorbed species and a gas-phase species | Catalyst lattice oxygen participates in the reaction |

| Rate-Determining Step | Surface reaction between adjacently adsorbed species | Surface reaction between adsorbed and gaseous species | Either the reduction or oxidation half-cycle |

| Key Requirement | Sufficient surface mobility/coverage of both reactants | One reactant must be strongly chemisorbed | Redox-active catalyst (e.g., metal oxide) |

| Typical Rate Expression | $r = \frac{k KA KB PA PB}{(1 + KA PA + KB PB)^2}$ | $r = \frac{k KA PA PB}{1 + KA P_A}$ | Complex; depends on the kinetics of reduction/oxidation |

| Example Applications | NH₃-SCR on metal-zeolites [2] | Hg⁰ oxidation by adsorbed HCl [2], Carbamate formation with MCO₃ [1] | CO oxidation on Au/TiO₂ [3], oxidation reactions on V₂O₅ |

Experimental Discrimination and Methodologies

Distinguishing which mechanism operates under given reaction conditions is a central challenge in catalysis research. A combination of kinetic measurements, isotopic labeling, and in-situ spectroscopic techniques is typically employed.

Kinetic Analysis

The first line of evidence often comes from analyzing the reaction order with respect to the reactants.

- For an L-H mechanism, the rate often shows a maximum as a function of reactant pressure due to competitive adsorption. If one reactant's pressure is held constant, the rate with respect to the other may first increase and then decrease.

- For an E-R mechanism, the rate is typically first-order with respect to the gas-phase reactant (B) and shows a Langmuirian dependence (saturation) on the adsorbed reactant (A).

- For an MvK mechanism, the reaction order in the oxidant (e.g., O₂) can provide clues. If the oxidation of the catalyst is the slow step, the rate may depend on O₂ pressure. Transient pulse experiments, like those performed in a Temporal Analysis of Products (TAP) reactor, can directly quantify the number of active lattice oxygen atoms and surface vacancies under steady-state conditions [3].

In-Situ Spectroscopic Techniques

Kinetics alone can be ambiguous, so direct observation of surface species is crucial.

- In-Situ DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy): This technique is used to identify adsorbed intermediates and monitor their behavior during reaction. For instance, in the NH₃-SCR reaction over Cu/SSZ-13 zeolites, pre-adsorbed NH₃ is observed to react with gas-phase NO, supporting an E-R pathway at certain temperatures [2]. Conversely, the simultaneous presence and reaction of adsorbed NO and NH₃ species would suggest an L-H mechanism.

- Isotopic Labeling Experiments: These are powerful for tracing the path of atoms. In a classic MvK experiment, the catalyst is first reacted with $^{18}$O₂ to label the lattice oxygen. When the reaction is then carried with $^{16}$O₂, the appearance of $^{18}$O in the product confirms that lattice oxygen is involved, which is a hallmark of the MvK mechanism.

Transient Reaction Studies

Probing the catalyst's response to sudden changes in the gas composition can reveal mechanistic details.

- Pre-adsorption/Scavenging Experiments: To test for an E-R mechanism, the catalyst can be pre-saturated with one reactant (A), and then the other reactant (B) is introduced in the gas phase. If the reaction proceeds immediately to form product, it supports the E-R model. Conversely, if both need to be co-adsorbed, an L-H mechanism is more likely.

- TAP Reactor Experiments: As used in studies of CO oxidation on Au/TiO₂, TAP reactors can inject small, precise pulses of reactants. This allows for the quantification of surface oxygen vacancies and the determination that the reaction proceeds via a Au-assisted MvK mechanism under specific conditions [3].

Advanced Research and Emerging Paradigms

The classical mechanisms remain foundational, but modern research has revealed greater complexity and introduced new concepts.

Dynamic and Cooperative Effects

The traditional view of static active sites is evolving. Under reaction conditions, catalyst surfaces can be dynamic.

- Dynamic Single-Atom Mechanisms: For example, a dynamic MvK mechanism has been proposed for CO oxidation on Au/TiO₂, where a Au-CO species detaches from a cluster, reacts with lattice oxygen, and then returns [3].

- Concerted Elementary Steps: Recent research on the oxygen evolution reaction (OER) over iridium dioxide suggests a "Walden-like mechanism," where water adsorption and oxygen desorption occur in a single, concerted step, blurring the lines between sequential steps in homogeneous and heterogeneous catalysis [4].

- Integrative Catalytic Pairs (ICPs): In complex reactions involving multiple intermediates, single, uniform active sites can be limiting. The concept of ICPs—featuring spatially adjacent, electronically coupled dual active sites that function cooperatively yet independently—has been proposed to enable concerted reactions, enhancing activity and selectivity [5].

The Role of Computational and Machine Learning Approaches

First-principles calculations and machine learning (ML) are becoming indispensable for elucidating mechanisms.

- Density Functional Theory (DFT): DFT calculations can model adsorption energies, reaction barriers, and identify stable intermediates, providing atomic-scale insights that are difficult to obtain experimentally.

- Machine Learning: ML is now used to overcome the limitations of traditional trial-and-error methods. It can analyze complex datasets to uncover hidden structure-property relationships, predict catalytic activity, and even guide the discovery of new catalytic materials [6]. Generative models, in particular, are emerging as powerful tools for the inverse design of catalyst surfaces and the efficient sampling of adsorption geometries [7].

Table 2: The Scientist's Toolkit: Key Reagents and Materials for Mechanistic Studies

| Reagent/Material | Function in Mechanistic Studies | Example Use Case |

|---|---|---|

| Isotopically Labeled Gases (e.g., $^{18}$O₂, $^{13}$CO) | To trace the origin of atoms in the product and identify the participation of lattice oxygen. | Proving MvK mechanism by detecting labeled oxygen in the oxidation product. |

| Probe Molecules (e.g., CO, NO, NH₃) | Used in in-situ spectroscopy to identify and quantify specific types of surface active sites (e.g., Lewis vs. Brønsted acid sites). | Pre-adsorbing NH₃ in DRIFTS to study its reaction with gaseous NO in SCR. |

| TAP Reactor System | Allows transient pulse experiments to quantify surface intermediates and vacancies with high temporal resolution. | Measuring steady-state concentration of oxygen vacancies on Au/TiO₂ during CO oxidation [3]. |

| Solid Alkaline Carbonates (e.g., CaCO₃, MgCO₃) | Act as heterogeneous catalysts for carbamate formation, providing a surface for amine adsorption. | Studying the E-R mechanism of CO₂ absorption with monoethanolamine (MEA) [1]. |

| Reducible Oxide Supports (e.g., TiO₂, CeO₂) | Provide a source of lattice oxygen for reactions proceeding via the MvK mechanism. | Serving as the support in Au/TiO₂ catalysts for low-temperature CO oxidation [3]. |

The Langmuir-Hinshelwood, Eley-Rideal, and Mars-van Krevelen mechanisms form the cornerstone of our understanding of heterogeneous catalysis. While the L-H mechanism, with its requirement for surface migration and reaction of adsorbed species, is the most prevalent, the E-R and MvK pathways are critically important in specific, technologically relevant reactions. Discriminating between these mechanisms requires a multi-faceted experimental approach, combining kinetic analysis with advanced spectroscopic and transient techniques. As catalysis science advances, it is clear that these classical models are not rigid but are adapting to encompass dynamic catalyst behavior, concerted reaction steps, and the cooperative action of multiple active sites. Furthermore, the integration of machine learning and powerful computational methods is accelerating the discovery of new catalysts and providing deeper, more nuanced insights into the fundamental mechanisms of catalyst action that remain a vibrant and essential field of research.

Single-atom catalysts (SACs) represent a transformative class of catalytic materials characterized by isolated metal atoms anchored to a solid support, creating highly uniform active sites with maximum atom utilization efficiency. The catalytic performance of SACs is predominantly governed by their precise coordination environment, which includes the identity, number, and spatial arrangement of atoms directly bonded to the central metal atom. Engineering this environment allows for precise manipulation of the electronic structure and geometric properties of the active site, enabling unprecedented control over activity, selectivity, and stability. This whitepaper examines the fundamental role of coordination engineering in SACs, framing it within the broader context of catalyst action mechanisms and adsorption research, which are pivotal for advancing sustainable energy technologies and chemical processes.

Fundamentals of Coordination Environments in SACs

The coordination environment of a single-atom catalyst consists of the central metal atom and its surrounding ligands, which typically include atoms from the support material such as nitrogen, oxygen, or sulfur. This structure mirrors the active sites found in metalloenzymes, where the local electronic structure dictates the catalyst's interaction with reactant molecules.

- Electronic Structure Modulation: The primary function of the coordination environment is to modulate the d-band electronic structure of the central metal atom. Incorporation of heteroatoms (e.g., S, B, P) into the coordination sphere can significantly alter the density of states near the Fermi level, thereby influencing the binding energy of adsorbates and reducing reaction overpotentials in key processes like the oxygen reduction reaction (ORR) [8].

- Geometric Effects: The coordination number and spatial arrangement of ligands create distinct geometric constraints that affect transition state stability and reaction pathways. For instance, square-planar Pt(II) sites, commonly stabilized in nitrogen-doped carbons, exhibit distinct reactivity profiles compared to tetrahedral or octahedral configurations [9].

- Metal-Support Interactions: The strength and nature of the bond between the metal atom and support material are crucial for stabilizing single atoms against aggregation. Strong covalent bonding with heteroatom-doped carbon supports (e.g., N-doped carbon) has proven particularly effective in creating thermally stable SACs with well-defined coordination structures [10].

Characterization Techniques for Coordination Environments

Resolving the precise structure of coordination environments requires advanced characterization techniques capable of probing atomic-scale structure and electronic properties.

Spectroscopic Methods

- Solid-State Nuclear Magnetic Resonance (NMR): Recent breakthroughs in ¹⁹⁵Pt ultra-wideline NMR spectroscopy have enabled detailed characterization of Pt SACs with molecular precision. The technique measures the chemical shift tensor parameters (δᵢₛₒ, Ω, κ), which serve as sensitive reporters of the Pt oxidation state, coordination geometry, and ligand identity. The span (Ω = δ₁₁ - δ₃₃) and skew (κ) parameters are particularly diagnostic for distinguishing between square-planar, tetrahedral, and octahedral coordination geometries [9].

- X-ray Absorption Spectroscopy (XAS): This includes both X-ray Absorption Near Edge Structure (XANES) and Extended X-ray Absorption Fine Structure (EXAFS). XANES provides information on oxidation states and electronic configuration, while EXAFS yields quantitative data on coordination numbers, bond lengths, and the identity of neighboring atoms [10].

- X-ray Photoelectron Spectroscopy (XPS): This technique offers insights into the elemental composition, chemical states, and electronic interactions between metal atoms and their support materials. High-resolution scans can identify specific metal-nitrogen bonding configurations in M-N-C catalysts [9].

Microscopic and Computational Approaches

- High-Angle Annular Dark-Field Scanning Transmission Electron Microscopy (HAADF-STEM): This technique directly visualizes the atomic dispersion of metal atoms on supports, confirming the single-atom nature, but provides limited information about the coordination chemistry [9].

- Density Functional Theory (DFT) Calculations: Computational modeling serves as a powerful complement to experimental techniques, allowing researchers to predict optimal coordination structures, simulate spectroscopic signatures, and establish structure-activity relationships through calculation of reaction pathways and adsorption energies [8] [10].

- Operando Techniques: The integration of multiple characterization methods (e.g., XAS, NMR) under actual reaction conditions provides unprecedented insights into the dynamic evolution of coordination environments during catalysis, revealing transient species and restructuring phenomena [8].

Table 1: Key Characterization Techniques for Coordination Environments in SACs

| Technique | Information Obtained | Applications in SACs |

|---|---|---|

| ¹⁹⁵Pt NMR Spectroscopy | Chemical shift tensor parameters (δᵢₛₒ, Ω, κ), oxidation state, coordination geometry, site homogeneity | Quantitative assessment of Pt site distribution, monitoring changes during synthesis and reaction [9] |

| X-ray Absorption Spectroscopy (XAS) | Oxidation state, coordination number, bond lengths, identity of neighboring atoms | Determining M-N coordination numbers in M-N-C catalysts, monitoring electronic structure [9] [10] |

| HAADF-STEM | Atomic dispersion, metal loading, distribution on support | Confirming single-atom dispersion, estimating surface atom density [9] |

| Density Functional Theory (DFT) | Optimized coordination structures, adsorption energies, reaction pathways, spectroscopic predictions | Predicting catalytic activity, guiding rational design, interpreting experimental spectra [8] [10] |

Synthesis Strategies for Engineering Coordination Environments

Precise control over coordination environments requires sophisticated synthesis techniques that can create well-defined atomic structures while preventing metal aggregation.

Wet-Chemical Methods

- Co-precipitation and Impregnation: Traditional approaches involving the deposition of metal precursors onto pre-formed supports, often followed by thermal treatment to establish strong metal-support bonds. The coordination environment is primarily determined by the surface functionality of the support [10].

- Two-Dimensional Confinement Strategy: A sophisticated approach where metal atoms are trapped within layered support materials or at specific surface sites, creating uniform coordination environments. This method has been successfully employed to create Ru₁Coₙ single-atom alloy catalysts with exceptional selectivity in Fischer-Tropsch synthesis [10].

Advanced Deposition and Pyrolysis Techniques

- Atomic Layer Deposition (ALD): This technique enables layer-by-layer deposition of metal precursors with atomic-level precision, allowing for controlled formation of coordination sites with tailored composition and structure [11].

- High-Temperature Pyrolysis: Thermal treatment of metal-organic precursors (e.g., metal phthalocyanines, porphyrins, or metal-organic frameworks) creates M-N-C sites with controlled coordination numbers. The pyrolysis temperature, atmosphere, and heating rate critically influence the resulting coordination environment [10].

- Anion and Cation Co-diffusion Method: A novel approach for creating heteroatom-coordinated SACs, as demonstrated in the synthesis of N and S co-coordinated Bi single-atom catalysts (Bi-SAs-NS/C). In this method, precursors simultaneously diffuse into a polymer matrix and are captured by coordination sites during thermal treatment [10].

Table 2: Synthesis Methods for Engineering Coordination Environments in SACs

| Synthesis Method | Key Features | Resulting Coordination Structures |

|---|---|---|

| Impregnation & Pyrolysis | Simple, scalable, uses pre-formed supports | M-Nₓ sites on N-doped carbon, coordination number depends on support functionality [10] |

| Atomic Layer Deposition (ALD) | Atomic-level precision, controlled layer-by-layer growth | Tailored coordination spheres with defined composition [11] |

| Two-Dimensional Confinement | Traps metal atoms at specific surface sites | Uniform single-atom alloys (e.g., Ru₁Coₙ) [10] |

| Anion/Cation Co-diffusion | Creates heteroatom-coordinated sites through simultaneous diffusion | Mixed coordination environments (e.g., Bi-N₃S) [10] |

| MOF-Derived Synthesis | Uses metal-organic frameworks as precursors/sacrificial templates | Well-defined M-N₄ sites in carbon matrices [10] |

Experimental Protocols for SAC Synthesis and Characterization

Protocol: Synthesis of Pt@NC Single-Atom Catalysts via Impregnation-Pyrolysis

Materials: Chloroplatinic acid (H₂PtCl₆) or alternative Pt precursors, nitrogen-rich carbon support (e.g., ZIF-8 derived N-doped carbon), inert gas (Ar/N₂)

Procedure:

- Support Preparation: Activate the N-doped carbon support at 150°C under vacuum for 12 hours to remove adsorbed contaminants.

- Wet Impregnation: Dissolve H₂PtCl₆ in deionized water (1 mg/mL) and slowly add to the carbon support (target loading: 1-5 wt%) with continuous stirring.

- Drying: Evaporate the solvent at 80°C with constant stirring, followed by complete drying at 100°C for 12 hours in a vacuum oven.

- First Annealing: Heat the material to 200°C (ramp rate: 5°C/min) under inert atmosphere and hold for 2 hours to partially decompose the precursor.

- Second Annealing: Further heat to 550°C (ramp rate: 3°C/min) and maintain for 3 hours to establish stable Pt-N coordination bonds.

- Cooling and Passivation: Slowly cool to room temperature under inert gas and optionally passivate with 1% O₂ in N₂ for 30 minutes [9].

Protocol: ¹⁹⁵Pt Solid-State NMR Characterization of Pt SACs

Equipment: Solid-state NMR spectrometer capable of ultra-wideline measurements, low-temperature MAS probe, 195Pt reference compounds (K₂PtCl₄, cis-Ptpy₂Cl₂)

Procedure:

- Sample Preparation: Pack approximately 50-100 mg of Pt@NC catalyst into a 3.2 mm zirconia MAS rotor under inert atmosphere.

- Static NMR Acquisition: Acquire wide spectra using frequency-stepped acquisition methods with 90° pulses and relaxation delays optimized for 195Pt (typically 0.2-1.0 s).

- MAS NMR Acquisition: Perform complementary measurements under MAS conditions (10-50 kHz) to assess site homogeneity.

- Data Processing: Process spectra with appropriate apodization functions and analyze using Monte Carlo simulations to extract CS tensor parameters (⟨δᵢₛₒ⟩, ⟨Ω⟩, ⟨κ⟩).

- Spectral Interpretation: Compare experimental patterns with molecular references (K₂PtCl₄, cis-Ptpy₂Cl₂) to identify predominant coordination geometries [9].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents for SAC Development

| Reagent/Material | Function | Application Examples |

|---|---|---|

| Metal Precursors (Chloroplatinic acid, Metal phthalocyanines) | Source of catalytically active metal atoms | H₂PtCl₆ for Pt SACs, FeCl₃ for Fe SACs, Metal-organic complexes for M-N-C catalysts [9] [10] |

| Nitrogen-Doped Carbon Supports (ZIF-8 derived carbon, N-rich polymers) | Stabilize single metal atoms through M-N coordination | Pyridinic N sites anchor Pt atoms, Graphitic N modifies electronic structure [9] [10] |

| Heteroatom Dopants (Thiourea, Boron trifluoride, Phosphoric acid) | Modify coordination environment and electronic structure | S-doping creates M-N₃S sites, B-doping alters d-band center [8] [10] |

| Molecular References (K₂PtCl₄, cis-Ptpy₂Cl₂) | Benchmark compounds for spectroscopic characterization | Provide reference ¹⁹⁵Pt NMR patterns for specific coordination geometries [9] |

| MOF Templates (ZIF-8, ZIF-67, UIO-66) | Sacrificial templates for creating porous supports with defined coordination sites | Pyrolysis creates uniform M-N₄ sites in hierarchical carbon structures [10] |

Applications in Catalytic Reactions and Energy Technologies

Engineering coordination environments in SACs has demonstrated remarkable improvements across various catalytic applications, particularly in sustainable energy technologies.

- Oxygen Reduction Reaction (ORR): M-N-C SACs with optimized first and higher coordination spheres significantly enhance the selectivity and efficiency of the 4-electron ORR pathway, which is crucial for fuel cells and metal-air batteries. Coordination engineering reduces overpotential and improves durability in acidic media [8] [11].

- Carbon Dioxide Reduction Reaction (CO₂RR): Precisely tuned coordination environments enable high selectivity toward specific products. For instance, Bi-SAs-NS/C catalysts with Bi-N₃S sites demonstrate exceptional performance in CO₂-to-formate conversion due to optimized adsorption of key intermediates [10].

- Thermocatalytic Reactions: SACs with engineered coordination environments exhibit superior performance in industrial processes such as Fischer-Tropsch synthesis. The Ru₁Coₙ single-atom alloy catalyst shows enhanced C–C coupling selectivity and reduced energy barriers for rate-determining steps [10].

- Environmental Catalysis: Copper single-atom catalysts on C₃N₄ (Cu-C₃N₄) effectively activate H₂O₂ to generate hydroxyl radicals for wastewater treatment, demonstrating the potential of SACs in environmental remediation applications [10].

Future Perspectives and Challenges

Despite significant advances, several challenges remain in the coordination engineering of SACs. Scaling the synthesis of defect-engineered SACs with precise coordination control while maintaining cost-effectiveness presents substantial manufacturing hurdles. Long-term stability under harsh operating conditions, particularly in acidic electrochemical environments, requires further improvement through robust coordination design. Advanced operando characterization techniques and machine learning-guided materials design are emerging as powerful tools to accelerate the discovery of optimal coordination environments. The development of multi-metallic SACs and dual-atom catalysts with complementary active sites represents a promising frontier for tackling complex catalytic transformations. Bridging the gap between molecular-level understanding achieved through fundamental studies and the practical requirements of industrial catalytic processes remains the ultimate challenge for the field [8] [9] [11].

The design of efficient transition metal catalysts hinges on a deep understanding of Structure-Activity Relationships (SARs), which connect the atomic and electronic structure of a catalytic material to its observed activity, selectivity, and stability. These relationships are fundamentally governed by the catalyst's interaction with reactant and intermediate species at the atomic level, primarily through adsorption processes. Research into these fundamental mechanisms of catalyst action and adsorption provides the critical framework for rationally designing next-generation catalytic systems. This whitepaper provides an in-depth technical examination of the SARs in four key transition metal systems—Iron (Fe), Copper (Cu), Cerium (Ce), and Cobalt (Co)—highlighting fundamental principles, modern design strategies, and advanced experimental protocols for researchers and scientists in the field.

Fundamental Mechanisms of Heterogeneous Catalysis

Heterogeneous catalysis, where the catalyst exists in a different phase from the reactants, typically proceeds through a multi-stage mechanism on the catalyst surface. The foundational Surface Adsorption Theory outlines five key stages [12]:

- Diffusion of Reactant(s) to the Surface: Reactants move from the bulk fluid phase to the catalyst surface, influenced by bulk concentration and the boundary layer thickness.

- Adsorption of Reactants: Reactant molecules form bonds with the catalyst surface. The efficiency of this process is described by the sticking coefficient.

- Reaction: Chemical bonds are formed and broken between the adsorbed atoms and molecules on the surface.

- Desorption of Products: The product molecules detach from the catalyst surface as the product-catalyst bonds are broken.

- Diffusion of Product(s) Away from the Surface: The desorbed products diffuse away from the catalyst surface into the bulk fluid stream.

The critical SARs are established during the adsorption, reaction, and desorption stages. The strength and nature of adsorption, whether physical (physisorption) or chemical (chemisorption), directly impact the reaction rate and pathway. For instance, in surface catalysis, a reactant forms a weak covalent bond with the catalyst surface, which weakens the bonds within the reactant molecule, thereby lowering the activation energy for the reaction [13]. A classic example is the decomposition of N₂O on a gold catalyst, where a weak covalent bond between the oxygen atom of N₂O and a surface gold atom weakens the N–O bond, facilitating decomposition into N₂ and O₂ [13].

Structure-Activity Relationships in Key Transition Metal Systems

The following sections dissect the SARs for Fe, Cu, Ce, and Co-based catalysts, with key performance data summarized in Table 1.

Table 1: Performance Summary of Transition Metal Catalysts in Key Reactions

| Catalyst System | Reaction | Key Performance Metrics | Reference |

|---|---|---|---|

| Fe-based (Haber-Bosch catalyst) | N₂ + 3H₂ → 2NH₃ | High activity and selectivity for ammonia synthesis | [12] |

| Cu-based (Cu92Sb5Pd3 SAA) | Electrochemical CO₂ to CO | 100% (±1.5%) CO selectivity at -402 mA cm⁻²; Stability >528 h | [14] |

| Ce-based (Mesoporous ACeOₓ, A=Co, Cu, Fe, Mn, Zr) | VOC Oxidation | Enhanced redox capabilities via oxygen vacancy concentration regulation | [15] |

| Ce-based (Ru-Nb co-doped CeO₂) | Chlorinated VOC Oxidation | Sustained catalytic efficiency via optimal bonding energy balance | [15] |

Iron (Fe) Catalysts

Iron-based catalysts are paradigmatic in heterogeneous catalysis, most famously in the Haber-Bosch process for ammonia synthesis (N₂ (g) + 3H₂ (g) ⇌ 2NH₃ (g)) [12]. The original catalysts used osmium, but modern systems rely on a less expensive, promoted iron catalyst [12]. The SAR is defined by the mechanism involving distinct adsorption and dissociation steps on the iron surface [12]:

- N₂ (g) → N₂ (adsorbed)

- N₂ (adsorbed) → 2N (adsorbed)

- H₂ (g) → H₂ (adsorbed)

- H₂ (adsorbed) → 2H (adsorbed)

- N (adsorbed) + 3H (adsorbed) → NH₃ (adsorbed)

- NH₃ (adsorbed) → NH₃ (g)

The rate-determining step is typically the dissociation of chemisorbed N₂ into nitrogen atoms (Step 2). The structure of the iron catalyst, including its crystal facets and the presence of promoters like Al₂O₃ and K₂O, significantly influences the binding energy of the N₂ molecule and the energy barrier for its dissociation, thereby dictating the overall activity.

Copper (Cu) Catalysts

Copper is a unique catalyst capable of activating CO₂ and producing a wide range of products, but pristine Cu suffers from poor selectivity [14]. The SAR for Cu is profoundly altered by forming single-atom alloys (SAAs), where isolated heteroatoms are dispersed within the Cu matrix. This strategy fine-tunes the electronic structure of Cu active sites.

A prime example is the trimetallic SAA Cu92Sb5Pd3 for the electrochemical CO₂ reduction reaction (CO₂RR) to CO [14]. The SAR here is governed by:

- Electronic Structure Modulation: Isolated Sb and Pd atoms cause charge redistribution, leading to a partially electron-deficient Cu matrix. This shifts the d-band center of Cu, weakening the binding strength of the *CO intermediate and favoring its desorption as a final product instead of further hydrogenation or C–C coupling [14].

- Synergistic Effects: Sb and Pd act synergistically; Sb primarily enhances CO selectivity, while Pd improves stability. This combination suppresses the competing Hydrogen Evolution Reaction (HER) [14].

- Entropic Stabilization: The increased configurational entropy from incorporating two dopant elements results in a lower mixing free energy (ΔG = ΔH - TΔS), enhancing the thermodynamic stability of the catalyst and preventing atom aggregation under high-current-density operation [14].

Cerium (Ce) Catalysts

Cerium dioxide (CeO₂, ceria) is a cornerstone material in oxidation catalysis due to its excellent redox properties and high oxygen storage capacity (OSC), facilitated by the reversible Ce⁴⁺/Ce³⁺ transition and the formation of oxygen vacancies [15]. The SAR in CeO₂-based catalysts is intricately linked to its surface and defect chemistry. Key structural parameters governing activity include:

- Oxygen Vacancy Concentration: The formation energy and concentration of oxygen vacancies are critical for activating molecular oxygen and facilitating oxidation reactions. Doping with transition metals (e.g., Co, Cu, Fe, Mn) is a primary strategy to regulate vacancy concentration [15]. For instance, He et al. constructed mesoporous ACeOₓ (A = Co, Cu, Fe, Mn, Zr) composites, demonstrating how the dopant metal type directly tunes the oxygen vacancy concentration and enhances redox capabilities [15].

- Crystal Facet Engineering: Different CeO₂ crystal facets exhibit varying surface energies and oxygen vacancy formation energies. The (110) facet has been shown to have a specific adsorption mechanism for aromatic compounds, making its controlled exposure crucial for VOC oxidation [15].

- Metal-Support Interactions (MSI): In composite catalysts, the strength of MSI can control the exposure of active sites. Zhang et al. established a quantitative relationship between MSI strength and active site exposure, challenging the traditional view that stronger MSI always leads to better performance [15].

These principles are applied in advanced catalysts like Ru-Nb co-doped CeO₂, where dual-metal synergy creates an optimal bonding energy balance for sustained catalytic efficiency in chlorinated VOC oxidation [15].

Cobalt (Co) Catalysts

While the search results provide less specific detail on Co-only systems, Cobalt is frequently used as a dopant in other catalyst systems to modify structure and activity. For example, in CeO₂-based catalysts, Co is listed among the transition metals (along with Cu, Fe, Mn, Zr) used to dope mesoporous ACeOₓ composites. The role of Co in such systems is typically to enhance the redox properties and oxygen mobility of the host material, analogous to other transition metal dopants [15]. Its incorporation can alter the oxygen vacancy formation energy and provide active sites for specific reaction steps, thereby improving the overall catalytic activity for reactions like VOC oxidation.

Experimental Protocols for Catalyst Synthesis and Evaluation

Synthesis of Trimetallic Single-Atom Alloy Catalysts (e.g., Cu92Sb5Pd3)

Objective: To synthesize a thermodynamically stable, atomically dispersed trimetallic catalyst with precisely controlled composition [14].

Materials:

- Metal Precursors: Copper salt (e.g., Cu(NO₃)₂), Palladium salt (e.g., PdCl₂), Antimony salt (e.g., SbCl₃).

- Solvent: Absolute ethanol (non-aqueous), used to prevent hydrolysis and precipitation of Sb³⁺ ions, eliminating the need for complexing agents.

- Reducing Agent: Sodium borohydride (NaBH₄) or similar.

Procedure:

- Solution Preparation: Dissolve stoichiometric amounts of the Cu, Sb, and Pd precursors in pure ethanol under an inert atmosphere to prevent oxidation. The target atomic ratio is Cu:Sb:Pd = 92:5:3.

- Co-reduction: Rapidly add a freshly prepared, ice-cold aqueous solution of NaBH₄ (strong reducing agent) to the ethanolic metal precursor solution under vigorous stirring.

- Aging and Collection: Allow the reaction mixture to stir for several hours to ensure complete reduction and alloy formation. Collect the resulting solid product via centrifugation.

- Washing and Drying: Wash the precipitate thoroughly with ethanol and deionized water to remove ions and by-products. Dry the final catalyst under vacuum.

Characterization: The successful formation of the single-atom alloy must be confirmed using a combination of techniques [14]:

- Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES): To verify the bulk composition.

- High-Angle Annular Dark-Field Scanning Transmission Electron Microscopy (HAADF-STEM): To visually confirm the atomic dispersion of Sb and Pd atoms in the Cu matrix and rule out nanoparticle formation.

- Extended X-ray Absorption Fine Structure (EXAFS): To probe the local coordination environment of Sb and Pd atoms, confirming the presence of Sb-Cu and Pd-Cu bonds and the absence of Sb-Sb or Pd-Pd bonds.

- X-ray Photoelectron Spectroscopy (XPS): To analyze surface composition and elemental oxidation states.

Protocol for Evaluating Catalytic VOC Oxidation

Objective: To assess the activity, selectivity, and stability of catalysts (e.g., doped CeO₂) for the oxidation of volatile organic compounds (VOCs) [15].

Materials:

- Reactor System: A fixed-bed continuous-flow quartz tubular reactor.

- Catalyst: Powdered catalyst, often pressed and sieved to a specific particle size range (e.g., 40-60 mesh).

- VOC Feed: A standard VOC (e.g., toluene, chlorobenzene) in a gaseous stream, typically generated by passing an inert gas (e.g., N₂) through a saturator containing the liquid VOC and diluting with air or O₂.

- Analytical Instrumentation: Online Gas Chromatograph (GC) equipped with a Flame Ionization Detector (FID) and/or a Thermal Conductivity Detector (TCD) for quantifying VOC, CO₂, and other products.

Procedure:

- Catalyst Loading: A known mass (e.g., 100 mg) of catalyst is loaded into the reactor.

- Pre-treatment: The catalyst is pre-treated in a specific gas stream (e.g., O₂, He) at a set temperature (e.g., 300°C) for a fixed time (e.g., 1 hour) to clean the surface and establish a consistent initial state.

- Reaction Test: The VOC/air feed stream is introduced into the reactor at a defined gas hourly space velocity (GHSV). The reactor temperature is increased in a stepwise manner (light-off test) or held at a constant temperature.

- Product Analysis: The effluent gas from the reactor is automatically sampled and analyzed by the GC at regular intervals.

- Stability Test: The catalyst is tested under constant reaction conditions (temperature, feed) for an extended period (e.g., 50-100 hours) to evaluate deactivation.

Data Analysis:

- VOC Conversion (%): Calculated as

[(C_in - C_out) / C_in] * 100, where C is the VOC concentration. - CO₂ Selectivity (%): The percentage of converted carbon that is oxidized to CO₂.

- T₅₀ and T₉₀ (°C): The temperatures required for 50% and 90% VOC conversion, respectively, used to compare catalyst activity.

Visualization of Catalytic Mechanisms and Workflows

The following diagrams, generated using DOT language and adhering to the specified color and contrast guidelines, illustrate key concepts and processes.

Heterogeneous Catalysis Mechanism

Diagram 1: Five Stages of Heterogeneous Catalysis. This workflow outlines the fundamental steps of a surface-catalyzed reaction, from reactant diffusion to product desorption [12].

Cu-SAA Electronic Structure Modulation

Diagram 2: Synergistic Electronic Effect in Cu92Sb5Pd3 Catalyst. Isolated Sb and Pd atoms induce charge redistribution in the Cu matrix, leading to optimized intermediate binding and improved performance [14].

Catalyst Synthesis & Evaluation Workflow

Diagram 3: Workflow for Catalyst Synthesis and Structure-Activity Analysis. This protocol outlines the key steps from catalyst preparation to performance evaluation and mechanistic understanding.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagents and Materials for Catalyst Research and Development

| Item Name | Function / Application | Technical Notes |

|---|---|---|

| Vanadium(V) Oxide (V₂O₅) | Solid catalyst for the Contact Process (SO₂ oxidation to SO₃). | Preferred over Pt due to resistance to arsenic poisoning [12]. |

| Promoted Iron Catalyst | High-activity catalyst for ammonia synthesis via the Haber Process. | Typically promoted with Al₂O₃ and K₂O for enhanced activity and stability [12]. |

| Ce-MOF Precursors | Pyrolyzed to synthesize CeO₂ catalysts with high oxygen vacancy concentration. | Enables unique low-temperature reducibility [15]. |

| Metal Salts (Cu, Sb, Pd) | Precursors for the synthesis of single-atom alloy catalysts (e.g., Cu92Sb5Pd3). | Non-aqueous solvents (e.g., ethanol) prevent hydrolysis of certain ions like Sb³⁺ [14]. |

| Sodium Borohydride (NaBH₄) | Strong reducing agent for the co-reduction of metal precursors in solution synthesis. | Used in the preparation of metallic nanoparticles and alloys [14]. |

| Fixed-Bed Flow Reactor | Standard laboratory system for testing catalyst performance in gas-solid reactions. | Used for VOC oxidation, CO/NO reduction, etc. [15]. |

| Online Gas Chromatograph (GC) | For real-time quantification of reactants and products in a gas stream. | Essential for calculating conversion and selectivity metrics [15]. |

The intricate coordination environments found in natural enzymes, characterized by precisely positioned metal centers and amino acid side chains within protein scaffolds, are fundamental to their exceptional catalytic efficiency and specificity. These enzyme-mimetic coordinations are now a central design principle in creating artificial catalytic systems that bridge the performance gap between biological and synthetic catalysts. The primary motivation for this field stems from the inherent limitations of natural enzymes—their fragility under industrial conditions, high production costs, and limited shelf-life—which restrict their application in areas like industrial biotechnology and biomedicine [16] [17]. Artificial systems designed with biomimetic coordination seek to replicate the catalytic prowess of natural enzymes while offering enhanced stability, tunability, and simplicity.

This paradigm is powered by advances in supramolecular chemistry, nanotechnology, and computational modeling, enabling the rational design of structures from single-atom catalysts to complex metal-organic frameworks [17]. These systems are engineered not as exact atomic replicas of natural enzymes but as functional mimics that capture the essential chemical features of natural active sites. The resulting catalysts demonstrate significant potential for applications ranging from targeted drug delivery and biosensing to green manufacturing and sustainable energy production, effectively bridging the fundamental mechanisms of natural catalytic action with the practical demands of modern technology [16] [17] [18].

Fundamental Coordination Principles in Natural and Artificial Systems

Active Site Coordination in Natural Enzymes

Natural enzymes achieve catalysis through precisely arranged metal ions and organic residues within a protected pocket. Common coordination geometries include:

- Tetrahedral Coordination: Found in zinc enzymes like carbonic anhydrase, where the metal ion is coordinated by three histidine residues and a water molecule.

- Octahedral Coordination: Present in many iron-dependent oxidoreductases.

- Distorted Geometries: Created by protein scaffold constraints to fine-tune redox properties and substrate binding affinity.

These arrangements facilitate substrate binding, transition state stabilization, and product release with remarkable efficiency and selectivity, operating under mild physiological conditions [17]. The coordination environment directly controls the electronic structure of the metal center, thereby determining its catalytic properties.

Key Coordination Elements in Artificial Mimics

Artificial enzyme mimics incorporate several key design elements to replicate natural enzymatic function:

- Spatial Confinement: Supramolecular architectures and porous materials create protected microenvironments that mimic enzyme active sites, concentrating substrates and stabilizing transition states through pre-organized coordination spaces [16].

- Ligand Field Engineering: The electronic properties of metal centers are tuned through carefully selected coordinating atoms (typically N, O, S) from supporting ligands or frameworks, directly influencing intermediate adsorption energies and catalytic selectivity [19] [20].

- Secondary Coordination Sphere Interactions: Advanced designs incorporate features beyond the primary coordination shell, including hydrogen-bonding networks, electrostatic interactions, and hydrophobic pockets that work cooperatively with the metal center to enhance catalysis and substrate specificity [17].

Table 1: Comparison of Coordination Environments in Natural Enzymes and Artificial Mimics

| Feature | Natural Enzymes | Single-Atom Nanozymes | Supramolecular Catalysts | MOF-Based Enzymes |

|---|---|---|---|---|

| Coordination Geometry | Defined by protein fold | M-N-C common (M=Fe, Cu, Zn) | Variable, host-guest defined | Varies with metal and linker |

| Primary Coordination | Amino acid side chains | Heteroatoms in carbon support | Synthetic organic ligands | Organic linkers |

| Secondary Interactions | Extensive H-bond network | Limited but tunable | Designed via supramolecular chemistry | Possible in functionalized pores |

| Structural Flexibility | High (induced fit) | Low (rigid support) | Moderate to high | Low (crystalline) |

| Typical Metal Utilization | High (100% in active site) | High (approaching 100%) | High in designed systems | Variable |

Material Platforms and Design Strategies

Single-Atom Nanozymes (SAzymes)

Single-atom catalysts with enzyme-mimetic properties represent a minimalist approach to biomimetic catalysis. In these systems, isolated metal atoms (typically Fe, Cu, Zn, Mn, or Co) are anchored on supporting substrates through coordination with heteroatoms such as nitrogen, oxygen, or sulfur [20]. The most common configuration features metal atoms tetrahedrally coordinated by four nitrogen atoms within a carbon matrix (M-N-C), creating active centers that structurally and electronically resemble natural metalloenzyme active sites [20].

The catalytic properties of SAzymes can be precisely tuned by manipulating the coordination number, geometry, and identity of coordinating atoms. For instance, changing the primary coordination sphere from M-N₄ to M-N₃O or M-N₃S significantly alters the electronic density at the metal center, thereby influencing its interaction with substrates and catalytic intermediates [20]. These systems exhibit various enzyme-like activities including peroxidase (POD)-, oxidase (OXD)-, catalase (CAT)-, and superoxide dismutase (SOD)-like behavior, making them suitable for biomedical applications such as cancer therapy, antibacterial treatment, and cytoprotection against oxidative stress [20].

Supramolecular Coordination Complexes

Supramolecular architectures, including coordination cages, capsules, and helicates, provide three-dimensional environments that mimic the confined active sites of enzymes [16]. These structures are formed through self-assembly processes driven by coordination bonds between metal ions (directionally defining vertices) and organic bridging ligands (forming edges). The resulting cavities create molecular nano-reactors that can encapsulate substrates, position catalytic groups, and stabilize transition states through multipoint interactions [16] [17].

These systems are particularly valuable for their dynamic responsiveness to external stimuli such as pH, light, or competing ligands, allowing for tunable catalytic activity that can be regulated in real-time [16]. This responsiveness makes them promising candidates for applications in controlled drug delivery and smart catalysis where temporal and spatial control over reaction initiation and termination is desired.

Metal-Organic Frameworks (MOFs) as Enzyme Mimics

MOFs offer exceptional versatility as enzyme-mimetic platforms due to their crystalline nature, high surface areas, and extraordinary structural and functional tunability [21]. Specific MOF families—including zeolitic imidazolate frameworks (ZIFs), Materials of Institut Lavoisier (MILs), Prussian blue analogs (PBAs), and porous coordination networks (PCNs)—have demonstrated particularly promising multi-enzyme mimetic capabilities [21].

The enzyme-mimetic properties of MOFs can be enhanced through several design strategies:

- Metal Node Engineering: Selection of specific metal clusters (e.g., Fe, Cu, Zr) that mimic the redox-active centers of natural enzymes.

- Linker Functionalization: Incorporation of catalytically active functional groups into organic linkers.

- Defect Creation: Introduction of missing-linker or missing-node defects to generate unsaturated coordination sites that can serve as active centers.

- Biomolecule Incorporation: Integration of peptides, nucleobases, or other biomolecules into the framework to create more enzyme-like environments [21].

Table 2: Catalytic Performance Metrics for Selected Enzyme-Mimetic Systems

| Catalyst Type | Enzyme Activity | Turnover Number (min⁻¹) | KM (mM) | Optimal pH | Thermal Stability |

|---|---|---|---|---|---|

| Natural Peroxidase | Peroxidase | ~10³ | 0.1-1.0 | ~7.0 | Limited (<50°C) |

| Fe-N-C SAzyme | Peroxidase | ~10²-10³ | 0.5-2.0 | 2.0-6.0 | High (>80°C) |

| MOF (ZIF-8) | Multiple activities | Varies by substrate | N/A | 3.0-9.0 | Moderate-High |

| DNAzyme | RNA cleavage | 1-5 | Substrate-dependent | 6.0-8.0 | Moderate |

| Supramolecular Cage | Hydrolysis/oxidation | 10-100 | 0.1-5.0 | Tunable | Variable |

Characterization and Analytical Methods

Structural Validation Techniques

Confirming the atomic-level structure of enzyme-mimetic systems requires a multidisciplinary analytical approach:

X-ray Absorption Spectroscopy (XAS): This technique, particularly extended X-ray absorption fine structure (EXAFS), is indispensable for characterizing single-atom catalysts. It provides information about the oxidation state of metal centers (through XANES) and the local coordination environment including bond distances and coordination numbers (through EXAFS) [20]. The absence of metal-metal scattering paths in EXAFS spectra confirms atomic dispersion of metal sites.

High-Angle Annular Dark-Field Scanning Transmission Electron Microscopy (HAADF-STEM): This microscopy technique allows direct visualization of isolated metal atoms as bright dots against the darker support material, providing unambiguous evidence of single-atom dispersion when combined with spectroscopic methods [20].

X-ray Photoelectron Spectroscopy (XPS): Provides information about the elemental composition, chemical state, and electronic structure of metal centers and their coordinating atoms in the support material [20].

Functional Characterization

Catalytic performance assessment follows established enzymology protocols:

Steady-State Kinetics: Measurement of initial reaction rates under conditions where substrate concentration exceeds catalyst concentration. Parameters including kcat (turnover number), KM (Michaelis constant), and Vmax (maximum velocity) are determined from Lineweaver-Burk or Eadie-Hofstee plots [17] [20].

Enzyme-Mimetic Activity Assays:

- Peroxidase-like activity: Typically measured using chromogenic substrates like 3,3',5,5'-tetramethylbenzidine (TMB) in the presence of H₂O₂, monitoring color development at 652 nm [20].

- Oxidase-like activity: Assessed using TMB or 2,2'-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) without H₂O₂.

- Catalase-like activity: Quantified by measuring oxygen evolution from H₂O₂ decomposition using an oxygen electrode or manometry.

- Superoxide dismutase-like activity: Evaluated by monitoring inhibition of superoxide-dependent reduction of cytochrome c or nitrobue tetrazolium [20].

Diagram 1: Catalyst Characterization Workflow. This integrated approach combines structural and functional analysis to establish structure-activity relationships.

Experimental Protocols for Key Methodologies

Synthesis of Metal-Nitrogen-Carbon Single-Atom Nanozymes

Pyrolysis Method for M-N-C SAzymes [20]:

Precursor Preparation: Dissolve metal salt (e.g., FeCl₃, Zn acetate, Cu nitrate) and nitrogen-rich organic ligand (e.g., 1,10-phenanthroline, 2-methylimidazole) in suitable solvent at molar ratios typically between 1:2 and 1:10 (metal:ligand).

Impregnation: Mix the precursor solution with high-surface-area carbon support (e.g., graphene oxide, carbon black, mesoporous carbon) and stir for 12-24 hours to ensure uniform adsorption.

Drying: Remove solvent by rotary evaporation or freeze-drying to obtain a homogeneous powder.

First-Stage Pyrolysis: Heat the material under inert atmosphere (N₂ or Ar) at 400-600°C for 1-2 hours to decompose precursors and initiate coordination structure formation.

Acid Leaching: Treat the pyrolyzed material with concentrated acid (typically 0.5M H₂SO₄ or HCl) at 60-80°C for 8-12 hours to remove unstable nanoparticles and aggregates, leaving predominantly atomically dispersed metal sites.

Second-Stage Pyrolysis: Subject the acid-washed material to a second pyrolysis at 700-900°C for 1-3 hours under inert atmosphere to optimize the coordination environment and enhance graphitization.

Characterization: Validate successful synthesis through HAADF-STEM, XAS, and XPS as described in Section 4.1.

Assessment of Peroxidase-Like Activity

Standard TMB Oxidation Protocol [20]:

Reagent Preparation:

- Prepare 0.5M acetate buffer (pH 4.0) or 0.5M phosphate buffer (pH 6.0)

- Prepare 10 mM TMB solution in DMSO

- Prepare 100 mM H₂O₂ solution in deionized water

- Prepare catalyst suspension at 0.1-1.0 mg/mL in buffer

Reaction Setup:

- Mix 500 μL buffer, 100 μL catalyst suspension, 100 μL TMB solution, and 200 μL H₂O₂ solution

- Incubate at desired temperature (typically 25-37°C) for precisely timed intervals (0.5-10 minutes)

Reaction Monitoring:

- Measure absorbance at 652 nm at regular time intervals

- For kinetic parameter determination, vary TMB concentration (0.1-2.0 mM) while keeping H₂O₂ constant (5 mM), then vary H₂O₂ concentration (0.5-20 mM) while keeping TMB constant (0.5 mM)

Data Analysis:

- Calculate initial velocities from the linear portion of absorbance vs. time plots

- Determine KM and Vmax using Lineweaver-Burk plots or nonlinear regression fitting to the Michaelis-Menten equation

Table 3: Essential Research Reagents for Enzyme-Mimetic Coordination Studies

| Reagent Category | Specific Examples | Primary Function | Key Considerations |

|---|---|---|---|

| Metal Precursors | FeCl₃, Cu(NO₃)₂, Zn acetate, H₂PtCl₆ | Provide metal centers for active sites | Purity affects coordination geometry; anion influences precursor decomposition |

| Nitrogen Sources | 1,10-phenanthroline, 2-methylimidazole, melamine, dicyandiamide | Create M-N coordination environments | Thermal stability and decomposition pathway affect final coordination structure |

| Carbon Supports | Graphene oxide, mesoporous carbon, carbon nanotubes, carbon black | Provide high-surface-area anchoring sites | Surface functionality and defect density crucial for metal anchoring |

| Characterization Standards | TMB, ABTS, OPD, ADHP | Quantify enzyme-mimetic activities | Substrate selectivity varies among different mimics; multiple substrates recommended |

| Buffer Systems | Acetate (pH 3-6), phosphate (pH 6-8), borate (pH 8-9), carbonate (pH 9-11) | Maintain pH for activity assays | Buffer components can coordinate metals and affect catalytic measurements |

Applications in Biomedicine and Industrial Catalysis

Therapeutic Applications

Enzyme-mimetic catalysts demonstrate significant potential in biomedical applications:

Cancer Therapy: SAzymes with peroxidase-like activity can catalyze the conversion of endogenous H₂O₂ in tumor microenvironments to highly cytotoxic hydroxyl radicals (•OH), enabling specific tumor cell apoptosis without significant damage to normal tissues [20]. The fine-tuned coordination environment allows these catalysts to maintain activity under the mildly acidic conditions characteristic of tumors while showing limited activity at physiological pH.

Antibacterial Treatment: Nanozymes exhibiting oxidase- and peroxidase-like activities generate reactive oxygen species (ROS) that disrupt bacterial membranes and intracellular components, offering an alternative to conventional antibiotics with reduced risk of resistance development [22] [20].

Cytoprotection: SOD- and catalase-mimetic systems protect against oxidative stress by scavenging superoxide radicals and decomposing hydrogen peroxide, showing potential for treating inflammatory conditions, neurodegenerative diseases, and ischemia-reperfusion injury [20].

Biosensing and Diagnostic Applications

The predictable coordination environments and tunable substrate specificity of enzyme mimics make them valuable for biosensing applications:

Metabolite Detection: SAzymes with peroxidase-like activity serve as robust substitutes for natural horseradish peroxidase in enzymatic cascade systems for detecting glucose, cholesterol, uric acid, and other biomarkers [20].

Pathogen Identification: Functionalized nanozymes conjugated with antibodies or aptamers enable colorimetric detection of pathogens through catalytic signal amplification, offering sensitivity comparable to natural enzyme-based detection with significantly improved shelf-life and stability [20].

Environmental Monitoring: MOF-based enzyme mimics with multiple catalytic activities can detect toxic metals, gases, and organic pollutants through distinct colorimetric or fluorometric responses [21].

Diagram 2: Application Domains for Enzyme-Mimetic Catalysts. These systems enable diverse applications across biomedical, industrial, and environmental fields.

Industrial and Environmental Applications

Beyond biomedical applications, enzyme-mimetic coordination systems contribute to sustainable industrial processes:

Green Chemical Synthesis: Supramolecular catalysts and MOF-based enzymes facilitate stereoselective transformations under mild conditions, reducing energy consumption and waste generation in pharmaceutical and fine chemical manufacturing [17] [23].

Energy Conversion: SACs with optimized coordination environments demonstrate exceptional activity for reactions such as the hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR), enabling more efficient fuel cells and water electrolysis systems [19] [18].

Environmental Remediation: Enzyme-mimetic systems designed to degrade persistent organic pollutants, capture heavy metals, or neutralize toxic compounds offer innovative solutions for environmental cleanup [17] [21].

The strategic design of enzyme-mimetic coordinations has created a robust bridge between natural enzymatic systems and artificial catalysts, establishing fundamental principles for constructing highly efficient, selective, and stable catalytic systems. Through precise control of primary coordination spheres and thoughtful engineering of secondary interaction networks, researchers have developed materials that capture the essential functional attributes of natural enzymes while surpassing their operational limitations.

Future advances in this field will likely focus on several key areas: (1) developing more sophisticated dynamic and responsive systems that can adapt their coordination environments in response to substrate binding or environmental cues; (2) creating multi-functional catalysts with orchestrated cascade capabilities through precise spatial organization of different active sites; (3) enhancing biocompatibility and biodegradability profiles, particularly for biomedical applications where long-term toxicity concerns remain [22]; and (4) leveraging artificial intelligence and machine learning approaches to accelerate the discovery and optimization of novel coordination geometries with tailored catalytic properties [17].

As characterization techniques continue to improve, providing increasingly detailed insights into atomic-scale structures and reaction dynamics, our understanding of the fundamental mechanisms governing catalyst action and adsorption will deepen. This knowledge, in turn, will enable the rational design of next-generation enzyme-mimetic systems with enhanced capabilities, further blurring the distinction between biological and artificial catalysis while addressing pressing challenges in sustainable technology, medicine, and environmental protection.

Surface Synergetic Oxygen Vacancies and Their Role in Reaction Pathways

Surface oxygen vacancies (Ov), defined as sites where oxygen atoms are missing from the standard lattice structure of a metal oxide, have emerged as critical components in modern heterogeneous catalysis. Within the broader context of fundamental mechanisms of catalyst action and adsorption research, these defects are not merely passive structural imperfections but active sites that can dramatically enhance catalytic performance. The synergetic effect between oxygen vacancies and supported metal sites or other cationic defects creates unique electronic environments that lower activation energy barriers, modify reaction pathways, and improve product selectivity across diverse chemical transformations [24] [25] [26]. This whitepaper examines the fundamental role of surface synergetic oxygen vacancies in modulating reaction pathways, with particular emphasis on their application in energy-related catalytic processes and environmental remediation.

The strategic importance of oxygen vacancy engineering continues to grow within catalysis science, especially for researchers and drug development professionals seeking to optimize reaction systems at the molecular level. By deliberately controlling the density, distribution, and stability of these vacancies, scientists can precisely tailor catalyst properties to achieve desired outcomes in complex reaction networks, including those relevant to pharmaceutical synthesis and biomass conversion [24] [27]. This document provides a comprehensive technical examination of oxygen vacancy characterization, quantification, and their mechanistic roles in catalytic cycles, supported by experimental data and visualization of key concepts.

Fundamental Mechanisms of Oxygen Vacancy Formation and Function

Creation and Stabilization of Oxygen Vacancies

Oxygen vacancies can be introduced into metal oxide frameworks through multiple synthesis and post-synthesis treatments, each method imparting distinct characteristics to the resulting defective structure:

- Doping with Heteroatoms: Incorporation of lower-valence cations (e.g., Co²⁺ in CeO₂) creates charge imbalances that are compensated by oxygen vacancy formation. In Pt/CoCeOx catalysts, cobalt doping induces lattice contraction confirmed by XRD peak shifts of 0.28° to higher angles and increases oxygen vacancy concentration to 0.72 mmol g⁻¹ [24].

- Thermal Treatments in Reducing Atmospheres: Calcination under low oxygen chemical potential (LOCP) conditions, such as hydrogen-containing environments, selectively removes lattice oxygen atoms. A representative protocol involves treating ZnO in 10% H₂/Ar at 500°C, which significantly enhances oxygen vacancy density without compromising crystallinity [28] [29].

- Plasma and Radiation Treatments: These methods create localized defects through energy transfer, often resulting in highly controlled vacancy distributions suitable for specialized applications.

The stability of these vacancies under reaction conditions is paramount for sustained catalytic performance. In thermally driven reactions, vacancies often maintain stability throughout the catalytic cycle, while in photocatalytic and electrocatalytic systems, vacancy regeneration can become rate-limiting, particularly when driven solely by photon input without thermal assistance [25].

Electronic and Structural Effects

The presence of oxygen vacancies fundamentally alters the electronic structure of host materials through several interconnected mechanisms:

- Charge Redistribution: Vacancies create localized electron-rich regions that facilitate charge transfer to supported metal nanoparticles. In Pt/CoCeOx systems, this transfer significantly increases electron density at Pt sites, enhancing their capability for H₂ activation [24].

- Band Gap Modulation: The introduction of defect states within the band gap reduces the energy required for electron excitation, a critical factor in photocatalytic applications. Oxygen vacancy-enriched ZnO demonstrates improved visible light absorption and charge separation efficiency [28].

- Surface Polarization: The asymmetric charge distribution around vacancy sites creates localized electric fields that promote the adsorption of specific reactant molecules and reaction intermediates.

Table 1: Characterization Techniques for Oxygen Vacancy Analysis

| Technique | Principal Information | Key Observations |

|---|---|---|

| X-ray Photoelectron Spectroscopy (XPS) | Chemical state, oxygen deficiency | Binding energy shifts in O 1s and metal core levels |

| Electron Paramagnetic Resonance (EPR) | Unpaired electrons associated with Ov | Signal at g-factor ~2.0 indicates oxygen vacancy presence |

| Photoluminescence Spectroscopy | Defect-related electronic transitions | Emission peaks associated with Ov-related states |

| X-ray Diffraction (XRD) | Lattice parameter changes | Peak shifts indicating lattice contraction/expansion |

| Electron Energy Loss Spectroscopy (EELS) | Local chemical environment | Weakened O pre-edge peak intensity near surface |

Quantitative Analysis of Oxygen Vacancy Impact on Catalytic Performance

The relationship between oxygen vacancy concentration and catalytic performance has been quantitatively established across multiple material systems and reactions. Controlled synthesis approaches enable systematic variation of vacancy density, allowing researchers to correlate this parameter with catalytic activity, selectivity, and stability metrics.

In the context of furfural hydrogenation, Pt/CoCeOx catalysts with optimized oxygen vacancy concentrations (0.72 mmol g⁻¹) demonstrated exceptional performance in converting furfural to furfuryl alcohol, a reaction of considerable industrial importance. The oxygen vacancies in this system served dual functions: as electron-enrichment centers that modified Pt electronic properties, and as anchoring sites that stabilized metal nanoparticles against sintering [24].

For glycerol electrooxidation, precisely controlling oxygen vacancy density in CuCo₂O₄ nanosheets directly influenced product selectivity. Catalysts with the highest oxygen vacancy density achieved nearly 100% selectivity toward C1 molecules through complete C-C bond cleavage, with a Faradaic efficiency of ≈99%. Density functional theory (DFT) calculations confirmed that closely spaced oxygen vacancies act synergistically to facilitate charge transfer between the catalyst and key reaction intermediates, thereby promoting selective bond scission [27].

Table 2: Quantitative Performance Metrics of Oxygen Vacancy-Engineered Catalysts

| Catalytic System | Reaction | Ov Concentration | Performance Metrics | Reference |

|---|---|---|---|---|

| Pt/CoCeOₓ | Furfural hydrogenation | 0.72 mmol g⁻¹ | Enhanced H₂ activation capability; High FA selectivity | [24] |

| CuCo₂O₄₋ₓ NS | Glycerol electrooxidation | Maximized via kinetic reduction | ~100% C1 selectivity; ~99% Faradaic efficiency | [27] |

| Cu/CeO₂₋ₓ | CO₂ to ethanol | Not specified | ~95% ethanol selectivity at ~5% CO₂ conversion | [30] |

| ZnO (Ov-enriched) | Photocatalytic dye degradation | Not specified | Enhanced dye removal efficiency; pH-dependent activity | [28] |

| NaNi₀.₃₅Fe₀.₂Mn₀.₃Cu₀.₀₅Ti₀.₁O₂ | Sodium-ion battery cathode | Surface Ov layer ~12 nm | 85.6% capacity retention after 500 cycles | [29] |

Experimental Protocols for Oxygen Vacancy Characterization and Catalytic Testing

Synthesis of Oxygen Vacancy-Enriched ZnO for Photocatalytic Applications

Materials: ZnO nanopowder, 10% H₂/Ar gas mixture, tubular furnace, cationic dyes (malachite green, safranin O), anionic dyes (methyl red, rose bengal).

Procedure:

- Place 1.0 g of commercial ZnO nanopowder in a quartz boat positioned within a tubular furnace.

- Purge the system with inert gas (Ar) for 30 minutes to eliminate residual oxygen.

- Heat the sample at 10°C/min to 500°C under a continuous 10% H₂/Ar flow (100 mL/min).

- Maintain the target temperature for 2 hours to ensure uniform vacancy formation.

- Cool naturally to room temperature under the same gas atmosphere.

- Characterize the resulting oxygen vacancy-enriched material using XRD, XPS, and EPR to confirm vacancy formation and quantify concentration [28].

Photocatalytic Testing:

- Prepare dye solutions (20 mg/L) in deionized water and adjust pH using HCl or NaOH.

- Combine 50 mL of dye solution with 0.1 g/L catalyst in a photoreactor.

- Conduct adsorption equilibrium in dark conditions for 60 minutes with continuous stirring.

- Illuminate with a UVA or visible light source (e.g., 300 W Xe lamp) while maintaining constant stirring.

- Collect samples at regular intervals, centrifuge to remove catalyst particles, and analyze dye concentration via UV-Vis spectroscopy.

- Model degradation kinetics using appropriate mathematical formulations that account for adsorption-desorption equilibrium and surface/solution phase reactions [28].

Construction of Pt/CoCeOₓ Catalysts for Selective Hydrogenation

Materials: Cerium(III) nitrate hexahydrate, cobalt(II) nitrate hexahydrate, terephthalic acid, chloroplatinic acid hexahydrate, furfural, furfuryl alcohol.

Support Synthesis (CoCeOₓ):

- Dissolve Ce(NO₃)₃·6H₂O and Co(NO₃)₂·6H₂O in molar ratio 1:0.05-0.2 in DMF/ethanol mixture.

- Add terephthalic acid as organic linker and hydrothermally treat at 150°C for 12 hours.

- Recover precipitate by centrifugation, wash thoroughly with ethanol, and dry at 80°C.

- Calcine at 400°C in air for 4 hours to obtain Co-doped CeO₂ support [24].

Pt Deposition:

- Employ wet impregnation method using H₂PtCl₆·6H₂O as precursor.

- Reduce under H₂ flow at 300°C for 2 hours to form metallic Pt nanoparticles.

- Characterize resulting material with XRD, HR-TEM, H₂-TPR, and XPS to confirm Pt dispersion and metal-support interactions [24].

Catalytic Testing:

- Conduct furfural hydrogenation in a batch reactor at 80-120°C under H₂ pressure (10-30 bar).

- Monitor reaction progress by sampling at intervals and analyzing with GC-MS.

- Calculate key performance metrics: conversion, selectivity, and turnover frequency (TOF).

Visualization of Oxygen Vacancy-Mediated Reaction Pathways

The following diagrams illustrate key mechanistic pathways and experimental workflows involving oxygen vacancies in catalytic systems.

Synergistic Mechanism in Pt/CoCeOₓ for H₂ Activation

This diagram illustrates the synergistic mechanism between Pt nanoparticles and oxygen vacancies in CoCeOₓ support materials for hydrogen activation. The process begins with H₂ adsorption and dissociation on electron-rich Pt sites, facilitated by charge transfer from adjacent oxygen vacancies. The resulting hydrogen atoms then spill over onto the support surface, where oxygen vacancies stabilize reaction intermediates and lower overall activation energy barriers [24].

Experimental Workflow for Oxygen Vacancy Characterization

This workflow outlines the integrated experimental approach for creating and characterizing oxygen vacancies in functional materials. The process begins with material synthesis followed by low oxygen chemical potential (LOCP) treatments to generate controlled oxygen vacancies. Multiple characterization techniques provide complementary information about structural, electronic, and surface properties, enabling correlation of vacancy characteristics with catalytic performance metrics [24] [28] [29].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential Research Reagents for Oxygen Vacancy Studies

| Reagent/Material | Function/Role | Application Examples |

|---|---|---|

| Transition Metal Salts | Precursors for doped oxide catalysts | Co(NO₃)₂·6H₂O for CoCeOₓ synthesis [24] |

| Hydrogen/Argon Mixtures | Creating reducing environments for Ov formation | 10% H₂/Ar for thermal reduction of ZnO [28] |

| Chloroplatinic Acid | Source of supported noble metal nanoparticles | H₂PtCl₆·6H₂O for Pt/CoCeOₓ catalysts [24] |

| Organic Linkers | Construction of MOF precursors for oxides | Terephthalic acid for bimetallic MOF-derived catalysts [24] |

| Probe Molecules | Characterization of Ov concentration and strength | CO, O₂, H₂ for TPD and TPR experiments [24] |

| Spectroscopic Standards | Reference materials for quantification | Standard oxides for XPS and EPR calibration |