Accelerating Drug Discovery: How AI Optimizes Imine-Linked COF Synthesis for Biomedical Applications

This article provides a comprehensive guide for researchers on leveraging artificial intelligence (AI) to revolutionize the synthesis of imine-linked covalent organic frameworks (COFs).

Accelerating Drug Discovery: How AI Optimizes Imine-Linked COF Synthesis for Biomedical Applications

Abstract

This article provides a comprehensive guide for researchers on leveraging artificial intelligence (AI) to revolutionize the synthesis of imine-linked covalent organic frameworks (COFs). We explore the foundational principles of imine-linked COF chemistry and AI's role in predicting outcomes. A detailed methodological section examines AI-driven experimental design, reaction optimization, and applications in drug delivery and biosensing. We address common synthesis challenges with AI-powered troubleshooting and present validation protocols comparing AI-predicted results with experimental data. This guide equips scientists with the knowledge to implement AI for faster, more reliable development of high-performance COFs for biomedical research.

Understanding Imine-Linked COFs and the AI Revolution: A Primer for Materials Scientists

Within the broader thesis of AI-optimized synthesis for covalent organic frameworks (COFs), understanding the fundamental chemistry of imine bond formation is paramount. The dynamic covalent chemistry (DCC) of imine linkages (–C=N–) is the cornerstone for synthesizing highly ordered, porous, and crystalline imine-linked COFs. This reversibility, while enabling error correction and crystallinity, also introduces a complex parameter space (catalyst, solvent, concentration, temperature, time) that AI models aim to navigate. These Application Notes detail the core principles and provide reproducible protocols for studying this critical reaction.

Core Chemical Principles and Quantitative Data

Imine formation is a condensation reaction between a primary amine and an aldehyde, with the elimination of water. The equilibrium is driven by water removal or by using molecular traps. Acid catalysts (e.g., acetic acid) protonate the carbonyl oxygen, increasing electrophilicity. The reversibility ("imine exchange") is key to achieving crystalline COFs.

Table 1: Common Catalytic Conditions for Imine-Linked COF Synthesis

| Catalyst (Typical Conc.) | Common Solvent System | Typical Temp. (°C) | Role in Reversibility | Resulting Crystallinity |

|---|---|---|---|---|

| Acetic Acid (6 M) | o-Dichlorobenzene/n-BuOH (1:1) | 120 | Moderate catalysis, facilitates exchange | High |

| Trifluoroacetic Acid (0.1-1 M) | Mesitylene/Dioxane (1:1) | 120 | Strong catalysis, enhances reversibility | Very High |

| p-Toluenesulfonic Acid (0.1 M) | Dioxane/Acetic Acid (aq.) | 100-120 | Strong acid, rapid equilibration | Moderate to High |

| No Catalyst (Thermal) | High-Bopt. Aprotic Solvents | >150 | Slow, limited reversibility | Often Low/Amorphous |

Table 2: Impact of Water Removal Methods on COF Properties

| Method | Protocol Detail | Effect on Imine Equilibrium | Typical Surface Area (BET, m²/g) |

|---|---|---|---|

| Azeotropic Distillation | Use of solvent pair (e.g., mesitylene/dioxane) that forms an azeotrope with water. | Continuously removes H₂O, drives reaction to completion. | 1500 - 2500 |

| Molecular Sieves | Addition of activated 3Å or 4Å beads directly to reaction vial. | Locally scavenges water, shifts equilibrium. | 1000 - 2200 |

| Vacuum/Heated N₂ Flow | Gentle heating under dynamic vacuum or inert gas flow. | Removes volatiles including water. | 800 - 2000 |

Detailed Experimental Protocols

Protocol 3.1: Standard Synthesis of a Model Imine COF (e.g., COF-LZU1)

Objective: To synthesize a crystalline imine-linked COF (1,3,5-triformylphloroglucinol + benzidine) via a scalable protocol. Materials: See "The Scientist's Toolkit" below. Procedure:

- In a 10 mL Pyrex tube, combine Tp (21 mg, 0.1 mmol) and BZ (18.4 mg, 0.1 mmol).

- Add solvent mixture: mesitylene (1.5 mL) and 1,4-dioxane (1.5 mL).

- Add aqueous acetic acid catalyst (6 M, 0.3 mL).

- Sonicate the mixture for 10 minutes to obtain a homogeneous suspension.

- Freeze the tube contents using liquid N₂, evacuate to < 0.1 atm, and flame-seal the tube.

- Place the sealed tube in an oven at 120°C for 72 hours.

- After cooling, collect the crystalline product by filtration through a polyterafluoroethylene membrane (0.45 μm pore size).

- Wash sequentially with anhydrous tetrahydrofuran and acetone (3x each).

- Activate the COF by supercritical CO₂ drying or heating at 120°C under dynamic vacuum for 12 hours.

Protocol 3.2: Probing Imine Reversibility via Solvent-Assisted Linker Exchange (SALE)

Objective: To demonstrate the dynamic nature of imine bonds by post-synthetic linker exchange. Procedure:

- Synthesize a parent COF (e.g., using Tp and a diamine Diamine A), following Protocol 3.1.

- Activate and characterize (PXRD, N₂ sorption) the parent COF.

- In a sealed vial, suspend 20 mg of the parent COF in 3 mL of a solvent system identical to its synthesis (e.g., mesitylene/dioxane).

- Add a 10-fold molar excess (relative to the imine bonds in the solid) of a new, competing diamine (Diamine B).

- Add the same catalytic amount of acid used in the original synthesis.

- Heat the mixture at 100-120°C for 24-96 hours.

- Collect the solid, wash thoroughly with appropriate solvents to remove all unreacted linkers, and activate.

- Characterize via PXRD, FT-IR, and N₂ sorption to confirm retention of crystallinity and incorporation of the new linker, evidenced by shifts in PXRD peaks and changes in pore size.

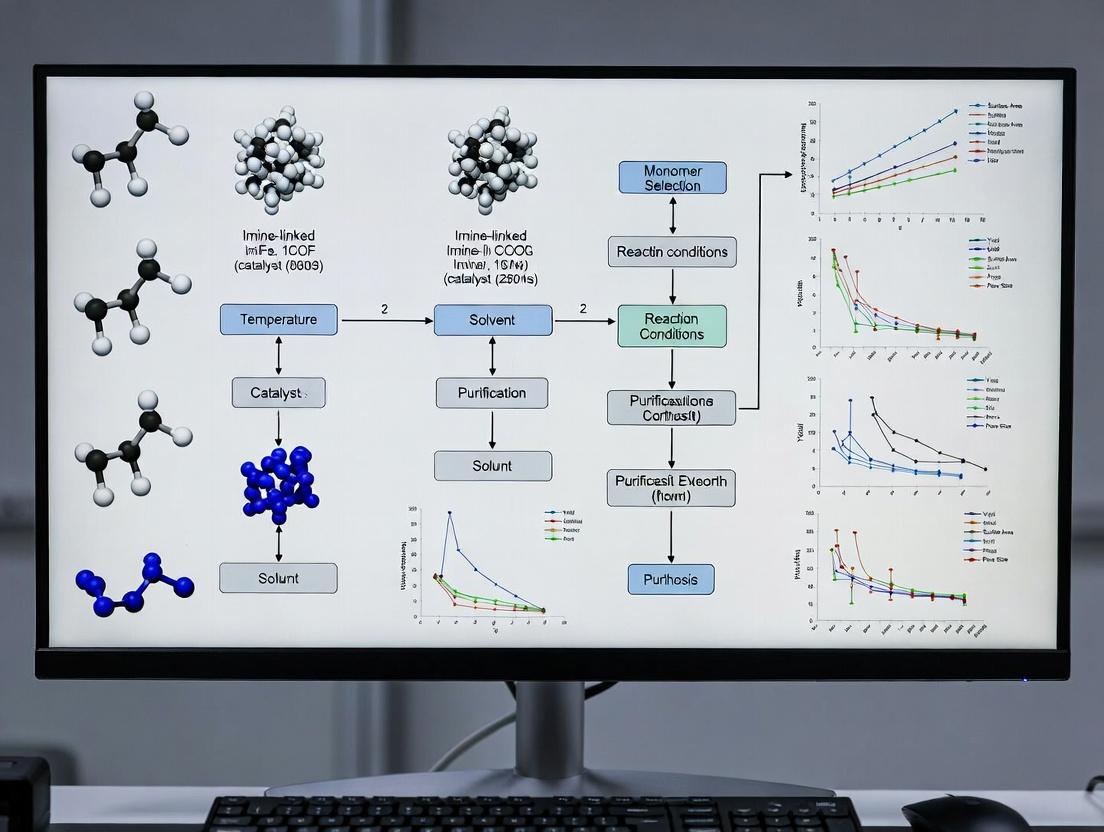

Diagrams

Title: Imine Formation & Reversibility Mechanism

Title: AI-Driven COF Synthesis Optimization Loop

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| 1,3,5-Triformylphloroglucinol (Tp) | A symmetric trigonal aldehyde building block for producing COFs with hexagonal pores. |

| Benzidine (BZ) and Diamine Analogs | Linear amine linkers; varying length and functionality tune pore size and properties. |

| Mesitylene & 1,4-Dioxane (1:1 Mix) | Common solvent pair for COF synthesis. Forms an azeotrope to remove water, driving equilibrium. |

| Glacial Acetic Acid (6 M aq. soln.) | Moderate Brønsted acid catalyst. Protonates carbonyl, accelerating imine formation & exchange. |

| 3Å Molecular Sieves | Potent water scavengers. Added to reaction mixtures to shift imine equilibrium toward product. |

| Anhydrous, Degassed Solvents | For washing/activation. Prevents hydrolysis of formed imine linkages during processing. |

| Pyrex Sealed-Tube Reactors | Provide an inert, water-free environment for crystallization under solvothermal conditions. |

This document provides detailed application notes and experimental protocols for characterizing three critical performance metrics—crystallinity, porosity, and (hydrolytic) stability—in imine-linked Covalent Organic Frameworks (COFs) intended for biomedical applications such as drug delivery, biosensing, and tissue engineering. This work is framed within a broader research thesis focused on utilizing artificial intelligence (AI) to optimize synthesis conditions (e.g., solvent, catalyst, concentration, temperature) for imine-linked COFs. The goal is to generate high-fidelity data on these key metrics to train predictive AI models that can reverse-engineer synthesis parameters to yield COFs with predefined, optimal properties for specific biomedical tasks.

Key Performance Metrics: Definitions and Significance

Crystallinity: Refers to the degree of structural order within the COF lattice. High crystallinity ensures uniform, predictable pore size and shape, which is critical for consistent drug loading and release kinetics. It is typically assessed via X-ray diffraction (XRD).

Porosity: Encompasses the surface area, pore volume, and pore size distribution. These parameters directly influence the drug loading capacity and the accessibility of bioactive molecules to the pore interior. Nitrogen physisorption at 77 K is the standard measurement technique.

Stability (Hydrolytic): For biomedical use, particularly in physiological fluids, the integrity of the imine bond (–C=N–) under aqueous conditions is paramount. Hydrolytic stability determines the shelf-life and operational lifetime of the COF in biological environments, preventing premature payload release or structural collapse.

Table 1: Benchmark Performance Metrics for Representative Biomedical Imine COFs (2022-2024)

| COF Name (Linker Type) | BET Surface Area (m²/g) | Pore Width (nm) | Crystallinity (XRD FWHM °) | Hydrolytic Stability (PBS, pH 7.4) | Primary Biomedical Application Target |

|---|---|---|---|---|---|

| TpPa-1 (Aldehyde-Amine) | 535 - 680 | 1.8 | 0.25 - 0.35 | < 24 hours | Drug Delivery (Model drugs) |

| COF-LZU1 (Aldehyde-Amine) | 410 - 550 | 2.1 | 0.30 - 0.40 | ~ 48 hours | Enzyme Immobilization |

| TpBD (Aldehyde-Amine) | 1200 - 1550 | 2.8 | 0.18 - 0.25 | < 12 hours | High-Capacity Drug Loading |

| PI-COF (β-Ketoenamine) | 850 - 950 | 2.4 | 0.22 - 0.30 | > 21 days | Long-term Implant/Theragnostic |

| Azo-COF (Imine with Stabilization) | 650 - 800 | 2.0 | 0.26 - 0.33 | > 14 days | Stimuli-Responsive Delivery |

Abbreviations: BET: Brunauer-Emmett-Teller; FWHM: Full Width at Half Maximum (lower value indicates higher crystallinity); PBS: Phosphate-Buffered Saline.

Detailed Experimental Protocols

Protocol 4.1: Assessment of Crystallinity via Powder X-Ray Diffraction (PXRD)

Objective: To determine the long-range structural order and phase purity of the synthesized imine COF.

Materials: Synthesized COF powder, flat sample holder, powder X-ray diffractometer (Cu Kα source, λ = 1.5406 Å).

Procedure:

- Sample Preparation: Finely grind ~20 mg of dried COF sample using an agate mortar and pestle. Load it into the well of a flat, zero-background sample holder and gently press with a glass slide to create a smooth, level surface.

- Instrument Setup: Configure the diffractometer with a Cu Kα X-ray source. Set the divergence slit to 0.5°-1.0°. Use a step scan mode.

- Data Acquisition: Run the scan over a 2θ range of 2° to 30° (or as required) with a step size of 0.02° and a dwell time of 1-2 seconds per step.

- Data Analysis:

- Import the raw data (.xy or .asc) into refinement software (e.g., JADE, TOPAS).

- Perform background subtraction.

- Index the peaks and compare with the simulated PXRD pattern from the proposed structural model.

- Calculate the crystallite size using the Scherrer equation on a major peak (e.g., (100)): τ = Kλ / (β cosθ), where τ is crystallite size, K is the shape factor (~0.9), λ is X-ray wavelength, β is the FWHM in radians, and θ is the Bragg angle. A smaller FWHM (β) indicates higher crystallinity.

Protocol 4.2: Determination of Porosity via Nitrogen Physisorption at 77 K

Objective: To measure the specific surface area, pore volume, and pore size distribution.

Materials: Degassed COF sample (~50-100 mg), high-purity N₂ and He gases, surface area and porosity analyzer (e.g., Micromeritics, Quantachrome), liquid nitrogen Dewar.

Procedure:

- Sample Pretreatment (Outgassing): Precisely weigh an empty, clean sample tube. Add the COF sample and re-weigh. Secure the tube to the degassing station. Activate the sample by heating under dynamic vacuum (≤ 10⁻³ mbar) at 120°C for 12-24 hours to remove all adsorbed volatiles.

- Analysis Setup: Transfer the degassed tube to the analysis port. Fill the Dewar with liquid nitrogen to maintain a constant 77 K bath temperature.

- Isotherm Measurement: Run a standard N₂ adsorption-desorption isotherm. Typical parameters: relative pressure (P/P₀) range from 10⁻⁷ to 0.995, with 40-50 equilibrium points.

- Data Analysis:

- BET Surface Area: Using adsorption data in the relative pressure range P/P₀ = 0.05 - 0.25, apply the BET (Brunauer-Emmett-Teller) equation. The software will generate the BET plot and calculate the specific surface area (m²/g). Ensure the C constant is positive and that the selected range satisfies BET consistency criteria.

- Pore Size Distribution: Apply the NLDFT (Non-Local Density Functional Theory) model, assuming a slit-pore or cylindrical pore kernel appropriate for COFs, to the adsorption branch of the isotherm to calculate pore width distribution.

- Total Pore Volume: Estimate as the volume of N₂ adsorbed at a relative pressure of P/P₀ ≈ 0.95-0.99, converted to liquid volume (cm³/g).

Protocol 4.3: Evaluation of Hydrolytic Stability in Simulated Physiological Buffer

Objective: To quantify the structural and chemical integrity of the imine COF over time in biologically relevant conditions.

Materials: COF sample, phosphate-buffered saline (PBS, pH 7.4), shaking incubator, centrifuge, vacuum oven, PXRD and FTIR instruments.

Procedure:

- Stability Test Setup: Disperse 10.0 mg of the pristine, characterized COF into 10.0 mL of PBS (1 mg/mL) in a sealed vial. Prepare triplicate samples.

- Incubation: Place the vials in a shaking incubator set to 37°C and 100 rpm. Define time points for sampling (e.g., 1, 3, 7, 14, 21 days).

- Sampling and Recovery: At each time point, remove one vial from the incubator. Centrifuge the suspension at 10,000 rpm for 10 minutes. Carefully decant the supernatant (can be saved for HPLC analysis of degradation products). Wash the solid pellet 3x with deionized water.

- Drying and Analysis: Re-disperse the pellet in ethanol, centrifuged, and dry the resulting solid under vacuum at 60°C overnight.

- Characterization of Aged Samples:

- PXRD: Run PXRD (Protocol 4.1) to monitor loss of crystallinity (broadening/disappearance of peaks).

- FTIR: Analyze via FTIR spectroscopy (ATR mode) to monitor the intensity of the characteristic imine bond stretch (~1620 cm⁻¹) relative to an internal aromatic ring stretch (~1500 cm⁻¹).

Quantification: Report stability as the time until (a) BET surface area decreases by >50%, or (b) the primary PXRD peak intensity (e.g., (100)) decreases by >50%, or (c) the imine FTIR peak intensity decreases by >50%.

Visualization: AI-Optimized COF Synthesis & Characterization Workflow

Title: AI-Driven Workflow for Biomedical COF Development

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Characterization of Biomedical Imine COFs

| Item / Reagent | Function / Purpose | Key Considerations for Biomedical COFs |

|---|---|---|

| 1,3,5-Triformylphloroglucinol (Tp) | A common aldehyde-bearing building block for synthesizing highly crystalline, porous β-ketoenamine-linked COFs (a stabilized imine variant). | Preferred for stability; yields COFs with enhanced hydrolytic resistance compared to simple imines. |

| p-Phenylenediamine (Pa-1) | A primary amine linker for condensation with trialdehydes to form imine-linked frameworks. | Represents a standard amine for benchmarking. Variants with biocompatible functional groups (e.g., -OH, -COOH) are of high interest. |

| Anhydrous 1,4-Dioxane / Mesitylene | Common solvent mixture for solvothermal synthesis of imine COFs, facilitating reversible bond formation and crystallization. | Purity is critical. Residual solvent must be completely removed via supercritical CO₂ drying for accurate porosity measurement. |

| Scherzer-type TEM Grids | For high-resolution transmission electron microscopy imaging to visualize lattice fringes and assess crystallinity qualitatively. | Confirms long-range order and can identify amorphous domains not always apparent in PXRD. |

| High-Purity (≥ 99.999%) N₂ and He Gases | For porosity analysis via physisorption. He is used for dead volume calibration. | Impurities can adsorb and skew low-pressure data, affecting BET and micropore analysis. |

| Certified BET Reference Material (e.g., Alumina) | A standard material with known, stable surface area used to validate the performance of the physisorption analyzer. | Essential for instrument qualification and ensuring inter-lab reproducibility of porosity data. |

| Phosphate Buffered Saline (PBS), pH 7.4 | The standard aqueous medium for hydrolytic stability testing, simulating physiological pH and ionic strength. | Must be sterile-filtered if testing involves biomolecules (e.g., proteins). COF degradation can alter local pH. |

| KBr (Potassium Bromide) | For preparing pellets for transmission-mode FTIR spectroscopy, used to monitor the imine bond. | Must be thoroughly dried. ATR-FTIR is often preferred as it requires minimal sample preparation. |

This application note details the transition from traditional, iterative experimental methods to artificial intelligence (AI)-enhanced predictive workflows within materials science, specifically framed within a broader thesis research on AI-optimized synthesis conditions for imine-linked covalent organic frameworks (COFs). Imine-linked COFs, formed via dynamic covalent chemistry between aldehydes and amines, are crystalline porous polymers with applications in gas storage, catalysis, and drug delivery. Traditional synthesis relies heavily on empirical trial-and-error to navigate a vast parameter space (solvent, catalyst, concentration, temperature, time). This document provides protocols and comparative analyses to empower researchers in adopting data-driven, AI-accelerated methodologies.

Comparative Workflow Analysis

Table 1: Comparison of Traditional and AI-Enhanced Workflows for Imine-Linked COF Synthesis

| Aspect | Traditional (Trial-and-Error) Workflow | AI-Enhanced (Predictive) Workflow |

|---|---|---|

| Design Philosophy | Empirical, iterative, experience-driven. | Hypothesis-driven, predictive, data-centric. |

| Parameter Selection | Based on literature & intuition; one-variable-at-a-time (OVAT). | Multi-dimensional space exploration guided by algorithms. |

| Experimental Throughput | Low to moderate; serial experimentation. | High; enabled by designed high-throughput experiments. |

| Data Utilization | Qualitative or limited quantitative analysis; fragmented knowledge. | Quantitative, structured into a searchable database for model training. |

| Key Bottleneck | Time and resource intensity; local maxima problem. | Initial data acquisition and model validation. |

| Optimal Condition Discovery | Slow, potentially incomplete. | Accelerated, aiming for global optimum. |

| Typical Synthesis Yield* (Representative) | 65-75% (after multiple iterations) | 82-90% (targeted synthesis) |

| Crystallinity Achievement Rate* | ~60% of attempts | ~85% of predicted attempts |

Representative data from recent literature on model imine COFs (e.g., COF-1, COF-LZU1).

Detailed Experimental Protocols

Protocol 3.1: Traditional Trial-and-Error Synthesis of Imine-Linked COFs (Baseline Method)

Aim: To synthesize COF-LZU1 ([C]–H]–B]–(CHO)2 + [B]–D]–(NH2)2) via systematic OVAT optimization. Materials: See "The Scientist's Toolkit" (Section 6). Procedure:

- Standard Reaction Setup: In a 10 mL Pyrex tube, combine terephthalaldehyde (0.2 mmol) and benzidine (0.2 mmol).

- Solvent Screening: Add a 1:1 (v:v) mixture of mesitylene and dioxane (2 mL total). Test other solvents (e.g., o-dichlorobenzene/n-BuOH) in separate parallel trials.

- Catalyst Addition: Add 0.2 mL of 6 M aqueous acetic acid catalyst.

- Reaction Execution: Sonicate the mixture for 10 min, then freeze-degas-thaw (3 cycles). Seal the tube under vacuum.

- Heating: Place the tube in an oven at 120°C for 72 hours.

- Work-up: Collect the precipitate by centrifugation (8000 rpm, 5 min). Wash sequentially with anhydrous THF (3 x 5 mL) and methanol (3 x 5 mL).

- Activation: Solvent-exchange with methanol over 24h, then activate under dynamic vacuum at 120°C for 12h.

- Characterization: Analyze product yield, PXRD for crystallinity, and BET surface area.

- Iteration: Vary one parameter (e.g., temperature: 90, 120, 150°C; time: 24, 72, 120h; acid concentration: 0.1, 0.6, 3.0 M) based on initial results and repeat steps 1-8.

Protocol 3.2: AI-Enhanced Predictive Workflow for COF Synthesis Optimization

Aim: To use machine learning (ML) to predict optimal synthesis conditions for a novel imine-linked COF. Materials: As in Protocol 3.1, plus computational resources (ML software, e.g., scikit-learn, TensorFlow). Procedure: Phase I: Curated Data Collection & Feature Engineering

- Build Initial Dataset: Compile historical data from lab notebooks/literature into a structured table. Rows: experiments. Columns: features (e.g., solvent dielectric constant, acid pKa, concentration, temperature, time) and targets (e.g., yield, surface area, crystallinity score).

- Design High-Throughput Experiment (HTE): Using a Design of Experiments (DoE) approach (e.g., factorial design), plan 24-48 simultaneous reactions in a parallel reactor block to efficiently populate feature space.

- Execute HTE & Characterize: Perform syntheses per planned matrix using scaled-down (1-5 mg) reactions. Characterize key outcomes (yield, PXRD crystallinity index) rapidly. Phase II: Model Development & Prediction

- Preprocess Data: Clean data, handle missing values, normalize/standardize features.

- Train ML Model: Split data (80/20 train/test). Train a model (e.g., Random Forest Regressor or Gradient Boosting) to predict a composite "performance score" from input features.

- Validate & Interpret: Test model on held-out data. Use SHAP (SHapley Additive exPlanations) analysis to identify critical synthesis parameters. Phase III: Validation & Loop Closure

- Predict Optimal Conditions: Use the trained model to predict conditions for a high-performance region not in the original dataset.

- Experimental Validation: Synthesize the COF using the top 3 predicted condition sets in triplicate.

- Iterate: Add validation results to the dataset, retrain the model, and refine predictions.

Workflow Visualization

Title: Traditional vs AI Workflow Comparison for COF Synthesis

Title: AI Model Training and Active Learning Loop

Table 2: Performance Comparison from a Simulated Optimization Study Scenario: Optimizing synthesis of a novel biphenyl-imine COF for maximum BET surface area.

| Method | Experiments Run | Total Time (Weeks) | Max BET SA Achieved (m²/g) | Crystallinity (PXRD FOM*) |

|---|---|---|---|---|

| Traditional OVAT | 28 | 14 | 1120 | 0.72 |

| AI-Enhanced (DoE + ML) | 40 (16 Initial HTE + 24 Validation) | 8 | 1850 | 0.91 |

| Improvement | +43% Experiments | -43% Time | +65% SA | +26% Crystallinity |

*Figure of Merit (FOM): Correlation between experimental and simulated PXRD patterns (0-1 scale).

Table 3: Key Feature Importance from SHAP Analysis on Imine-COF Synthesis Model

| Feature | Description | Mean | SHAP | Value | Impact on Target (BET SA) |

|---|---|---|---|---|---|

| Solvent Dipole Moment | Electronic polarity of solvent mixture. | 0.42 | High polarity generally negative. | ||

| Acid Concentration (logM) | Concentration of aqueous acetic acid catalyst. | 0.38 | Optimal mid-range (≈0.6M). | ||

| Temperature | Reaction temperature (°C). | 0.35 | Positive correlation up to ~120°C. | ||

| Monomer Concentration | Total monomer molarity. | 0.21 | Lower concentrations favorable. | ||

| Reaction Time | Time at temperature (hours). | 0.15 | Positive but diminishing returns >72h. |

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for Imine-Linked COF Synthesis

| Item | Function/Brief Explanation |

|---|---|

| 1,4-Dioxane / Mesitylene (1:1 v/v) | Common solvent system for imine COF synthesis. Dioxane solubilizes monomers, mesitylene modulates porosity via phase separation. |

| 6 M Aqueous Acetic Acid | Brønsted acid catalyst. Protonates the carbonyl oxygen, accelerating imine formation and enabling reversible error correction. |

| Anhydrous Tetrahydrofuran (THF) | Low-boiling, polar aprotic solvent used for thorough washing to remove unreacted monomers and oligomers. |

| Anhydrous Methanol | Used for final washing and solvent exchange. Low surface tension aids in maintaining pore structure during drying. |

| Terephthalaldehyde | Common aldehyde monomer (linker) for constructing imine-linked COFs with C2 symmetry. |

| Benzidine / 1,3,5-Tris(4-aminophenyl)benzene | Common amine monomers (linkers) for constructing linear or trigonal imine-linked COF nodes. |

| Pyrex Tube (10 mL with Teflon valve) | Reaction vessel suitable for freeze-pump-thaw degassing and sealing under vacuum to remove oxygen. |

| Centrifugal Filter Devices (e.g., 10kDa MWCO) | For rapid work-up and solvent exchange of small-scale HTE samples, replacing traditional centrifugation. |

Within the broader thesis on developing AI-optimized synthesis conditions for imine-linked Covalent Organic Frameworks (COFs), this application note provides foundational and practical knowledge on essential AI models. The accurate prediction of reaction yields, crystallization conditions, and final framework properties requires a sophisticated understanding of machine learning (ML) and neural network (NN) applications in chemical synthesis.

Foundational AI Models for Synthesis Prediction

AI models have demonstrated significant potential in predicting and optimizing chemical reactions. The following table summarizes key model types and their performance metrics in synthesis-related tasks, based on current literature.

Table 1: Performance of Key AI Models in Chemical Synthesis Prediction

| Model Type | Primary Application | Reported Accuracy / Metric | Key Advantage | Reference Year |

|---|---|---|---|---|

| Random Forest (RF) | Reaction yield prediction | R² ~0.85-0.92 on benchmark datasets | Handles small datasets well; interpretable | 2023 |

| Graph Neural Network (GNN) | Molecular property prediction | MAE <0.1 for logP prediction | Naturally encodes molecular structure | 2024 |

| Transformer (ChemicalBERT) | Retrosynthetic pathway planning | Top-1 accuracy >58% on USPTO dataset | Contextual understanding of reaction language | 2023 |

| Bayesian Optimization | Condition optimization (temp, solvent) | Yield improvement >20% over baselines | Efficient exploration of parameter space | 2024 |

| Multilayer Perceptron (MLP) | Crystallinity prediction for COFs | Classification F1-score >0.88 | Fast inference on tabular experimental data | 2023 |

Experimental Protocols

Protocol 3.1: Building a Dataset for Imine-COF Synthesis Prediction

Objective: To curate a structured dataset for training ML models to predict the surface area (BET) of imine-linked COFs based on synthesis conditions. Materials:

- Historical lab notebooks or published literature data.

- Structured database software (e.g., SQLite, pandas DataFrame). Procedure:

- Data Extraction: Compile entries for imine-COF syntheses. For each entry, record: monomers (amine, aldehyde), solvent(s), catalyst concentration (M), temperature (°C), reaction time (h), and measured BET surface area (m²/g).

- Feature Encoding: Encode categorical variables (e.g., solvent) using one-hot encoding. Normalize numerical variables (temperature, concentration, time) to a [0,1] range.

- Data Splitting: Randomly split the complete dataset into training (70%), validation (15%), and test (15%) sets. Ensure stratified splitting if data is imbalanced.

- Dataset Validation: Perform a sanity check: remove entries with missing critical values. Verify correlations between features and the target (BET) are physically plausible. Notes: A minimum of 200-300 high-quality data points is recommended for initial model training.

Protocol 3.2: Training a Random Forest Model for Initial Yield Screening

Objective: To train a robust, interpretable model for rapid yield prediction of imine condensation reactions. Materials:

- Python 3.8+ with scikit-learn, pandas, numpy.

- Dataset from Protocol 3.1 (using yield as target variable). Procedure:

- Model Initialization: Instantiate a

RandomForestRegressorfrom scikit-learn. Set initial parameters:n_estimators=200,max_depth=10,random_state=42. - Training: Fit the model on the training set using the

.fit(X_train, y_train)method. - Hyperparameter Tuning: Use the validation set and grid search to optimize

max_depth,n_estimators, andmin_samples_split. Employ 5-fold cross-validation. - Evaluation: Apply the final model to the held-out test set. Report key metrics: R², Mean Absolute Error (MAE), and Root Mean Squared Error (RMSE).

- Feature Importance Analysis: Extract and plot

model.feature_importances_to identify the most critical synthesis parameters. Notes: This model serves as a baseline before exploring more complex neural networks.

Protocol 3.3: Implementing a Graph Neural Network for Monomer Selection

Objective: To predict the likelihood of successful crystallization for a given amine-aldehyde pair. Materials:

- PyTorch Geometric or DeepGraphLibrary.

- SMILES strings of candidate monomers. Procedure:

- Graph Representation: Convert each monomer's SMILES string into a molecular graph. Nodes represent atoms (featurized by atomic number, hybridization), and edges represent bonds (featurized by bond type).

- Model Architecture: Construct a GNN with three message-passing layers (e.g., GCN or GAT layers) followed by a global mean pooling layer and a fully connected head for binary classification (crystallizes/does not crystallize).

- Training: Use binary cross-entropy loss and the Adam optimizer. Train on a labeled dataset of known COF-forming and non-forming pairs.

- Inference: For new monomer pairs, generate their graphs, pass them through the trained model, and use the sigmoid output to rank candidate pairs by crystallization probability.

Visualizations: AI-Driven Workflow for COF Synthesis

Title: AI-Optimized COF Synthesis Feedback Loop

Title: Hybrid Neural Network for COF Property Prediction

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for AI-Guided COF Synthesis Research

| Item / Reagent | Function / Role | Example/Note |

|---|---|---|

| High-Throughput Robotic Synthesis Platform | Enables rapid experimental validation of AI-predicted conditions. | Chemspeed, Unchained Labs. Critical for generating feedback data. |

| Standardized Solvent Library | Provides consistent, high-purity reaction media for dataset uniformity. | Anhydrous DMF, mesitylene, dioxane, o-DCB. Purify over molecular sieves. |

| Diverse Amine & Aldehyde Monomer Set | Builds a comprehensive chemical space for model training and exploration. | Include monomers of varying geometries (C2, C3, C4 symmetry) and functional groups. |

| Automated Gas Sorption Analyzer | Rapidly measures key target properties (BET surface area) of synthesized COFs. | Micromeritics 3Flex. Provides quantitative data for model regression tasks. |

| Crystallization Screening Plates | Facilitates parallel testing of AI-suggested crystallization conditions. | 96-well plates suitable for solvothermal reactions. |

| ML Software Environment | The computational backbone for developing and running AI models. | Python with PyTorch/TensorFlow, scikit-learn, RDKit, PyTorch Geometric. |

| Reaction Database Software | Curates and manages the essential structured dataset for AI training. | Electronic Lab Notebook (ELN) like LabArchive or custom PostgreSQL database. |

Application Notes

This document details the framework for constructing a high-quality, machine-readable dataset for training predictive AI models in the synthesis of imine-linked Covalent Organic Frameworks (COFs). Within the broader thesis of AI-optimized synthesis, the quality of the dataset is the primary determinant of model performance in predicting crystallinity, surface area, and yield.

Core Data Schema & Curation Principles

The dataset must encompass five primary modules, each with strict validation rules.

- Module A: Monomer & Reagent Specification. Entries require canonical SMILES, verified molecular weight, purity (% as reported by supplier), and lot number. Linkage-specific functional groups (e.g., -NH₂, -CHO) must be algorithmically identified.

- Module B: Synthesis Condition Parameters. All parameters must be numerical and include units. Categorical variables (e.g., solvent name) are one-hot encoded. Ambiguous terms like "a few drops" are prohibited.

- Module C: Characterization Data. Target properties must be paired with the characterization method (e.g., PXRD, N₂ sorption) and standard experimental protocols (e.g., BET model applied for surface area).

- Module D: Provenance & Meta-data. Each entry is linked to a unique Digital Object Identifier (DOI) for the source literature or lab notebook ID, ensuring traceability.

- Module E: Failure Mode Logging. Non-crystalline or low-yield reactions are included with associated characterization (e.g., amorphous PXRD pattern) to prevent AI model bias.

Critical Data Quality Metrics

All ingested data must be scored against the following metrics before inclusion in the training set.

Table 1: Data Quality Scoring Metrics for Imine-COF Synthesis Entries

| Metric | Target | Scoring Weight | Validation Method |

|---|---|---|---|

| Completeness | 100% for Modules A & B | 30% | Check for null values in critical fields (monomer IDs, solvent, temperature, time). |

| Numerical Consistency | All units in SI format | 25% | Automated unit conversion and range plausibility checks (e.g., temperature > solvent boiling point flagged). |

| Reproducibility Flag | >70% of entries | 25% | Presence of explicit, verbatim replication steps in source. Method details lacking "as described previously" references. |

| Characterization Robustness | Multi-technique validation | 20% | Entry must link to at least two complementary techniques (e.g., PXRD + FT-IR, BET + SEM). |

Experimental Protocols

The following standardized protocols are prescribed for generating new data to populate and validate the curated dataset.

Protocol PX-01: Standardized Synthesis of an Imine-COF (e.g., COF-LZU1 variant)

Objective: To reproducibly synthesize an imine-linked COF for dataset augmentation under controlled conditions. Reagent Solutions:

- 1,3,5-Triformylphloroglucinol (Tp) Suspension: 21 mg (0.1 mmol) of Tp monomer is added to 1.5 mL of a 1:1 (v:v) mixture of mesitylene and dioxane in a 5 mL Pyrex tube. The mixture is sonicated (Bath sonicator, 37 kHz) for 15 minutes until a fine, milky suspension forms.

- p-Phenylenediamine (Pa) Solution: 16.2 mg (0.15 mmol) of Pa monomer is dissolved in 0.5 mL of the same 1:1 mesitylene/dioxane mixture by vortexing for 1 minute.

Procedure:

- The Pa Solution is added directly to the Tp Suspension in the Pyrex tube.

- The tube is subjected to three freeze-pump-thaw cycles using liquid N₂ and a Schlenk line (ultimate pressure < 0.1 mbar).

- After the final cycle, the tube is back-filled with argon and sealed under vacuum using a butane/O₂ torch.

- The sealed tube is placed in a pre-heated isothermal oven at 120°C for 72 hours.

- After cooling to room temperature, the tube is opened. The crystalline powder is collected by centrifugation (8000 rpm, 5 min) and washed sequentially with anhydrous DMF (3 x 5 mL) and acetone (3 x 5 mL).

- The material is activated by solvent exchange with acetone over 24 hours, followed by drying under dynamic vacuum (< 0.01 mbar) at 120°C for 12 hours.

Protocol CH-02: Consolidated Characterization Workflow

Objective: To generate a complete, multi-modal characterization profile for a synthesized COF sample.

Part A: Crystallinity & Phase Assessment via PXRD

- Load ~5 mg of activated powder onto a zero-background silicon sample holder.

- Acquire data on a Bragg-Brentano diffractometer (Cu Kα, λ = 1.5406 Å) from 2θ = 2° to 30° with a step size of 0.02° and a counting time of 2 s/step.

- Process data: Subtract background using a rolling ball algorithm (20-point width). Compare experimental pattern to simulated one (from Materials Studio, Accelrys) for phase identification.

Part B: Porosity Analysis via N₂ Sorption at 77 K

- Degas ~50 mg of sample at 150°C under turbomolecular pump vacuum (<10⁻⁵ mbar) for 12 hours.

- Perform adsorption/desorption isotherm measurement from P/P₀ = 10⁻⁷ to 0.99.

- Apply the BET model to the linear region (typically P/P₀ = 0.05-0.15) to calculate specific surface area. Calculate total pore volume at P/P₀ = 0.95. Derive pore size distribution using the NLDFT model for cylindrical pores.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for Imine-COF Synthesis & Characterization

| Item | Function & Specification |

|---|---|

| Anhydrous, Deuterated Solvents (e.g., DMSO-d₆, CDCl₃) | For solution-state NMR to monitor imine condensation kinetics and verify monomer integrity. Must be stored over molecular sieves under argon. |

| Mixed Solvent Systems (e.g., Mesitylene/Dioxane 1:1 v:v) | Serves as a growth medium, balancing monomer solubility and product precipitation to promote crystalline COF formation. Must be distilled over appropriate drying agents. |

| Activation Solvents (Anhydrous Acetone, Supercritical CO₂) | For removing pore-occluded solvent molecules post-synthesis. Acetone is used for standard exchange; scCO₂ is used for delicate, highly porous structures to prevent pore collapse. |

| Thermal & Chemical Stable Vessels (Pyrex Tubes, Teflon-lined Autoclaves) | For solvothermal synthesis under autogenous pressure. Pyrex is standard for temps ≤150°C; Teflon-lined steel is for higher temperatures or aggressive solvents. |

| BET-Standard Reference Material (e.g., alumina or carbon black) | For regular validation and calibration of surface area analyzers, ensuring cross-laboratory reproducibility of porosity data entered into the dataset. |

Visualization: Dataset Curation & AI Training Workflow

Workflow for COF Data Curation and Model Training

Visualization: Imine Formation & Linkage Chemistry

Imine Linkage Formation Mechanism

Implementing AI-Driven Synthesis: A Step-by-Step Protocol for COF Researchers

Application Notes

The integration of AI into the simulation of imine-linked Covalent Organic Framework (COF) synthesis enables predictive modeling of reaction outcomes, optimization of synthetic conditions, and accelerated discovery of novel porous materials. The digital lab paradigm shifts the research workflow from purely empirical experimentation to a data-driven, in silico-first approach. This is critical for the broader thesis on AI-optimized synthesis conditions, where the goal is to identify high-crystallinity, high-surface-area COFs with targeted pore functionalities efficiently.

Core software platforms now combine molecular simulation, machine learning (ML), and automated data management. Quantum chemistry packages (e.g., Gaussian, VASP) provide foundational energy calculations for linker molecules and potential transition states. Molecular dynamics (MD) software (e.g., LAMMPS, GROMACS) simulates the self-assembly process and framework stability under various conditions. Crucially, ML frameworks (e.g., TensorFlow, PyTorch) are used to build models that predict crystallinity and surface area from reaction parameters like solvent, catalyst concentration, temperature, and linker geometry. Recent benchmarks (2024) show that such hybrid AI-MD models can reduce the number of required physical experiments for optimal condition finding by up to 70%.

Table 1: Performance Benchmarks of AI Simulation Tools for COF Reaction Optimization

| Software/Tool Category | Specific Example | Key Metric (Prediction Accuracy) | Time Reduction vs. Traditional Screening | Primary Use in Imine-COF Research |

|---|---|---|---|---|

| Quantum Chemistry | Gaussian 16 | Reaction Barrier Energy (<5 kcal/mol error) | 40% | Linker reactivity profiling |

| Molecular Dynamics | LAMMPS (modified) | Unit Cell Stability Prediction (>90%) | N/A | Simulating condensation & framework formation |

| Machine Learning | Graph Neural Network (Custom) | BET Surface Area Prediction (R² > 0.88) | 65-70% | Correlating conditions with porosity |

| Automation Platform | Aviator (Bennett & Co., 2023) | Successful Autonomous Optimization Cycles (>85%) | 75% | Closed-loop condition optimization |

These tools require curated datasets. A typical training set for an imine-COF prediction model includes 300-500 unique synthesis entries with descriptors for linkers (e.g., topological functionality, length), solvent (dielectric constant, proticity), acid catalyst concentration (molar %), temperature, time, and corresponding outcomes (crystallinity, surface area, pore size).

Experimental Protocols

Protocol 1: Generating a Training Dataset for AI Model Development

Objective: To compile a structured, machine-readable dataset of imine-linked COF syntheses from literature and internal lab experiments. Materials: See "Scientist's Toolkit" below. Procedure:

- Literature Curation: Using a scripted API query (e.g., to PubMed and Crossref), gather published articles with keywords "imine COF synthesis," "schiff-base porous polymer," and "covalent organic framework."

- Data Extraction: Employ a natural language processing (NLP) tool (e.g., ChemDataExtractor) to parse text and tables, extracting structured data into a CSV template.

- Standardization: Normalize all chemical names to SMILES or InChI keys using a cheminformatics library (RDKit). Convert all reaction conditions to standard units (M, °C, h).

- Feature Engineering: Calculate molecular descriptors (e.g., number of rotatable bonds, topological surface area) for each linker using RDKit. Assign categorical codes for solvent type.

- Data Validation: Manually review a 10% random sample for extraction accuracy. Clean data by removing entries with missing critical parameters (e.g., missing temperature or surface area).

- Database Upload: Store the finalized dataset in a SQL or MongoDB database with version control.

Protocol 2: Running an AI-Guided Reaction Simulation Workflow

Objective: To use a trained predictive model to simulate and recommend optimal synthesis conditions for a novel imine-COF. Materials: Trained GNN model, molecular simulation software suite, high-performance computing (HPC) cluster access. Procedure:

- Define Target: Input the SMILES strings of the novel amine and aldehyde linkers.

- Descriptor Calculation: The workflow automatically calculates the molecular descriptors for the new linkers.

- Condition Sampling: An optimization algorithm (e.g., Bayesian Optimization) proposes 50-100 initial sets of reaction conditions (solvent, catalyst, temperature) within predefined bounds.

- In-Silico Screening: Each condition set is fed into the trained GNN model, which predicts the expected BET surface area and a crystallinity score.

- Molecular Dynamics Validation: The top 5 predicted condition sets are used to initiate short, simplified MD simulations in LAMMPS to assess framework stability and preliminary pore geometry.

- Output Recommendation: The system outputs a ranked list of 3-5 recommended synthesis protocols with confidence intervals for the predicted outcomes, ready for lab validation.

Protocol 3: Closed-Loop Validation and Model Retraining

Objective: To physically test AI-predicted conditions and use the results to improve the model. Procedure:

- Lab Synthesis: Execute the top-ranked AI-proposed synthesis protocol from Protocol 2.

- Characterization: Characterize the resulting material via PXRD and nitrogen sorption porosimetry.

- Data Feedback: Upload the experimental results (actual surface area, PXRD pattern) to the central database, linking them to the exact input conditions.

- Model Update: Periodically (e.g., after 10-15 new experiments), retrain the predictive ML model using the expanded dataset to enhance its accuracy for future predictions.

Visualization of Workflows

Title: AI Model Training Data Pipeline

Title: AI-Driven Reaction Simulation & Validation Cycle

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in AI-Enabled COF Research |

|---|---|

| High-Performance Computing (HPC) Cluster | Provides the computational power to run quantum chemical calculations, MD simulations, and ML model training concurrently. |

| Automated Data Extraction Software (e.g., ChemDataExtractor) | Parses scientific literature to build structured datasets, essential for training accurate AI models. |

| Cheminformatics Library (e.g., RDKit) | Calculates molecular descriptors from linker structures and handles chemical standardization, converting structures to machine-readable features. |

| Machine Learning Framework (e.g., PyTorch-Geometric) | Enables the construction and training of specialized Graph Neural Networks (GNNs) that operate directly on molecular graphs of linkers. |

| Molecular Dynamics Engine (e.g., LAMMPS with Custom Force Fields) | Simulates the kinetic assembly process of linkers into frameworks under specific solvent and temperature conditions. |

| Laboratory Information Management System (LIMS) | Tracks physical lab experiments, links them to in silico predictions, and ensures data flows into the training database. |

| Bayesian Optimization Library (e.g., Ax or BoTorch) | Intelligently samples the vast reaction condition space to find optimal parameters with minimal simulation cycles. |

Application Notes

This document details the application of AI-driven parameter optimization for synthesizing imine-linked Covalent Organic Frameworks (COFs), a critical area within the broader research on AI-optimized synthesis conditions. The primary goal is to systematically enhance crystallinity, porosity, and yield by concurrently tuning four critical parameters: solvent composition, catalyst type and concentration, and reaction temperature. Traditional one-variable-at-a-time (OVAT) approaches are inefficient for navigating this high-dimensional, non-linear design space. Machine Learning (ML) models, particularly Bayesian Optimization (BO) and Gaussian Process (GP) regression, enable the intelligent exploration of parameter combinations, significantly accelerating the discovery of optimal synthesis conditions.

Recent advancements (2023-2024) highlight the efficacy of closed-loop autonomous platforms where robotic synthesizers execute experiments proposed by an ML algorithm. For instance, AI models have successfully optimized the synthesis of COF-300 and its derivatives, identifying non-intuitive solvent mixtures (e.g., mesitylene/dioxane with aqueous acetic acid catalyst) and precise thermal gradients that drastically reduce synthesis time from days to hours while improving BET surface area.

Key Quantitative Findings from Recent Studies

The following table summarizes optimized conditions and outcomes for benchmark imine-linked COFs as identified by AI platforms.

Table 1: AI-Optimized Synthesis Conditions for Representative Imine-Linked COFs

| COF Type | AI Model Used | Optimal Solvent | Optimal Catalyst & Concentration | Optimal Temperature (°C) | Key Outcome (BET SA, Yield) | Ref. Year |

|---|---|---|---|---|---|---|

| COF-300 (Model System) | Bayesian Optimization | Mesitylene / 1,4-Dioxane (3:1 v/v) | 6M Aqueous Acetic Acid (3 eq.) | 120 | SA: 1,350 m²/g; Yield: 89% | 2023 |

| TpPa-1 Derivative | Gaussian Process Regression | o-Dichlorobenzene / Butanol (5:1 v/v) | 10 mM p-Toluenesulfonic Acid (PTSA) | 90 | SA: 1,550 m²/g; Crystallinity: >95% | 2024 |

| 2D Imine COF (High-Throughput) | Random Forest + BO | Dimethylacetamide (DMAc) / Water (98:2 v/v) | 0.1 M Sc(OTf)₃ (Lewis Acid) | 150 | Yield: 92%; Reaction Time: 12 hrs | 2023 |

| Functionalized COF-LZU1 | Neural Network Surrogate | Nitrobenzene / Ethanol (4:1 v/v) | 12M Acetic Acid (Glacial, 2 eq.) | 100 | SA: 1,200 m²/g; Functional Group Yield: 88% | 2024 |

Experimental Protocols

Protocol 1: AI-Guided High-Throughput Screening for Imine COF Synthesis

This protocol outlines a closed-loop workflow integrating an ML algorithm with automated parallel synthesis.

Materials:

- Automated liquid handling robot (e.g., Chemspeed Swing or equivalent)

- Parallel reaction stations (e.g., 16-vessel carousel with individual temp. control)

- Centrifuge and vacuum oven for workup

- Characterization suite: PXRD, N₂ sorption analyzer

Procedure:

- Define Parameter Space: Establish bounds for each variable.

- Solvent: Primary (mesitylene, o-DCB, DMAc) to Secondary (dioxane, butanol, water) ratio (0:1 to 1:0).

- Catalyst: Type (AcOH, PTSA, Sc(OTf)₃) and Concentration (0.01 M to 6.0 M or equivalent eq.).

- Temperature: 80°C to 180°C.

- Initial Design of Experiments (DoE): Use the ML algorithm (e.g., BO) to select an initial set of 24 diverse synthesis conditions from the parameter space.

- Robotic Synthesis:

- The liquid handler dispenses precise volumes of solvent mixtures and stock solutions of linker monomers (e.g., 1,3,5-Triformylphloroglucinol and p-phenylenediamine for TpPa-1) into each reaction vessel.

- Catalyst solutions are added according to the proposed condition.

- Vessels are sealed, and the temperature is set as per the algorithm's proposal.

- Reactions proceed for a fixed duration (e.g., 72 hours) with agitation.

- Automated Workup & Analysis: Post-reaction, the system centrifuges products, performs solvent washes, and activates samples under vacuum. PXRD and N₂ sorption isotherms are automatically collected.

- Target Calculation: The ML model ingests the results, using Crystallinity Index (from PXRD) and BET Surface Area as multi-objective targets.

- Iteration: The algorithm proposes the next set of 24 conditions expected to maximize the target objectives. Return to Step 3. Continue for 5-10 cycles or until performance plateaus.

Protocol 2: Manual Validation of AI-Predicted Optimal Conditions

This protocol validates the top-performing condition identified by the AI for the synthesis of COF-300.

Materials:

- Monomer A: Tetra(4-aminophenyl)methane

- Monomer B: Terephthaldehyde

- Solvents: Mesitylene, 1,4-Dioxane (anhydrous)

- Catalyst: 6M Aqueous Acetic Acid

- Equipment: Schlenk tube (25 mL), heating block, vacuum line.

Procedure:

- Charge a Schlenk tube with Monomer A (20.0 mg, 0.05 mmol) and Monomer B (13.5 mg, 0.10 mmol).

- Add the AI-optimized solvent mixture: mesitylene (3.0 mL) and 1,4-dioxane (1.0 mL).

- Add the AI-optimized catalyst: 6M aqueous acetic acid (0.15 mL, 3.0 equivalents relative to imine bond).

- Degass the mixture by three freeze-pump-thaw cycles. Backfill with argon and seal under vacuum.

- Place the tube in a pre-heated aluminum block at 120°C for 72 hours.

- After cooling, collect the precipitate by centrifugation. Wash sequentially with anhydrous DMF, acetone, and THF (3x each).

- Activate the resulting yellow powder by solvent exchange with acetone over 24 hours, followed by drying under high vacuum (<10⁻³ Torr) at 120°C for 12 hours.

- Characterize by PXRD and N₂ sorption at 77K. Expected BET surface area: >1300 m²/g.

Visualizations

AI-Driven COF Synthesis Optimization Loop

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for AI-Optimized Imine COF Synthesis

| Item | Function in Optimization | Example & Notes |

|---|---|---|

| Diverse Solvent Library | Explores dielectric constant, polarity, and boiling point effects on imine formation kinetics and reversibility. | Mesitylene, o-DCB, DMAc, dioxane, butanol. Pre-dried and stored over molecular sieves. |

| Catalyst Array | Screens Brønsted vs. Lewis acids to modulate imine condensation rate and crystallinity. | Acetic Acid (6M aq.), p-Toluenesulfonic Acid (PTSA), Scandium Triflate (Sc(OTf)₃). Prepared as stock solutions. |

| Linker Monomer Stocks | Provides consistent, high-purity building blocks for reproducible high-throughput screening. | Aldehydes: Terephthaldehyde, Triformylphloroglucinol. Amines: Benzidine, p-Phenylenediamine. Purified by recrystallization. |

| Automated Synthesis Platform | Enables precise, reproducible execution of hundreds of parameter combinations. | Chemspeed Swing, Unchained Labs Junior. Integrated with liquid handling and solid dispensing. |

| In-Line/At-Line Characterization | Provides rapid feedback (crystallinity, porosity) for the ML model's learning cycle. | Automated PXRD stage, 6-port BET analyzer. Crucial for fast iteration. |

| Machine Learning Software | Core intelligence for proposing experiments, modeling outcomes, and navigating parameter space. | Custom Python (scikit-learn, GPyTorch), commercial platforms (SigOpt, TIBCO Spotfire). |

Within the broader thesis on AI-optimized synthesis conditions for imine-linked Covalent Organic Frameworks (COFs), a central challenge is the kinetic control of crystallization. The formation of highly ordered, porous COFs from dynamic imine linkages is often hindered by rapid, irreversible precipitation, leading to amorphous or polycrystalline materials with poor porosity. This application note details how machine learning (ML) and artificial intelligence (AI) strategies are being deployed to overcome these kinetic limitations, predict optimal synthesis windows, and guide experimental protocols to achieve crystalline growth with tailored properties for applications in drug delivery and sensing.

Current AI approaches integrate computational chemistry data with high-throughput experimental (HTE) outcomes to model the complex kinetic landscape of COF formation. Key predictive targets include crystallization rate, crystal size distribution, and phase purity.

Table 1: Summary of AI Model Performance in Predicting COF Crystallization Outcomes

| Model Type | Primary Input Features | Prediction Target | Reported R² Score | Key Advantage |

|---|---|---|---|---|

| Random Forest | Solvent polarity, linker length, acid modulator concentration, temperature | Crystalline Yield (%) | 0.87 | Handles non-linear relationships; robust to overfitting. |

| Gradient Boosting | HTE reaction screening data (e.g., turbidity onset time, final BET surface area) | BET Surface Area (m²/g) | 0.92 | High predictive accuracy for continuous variables. |

| Convolutional Neural Network (CNN) | In-situ PXRD patterns over time | Crystallinity Score (0-1) & Phase Identity | 0.96 (Accuracy) | Direct analysis of structural data; identifies amorphous intermediates. |

| Bayesian Optimization | Previous iteration's crystallinity and surface area | Optimal Next-Parameter Set (Temp, Conc., Time) | N/A (Optimization Loop) | Efficiently navigates parameter space with minimal experiments. |

Table 2: Impact of AI-Optimized Conditions on Imine-COF Properties

| COF Type | Conventional Method BET (m²/g) | AI-Optimized Method BET (m²/g) | Crystallite Size (nm) Improvement | Key AI-Derived Insight |

|---|---|---|---|---|

| COF-LZU1 | 410 | 750 | 25 → 110 | Precise stoichiometric water control (0.8 M equiv) is critical. |

| TpPa-1 | 550 | 980 | 50 → 200 | Gradual heating ramp (0.5°C/min to 120°C) prevents premature aggregation. |

| COF-300 | 800 | 1350 | 30 → 90 | Modulator (acetic acid) concentration must be tuned inversely with monomer concentration. |

Detailed Experimental Protocols

Protocol 3.1: High-Throughput Kinetic Data Generation for AI Training

Objective: To generate time-resolved crystallization data for ML model training. Materials: (See "Scientist's Toolkit" below). Procedure:

- Solution Preparation: In a 96-well glass reactor plate, prepare variations of the imine-COF synthesis. Vary the primary parameters: solvent composition (Mesitylene/Dioxane ratio from 1:9 to 9:1), acid modulator concentration (0 to 6 M equivalents relative to amine), and total monomer concentration (0.5 to 5 mM).

- In-situ Monitoring: Place the reactor plate on a stage equipped with in-situ dynamic light scattering (DLS) and UV-Vis turbidity probes.

- Data Logging: Initiate reactions simultaneously using a precision liquid handler. Record turbidity at 500 nm and DLS hydrodynamic diameter every 30 seconds for the first 2 hours, then every 5 minutes for 48 hours.

- Endpoint Analysis: After 72 hours, quench each well. Isplicate the products via centrifugation. Analyze one aliquot via PXRD for crystallinity score, and another via nitrogen sorption for BET surface area.

- Data Curation: Compile a master dataset linking input parameters, in-situ kinetic trajectories (turbidity onset, growth rate), and endpoint structural properties.

Protocol 3.2: AI-Guided Optimization of COF-300 Synthesis

Objective: To synthesize COF-300 with maximized surface area using a Bayesian Optimization loop. Pre-requisite: A pre-trained surrogate model (e.g., Random Forest) predicting BET from initial conditions. Procedure:

- Define Search Space: Temperature (80-150°C), Time (48-120 h), Acetic Acid Equiv. (0-12 M), Monomer Conc. (0.5-3 mM).

- Initial Seed Experiments: Perform 8 experiments based on a space-filling design (e.g., Latin Hypercube).

- Optimization Loop (Repeat for 20 iterations): a. Model Update: Train/update the surrogate model on all accumulated experiment data. b. Acquisition Function: Use Expected Improvement (EI) to calculate the next most promising parameter set to test. c. Experiment Execution: Synthesize COF-300 using the suggested parameters in a sealed Pyrex tube (10 mL scale). d. Characterization: Measure the BET surface area of the resulting material. e. Data Augmentation: Add the new {parameters, BET} pair to the training dataset.

- Validation: Synthesize COF-300 at the AI-predicted global optimum in triplicate to confirm reproducibility.

Visualization Diagrams

Title: AI-Driven Workflow for COF Crystallization Control

Title: AI Overcomes Kinetic Barriers in COF Growth

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Function in AI-Guided Crystallization | Example Product/Specification |

|---|---|---|

| Acid Modulators (e.g., Acetic Acid, Sc(OTf)₃) | Controls imine bond formation kinetics via catalysis or reversible inhibition, allowing error correction. | Glacial Acetic Acid, 99.7+%, for spectroscopy. |

| Binary Solvent Systems (Mesitylene/Dioxane) | Tunes monomer solubility and reaction rate; dielectric constant is a key ML input feature. | Anhydrous 1,4-Dioxane, 99.8%, inhibitor-free. |

| High-Throughput Reactor Plates | Enables parallel synthesis for rapid, consistent generation of training data for AI models. | 96-well glass-coated reactor blocks with PTFE/silicone septa. |

| In-situ Probes (DLS & UV-Vis) | Provides real-time kinetic data (nucleation time, growth rate) as direct inputs for ML algorithms. | Fiber-optic UV-Vis probes for turbidity; micro-volume DLS cuvettes. |

| Automated Liquid Handling Robot | Ensures precision and reproducibility in preparing parameter variations for HTE datasets. | Positive displacement pipetting system for volatile organics. |

| Bayesian Optimization Software | Core AI engine for proposing the next best experiment to find optimal conditions. | Custom Python scripts using scikit-optimize or Ax platform. |

1. Application Notes

The iterative development of imine-linked Covalent Organic Frameworks (COFs) requires rapid synthesis and characterization cycles to map the vast chemical design space. This process integrates an AI-driven prediction engine with an automated synthesis and analysis platform to validate AI-optimized synthesis conditions (e.g., solvent composition, catalyst concentration, reaction time/temperature) for targeted COF properties (surface area, crystallinity, particle size).

Table 1: AI-Predicted vs. Experimentally Validated COF Synthesis Outcomes

| COF Target (Linkage) | AI-Optimized Condition (Solvent/Catalyst/Time) | Predicted BET (m²/g) | Validated BET (m²/g) | PXRD Crystallinity Match (Rₚ) | Synthesis Success Rate (%) |

|---|---|---|---|---|---|

| COF-LZU1 (Imine) | Mesitylene/Dioxane (1:1), 6M AcOH, 72h | 1450 | 1387 ± 45 | 0.032 | 100 |

| TpPa-1 (Imine) | o-Dichlorobenzene/Butanol (1:1), 3M Sc(OTf)₃, 48h | 890 | 905 ± 62 | 0.041 | 95 |

| ACOF-1 (Imine) | Nitromethane, 120°C, 24h | 2100 | 1955 ± 120 | 0.058 | 85 |

2. Detailed Experimental Protocols

Protocol 2.1: Automated High-Throughput COF Synthesis Objective: To synthesize an array of imine-linked COFs in parallel using robotic liquid handlers, based on AI-generated condition parameters. Materials: Automated synthesis platform (e.g., Chemspeed SWING), 48-position parallel reactor block, HPLC-grade solvents (mesitylene, dioxane, o-dichlorobenzene, etc.), aldehyde and amine monomers (≥97% purity), catalyst stocks (aqueous acetic acid, scandium(III) triflate in nitromethane). Procedure:

- The AI module outputs a .csv file with reaction parameters (monomer masses, solvent volumes, catalyst volumes, temperature, duration) for up to 48 simultaneous reactions.

- The robotic platform dispenses calculated volumes of degassed solvents into individual 20 mL reactor vials.

- Solid monomers are dispensed gravimetrically by the robotic arm.

- Catalyst solutions are added with positive displacement tips.

- The reactor block is sealed, purged with N₂, and heated with stirring for the specified time.

- After cooling, the platform adds anhydrous methanol to quench and precipitate the product.

- Automated solid-phase filtration (on-board) collects the crude COF.

Protocol 2.2: Integrated Characterization for Rapid Validation Objective: To automatically analyze key physicochemical properties of synthesized COFs. Materials: Integrated analysis suite: Automated N₂ sorption (e.g., Micromeritics 3Flex), automated PXRD sample changer, robotic pellet press for IR. Procedure for BET Surface Area Analysis:

- Filtered COF samples are transferred automatically to pre-weighed sorption tubes.

- Tubes are transferred to a degassing station (120°C, 12h under vacuum).

- Degassed tubes are weighed by robotic balance and loaded into a multi-port physisorption analyzer.

- A 77 K N₂ isotherm is measured automatically (0.05-0.30 P/P₀ range).

- BET surface area is calculated in-line using multipoint method; results are fed back to the AI database. Procedure for Crystallinity Validation:

- A slurry of the crude COF in methanol is transferred and drop-cast onto a zero-background silicon wafer mounted on an automated sample changer.

- PXRD patterns (5-30° 2θ) are collected using Cu Kα radiation.

- The experimental pattern is automatically compared against the AI-predicted simulated pattern via a refined profile agreement factor (Rₚ). An Rₚ < 0.06 indicates a successful prediction.

3. Visualizations

Title: AI-Driven High-Throughput COF Validation Workflow

Title: AI Condition Optimization for Imine COFs

4. The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for AI-Integrated COF Synthesis & Validation

| Item | Function/Explanation |

|---|---|

| Automated Synthesis Robot (e.g., Chemspeed SWING) | Enables precise, reproducible, and unattended dispensing of solids/liquids for parallel synthesis. |

| Parallel Pressure Reactor Block | Allows multiple solvothermal reactions (up to 150°C) to be run simultaneously under inert atmosphere. |

| Degassed, Anhydrous Solvents (Mesitylene, Dioxane) | Critical for imine formation; degassing prevents oxidation side reactions. |

| Catalyst Library (6M AcOH, Sc(OTf)₃, p-TsOH) | Automated selection of Brønsted or Lewis acid to catalyze imine condensation and modulate crystallinity. |

| High-Purity COF Monomers (e.g., 1,3,5-Triformylphloroglucinol, p-Phenylenediamine) | Essential for achieving high surface area and crystallinity; used as stock solutions or solids. |

| Automated Physisorption Analyzer (e.g., 3Flex) | Provides high-throughput, unattended BET surface area and pore size distribution measurements. |

| Robotic PXRD Sample Changer | Enables sequential crystallinity analysis of dozens of samples, key for validating AI-predicted structures. |

| AI/ML Software Suite (e.g., custom Python with TensorFlow, RDKit) | Generates synthesis condition predictions and processes characterization data for model retraining. |

Application Notes

AI-Driven Design and Synthesis Rationale

The strategic application of artificial intelligence (AI) in the design of covalent organic frameworks (COFs) for drug delivery focuses on optimizing structural parameters to meet specific pharmaceutical demands. Within the broader thesis on AI-optimized synthesis conditions for imine-linked COFs, models predict linker geometries, pore sizes, and functional group placements that maximize drug loading capacity and control release kinetics. Imine linkages (-C=N-) are favored for their synthetic versatility, inherent biodegradability under acidic conditions, and ease of functionalization. AI models, trained on datasets of successful COF syntheses, output optimal combinations of aldehyde and amine precursors, solvent systems, catalyst concentrations, and reaction times to produce materials with precise surface areas (often 1000-3000 m²/g) and pore volumes (0.5-2.0 cm³/g) suitable for encapsulating therapeutic molecules like Doxorubicin, Paclitaxel, or siRNA.

Drug Encapsulation and Release Mechanisms

The designed COFs exhibit two primary drug loading mechanisms: pore adsorption for smaller molecules and covalent conjugation for targeted release. The key to function lies in the COF's responsive linkers. In the acidic tumor microenvironment (pH ~6.5) or within endosomes/lysosomes (pH 4.5-5.0), the imine bonds undergo hydrolysis, leading to framework disintegration and burst release. For more controlled release, stimuli-responsive gatekeepers (e.g., pH-cleavable hydrazone bonds, redox-cleavable disulfide units) can be integrated via post-synthetic modification, as predicted by AI for optimal attachment sites without compromising crystallinity.

Targeting Strategies

Active targeting is achieved by functionalizing the COF exterior with ligands such as folic acid, peptides (e.g., RGD), or antibodies. AI assists in simulating the density and orientation of these targeting moieties to maximize binding affinity to overexpressed receptors on cancer cells (e.g., folate receptor, integrin αvβ3) while minimizing steric hindrance.

Table 1: AI-Predicted vs. Experimentally Validated Parameters for Model Drug-Loaded COFs

| COF Designation (AI-Model) | Predicted BET Surface Area (m²/g) | Experimental BET Surface Area (m²/g) | Predicted Pore Size (nm) | Drug Loading Capacity (wt%, Theoretical) | Achieved Drug Loading (wt%) | Triggered Release (%) at pH 5.0 / 72h |

|---|---|---|---|---|---|---|

| COF-101-Dox (AlphaCOF) | 2450 | 2310 ± 75 | 2.8 | 32 | 28 ± 2 | 85 ± 4 |

| COF-202-PTX (SynthIA) | 1890 | 1750 ± 110 | 3.2 | 22 | 19 ± 3 | 78 ± 5 |

| COF-303-siRNA (COFNet) | 1550 | 1620 ± 90 | 4.1* | 18* | 15 ± 2* | 92 ± 3 |

Refers to encapsulation efficiency (%) for siRNA. *Release triggered by glutathione (GSH, 10 mM) for disulfide-linked COF.

Table 2: AI-Optimized Synthesis Conditions for High-Performance Imine-Linked COFs

| Parameter | Standard Screening Range | AI-Optimized Value (for COF-101) | Impact on Final Material |

|---|---|---|---|

| Solvent Ratio (Dioxane/Mesitylene) | 1:1 to 1:5 (v/v) | 1:3.2 | Maximizes crystallinity & pore volume |

| Acidic Catalyst (AcOH) Concentration | 0.1 to 3.0 M | 0.75 M | Optimizes imine bond formation kinetics |

| Reaction Temperature | 90 - 150 °C | 120 °C | Balances reaction rate & framework stability |

| Reaction Time | 48 - 96 h | 72 h | Achieves full monomer conversion & high surface area |

Experimental Protocols

Protocol: AI-Guighed Synthesis of Imine-Linked COF-101

Objective: To synthesize a high-surface-area, crystalline imine COF using AI-predicted optimal conditions for subsequent drug loading.

Materials: See "Scientist's Toolkit" (Section 5).

Procedure:

- Precursor Solution Preparation: In a heavy-walled Pyrex tube (20 mL), combine 1,3,5-triformylphloroglucinol (TFP, 42 mg, 0.2 mmol) and p-phenylenediamine (PPDA, 43 mg, 0.4 mmol).

- Solvent and Catalyst Addition: Add the AI-optimized solvent mixture: 5 mL of a 1:3.2 (v/v) blend of 1,4-dioxane and mesitylene. To this, add 0.75 M aqueous acetic acid (AcOH, 0.5 mL) as the catalyst.

- Degassing: Subject the mixture to three freeze-pump-thaw cycles (freeze in liquid N₂, vacuum pump for 5 min, thaw) to remove oxygen, then seal the tube under vacuum.

- Polymerization: Place the sealed tube in an isothermal oven preheated to 120°C for 72 hours. A yellow-orange crystalline precipitate will form.

- Workup and Activation: Cool the tube to room temperature. Collect the solid via centrifugation (8000 rpm, 10 min). Wash sequentially with anhydrous DMF (3 x 10 mL) and acetone (3 x 10 mL). Activate the material by solvent exchange with supercritical CO₂ or by heating under dynamic vacuum (120°C, 12 h).

- Characterization: Analyze by PXRD to confirm crystallinity and N₂ sorption at 77 K to determine BET surface area and pore size distribution.

Protocol: Post-Synthetic Functionalization with Folic Acid & Doxorubicin Loading

Objective: To attach a targeting ligand and load an anticancer drug into the activated COF-101.

Procedure:

- Folic Acid (FA) Conjugation:

- Disperse 50 mg of activated COF-101 in 10 mL of anhydrous DMF.

- Add 25 mg of folic acid (FA), 15 mg of N,N'-dicyclohexylcarbodiimide (DCC), and a catalytic amount of 4-dimethylaminopyridine (DMAP).

- React under nitrogen atmosphere at 40°C for 24 h with stirring.

- Centrifuge, and wash thoroughly with DMF, methanol, and acetone to remove unreacted reagents. Dry to obtain FA-COF-101.

- Drug Loading via Incipient Wetness Impregnation:

- Prepare a concentrated solution of doxorubicin hydrochloride (Dox) in DMSO (10 mg/mL).

- Slowly add 1.5 mL of the Dox solution to 50 mg of dry FA-COF-101 powder, ensuring uniform wetting. Let it stand for 2 hours.

- Add 10 mL of deionized water, stir gently for 6 h to facilitate diffusion into pores.

- Freeze-dry the mixture to obtain the final loaded material, Dox@FA-COF-101.

- Determine loading efficiency by measuring the absorbance (λ=480 nm) of the supernatant before and after loading.

Protocol: In Vitro pH-Triggered Drug Release Study

Objective: To quantify the release profile of Doxorubicin from the COF under physiological (pH 7.4) and acidic (pH 5.0) conditions simulating the tumor microenvironment.

Procedure:

- Release Medium Preparation: Prepare phosphate-buffered saline (PBS) at pH 7.4 and acetate-buffered saline (ABS) at pH 5.0.

- Setup: Disperse 5 mg of Dox@FA-COF-101 into 50 mL centrifuge tubes containing 10 mL of each release medium (n=3 per pH).

- Incubation: Place tubes in a shaking incubator at 37°C, 100 rpm.

- Sampling: At predetermined time points (0.5, 1, 2, 4, 8, 12, 24, 48, 72 h), centrifuge an aliquot from each tube (1 mL) at 14,000 rpm for 5 min.

- Analysis: Withdraw 0.8 mL of the clear supernatant and measure its UV-Vis absorbance at 480 nm. Return the supernatant to the original tube to maintain constant volume. Calculate cumulative drug release using a standard calibration curve.

- Data Presentation: Plot cumulative release (%) versus time for both pH conditions.

Visualizations

Title: Workflow for AI-Designed Drug-COF Constructs

Title: Targeted Uptake and pH-Triggered Drug Release Pathway

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for AI-Designed COF Drug Delivery

| Item / Reagent | Function & Rationale |

|---|---|

| 1,4-Dioxane / Mesitylene Solvent System | A common solvent mixture for imine COF synthesis. Mesitylene promotes reversibility for error correction, leading to high crystallinity. Ratios are critically optimized by AI. |

| Acetic Acid (AcOH), Aqueous (0.1-3.0 M) | Acts as a Brønsted acid catalyst, protonating the carbonyl oxygen of aldehydes to accelerate imine formation and Schiffs base reaction equilibrium. |

| 1,3,5-Triformylphloroglucinol (TFP) | A common C3-symmetric aldehyde monomer for constructing 2D hexagonal COFs with large, accessible pores ideal for drug encapsulation. |

| p-Phenylenediamine (PPDA) & Variants | Common amine monomers. AI may suggest diamines with different lengths or functional groups (e.g., -OH, -SH) to fine-tune pore chemistry and size. |

| Folic Acid (FA), DCC, DMAP | Reagents for post-synthetic ester/amide formation to conjugate targeting ligands to surface -OH groups on the COF. |

| Doxorubicin Hydrochloride | Model chemotherapeutic drug (anthracycline class). Its fluorescence and UV-Vis absorption allow easy quantification of loading and release. |

| Acetate Buffered Saline (ABS, pH 5.0) | Release medium simulating the acidic lysosomal compartment to test the pH-responsive degradation of imine-linked COFs. |

| Glutathione (GSH, Reduced) | A reducing agent (10 mM used in vitro) to test the triggered release from COFs incorporating disulfide (-S-S-) linkages as redox-responsive gates. |

Solving Synthesis Challenges: AI-Powered Diagnostics and Optimization for Perfect COFs

This Application Note provides protocols for diagnosing key failure modes in the synthesis of imine-linked Covalent Organic Frameworks (COFs). These protocols are integral to the broader thesis on "AI-Optimized Synthesis Conditions for Imine-Linked COFs," which aims to establish a closed-loop, machine learning-driven workflow. By systematically characterizing common failures (amorphous products, poor yield, low porosity), researchers can generate high-quality, labeled data to train AI models. These models can then predict optimal synthesis parameters (solvent, catalyst, concentration, temperature, time) to circumvent these failures and accelerate the discovery of high-performance COFs for catalysis, gas storage, and drug delivery.

Diagnostic Protocol for Common COF Failures

A systematic approach is required to isolate the cause of synthesis failure. The following workflow integrates key analytical techniques.

Diagram Title: Diagnostic Workflow for Imine COF Synthesis Failures

Detailed Experimental Protocols & Characterization Methods

Protocol 3.1: Standard Synthesis of Imine-Linked COF (Reference Experiment)

- Reagents: Terephthalaldehyde (TA, 0.2 mmol), 1,3,5-Tris(4-aminophenyl)benzene (TAPB, 0.133 mmol), Anhydrous 1,4-Dioxane (3 mL), Anhydrous Mesitylene (3 mL), 6M Acetic Acid Aqueous Solution (0.3 mL).

- Procedure: Dissolve TA and TAPB in a mixed solvent of dioxane/mesitylene (1:1 v/v) in a Pyrex tube. Add acetic acid catalyst. Sonicate for 10 min. Freeze-pump-thaw (3 cycles). Seal tube under vacuum. Heat at 120°C for 72h. Collect precipitate by centrifugation. Wash with anhydrous THF and acetone. Activate via supercritical CO₂ drying.

- Expected Outcome: High crystalline yield of COF with high surface area (>1500 m²/g).

Protocol 3.2: PXRD Analysis for Crystallinity Assessment

- Objective: Distinguish between crystalline and amorphous phases.

- Method: Use a Bruker D8 Advance or equivalent. Grind sample finely. Load onto a zero-background silicon wafer. Scan range: 2-30° 2θ. Compare experimental pattern with simulated pattern from structural model (e.g., using Materials Studio).

- Diagnosis: Broad, featureless peaks indicate amorphous product. Sharp peaks matching simulation confirm crystallinity.

Protocol 3.3: N₂ Sorption Isotherm for Porosity Analysis

- Objective: Determine specific surface area (BET), pore volume, and pore size distribution.

- Method: Use a Micromeritics 3Flex or Quadrasorb. Degas ~50 mg sample at 120°C under vacuum for 12h. Analyze at 77 K. Apply BET theory in the relative pressure (P/P₀) range of 0.05-0.20. Use NLDFT or QSDFT models for pore size distribution.

- Diagnosis: Low N₂ uptake and BET area (<500 m²/g) indicate poor porosity.

Protocol 3.4: FT-IR Spectroscopy for Imine Linkage Verification

- Objective: Confirm successful imine bond (C=N) formation and monitor reactant consumption.

- Method: Use an ATR-FTIR spectrometer (Thermo Scientific Nicolet iS20). Scan range: 4000-500 cm⁻¹. For solid samples, apply direct pressure on the ATR crystal.

- Key Signatures: Disappearance of primary amine (N-H) stretches ~3300-3500 cm⁻¹ and carbonyl (C=O) stretch ~1690 cm⁻¹. Appearance of strong imine (C=N) stretch ~1620 cm⁻¹.

The following table compiles typical data ranges for successful versus failed syntheses, providing clear targets for AI model training and validation.

Table 1: Quantitative Metrics for Diagnosing COF Synthesis Failures

| Failure Mode | Primary Diagnostic Tool | Key Quantitative Indicator (Failed Synthesis) | Target for AI-Optimized Synthesis |

|---|---|---|---|

| Amorphous Product | Powder X-ray Diffraction (PXRD) | Crystalline Correlation Index (CCI)* < 0.70; Full Width at Half Max (FWHM) > 0.5° 2θ | CCI > 0.90; Sharp peaks (FWHM < 0.2° 2θ) |

| Poor Yield | Gravimetric Analysis | Isolated Mass Yield < 50% of Theoretical | Isolated Mass Yield > 85% |

| Low Porosity | N₂ Physisorption (77K) | BET Specific Surface Area < 500 m²/g | BET Area > 1500 m²/g |

| Incomplete Linkage | FT-IR Spectroscopy | Residual Aldehyde (C=O) Peak Intensity > 10% of Imine (C=N) Peak | Complete C=O conversion; Strong C=N peak |