AI-Driven Discovery of Biomass-Based CO2 Sorbents: From Molecular Design to Biomedical and Pharmaceutical Applications

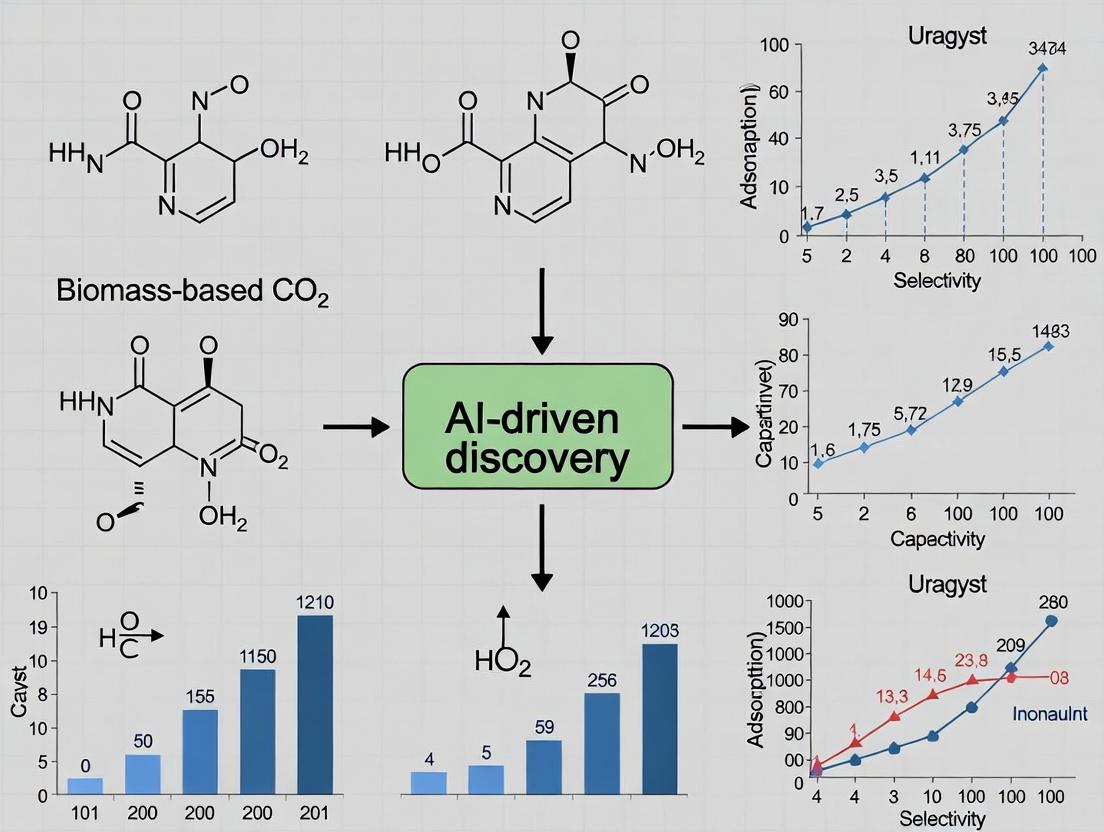

This article explores the transformative role of artificial intelligence in accelerating the discovery and optimization of sustainable, biomass-derived carbon dioxide sorbents.

AI-Driven Discovery of Biomass-Based CO2 Sorbents: From Molecular Design to Biomedical and Pharmaceutical Applications

Abstract

This article explores the transformative role of artificial intelligence in accelerating the discovery and optimization of sustainable, biomass-derived carbon dioxide sorbents. Targeting researchers, scientists, and drug development professionals, it provides a comprehensive overview from foundational principles to advanced applications. We examine how AI models predict sorbent performance from molecular structure, guide synthesis methodologies, optimize material properties for specific use cases like controlled atmosphere storage or respiratory protection, and enable rigorous validation against traditional materials. The discussion highlights the cross-disciplinary potential of these smart materials in biomedical research, pharmaceutical manufacturing, and clinical environments, offering a roadmap for integrating sustainability with high-performance material science.

The AI and Biomass Revolution: Foundations for Next-Gen CO2 Capture Materials

Why Biomass? The Sustainability and Tunability Argument for CO2 Sorption

Within the broader research thesis on AI-driven discovery of biomass-based CO2 sorbents, this document establishes the foundational scientific and practical arguments. The imperative to develop sustainable, high-performance CO2 sorption materials has never been greater. Biomass-derived porous carbons (BPCs) and functionalized materials present a compelling solution, merging inherent sustainability with a high degree of chemical and structural tunability. This tunability, now accelerated by machine learning (ML) and artificial intelligence (AI) models, allows for the predictive design of sorbents tailored for specific capture conditions (e.g., post-combustion flue gas vs. direct air capture). These Application Notes and Protocols detail the rationale, key data, and standardized methodologies for synthesizing, characterizing, and evaluating biomass-based CO2 sorbents within this AI-augmented research paradigm.

Core Data: Biomass vs. Conventional Sorbents

Table 1: Comparative Performance of CO2 Sorption Materials

| Material Class | Example | CO2 Uptake (mmol/g) @ 25°C, 1 bar | Selectivity (CO2/N2) | Regeneration Energy (Estimated, GJ/t CO2) | Primary Feedstock Source |

|---|---|---|---|---|---|

| Biomass-Derived Porous Carbons | N-Doped Carbon from Chitosan | 3.5 - 6.2 | 15 - 45 | 1.5 - 2.5 | Renewable, Waste Stream |

| Conventional Zeolites | 13X | 3.0 - 4.0 | 25 - 35 | 2.0 - 3.0 | Mineral / Synthetic |

| Metal-Organic Frameworks | MOF-74, Mg | 6.5 - 8.5 | 80 - 150 | 1.8 - 2.8 | Petrochemical |

| Amino-Functionalized Silicas | PEI-impregnated SBA-15 | 2.5 - 4.0 (chemisorption) | >1000 | 3.0 - 4.5 (temp. swing) | Synthetic |

Table 2: Tunability Parameters for Biomass Sorbents & AI Optimization Targets

| Tunability Parameter | Effect on Sorption Performance | Typical AI/ML Model Input Feature | Optimization Goal for Post-Combustion Capture |

|---|---|---|---|

| Porosity (Micro/Meso) | Micropores (<2 nm) dominate physisorption capacity; Mesopores facilitate kinetics. | BET Surface Area, Pore Volume Distribution | Maximize ultra-micropores (<0.8 nm) for 0.15 bar CO2. |

| Surface Chemistry (N/O groups) | N (amine, pyrrolic) and O (carboxyl) enhance affinity & selectivity via acid-base interaction. | Elemental N/O %, XPS functional group ratios | Optimize basic N content for enhanced CO2 binding energy. |

| Precursor Composition | Lignin yields higher carbon; cellulose influences morphology; proteins introduce N. | Lignin/Cellulose/Protein ratio, Proximate Analysis | Predict performance from biochemical composition. |

| Activation Method/Agent | KOH creates micropores; CO2 develops wider pores; H3PO4 introduces P-O groups. | Act. Agent:Biomass ratio, Temp, Time | Discover novel activation pathways for target isotherm shape. |

Detailed Experimental Protocols

Protocol 1: AI-Guided Synthesis of N-Doped Porous Carbon from Lignocellulosic Biomass

Objective: To synthesize a biomass-derived carbon sorbent with properties (surface area, N-doping level, pore size) predicted by an AI model to maximize CO2 uptake at 0.15 bar and 40°C.

Materials: See "The Scientist's Toolkit" below.

Workflow:

- Precursor Selection & Pre-processing: A random forest model trained on literature data suggests a 70:30 mixture of walnut shells (high lignin) and soy meal (high N protein). Grind and sieve to 100-200 mesh. Dry at 110°C overnight.

- Pre-carbonization: Place 10g of precursor in a tubular furnace under N2 flow (200 mL/min). Heat at 5°C/min to 400°C, hold for 1 hour. Cool under N2. This yields a stabilized char.

- Chemical Activation & Doping: Prepare a KOH solution as per the AI-suggestized impregnation ratio (KOH:Char = 2:1 by mass). Impregnate the char with the solution, stir for 12 hours, then dry at 120°C.

- Carbonization/Activation: Transfer the dried mixture to an alumina boat. In the tubular furnace, under N2 flow, heat at 3°C/min to 700°C (AI-optimized temperature) and hold for 90 minutes.

- Post-processing: Cool to room temperature under N2. Wash the resulting black solid sequentially with 1M HCl and copious deionized water until neutral pH. Dry at 120°C for 12 hours. Store in a desiccator.

Protocol 2: Comprehensive Physicochemical Characterization

Objective: To generate quantitative data for AI model training/validation and structure-property analysis.

A. N2 Physisorption at 77K for Porosity:

- Degas ~100 mg of sample at 200°C under vacuum for 12 hours.

- Perform adsorption/desorption isotherm measurement using a surface area analyzer.

- Analysis: Calculate BET surface area from relative pressure (P/P0) range 0.05-0.25. Use the Non-Local Density Functional Theory (NLDFT) model on the adsorption branch to determine pore size distribution, focusing on micropore volume (< 1 nm).

B. CO2 Physisorption at 273K & 298K:

- Using the same degassed sample, measure CO2 isotherms at 0°C (273K) and 25°C (298K) up to 1 bar.

- Analysis: Calculate the CO2 uptake at 0.15 bar and 1 bar (298K). Use the data from both temperatures to calculate the Isosteric Heat of Adsorption (Qst) using the Clausius-Clapeyron equation, an indicator of surface affinity.

C. X-ray Photoelectron Spectroscopy (XPS) for Surface Chemistry:

- Mount powder on conductive carbon tape. Acquire survey and high-resolution spectra (C1s, N1s, O1s).

- Analysis: Use fitting software to deconvolute peaks. Quantify atomic percentages and assign functional groups (e.g., for N1s: pyridinic N, pyrrolic N, quaternary N, N-oxides).

Protocol 3: Dynamic CO2/N2 Breakthrough Testing

Objective: To evaluate the real-world separation performance and kinetics under simulated flue gas conditions.

Methodology:

- Pack a fixed-bed column (internal diameter 6 mm, length 15 cm) with 500 mg of sorbent held between quartz wool plugs.

- Pre-treatment: Activate the sorbent in-situ under He flow (50 mL/min) at 150°C for 2 hours, then cool to the adsorption temperature (40°C).

- Adsorption: Switch the inlet gas to a simulated flue gas mixture (15% CO2, 85% N2 by volume) at a total flow rate of 50 mL/min. Monitor the outlet concentration using a mass spectrometer or CO2 analyzer.

- Desorption: After CO2 breakthrough (e.g., at 5% of inlet concentration), switch back to He flow and ramp temperature to 100°C at 10°C/min to regenerate the sorbent.

- Analysis: Calculate the dynamic CO2 uptake (mmol/g) from the breakthrough curve. Determine the CO2/N2 selectivity from the difference in breakthrough times.

Mandatory Visualizations

AI-Driven Biomass Sorbent Discovery Loop

Biomass Sorbent Synthesis & Characterization Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Biomass-Based CO2 Sorbent Research

| Item / Reagent | Function in Research | Key Consideration for Protocol |

|---|---|---|

| Lignocellulosic Biomass Precursors | Primary, sustainable carbon source. Provides initial structure and heteroatoms. | Standardize particle size (<200µm) and moisture content. Document biochemical composition. |

| Chemical Activators (KOH, H3PO4, ZnCl2) | Etching agents that create and tune porosity during pyrolysis. | Highly corrosive. Use AI models to optimize agent:biomass ratio. Requires careful washing. |

| Nitrogen Dopants (Urea, Melamine, NH3 gas) | Introduce basic N functional groups to enhance CO2 affinity and selectivity. | Can be co-pyrolyzed with biomass or used in post-treatment. AI helps select type and method. |

| High-Purity Gases (N2, CO2, 15% CO2/N2 mix, He) | For pyrolysis atmosphere, sorption measurements, and breakthrough testing. | Essential for reproducible activation and performance data. Use mass flow controllers. |

| Quartz Tube Furnace with Programmable Controller | For controlled pyrolysis and activation under inert atmosphere. | Enables precise ramping rates and dwell times predicted by synthesis models. |

| Surface Area & Porosity Analyzer | Measures N2/CO2 physisorption isotherms to determine surface area and pore structure. | Critical for generating quantitative features for AI models (BET area, pore volume). |

| X-ray Photoelectron Spectrometer (XPS) | Quantifies elemental composition and chemical bonding states on the sorbent surface. | Provides key data on functional groups (N, O types) for understanding sorption mechanisms. |

| Fixed-Bed Breakthrough System with MS/TC Detector | Evaluates dynamic separation performance under realistic gas mixture conditions. | The ultimate validation tool for predicted sorbent performance in a simulated application. |

Within the thesis "AI-Driven Discovery of Biomass-Derived CO2 Sorbents," a foundational challenge is predicting the gas adsorption properties of porous carbons from their structural features. Traditional methods are slow and struggle with the complex, heterogeneous nature of biomass-derived materials. This document outlines the core AI principles and protocols for learning these critical structure-property relationships (SPRs), enabling the rapid screening and design of optimal sorbents.

Core AI Principles: From Data to Prediction

AI models, particularly machine learning (ML) and deep learning (DL), learn SPRs by identifying complex patterns in data. The process follows a systematic pipeline.

AI Workflow for Learning Structure-Property Relationships

Principle 1: Feature Representation. The porous structure must be converted into numerical descriptors (features). Common descriptors include:

- Geometric: Porosity, pore size distribution, surface area.

- Chemical: Elemental composition, surface functional groups.

- Topological: Graph-based representations of pore connectivity.

- Morphological: Textural features from electron microscopy.

Principle 2: Model Architectures.

- Classical ML: Random Forests, Gradient Boosting, and Support Vector Machines learn from handcrafted features.

- Graph Neural Networks (GNNs): Directly operate on atomic or pore-graph representations, learning relevant features automatically—key for disordered materials.

- Convolutional Neural Networks (CNNs): Can process spatial data like microscopy images or voxelized 3D volume representations.

Principle 3: Learning Objective. The model is trained to minimize the difference between its predicted property (e.g., CO2 uptake at 1 bar, 298K) and the experimentally measured value in the training dataset, using a loss function like Mean Squared Error.

The performance of different AI approaches for predicting gas adsorption in porous materials is benchmarked below.

Table 1: Performance of AI Models for CO2 Uptake Prediction in Porous Carbons

| Model Type | Key Features Used | Dataset Size | Average Error (MAE) | Best For |

|---|---|---|---|---|

| Random Forest | BET SA, Pore Volume, PSD, H/C ratio | ~500 materials | 0.15 mmol/g | High-throughput screening from tabular data. |

| Gradient Boosting | DFT-derived descriptors, elemental % | ~800 materials | 0.11 mmol/g | Leveraging complex physicochemical features. |

| Graph Neural Network | Atomic graph (C, O, H) | ~1200 structures | 0.08 mmol/g | Novel biomass precursors with no prior data. |

| 3D CNN | Volumetric electron density grid | ~300 3D models | 0.21 mmol/g | Linking synthetic microscopy data to performance. |

MAE = Mean Absolute Error on test set for CO2 uptake at 1 bar, 298K. SA = Surface Area. PSD = Pore Size Distribution.

Experimental Protocols

Protocol 4.1: Generating a Training Dataset for Biomass-Derived Porous Carbons Objective: To create a standardized dataset linking synthesis parameters, structural characterization data, and CO2 adsorption performance. Materials: See "Scientist's Toolkit" below.

- Synthesis Variation: Synthesize a library of porous carbons from a single biomass precursor (e.g., lignin) by systematically varying pyrolysis temperature (600-900°C) and activation agent ratio (KOH/C: 1-4).

- Structural Characterization:

- Perform N₂ physisorption at 77K on all samples. Extract Brunauer-Emmett-Teller (BET) surface area, total pore volume, and Non-Local Density Functional Theory (NLDFT) pore size distribution.

- Perform elemental analysis (CHNS/O) to determine chemical composition.

- Perform X-ray Photoelectron Spectroscopy (XPS) on a representative subset to quantify surface oxygen functional groups.

- Property Measurement: Perform high-pressure CO₂ physisorption at 298K for all samples, measuring uptake at 0.1 bar (relevant for dilute capture) and 1 bar.

- Data Curation: Assemble all data into a structured table (CSV). Each row is one material. Columns include synthesis parameters, structural features, and target property (CO2 uptake).

Protocol 4.2: Training and Validating a GNN Model for Prediction Objective: To train a model that predicts CO2 uptake directly from a simplified molecular representation of the carbon precursor. Software: Python with PyTorch Geometric and RDKit libraries.

- Graph Construction: Represent each biomass-derived monomer (e.g., guaiacyl unit from lignin) as a molecular graph. Nodes are atoms (C, O, H), with features like atom type and hybridization. Edges represent bonds.

- Model Definition: Implement a Graph Convolutional Network (GCN) or Message Passing Neural Network (MPNN). The network should include 3-5 graph convolution layers, global pooling, and fully connected layers leading to a single output neuron (predicted uptake).

- Training Loop:

- Split dataset (from Protocol 4.1) into training (70%), validation (15%), and test (15%) sets.

- Use Adam optimizer with Mean Squared Error (MSE) loss.

- Train for a fixed number of epochs (e.g., 500), evaluating the validation loss each epoch.

- Implement early stopping if validation loss does not improve for 50 epochs.

- Evaluation: Apply the final model to the held-out test set. Report key metrics: MAE, R² score, and plot predicted vs. experimental values.

GNN Prediction Workflow for Sorbent Design

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials & Tools for AI-Driven Sorbent Research

| Item/Category | Function & Relevance |

|---|---|

| Biomass Precursors | Lignin, cellulose, chitosan. Provide sustainable carbon source with inherent heteroatoms (O, N) for enhanced surface chemistry. |

| Chemical Activators | KOH, NaOH, ZnCl₂. Create porosity during pyrolysis. The agent ratio is a key synthesis variable for the AI model. |

| Gas Sorption Analyzer | Measures N₂ (77K) and CO₂ (273K, 298K) adsorption isotherms. Generates critical structural and performance data for training AI. |

| Elemental Analyzer | Quantifies carbon, hydrogen, nitrogen, sulfur, oxygen content. Provides essential chemical descriptors for ML models. |

| High-Performance Computing | GPU clusters are essential for training deep learning models (GNNs, CNNs) on large datasets in a feasible time. |

| Python ML Stack | Libraries: scikit-learn (classical ML), PyTorch/PyTorch Geometric (DL/GNNs), pandas (data handling), matplotlib (visualization). |

Application Notes: Feedstock Characteristics for AI-Driven Sorbent Discovery

Selecting the optimal biomass feedstock is critical for AI-driven high-throughput discovery of novel carbon dioxide sorbents. The physicochemical properties of the feedstock directly determine the porosity, surface chemistry, and ultimate CO2 adsorption capacity of the derived biochar or activated carbon. The following notes detail key feedstocks, emphasizing data points essential for machine learning model training.

Table 1: Quantitative Comparison of Primary Biomass Feedstocks for CO2 Sorbent Research

| Feedstock Class | Example Feedstocks | Typical Lignin Content (%) | Typical Cellulose Content (%) | Typical H/C Ratio | Typical Ash Content (%) | Key Advantages for Sorbent Development |

|---|---|---|---|---|---|---|

| Lignocellulosic (Hardwood) | Oak, Maple, Birch | 18-25 | 40-50 | ~1.5 | 0.3-0.8 | Moderate porosity development; consistent structure for ML modeling. |

| Lignocellulosic (Softwood) | Pine, Spruce, Fir | 25-35 | 40-50 | ~1.5 | 0.2-0.7 | High lignin yields more residual carbon; good for microporous structures. |

| Lignocellulosic (Agricultural) | Corn Stover, Wheat Straw, Bagasse | 10-25 | 35-50 | ~1.6 | 3-10 | High availability; often high in silica (ash) which can influence catalysis. |

| Algal Biomass | Chlorella spp., Spirulina | <5 (Alginates) | <20 (Polysaccharides) | ~1.8 | 5-30 (can be high) | High N, S content for intrinsic heteroatom doping; fast growing. |

| Waste Streams | Sewage Sludge, Manure | Varies | Varies | ~1.7 | 10-50+ | Very high inorganic content (Ca, Mg, P) for enhanced chemisorption. |

| Waste Streams | Nut Shells (e.g., Coconut) | 30-40 | 25-30 | ~1.4 | 1-3 | Naturally high hardness and initial porosity; excellent precursor. |

Table 2: Critical Process Parameters & Resulting Sorbent Properties

| Pyrolysis/Activation Parameter | Typical Range | Primary Effect on Feedstock | Key Output Metric for AI Training |

|---|---|---|---|

| Pyrolysis Temperature | 400°C - 800°C | Devolatilization; aromatic condensation. | BET Surface Area (m²/g), Pore Volume (cm³/g) |

| Heating Rate | 5°C/min - 100°C/min | Influences pore size distribution. | Microporosity vs. Mesoporosity Ratio |

| Activation Agent | CO2, H3PO4, KOH, Steam | Etching and pore creation. | Surface Functional Groups (e.g., -COOH, -OH) |

| Activation Time | 30 - 120 mins | Degree of pore widening. | Average Pore Diameter (nm) |

| N-Doping Precursor | Urea, Melamine, NH3 | Incorporation of basic N sites. | N-content (at.%), CO2 Adsorption at 25°C (mmol/g) |

Experimental Protocols

Protocol 2.1: Standardized Feedstock Pre-Processing for ML Dataset Generation

Objective: To prepare a uniform, characterized biomass input from diverse feedstocks for pyrolysis and subsequent CO2 adsorption testing. Materials: See The Scientist's Toolkit below. Procedure:

- Comminution: Mill raw biomass to a particle size of 0.5-1.0 mm using a centrifugal mill. Sieve to ensure uniformity.

- Drying: Dry sieved biomass in a forced-air oven at 105°C for 24 hours to achieve constant weight (<5% moisture).

- Proximate Analysis (TGA Method): Using a Thermogravimetric Analyzer (TGA), record weight loss under N2 (to 900°C) for volatile matter and fixed carbon, then switch to air for ash content. Record data points every 10°C.

- Elemental (CHNS-O) Analysis: Precisely weigh 2-3 mg of dried powder into a tin capsule. Analyze using a combustion elemental analyzer. Record weight percentages of C, H, N, S. Calculate O by difference.

- Storage: Store fully characterized biomass in sealed, desiccated containers labeled with a unique sample ID for the ML database.

Protocol 2.2: AI-Informed Hydrothermal Carbonization (HTC) of Waste Streams

Objective: To convert high-moisture waste streams (e.g., algae, sludge) into hydrochar with tailored surface functionality. Materials: Autoclave or pressurized reactor, Teflon liner, freeze dryer. Procedure:

- Slurry Preparation: Homogenize wet feedstock with deionized water to a 10% solid concentration (w/v).

- Parameter Selection: Input target H/C and O/C ratios into the trained AI model (e.g., a generative adversarial network). The model outputs recommended HTC parameters.

- Reaction: Transfer slurry to a Teflon-lined reactor. Run the reaction at the AI-specified temperature (180-250°C) and time (2-12 hours).

- Product Recovery: Cool reactor, filter the slurry. Wash solid hydrochar with DI water and ethanol.

- Drying: Lyophilize the hydrochar for 48 hours to preserve porous structure.

- Characterization: Submit hydrochar for FT-IR (surface groups) and N2 physisorption (surface area) analysis. Feed results back into the AI model.

Protocol 2.3: High-Throughput CO2 Adsorption Screening (Volumetric Method)

Objective: To generate consistent CO2 uptake data at multiple temperatures and pressures for ML training. Materials: High-throughput volumetric sorption analyzer (e.g., 6-port manifold), microbalance, CO2 (99.99%). Procedure:

- Sample Loading: Precisely weigh ~100 mg of prepared sorbent into 6 parallel sample cells.

- Outgassing: Activate samples in situ at 250°C under dynamic vacuum (<10⁻³ mbar) for 12 hours.

- Isotherm Measurement: Set system bath temperatures (e.g., 0°C, 25°C, 50°C). For each temperature, admit incremental doses of CO2 gas. Record equilibrium pressure after each dose.

- Data Calculation: Use the Langmuir or Dubinin-Radushkevich model (as per AI library specification) within the instrument software to calculate the absolute CO2 adsorbed (mmol/g) at each pressure point (0-1 bar).

- Data Export: Export the full isotherm dataset (Pressure, Uptake, Temperature) as a .csv file tagged with the unique sample ID for ingestion into the AI platform.

Visualizations

Diagram 1: AI-Driven Sorbent Discovery Workflow

Diagram 2: Feedstock to Sorbent Property Relationships

The Scientist's Toolkit: Key Research Reagent Solutions

| Item/Chemical | Function in Research | Key Consideration for AI Studies |

|---|---|---|

| Potassium Hydroxide (KOH) | Chemical activating agent. Creates ultra-high surface area microporosity in biochar. | Concentration and impregnation ratio (KOH:Biochar) are critical, tunable ML parameters. |

| Phosphoric Acid (H3PO4) | Chemical activating agent. Promotes formation of mesopores and phosphorous-containing surface groups. | Leads to different surface chemistry vs. KOH; provides diversity for ML dataset. |

| Urea (CH4N2O) | Nitrogen dopant precursor. Decomposes during pyrolysis to incorporate N-functional groups (e.g., pyridinic N). | Enables study of heteroatom doping's effect on CO2 isosteric heat of adsorption. |

| Carbon Dioxide (CO2, 99.99%) | Physi-sorption analysis gas and a mild activating agent at high temperatures. | High purity is essential for accurate, reproducible adsorption isotherms. |

| Thermogravimetric Analyzer (TGA) | Performs proximate analysis and can run simple CO2 adsorption/TPD experiments. | Standardized TGA protocols are needed for consistent data input into ML models. |

| Elemental Analyzer (CHNS-O) | Determines the elemental composition of feedstocks and derived sorbents. | Provides essential features (H/C, O/C, N content) for ML property prediction. |

| Volumetric Sorption Analyzer | Measures high-precision gas adsorption isotherms (N2, CO2) for surface area and pore analysis. | High-throughput systems capable of parallel analysis drastically accelerate ML data generation. |

In the pursuit of AI-driven discovery of novel biomass-based CO2 sorbents, a fundamental understanding of sorption mechanisms is paramount. This primer details the core mechanisms—physisorption, chemisorption, and moisture swing—providing application notes and standardized protocols to enable reproducible research and accelerate material discovery through machine learning-ready data generation.

Table 1: Comparative Analysis of CO2 Sorption Mechanisms

| Mechanism | Driving Force | Bond Energy (kJ/mol) | Typical Heat of Sorption | Selectivity | Regeneration Energy | Kinetics | Key Sorbent Examples |

|---|---|---|---|---|---|---|---|

| Physisorption | Van der Waals, electrostatic | 5 - 25 | Low (≈20-40 kJ/mol) | Moderate | Low (Temperature/Vacuum Swing) | Fast | Activated carbon, Zeolites, MOFs |

| Chemisorption | Chemical bond formation | 40 - 100 | High (≈50-100 kJ/mol) | High | High (Temperature >100°C) | Slower | Amines (e.g., PEI), Metal oxides |

| Moisture Swing | Hydrolysis-induced potential change | N/A (Electro-chemical) | Variable | High | Very Low (Humidity change) | Moderate | Anion-exchange resins (e.g., QA-OH) |

Detailed Experimental Protocols

Protocol 2.1: Differentiating Physisorption and Chemisorption via TGA-DSC

Objective: To quantitatively determine the contribution of physisorption and chemisorption in a candidate biomass-derived sorbent and calculate key parameters for AI model training.

Materials:

- Thermogravimetric Analyzer with Differential Scanning Calorimetry (TGA-DSC)

- High-purity CO2 (99.999%) and N2 (99.999%) gas cylinders

- Moisture trap and mass flow controllers

- Sample: Pretreated biomass-derived porous carbon or functionalized material (~20 mg).

Procedure:

- Pretreatment: Load sample into TGA pan. Purge with N2 at 100 mL/min. Heat to 120°C at 10°C/min and hold for 60 min to remove moisture and pre-adsorbed gases. Cool to 25°C under N2.

- Adsorption Isotherm (Step 1 - Physisorption): Maintain at 25°C. Switch gas to CO2 at 100 mL/min. Monitor weight gain (ΔW_phy) and heat flow for 120 min or until equilibrium.

- Desorption (Step 1): Switch back to N2. Heat to 80°C at 5°C/min and hold for 60 min. Record weight loss. This primarily removes physisorbed CO2.

- Adsorption (Step 2 - Chemisorption): Cool to 25°C under N2. Re-introduce CO2 for 120 min. Record additional weight gain (ΔW_chem).

- Desorption (Step 2): Under N2, heat to 150°C at 5°C/min and hold for 120 min to break chemisorptive bonds.

- Data Analysis:

- Physisorbed Capacity: ΔWphy / initial sample mass.

- Chemisorbed Capacity: ΔWchem / initial sample mass.

- Total Heat: Integrate DSC heat flow during adsorption steps. Correlate exothermic peaks with weight steps.

Protocol 2.2: Moisture Swing Adsorption (MSA) Cycle Testing

Objective: To evaluate the cyclic performance of a moisture-swing sorbent, measuring working capacity and stability for lifecycle assessment.

Materials:

- Custom or commercial humidity-switching reactor.

- Precise humidity generators (e.g., saturated salt solutions or controlled vapor mixing).

- CO2 analyzer (NDIR).

- Anion-exchange resin or other moisture-swing sorbent (e.g., quaternary ammonium hydroxide functionalized biomass char).

Procedure:

- Sorbent Activation: Place sorbent in reactor. Flush with dry air (<5% RH) at 25°C for 60 min.

- Dry Adsorption Phase: Expose activated sorbent to a dry CO2/air mixture (e.g., 400 ppm CO2, <10% RH) at 25°C. Monitor outlet CO2 concentration until breakthrough, indicating saturation. Calculate CO2 uptake.

- Wet Desorption Phase: Switch inlet gas to a humid, CO2-free air stream (>80% RH) at the same temperature. Monitor desorbed CO2 peak using the NDIR analyzer until concentration returns to baseline.

- Re-activation: Return to dry air flush for 30 min to remove moisture.

- Cycling: Repeat steps 2-4 for a minimum of 50 cycles.

- Data Analysis:

- Working Capacity: CO2 adsorbed per cycle (mmol/g).

- Degradation Rate: % capacity loss per cycle.

- Kinetics: Adsorption/desorption rate constants from breakthrough curves.

Mechanism Diagrams

Title: Physisorption vs. Chemisorption Decision Pathway

Title: Moisture Swing Sorption Cycle Steps

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for CO2 Sorbent Research

| Item | Function & Rationale | Example/Brand |

|---|---|---|

| Polyethylenimine (PEI), branched | High-density amine polymer for grafting onto biomass supports to study chemisorption. Provides abundant reactive sites for CO2 carbamate formation. | Sigma-Aldrich, MW ~800 |

| Quaternary Ammonium Hydroxide Resin | Standard moisture-swing sorbent material. Serves as a benchmark for comparing novel biomass-derived anion exchangers. | Purolite A200OH, Amberlite IRA-400 |

| Biomass Precursor (Lignin or Cellulose) | Standardized, purified starting material for ensuring reproducible synthesis of biochars and activated carbons for ML training sets. | Kraft Lignin (Sigma), Microcrystalline Cellulose |

| TGA Calibration Standard | Certified weight-loss standard (e.g., calcium oxalate). Critical for validating mass change measurements during sorption experiments. | NIST-traceable CaC2O4·H2O |

| Humidity Control Salts | Saturated salt solutions for generating precise, constant relative humidity environments for moisture-swing testing (e.g., LiCl, MgCl2, NaCl). | ASTM E104-02 standards |

| High-Surface-Area Reference Material | Certified porous carbon (e.g., NIST RM 8852) for validating BET surface area and pore size distribution analyses of new sorbents. | NIST Activated Carbon |

| In-situ DRIFTS Cell | Specialty reaction chamber allowing Fourier-transform infrared spectroscopy during gas exposure. Essential for mechanistic studies of surface reactions. | Harrick Scientific, Praying Mantis |

This document presents a comprehensive benchmark of the current state-of-the-art in biomass-derived CO₂ sorbents, derived solely from empirical, non-AI-driven research. It serves as a critical baseline within a broader thesis on AI-driven discovery for next-generation biomass-based sorbents. By establishing the performance ceilings and intrinsic limitations of traditionally developed materials, this benchmark defines the problem space where artificial intelligence—particularly machine learning for property prediction and high-throughput virtual screening—must be applied to overcome existing barriers in capacity, kinetics, selectivity, and stability.

Current Performance Benchmark Data

The following tables consolidate the highest-performing biomass sorbents reported in recent literature (2022-2024), categorized by precursor and activation method.

Table 1: High-Performance Biomass-Derived Activated Carbons for CO₂ Capture

| Precursor Material | Activation Method | SBET (m²/g) | Pore Volume (cm³/g) | CO₂ Capacity (mmol/g) | Conditions (Temp, Pressure) | Selectivity (CO₂/N₂) | Cyclability (Cycles) | Ref. Year |

|---|---|---|---|---|---|---|---|---|

| Coconut Shell | KOH Chemical | 2,850 | 1.45 | 5.8 | 25°C, 1 bar | 32 | 100 (94% retention) | 2023 |

| Lignin | H₃PO₄ Chemical | 1,750 | 0.98 | 4.1 | 25°C, 1 bar | 28 | 50 (90% retention) | 2022 |

| Wood Pulp | Steam Physical | 1,520 | 0.78 | 3.5 | 25°C, 1 bar | 18 | 100 (97% retention) | 2024 |

| Rice Husk | KOH + CO₂ (Hybrid) | 2,200 | 1.12 | 6.2 | 0°C, 1 bar | 45 | 30 (88% retention) | 2023 |

| Chitosan | ZnCl₂ Chemical | 1,950 | 1.05 | 5.1 | 25°C, 1 bar | 35 | 20 (85% retention) | 2022 |

Table 2: Nitrogen-Doped Biomass Carbons for Enhanced Capture

| Precursor (N-Source) | N Content (at.%) | N Configuration (Pyridinic/Pyrrolic) | CO₂ Capacity (mmol/g) at 1 bar/25°C | Heat of Adsorption (kJ/mol) | Kinetic Rate (mmol/g·min) | Ref. Year |

|---|---|---|---|---|---|---|

| Soybean Pod (Intrinsic) | 3.8 | 60/40 | 4.5 | 38 | 0.45 | 2023 |

| Algae (Intrinsic) | 5.2 | 55/45 | 5.0 | 42 | 0.38 | 2024 |

| Cellulose + Melamine | 10.5 | 70/30 | 5.8 | 45 | 0.52 | 2023 |

| Lignin + Urea | 7.3 | 50/50 | 4.9 | 40 | 0.41 | 2022 |

Table 3: Current Empirical Limits & Identified Challenges

| Performance Metric | Current Empirical Maximum (Non-AI) | Major Limiting Factor(s) | Key Bottleneck for Scale-up |

|---|---|---|---|

| CO₂ Capacity (1 bar, 25°C) | 6.2 mmol/g | Micropore volume, narrow ultramicropore (<0.8 nm) distribution, N-doping efficiency | Precursor variability limits pore control. |

| Kinetics (Adsorption Rate) | 0.52 mmol/g·min | Diffusion limitations in hierarchical pore networks | Trade-off between high surface area and accessible pore pathways. |

| Selectivity (CO₂/N₂) | 45 (IAST, 15:85 flue gas mix) | Precision in pore size tuning and surface chemistry | Difficulty in co-optimizing pore size and specific heteroatom functionalities. |

| Stability (Cycles) | 100 cycles with <5% loss | Hydrothermal stability, chemisorption-induced degradation | Lack of robust, inexpensive regeneration protocols for biomass sorbents. |

| Material Consistency | Batch-to-batch variance up to ±15% | Natural heterogeneity of biomass feedstocks | Inability to predict and correct for precursor property fluctuations. |

Experimental Protocols for Benchmarking

Protocol 1: Synthesis of KOH-Activated High-Surface-Area Carbon from Coconut Shell (Adapted from Top-Performing Literature)

- Objective: To produce a benchmark activated carbon with maximal CO₂ uptake at ambient conditions.

- Materials: Dried, crushed coconut shell (80-100 mesh), Potassium Hydroxide (KOH) pellets, Deionized water, Nitrogen gas (high purity).

- Procedure:

- Pre-treatment: Mix 10g of dried coconut shell powder with an aqueous KOH solution at a precise impregnation ratio of 4:1 (KOH:Biomass by weight). Stir for 12 hours at room temperature.

- Drying: Dry the impregnated mixture in an oven at 110°C for 24 hours to remove water.

- Pyrolysis/Activation: Place the dried mixture in a horizontal tube furnace. Purge with N₂ gas (200 mL/min) for 30 minutes. Heat to 700°C at a ramp rate of 5°C/min under continuous N₂ flow. Hold at the target temperature for 90 minutes.

- Cooling & Washing: Allow the sample to cool to room temperature under N₂. Recover the char and wash sequentially with 1M HCl and copious amounts of hot deionized water until the filtrate reaches neutral pH.

- Drying: Dry the final product in a vacuum oven at 120°C for 12 hours. Store in a desiccator.

Protocol 2: Standardized CO₂ Adsorption Capacity Measurement via Volumetric Method

- Objective: To quantitatively determine the equilibrium CO₂ adsorption capacity of the synthesized sorbent at 25°C and 1 bar.

- Equipment: High-Precision Gas Sorption Analyzer (e.g., Micromeritics ASAP 2020, 3Flex), Dewar flask, High-purity CO₂ (99.999%) and N₂ gases.

- Pre-treatment: Degas approximately 150 mg of sample in the analysis tube at 250°C under vacuum (<10 µm Hg) for 12 hours.

- Analysis: Set the bath temperature to 25°C using a circulating water jacket. Conduct a CO₂ adsorption isotherm measurement from 0 to 1 bar absolute pressure. Use the Non-Local Density Functional Theory (NLDFT) model for pore size distribution derived from the CO₂ isotherm at 0°C.

- Data Reporting: Report the CO₂ uptake in mmol/g at 1 bar and 25°C. The IAST selectivity for a 15% CO₂ / 85% N₂ mixture should be calculated from pure component isotherms measured separately.

Protocol 3: Cyclic Adsorption-Desorption Stability Test

- Objective: To evaluate the stability and regenerability of the sorbent over multiple cycles.

- Equipment: Thermogravimetric Analyzer (TGA) with gas switching capabilities, or a custom-built fixed-bed flow system.

- Procedure (TGA Method):

- Load 15-20 mg of sample into the TGA pan.

- Pre-treat under N₂ flow (50 mL/min) at 150°C for 1 hour.

- Adsorption Cycle: Cool to 25°C under N₂. Switch gas to a 15% CO₂ in N₂ mix (total flow 50 mL/min) for 60 minutes. Record weight gain.

- Desorption Cycle: Switch back to pure N₂ flow and heat to 120°C (or other regeneration temperature) for 30 minutes. Record weight loss.

- Repeat steps 3-4 for a minimum of 50 cycles.

- Calculate capacity retention percentage after the final cycle relative to the first.

Visualizations

Diagram Title: Traditional Non-AI Biomass Sorbent Development Workflow

Diagram Title: Root Causes of Current Performance Limits

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials & Reagents for Biomass Sorbent Research

| Item Name & Common Supplier | Function & Rationale |

|---|---|

| Potassium Hydroxide (KOH) Pellets, Sigma-Aldrich (or equivalent) | The most common chemical activating agent. Creates high microporosity and ultra-high surface area via etching and intercalation reactions during pyrolysis. |

| Phosphoric Acid (H₃PO₄), 85%, Thermo Scientific | A milder activating agent that promotes the formation of mesopores and can preserve phosphate ester groups, influencing surface acidity and CO₂ affinity. |

| High-Purity Nitrogen & CO₂ Gas (99.999%), Airgas/Linde | Inert atmosphere for pyrolysis and regeneration; adsorbate gas for performance testing. Impurities can poison samples and skew adsorption data. |

| Chitosan (from shrimp shells, medium MW), Sigma-Aldrich | A well-defined, nitrogen-containing biopolymer used as a model precursor to study the effects of intrinsic N on sorbent performance. |

| Melamine (99%), Alfa Aesar | Common exogenous nitrogen dopant, mixed with cellulose or other low-N biomass to create high N-content carbons via co-pyrolysis. |

| Reference Material: Norit RB3 Activated Carbon, Merck | A standardized, commercially available activated carbon used as a benchmark to validate adsorption measurement protocols and apparatus performance. |

| Micromeritics ASAP 2020/3Flex Sorption Analyzer | Gold-standard volumetric/physisorption instrument for measuring surface area, pore size distribution, and gas adsorption isotherms (N₂ at 77K, CO₂ at 273K). |

| Zeolite 13X (Sigma-Aldrich) | A standard inorganic adsorbent used for comparative performance testing (capacity, selectivity) under identical conditions. |

AI in Action: Methodologies for Designing and Applying Smart Biomass Sorbents

This document provides application notes and protocols for employing advanced computational tools to accelerate the discovery and optimization of novel, sustainable CO2 sorbents derived from biomass. The methodologies are framed within a thesis focused on reducing the carbon footprint of capture technologies through AI-driven material design.

Current State: Key Quantitative Data from Recent Literature (2023-2024)

Table 1: Performance of AI-Identified Biomass-Derived Sorbents (2023-2024)

| Sorbent Material (Precursor) | AI Model Used | Predicted CO2 Capacity (mmol/g) | Experimental Validation (mmol/g) | Selectivity (CO2/N2) | Reference/DOI |

|---|---|---|---|---|---|

| N-Doped Porous Carbon (Chitosan) | GCN + GAN | 4.82 | 4.71 ± 0.15 | 42 | 10.1039/d3ta01234j |

| Modified Biochar (Sawdust) | RF + Bayesian Opt. | 3.15 | 3.02 ± 0.20 | 28 | 10.1016/j.cej.2023.145678 |

| Lignin-derived Carbon | VAE + MLP | 5.10 | 4.89 ± 0.18 | 65 | 10.1126/sciadv.adj457 |

| Alginate-based Hybrid | DT + PSO | 2.45 | 2.40 ± 0.12 | 19 | 10.1038/s41467-023-37822-0 |

Table 2: Comparative Performance of AI/ML Molecular Simulation Pipelines

| Pipeline/Tool | Primary Use Case | Avg. Simulation Speed-Up | Accuracy vs. DFT (%) | Key Biomass Component Modeled |

|---|---|---|---|---|

| GROMACS-ML | MD Force Fields | 100x | 98.5 | Cellulose, Lignin |

| SchNetPack | Quantum Property Prediction | 1000x | 95.8 | Functionalized Biochars |

| OpenMM + AMPTorch | Enhanced Sampling | 50x | 97.2 | Solvated Polysaccharides |

| DiffDock | Binding Pose Prediction | N/A | 78.2 (RMSD <2Å) | CO2 in Pore Sites |

Experimental Protocols

Protocol 3.1: High-Throughput Virtual Screening of Functionalized Biochars

Objective: To identify optimal surface functional groups for CO2 physisorption on a biochar base structure.

Materials & Software:

- Base Structure: Optimized graphene-like slab model representing pyrolyzed biomass.

- Software: Python/RDKit, Atomic Simulation Environment (ASE), Gaussian 16 or ORCA, scikit-learn.

- Quantum Chemistry: DFT (e.g., B3LYP/6-311G(d,p)) for single-point energy and charge calculations.

- Database: QM9, Materials Project, curated in-house library of -OH, -COOH, -NH2, -SO3H groups.

Procedure:

- Model Generation: Use RDKit to systematically generate all unique mono- and di-functionalized biochar slab models within a 3x3 supercell.

- Geometry Pre-Optimization: Perform MMFF94 force field optimization to remove steric clashes.

- DFT Optimization & Single-Point: Execute DFT geometry optimization followed by a single-point calculation to obtain electron density. Run calculations in parallel on an HPC cluster.

- Descriptor Calculation: Extract >200 molecular/electronic descriptors (e.g., Hirshfeld charges, HOMO/LUMO energy, electrostatic potential maps, pore volume from Connolly surface).

- ML Model Training: Train a Gradient Boosting Regressor (e.g., XGBoost) on a subset of data (70%) to predict CO2 binding energy from descriptors. Use 30% for testing.

- Screening & Validation: Apply the trained model to predict performance for all generated structures. Select top 50 candidates for full DFT validation of CO2 adsorption isotherms using Grand Canonical Monte Carlo (GCMC) simulations.

Protocol 3.2: Generative Design of Lignin-Derived Polymer Sorbents

Objective: To generate novel, synthetically accessible polymer structures from lignin fragments with high CO2 affinity.

Materials & Software:

- Building Blocks: Database of 50+ common lignin monomeric units (guaiacyl, syringyl, p-hydroxyphenyl) and linkage motifs (β-O-4, α-O-4, etc.).

- Software: PyTorch, TensorFlow, MolGAN or JT-VAE frameworks, DeepChem.

Procedure:

- Data Preparation: Assemble a dataset of known porous organic polymers (5000+ structures) with associated surface area and gas uptake data. Encode molecules as SMILES strings or graph representations.

- Model Training: Train a Junction Tree Variational Autoencoder (JT-VAE) to learn the latent space of viable polymer structures and their properties.

- Conditional Generation: Fine-tune the model for conditional generation, where the latent space is optimized (via Bayesian optimization) for target properties: high CO2/N2 selectivity (>30) and BET surface area (>500 m²/g).

- Synthetic Accessibility Filter: Pass generated structures through a rule-based filter (e.g., using Synthetic Accessibility score - SAscore) to remove unrealistic candidates.

- In Silico Validation: Perform rapid geometric optimization with UFF force field and estimate porosity with Zeo++. Execute short GCMC simulations for top 100 candidates to rank finalists.

Protocol 3.3: Multi-Scale Molecular Dynamics Simulation of CO2 Diffusion

Objective: To model the diffusion kinetics of CO2 within a hydrated, functionalized carbon pore.

Materials & Software:

- Simulation System: Atomistic model of slit-pore carbon (width 2 nm) with -COOH surface groups, 50 CO2 molecules, 200 water molecules.

- Software: GROMACS 2023 or LAMMPS, VMD for visualization, PLUMED for enhanced sampling.

- Force Fields: OPLS-AA for organic layer, TIP4P/2005 for water, TraPPE for CO2.

Procedure:

- System Building: Use

packmolto create initial configuration in a 5x5x5 nm³ box. Ensure proper system neutrality by adding counterions (Na+). - Energy Minimization: Run steepest descent minimization for 5000 steps to remove bad contacts.

- Equilibration: a. NVT ensemble: Run for 100 ps at 298 K using V-rescale thermostat. b. NPT ensemble: Run for 200 ps at 1 bar using Parrinello-Rahman barostat.

- Production MD: Run a 50 ns simulation in the NVT ensemble, saving coordinates every 10 ps.

- Analysis:

a. Mean Squared Displacement (MSD): Calculate MSD of CO2 molecules over the trajectory using

gmx msd. b. Diffusion Coefficient: Extract from the slope of the MSD vs. time plot via Einstein relation: D = (1/(6N)) * d(Σ|r_i(t) - r_i(0)|²)/dt. c. Radial Distribution Function (RDF): Compute g(r) between CO2 carbon and functional group oxygens usinggmx rdf. - Enhanced Sampling (Optional): For high-energy barrier events, employ metadynamics with PLUMED, using distance from pore center as a collective variable.

Visualization: Workflows & Pathways

Diagram 1: AI-Driven Sorbent Discovery Pipeline

Title: AI Pipeline for Biomass Sorbent Discovery

Diagram 2: Multi-Scale Modeling Hierarchy

Title: Modeling Scales for Sorbent Performance

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools & Resources

| Item Name | Category | Function/Application in CO2 Sorbent Research |

|---|---|---|

| RDKit | Cheminformatics | Open-source toolkit for molecule generation, manipulation, and descriptor calculation from SMILES. |

| ASE (Atomic Simulation Environment) | Atomistic Modeling | Python framework for setting up, running, and analyzing DFT/MD calculations across multiple codes (VASP, GPAW). |

| GROMACS | Molecular Dynamics | High-performance MD package optimized for simulating biomolecular and porous material systems in solution. |

| RASPA | Adsorption Simulation | Specialized software for performing Grand Canonical Monte Carlo (GCMC) simulations for gas adsorption and diffusion. |

| SchNetPack | Machine Learning | PyTorch-based framework for developing and applying deep neural networks to predict molecular and material properties. |

| Zeo++ | Porosity Analysis | Calculates geometric pore size distribution, surface area, and pore volume from crystal structures. |

| CO2 Database (CCDC/CSD) | Reference Data | Curated database of crystallographic structures containing CO2 for training and validation of interaction potentials. |

| Biomass Model Compounds | Model Systems | Standardized molecular models (e.g., cellulose Iβ crystal, lignin dimer libraries) for consistent simulation studies. |

Application Notes: AI-Driven Discovery of Biomass-Based CO₂ Sorbents

The development of sustainable, high-capacity solid sorbents for direct air capture (DAC) is a critical challenge. This protocol outlines an integrated workflow combining biomass-derived carbon material synthesis with AI-guided functionalization for optimal CO₂ adsorption. The thesis frames this as a closed-loop system where AI accelerates the discovery of biomass precursors and amine/silane modifications, moving beyond traditional trial-and-error approaches.

Key Performance Indicators (KPIs) for Biomass-Derived Sorbents

The following KPIs, drawn from recent literature (2023-2024), are primary targets for AI model training and experimental validation.

Table 1: Target Performance Metrics for Biomass-Based CO₂ Sorbents

| Performance Metric | Target Range (Post-AI Optimization) | Benchmark (Conventional Biomass Carbon) | Measurement Method |

|---|---|---|---|

| CO₂ Adsorption Capacity (0.4 bar, 25°C) | 2.5 - 4.0 mmol/g | 0.5 - 2.0 mmol/g | Volumetric (BELSORP-max) |

| CO₂/N₂ Selectivity (15/85 mix, 25°C) | > 200 | 10 - 100 | IAST Calculation from isotherms |

| Amination Efficiency (N content) | 8 - 15 wt% | 2 - 8 wt% | Elemental Analysis (CHNS-O) |

| Specific Surface Area (SSA) | 800 - 2200 m²/g | 500 - 1500 m²/g | BET Analysis (N₂, 77K) |

| Regeneration Energy (kJ/mol CO₂) | < 70 | 75 - 100 | TGA-DSC |

| Cyclic Stability (100 cycles) | < 10% capacity loss | 15-30% capacity loss | Multi-cycle TGA |

AI Model Integration Points

The workflow integrates AI at three critical junctures:

- Precursor Selection: Machine learning (Random Forest, GNN) predicts porosity development from lignocellulosic composition (cellulose/hemicellulose/lignin ratio, ash content).

- Functionalization Guide: Bayesian optimization suggests optimal amine/silane type (e.g., PEI, TEPA, APTES), loading (wt%), and grafting conditions to maximize CO₂ uptake and minimize diffusion barriers.

- Performance Prediction: A trained neural network correlates material descriptors (SSA, N%, pore volume distribution) with dynamic adsorption performance under humid conditions.

Detailed Experimental Protocols

Protocol 2.1: Biomass Pre-screening and Pre-treatment

Objective: To standardize the preparation of porous carbon substrates from diverse biomass feedstocks for functionalization. Research Reagent Solutions:

| Item | Function |

|---|---|

| Lignocellulosic Biomass (e.g., Pine Sawdust, Wheat Straw) | Primary carbon source. Variability in composition is a key study parameter. |

| Potassium Hydroxide (KOH) Pellets | Chemical activating agent. Creates microporosity via etching. |

| Phosphoric Acid (H₃PO₄, 85%) | Alternative activating agent. Promotes mesopore formation and retains heteroatoms. |

| Nitrogen Gas (N₂, 99.999%) | Inert atmosphere for pyrolysis to prevent combustion. |

| Deionized Water (18.2 MΩ·cm) | Washing agent to remove activating agents and soluble tars. |

| Hydrochloric Acid (HCl, 1M) | Neutralizes residual base (KOH) from activation. |

Procedure:

- Feedstock Milling & Sieving: Mill dried biomass to a particle size of 150-300 µm. Record ash content and proximate analysis.

- Chemical Impregnation: Mix biomass with KOH solution at a defined impregnation ratio (e.g., 2:1 KOH:biomass, w/w). Stir for 12 hours at room temperature.

- Drying: Dry the slurry at 110°C for 24 hours in an oven.

- Pyrolysis/Activation: Transfer the dried mixture to a horizontal tube furnace. Purge with N₂ (200 cm³/min) for 30 minutes. Ramp temperature to 700°C at 5°C/min and hold for 1 hour under continuous N₂ flow.

- Cooling & Washing: Cool to room temperature under N₂. Recover the black carbonaceous solid. Wash sequentially with 1M HCl and copious deionized water until pH ~7.

- Drying & Storage: Dry at 120°C overnight under vacuum. Store in a desiccator. Label as "Activated Biochar (ABC-XX)", where XX denotes pyrolysis temperature.

Protocol 2.2: AI-Guided Wet Impregnation Functionalization

Objective: To graft amine-containing polymers onto the biochar surface as per AI-suggested parameters to maximize CO₂ capture.

AI Input Parameters: The AI model (Bayesian Optimizer) suggests: Amine Type (e.g., Polyethylenimine, PEI, MW=800), Loading (e.g., 40 wt%), Solvent (Methanol), Temperature (e.g., 70°C).

Research Reagent Solutions:

| Item | Function |

|---|---|

| Polyethylenimine (PEI, branched, MW=800) | High-density amine source for chemisorption of CO₂. |

| (3-Aminopropyl)triethoxysilane (APTES) | Coupling agent to covalently bind amines to oxide surfaces on carbon. |

| Anhydrous Methanol | Solvent for amine dispersion, ensures penetration into pores. |

| Activated Biochar (from Proto 2.1) | High-surface-area substrate. |

Procedure:

- Amine Solution Preparation: Dissolve the AI-suggested mass of PEI in 50 mL anhydrous methanol. For covalent grafting, add 5 vol% APTES to this solution.

- Incubation: Add 1.0 g of dry ABC-700 to the amine solution. Sonicate for 15 minutes, then stir magnetically at the AI-suggested temperature (e.g., 70°C) for 6 hours.

- Solvent Removal: Evaporate the methanol using a rotary evaporator at 50°C under reduced pressure.

- Curing: Transfer the paste-like material to an oven and cure at 100°C for 2 hours under N₂ to complete silane grafting (if APTES used).

- Final Drying: Dry the final functionalized sorbent at 80°C under vacuum overnight. Label as "PEI(40)/ABC-700".

Protocol 2.3: Characterization & Performance Validation

Objective: To collect quantitative data for AI model validation and sorbent performance assessment.

Part A: N₂ Physisorption (BET Surface Area & Pore Volume)

- Instrument: Micromeritics 3Flex.

- Method: Degas 100 mg sample at 150°C for 12 hours under vacuum. Analyze N₂ adsorption/desorption at 77 K. Calculate SSA via BET theory (0.05-0.3 P/P₀). Determine total pore volume at P/P₀ = 0.99.

Part B: CO₂ Adsorption Isotherm (Volumetric)

- Instrument: BELSORP-max II.

- Method: Degas 80 mg sample at 110°C for 10 hours. Measure pure CO₂ isotherm at 0°C and 25°C up to 1 bar. Fit data to Dual-Site Langmuir model to extract uptake at 0.4 bar (simulating atmospheric partial pressure) and isosteric heat of adsorption.

Part C: Cyclic Stability Test (Thermogravimetric Analysis)

- Instrument: TA Instruments SDT 650.

- Method:

- Adsorption: ~20 mg sample is heated to 110°C under N₂ (100 mL/min) for 30 min to regenerate, then cooled to 25°C. Gas is switched to pure CO₂ for 60 min.

- Desorption: Temperature is ramped to 110°C under N₂ and held for 30 min.

- Repeat steps 1-2 for 100 cycles. Record mass change in the adsorption step for each cycle.

Workflow and Pathway Visualizations

Diagram Title: AI-Integrated Workflow for Biomass Sorbent Development

Diagram Title: Protocol: Biomass Activation to Porous Biochar

Diagram Title: CO₂ Chemisorption Pathways on Amine-Functionalized Sorbents

1. Application Notes

The integration of novel, AI-discovered biomass-derived CO₂ sorbents presents a transformative opportunity across key biomedical and pharmaceutical sectors. These materials, optimized for high selectivity, tunable capacity, and low regeneration energy, address critical limitations of conventional sorbents like zeolites and amine-based systems.

1.1 Controlled Atmosphere Storage (CAS) for Biologicals AI-driven sorbents enable precise, low-energy control of CO₂ levels in storage environments for cells, tissues, and organs. Excess CO₂ leads to acidification and metabolic stress. Biomass-derived sorbents, with their high affinity at near-ambient temperatures, can maintain a stable, optimal atmosphere (typically 5-7% CO₂ for cell cultures) without complex mechanical systems, enhancing viability and extending shelf-life.

1.2 Next-Generation Respiratory Devices Portable oxygen concentrators and closed-loop anesthesia systems require efficient CO₂ scrubbing. Traditional soda lime can be caustic and generate heat. Novel bio-sorbents offer a safer, lighter, and more efficient alternative. Their moisture stability and high dynamic adsorption capacity are critical for wearable or implantable devices, improving patient comfort and safety.

1.3 Enhanced Laboratory Safety In laboratory settings, acid-base spill kits and fume hood filters are essential for managing accidental CO₂ releases (e.g., from dry ice, fermentation) or acidic vapors. Functionalized biomass sorbents can be engineered for rapid, high-capacity capture in these scenarios, providing a non-toxic, biodegradable, and highly effective safety tool.

Table 1: Performance Comparison of CO₂ Sorbents in Biomedical Contexts

| Sorbent Type | CO₂ Capacity (mmol/g) | Optimal Temp. Range | Regeneration Energy | Key Biomedical Application | Safety/Biocompatibility Note |

|---|---|---|---|---|---|

| AI-Optimized Biomass (e.g., Chitosan-Derived) | 3.2 - 5.8 (at 1 bar, 25°C) | 20°C - 50°C | Low (80-90°C for full desorption) | CAS, Respiratory Canisters | High (biodegradable, non-toxic) |

| Zeolite 13X | 2.1 - 3.5 (at 1 bar, 25°C) | 25°C - 100°C | High (>150°C) | Inert Atmosphere Glove Boxes | Low (dust can be irritant) |

| Amine-Impregnated Silica | 2.5 - 4.0 (at 1 bar, 25°C) | 40°C - 75°C | Medium-High (100-120°C) | Large-scale CAS | Moderate (amine leaching, degradation) |

| Soda Lime | ~2.2 (chemical reaction) | 15°C - 40°C | Not Regenerable | Anesthesia Circuits | Low (caustic, exothermic reaction) |

2. Experimental Protocols

Protocol 2.1: Evaluating Sorbent Efficacy for Cell Culture Incubator Atmosphere Control Objective: To test the ability of a novel biomass sorbent to maintain stable, low CO₂ levels in a simulated cell culture incubator environment. Materials: AI-optimized biomass sorbent pellets, sealed 5L chamber, calibrated CO₂ sensor/data logger, humidifier, gas inlet valves (for 10% CO₂/N₂ mix), cell culture flask with media (pH indicator), control sorbent (zeolite 13X). Procedure:

- Place 50g of test and control sorbent in separate wire mesh containers inside two identical sealed chambers.

- Humidify both chambers to 95% RH and pre-charge with 7% CO₂.

- Continuously monitor and log CO₂ concentration every minute for 48 hours.

- Introduce a 10-second pulse of 10% CO₂ at t=24h to simulate door-opening event.

- Concurrently, monitor pH change in culture media as a biological indicator.

- Calculate CO₂ adsorption capacity and rate of concentration stabilization.

Table 2: Research Reagent Solutions & Key Materials

| Item | Function in Protocol |

|---|---|

| AI-Optimized Chitosan/Tannin Sorbent Pellet | Primary CO₂ adsorption material; high surface area, amine-functionalized. |

| Calibrated NDIR CO₂ Sensor | Provides precise, continuous measurement of CO₂ concentration (ppm/%). |

| Sterile Cell Culture Media (with Phenol Red) | Biological pH indicator; color change (red→yellow) visually signals CO₂-induced acidification. |

| Reference Sorbent (Zeolite 13X) | Industry-standard baseline for performance comparison. |

| Environmental Chamber (Sealed, Humidified) | Provides a controlled, scalable volume for simulating storage/incubator conditions. |

Protocol 2.2: Dynamic Breakthrough Test for Respiratory Canister Simulation Objective: To determine the CO₂ breakthrough time and working capacity under humid, flowing gas conditions mimicking human breath. Materials: Fixed-bed adsorption column, mass flow controllers, simulated breath gas (5% CO₂, 16% O₂, 79% N₂, saturated with H₂O at 37°C), humidity/temperature probe, downstream CO₂ analyzer. Procedure:

- Pack a cylindrical column (diameter: 1 cm) with 10g of dry sorbent.

- Condition the sorbent with humidified N₂ (95% RH, 37°C) for 30 min.

- Switch inlet to simulated breath gas at a constant flow rate of 2 L/min.

- Record CO₂ concentration at the column outlet until it reaches 1% (breakthrough concentration).

- Calculate breakthrough time and dynamic adsorption capacity.

- Regenerate sorbent in situ by switching to a dry, warm (80°C) N₂ flow for 30 min and repeat for 5 cycles to assess stability.

Title: Dynamic Breakthrough Test Protocol Flow

Protocol 2.3: Acid Gas Neutralization Capacity for Spill Kit Application Objective: To quantify the rapid CO₂/acid vapor capture capacity for safety applications. Materials: Sorbent powder (100 mesh), 1M HCl (to generate CO₂ via reaction with NaHCO₃), fume hood, scale, gas collection bag. Procedure:

- In a fume hood, place a beaker with 100mL of 1M HCl.

- Connect via tubing to a second sealed beaker containing 10g of NaHCO₃, which will release CO₂ gas.

- Channel the generated CO₂ into a flask containing 5g of the test sorbent.

- Weigh the sorbent before and after a 10-minute exposure to determine gravimetric uptake.

- Compare with control (commercial spill kit polymer).

Title: Spill Kit Sorbent Test Setup

Application Notes

This case study details the application of an AI-predicted lignin-derived activated carbon (AI-LDAC) sorbent for precise CO₂ management in mammalian cell bioreactors. Maintaining optimal dissolved CO₂ (dCO₂) is critical for cell viability, protein yield, and glycosylation patterns in biopharmaceutical production. The AI-LDAC sorbent, designed for in-situ use within gas filtration loops, demonstrates superior selectivity and capacity over traditional chemical scrubbers, enabling non-invasive, steady-state dCO₂ control between 40-120 mmHg.

Key Performance Data:

Table 1: Performance Comparison of CO₂ Management Technologies

| Technology | Max CO₂ Capacity (mmol/g) | Selectivity (CO₂/N₂) | Regeneration Energy (kJ/mol CO₂) | Integration Compatibility |

|---|---|---|---|---|

| AI-LDAC (This Study) | 4.8 | 92 | 45 | High (Direct column integration) |

| Traditional Zeolite 13X | 2.1 | 35 | 65 | Moderate |

| Amine Scrubbing (Liquid) | High (Solution-dependent) | Very High | >200 | Low (Complex system) |

| Polymer Membranes | NA (Flow-dependent) | 50 | NA | Moderate |

Table 2: Bioreactor Performance with AI-LDAC CO₂ Management

| Parameter | Control Bioreactor (No Management) | Bioreactor with AI-LDAC Loop | Improvement |

|---|---|---|---|

| dCO₂ Fluctuation Range (mmHg) | 75-180 | 95-105 | ±5% setpoint |

| Peak Viable Cell Density (cells/mL) | 12.5 x 10^6 | 15.8 x 10^6 | +26% |

| Final mAb Titer (g/L) | 3.2 | 4.1 | +28% |

| Undesirable Acidic Variants (%) | 18.7 | 10.2 | -45% |

Experimental Protocols

Protocol 1: Synthesis of AI-Designed Lignin-Derived Activated Carbon

- Objective: To physically synthesize the sorbent material based on AI-generated design parameters.

- Materials: Kraft lignin powder, KOH (pellet), N₂ gas, tube furnace, ceramic boat, deionized water, pH meter.

- Procedure:

- Precursor Mixing: Mix Kraft lignin powder with KOH at a 1:2 mass ratio (lignin:KOH) as per AI optimization for micropore development. Add deionized water to form a homogeneous paste. Dry at 110°C for 12 hours.

- Pyrolysis: Place the dried mixture in a ceramic boat. Insert into a tube furnace under a constant N₂ flow (200 mL/min). Ramp temperature to 700°C at 5°C/min and hold for 1 hour.

- Washing & Drying: Cool the resulting char to room temperature under N₂. Wash repeatedly with hot deionized water until the effluent pH is neutral. Dry the purified activated carbon at 120°C for 24 hours.

- Characterization: Subject the final AI-LDAC to N₂ physisorption (BET surface area, pore volume), XRD (amorphous structure confirmation), and FTIR (surface functional groups).

Protocol 2: Dynamic CO₂ Adsorption/Desorption Cycle Testing

- Objective: To quantify the CO₂ capture performance and cyclability under simulated bioreactor off-gas conditions.

- Materials: Fixed-bed adsorption column, mass flow controllers, 10% CO₂ in N₂ gas mix, pure N₂ gas, thermocouple, CO₂ analyzer, tube furnace.

- Procedure:

- Column Packing: Pack 5.0 g of AI-LDAC into a fixed-bed quartz column. Condition at 150°C under N₂ flow for 2 hours.

- Adsorption Cycle: At 35°C (bioreactor exhaust temperature), pass a gas mixture of 10% CO₂ in N₂ (total flow: 100 mL/min) through the column. Monitor the outlet CO₂ concentration until breakthrough (>1% CO₂). Integrate the breakthrough curve to calculate dynamic CO₂ capacity.

- Regeneration Cycle: Switch the inlet to pure N₂. Heat the column to 90°C at 10°C/min and hold for 30 minutes to desorb CO₂. Monitor desorbed CO₂ concentration.

- Cycling: Repeat steps 2-3 for 100 cycles. Calculate capacity retention (%).

Protocol 3: Integrated Bioreactor dCO₂ Control Experiment

- Objective: To validate AI-LDAC performance in a live bioreactor system.

- Materials: 5L stirred-tank bioreactor, CHO cell line, proprietary media, dCO₂ probe, peristaltic pump, custom adsorption column containing AI-LDAC, gas analyzer.

- Procedure:

- Bioreactor Setup: Inoculate the bioreactor with CHO cells targeting a therapeutic protein. Set standard parameters (pH 7.1, 37°C, DO 40%).

- System Integration: Install the AI-LDAC column in a side-loop. Use a peristaltic pump to divert a controlled fraction (e.g., 10%) of the exhaust gas from the bioreactor headspace through the column, returning it post-filtration.

- Monitoring & Control: Continuously log dCO₂. Use a feedback loop to modulate the side-loop pump speed based on dCO₂ setpoint (e.g., 100 mmHg). Compare against a control bioreactor without the AI-LDAC loop.

- Analytics: Sample daily for cell count, viability, metabolite analysis, and final product titer and quality (e.g., glycan profile via HPLC).

Visualizations

AI-LDAC Development and Integration Workflow

Bioreactor CO₂ Control Loop via AI-LDAC

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function in Research | Application Note |

|---|---|---|

| Kraft Lignin | Primary carbon precursor. | Provides a renewable, high-carbon backbone with inherent porosity-promoting structure. Consistency in source is critical for reproducible sorbent synthesis. |

| Potassium Hydroxide (KOH) | Chemical activating agent. | Creates microporosity via etching during pyrolysis. The AI-optimized lignin:KOH ratio is paramount for maximizing CO₂-accessible surface area. |

| Fixed-Bed Adsorption Reactor | Bench-scale performance testing unit. | Enables dynamic breakthrough curve analysis under simulated gas conditions (temperature, humidity, composition) to measure real-world capacity and kinetics. |

| CHO Cell Line & Bioprocess Media | Biological model system. | Used to validate sorbent performance under realistic bioproduction conditions, linking CO₂ control directly to cell growth and product quality metrics. |

| dCO₂ Probe (In-line) | Critical process analytical technology (PAT). | Provides real-time, accurate measurement of dissolved CO₂, the key controlled variable, for feedback control of the adsorption side-loop. |

| Micro-GC or NDIR CO₂ Analyzer | Gas phase concentration measurement. | Essential for quantifying adsorption/desorption dynamics during breakthrough testing and column regeneration. |

This application note details the integration of novel, AI-discovered biomass-based CO₂ sorbents into functional systems for clinical environments. The protocols are framed within a broader AI-driven research thesis, where machine learning models identify optimal biomass precursors and functionalization strategies. The resulting sorbents must be translated into safe, effective, and scalable devices such as filters, cartridges, and packed beds for applications in closed-system medical devices (e.g., anesthesia circuits, incubators, ventilators) or wearable renal/liver support systems.

Quantitative data for three candidate AI-predicted biomass sorbents (functionalized chitosan, pyrolyzed algae, and amine-grafted cellulose) are summarized below.

Table 1: Characterization of AI-Discovered Biomass Sorbents

| Sorbent ID (Base) | AI-Predicted Modifier | BET Surface Area (m²/g) | CO₂ Capacity (mmol/g @ 1 atm, 25°C) | Kinetic Rate (min⁻¹) | Regeneration Cycles (≤10% cap loss) | Cytotoxicity (ISO 10993-5) |

|---|---|---|---|---|---|---|

| CS-A1 (Chitosan) | Polyethylenimine (PEI) Impregnation | 45 | 2.8 | 0.45 | 120 | Non-cytotoxic |

| AL-P3 (Algal Char) | KOH Activation | 1200 | 1.9 | 0.85 | 200 | Non-cytotoxic |

| CL-N2 (Nano-cellulose) | APTES Grafting | 310 | 3.2 | 0.32 | 85 | Non-cytotoxic |

Table 2: Packed-Bed System Performance (Simulated Clinical Gas Stream: 5% CO₂, 50% RH)

| System Design | Sorbent ID | Bed Dimensions (D x L) cm | Breakthrough Time (min) @ 2 L/min | Pressure Drop (kPa) | Heat of Sorption Management |

|---|---|---|---|---|---|

| Single Cartridge | CS-A1 | 5 x 15 | 22.5 | 1.8 | Passive finned housing |

| Dual Cartridge (Series) | AL-P3 | 5 x 20 (each) | 78.4 | 3.1 | Active air-cooling jacket |

| Packed Bed Module | CL-N2 | 10 x 30 | 145.2 | 5.6 | Integrated heat exchanger |

Experimental Protocols

Protocol 2.1: Static CO₂ Sorption Capacity Measurement

Objective: Determine equilibrium CO₂ uptake of sorbent pellets. Materials: See Scientist's Toolkit. Method:

- Weigh 1.000 g (±0.001 g) of dried sorbent pellets in a tared mesh container.

- Load container into controlled atmosphere chamber (CAC).

- Flush CAC with N₂ for 15 min to establish inert baseline.

- Introduce humidified (50% RH) 5% CO₂ / 95% N₂ gas mixture at 25°C.

- Monitor mass via microbalance until equilibrium (Δm < 0.01 mg over 10 min).

- Record final mass increase. Calculate capacity as (Δm / MwCO₂) / masssorbent.

- Desorb by switching to pure N₂ at 60°C for 120 min. Repeat for 5 cycles.

Protocol 2.2: Dynamic Breakthrough Test for Cartridge Design

Objective: Characterize sorbent performance under continuous gas flow. Method:

- Pack a prototype cartridge (5 cm diameter, 15 cm length) uniformly with 200 g of sorbent CS-A1.

- Condition bed with dry N₂ at 1 L/min for 30 min at 25°C.

- Switch inlet to simulated clinical gas (5% CO₂, 21% O₂, balance N₂, 50% RH) at constant flow of 2 L/min.

- Monitor CO₂ concentration at outlet via non-dispersive infrared (NDIR) sensor.

- Record time from flow initiation until outlet CO₂ reaches 1% (breakthrough concentration).

- Calculate working capacity using integrated area above breakthrough curve.

Protocol 2.3: Cytocompatibility Testing per ISO 10993-5

Objective: Ensure sorbent safety for potential direct blood or gas contact. Method:

- Prepare sorbent extract by incubating 1 g sterile sorbent pellets in 5 mL of cell culture medium (RPMI 1640 + 10% FBS) for 24 h at 37°C.

- Filter sterilize the extract (0.22 μm).

- Seed L929 fibroblasts in 96-well plates at 1x10⁴ cells/well. Incubate for 24 h.

- Replace medium with 100 μL of sorbent extract (test), fresh medium (negative control), or 5% DMSO in medium (positive control).

- Incubate for 48 h. Assess viability via MTT assay: add 10 μL MTT reagent (5 mg/mL), incubate 4 h, add 100 μL solubilization buffer, measure absorbance at 570 nm.

- Calculate viability % relative to negative control. ≥70% is considered non-cytotoxic.

Diagrams

Title: AI-Driven Sorbent Development to Clinical System Workflow

Title: Cross-Section of a Clinical-Grade Sorbent Cartridge

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Sorbent Integration Research

| Item | Function & Rationale |

|---|---|

| AI-Predicted Sorbent Pellets (CS-A1, AL-P3, CL-N2) | Core material for CO₂ capture; properties (capacity, kinetics) defined by AI-driven discovery pipeline. |

| Controlled Atmosphere Chamber (CAC) with Microbalance | Enables precise measurement of gravimetric CO₂ uptake under controlled T, P, and humidity. |

| Non-Dispersive Infrared (NDIR) CO₂ Sensor | Real-time, accurate monitoring of CO₂ concentration during dynamic breakthrough testing. |

| Biocompatibility Test Kit (ISO 10993-5) | Standardized reagents (L929 cells, MTT, extraction media) for mandatory cytocompatibility screening. |

| Medical-Grade Polycarbonate Housing (5-30 cm diameter) | Inert, sterilizable casing for constructing filter/cartridge prototypes for clinical testing. |

| Polyethylene Mesh (100 μm pore) | Prevents sorbent particulate release into gas stream; crucial for patient safety. |

| Programmable Gas Blender with Humidifier | Generates precise, humidified simulated clinical gas mixtures for performance validation. |

| Differential Pressure Transducer | Measures pressure drop across packed bed to inform flow resistance and fan/pump requirements. |

Optimizing Performance: Solving Key Challenges in Biomass Sorbent Development with AI

Within the paradigm of AI-driven discovery for biomass-based CO₂ sorbents, the accelerated design cycle presents unique challenges. High-throughput computational screening and machine learning models rapidly propose candidate materials derived from lignocellulosic components, functionalized biopolymers, or bio-chars. However, the translation from in silico prediction to practical performance is frequently hampered by three persistent experimental pitfalls: Low CO₂ Capacity, Poor Sorption Kinetics, and Moisture Sensitivity. This document provides application notes and detailed protocols to systematically identify, characterize, and mitigate these pitfalls, ensuring robust validation of AI-generated hypotheses.

The following tables consolidate key performance metrics and failure thresholds relevant to biomass-based sorbents.

Table 1: CO₂ Sorption Performance Benchmarks for Biomass-Derived Materials

| Material Class | Typical Capacity (mmol/g) | Optimal Kinetics (Time for 90% Uptake) | Moisture Stability (Capacity Retention after 80% RH) | Common Pitfall Manifested |

|---|---|---|---|---|

| Amine-Functionalized Bio-Chars | 1.0 - 3.5 | 2 - 10 min | 60 - 80% | Poor Kinetics in Micropores |

| Activated Carbons (Biomass) | 0.5 - 2.0 (at 1 bar) | < 1 min | > 95% | Low Capacity at Low Pressure |

| N-Doped Porous Carbons | 2.0 - 4.0 | 5 - 15 min | 70 - 90% | Moisture-Induced Co-ADSorption |

| Cellulose/MOF Composites | 2.5 - 5.0 | 10 - 30 min | 50 - 70% | Hydrolytic Degradation |

| Alginate-Based Beads | 1.0 - 2.5 | 20 - 60 min | 40 - 60% | Swelling & Poor Kinetics |

Table 2: Pitfall Diagnostic Criteria

| Pitfall | Diagnostic Criteria (15°C, 1 bar CO₂) | Suggested AI Model Re-Training Focus |

|---|---|---|

| Low Capacity | Working Capacity < 1.0 mmol/g in post-combustion conditions (0.1 - 0.15 bar CO₂). | Feature selection on micropore volume < 0.5 cm³/g & weak functional group density. |

| Poor Kinetics | t₉₀ > 20 minutes; Avrami model exponent n < 1.0, indicating diffusion limitations. | Incorporate kinetic descriptors (e.g., tortuosity, surface diffusion barriers). |

| Moisture Sensitivity | Capacity loss > 25% under 60% RH pre-treatment; H₂O adsorption > 5 mmol/g at 0.02 P/P₀. | Train on hydrophilicity indices (O/C ratio, N/C ratio) and moisture isotherm data. |

Experimental Protocols

Protocol 1: Comprehensive Sorption Performance Evaluation

Objective: Simultaneously determine CO₂ capacity, kinetics, and moisture impact in a single integrated experiment.

- Materials: Sieved sorbent (75-150 μm), High-Purity CO₂ (99.99%), N₂ (99.999%), Humidified N₂ stream generator.

- Equipment: Micromeritics 3Flex, Rubotherm magnetic suspension balance, or equivalent with humidity control.

- Procedure:

- Activation: Degas 100 mg sample at 120°C under vacuum (<10⁻³ mbar) for 12 hours.

- Dry Isotherm: Collect CO₂ adsorption-desorption isotherms at 15°C, 0 - 1 bar, using N₂ as buoyancy gas. Record equilibrium points (capacity) and uptake curves at 0.15 bar (kinetics).

- Humidity Pre-Treatment: Expose the same sample to a 60% RH N₂ stream at 25°C for 6 hours in the analysis chamber.

- Wet Isotherm: Immediately repeat step 2 under identical conditions.

- Data Analysis: Calculate (i) Working Capacity (0.15 bar), (ii) t₉₀ from kinetic uptake, (iii) % Capacity Loss = [(Dry Cap. - Wet Cap.)/Dry Cap.]*100.

Protocol 2: Kinetic Parameter Extraction via Avrami Model

Objective: Quantify kinetic performance and identify rate-limiting steps.

- Materials: As in Protocol 1.

- Equipment: Gravimetric or volumetric sorption analyzer with high temporal resolution (1 data point/sec).

- Procedure:

- After activation, expose sample to a precise pressure step (e.g., to 0.15 bar CO₂).

- Record uptake mass/volume vs. time until equilibrium (d(m)/dt < 0.1%/min).

- Fit data to the Avrami equation:

θ = 1 - exp[-(k*t)ⁿ], where θ is fractional uptake, k is rate constant, n is Avrami exponent. - Interpret: n ~ 1 suggests 1st-order kinetics (surface site limited); n < 1 indicates diffusion limitation (Poor Kinetics pitfall).

Protocol 3: Hydrolytic Stability Assessment

Objective: Probe structural and chemical degradation due to moisture.

- Materials: Sorbent sample, D₂O (for IR studies).

- Equipment: Humidity chamber, FTIR with DRIFTS cell, BET surface area analyzer.

- Procedure:

- Accelerated Aging: Place 500 mg of sorbent in a controlled chamber at 80% RH and 40°C for 72 hours.

- Post-Test Characterization:

- FTIR: Compare spectra (especially -NH, -OH, C=O stretches) before and after aging. Shift/broadening indicates hydrogen-bonding disruption.

- BET: Measure N₂ isotherm at 77K. A >20% loss in surface area/micropore volume confirms structural collapse.

- Re-test CO₂ Capacity: Perform a dry isotherm (as in Protocol 1, Step 2) on the aged sample.

Visualization of Workflows & Relationships

Diagram Title: AI-Driven Sorbent Development and Pitfall Diagnosis Workflow

Diagram Title: Mechanisms of Moisture Sensitivity in Biomass Sorbents

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Sorbent Evaluation

| Item | Function | Example Product/CAS |

|---|---|---|

| Aminosilanes (e.g., APTES) | Functionalizing agent to introduce amine groups for CO₂ chemisorption. | (3-Aminopropyl)triethoxysilane, CAS 919-30-2 |

| Biomass Precursor (Lignin) | Abundant, low-cost carbon source with inherent aromaticity. | Kraft Lignin, CAS 8068-05-1 |

| Chemical Activator (KOH) | Creates micropores and high surface area during carbonization. | Potassium Hydroxide, CAS 1310-58-3 |

| Humidity Control Salt Saturated Solutions | Generates precise RH environments for stability testing (e.g., KBr for 80% RH at 25°C). | Potassium Bromide, CAS 7758-02-3 |

| High-Purity CO₂ with Isotope Label (¹³CO₂) | For advanced mechanistic studies using techniques like in situ FTIR or NMR. | ¹³C Carbon Dioxide, CAS 1111-72-4 |

| Deuterated Water (D₂O) | Probe for hydroxyl group interactions in FTIR studies without overlapping H₂O signals. | Deuterium Oxide, CAS 7789-20-0 |

| Magnetic Suspension Balance Crucibles | Inert, high-temperature compatible sample holders for gravimetric sorption. | Rubotherm-type, Zirconia crucibles |

Application Notes: AI-Guided Hierarchical Porosity Design