Bridging the Gap: Optimizing Catalyst Performance from Laboratory to Industrial Scale

This article provides a comprehensive analysis of the critical challenges and solutions in translating catalyst performance from controlled laboratory environments to demanding industrial-scale operations.

Bridging the Gap: Optimizing Catalyst Performance from Laboratory to Industrial Scale

Abstract

This article provides a comprehensive analysis of the critical challenges and solutions in translating catalyst performance from controlled laboratory environments to demanding industrial-scale operations. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of catalyst deactivation, advanced methodologies for realistic testing and simulation, strategic troubleshooting for performance optimization, and robust frameworks for validation. By synthesizing current research and industrial practices, this guide aims to equip readers with the knowledge to design more robust, scalable, and efficient catalytic processes for biomedical and chemical manufacturing.

The Lab-to-Plant Divide: Understanding Core Challenges in Catalyst Scaling

In both academic research and industrial application, the performance of a catalyst is primarily defined by three critical metrics: activity, selectivity, and stability. Activity refers to the rate at which a catalyst accelerates a chemical reaction toward equilibrium, typically measured as turnover frequency (TOF). Selectivity describes the catalyst's ability to direct the reaction toward a desired product pathway among multiple thermodynamically feasible options. Stability represents the catalyst's resistance to deactivation over time under operational conditions, encompassing mechanical, thermal, and chemical degradation mechanisms.

The evaluation of these metrics reveals a significant performance gap between laboratory and industrial environments. While laboratory conditions often demonstrate exceptional catalyst performance in controlled settings, industrial application introduces complex challenges including feedstock impurities, fluctuating process conditions, and extended operational timelines that accelerate deactivation mechanisms. This article provides a comprehensive comparison of catalyst performance across different environments, examining the root causes of this performance gap and methodologies for its assessment.

Performance Metrics: Comparative Analysis Across Environments

Quantitative Performance Comparison

Table 1: Comparative performance metrics for catalysts in laboratory versus industrial environments

| Performance Metric | Laboratory Performance | Industrial Performance | Performance Gap Magnitude | Primary Contributing Factors |

|---|---|---|---|---|

| Activity Lifetime | Several hours to days at high conversion | Months to years with maintained activity | 10-100x longer in industry | Continuous vs. batch operation, harsher conditions |

| Selectivity to Target Product | Often >90% under optimized feed | Typically 70-85% with impurities | 5-20% absolute decrease | Feedstock impurities, heat/mass transfer limitations |

| Deactivation Rate | 0.1-1% per hour in accelerated tests | 0.01-0.1% per hour in operation | 10-100x slower deactivation | Real-world poisoning, thermal stress, mechanical attrition |

| Regeneration Efficiency | Near-complete activity restoration | 70-90% of original activity restored | 10-30% lower regeneration | Irreversible structural changes, incomplete coke removal |

| Metal Sintering Resistance | Minimal in short-term tests | Significant over thousands of hours | Difficult to quantify | Thermal cycling, redox environments |

Stability Challenges Across Applications

Table 2: Primary deactivation mechanisms and their impact across different catalytic processes

| Catalytic Process | Dominant Deactivation Mechanisms | Laboratory Observation | Industrial Manifestation | Typical Lifetime |

|---|---|---|---|---|

| Refining (FCC) | Coking, metal poisoning, thermal degradation | Hours to days in micro-reactors | Seconds to minutes (continuous regeneration) | Catalyst inventory years with daily regeneration |

| Petrochemicals | Coke formation, sintering, poisoning | Weeks in accelerated tests | 1-3 years between replacements | 2-5 years with in-situ regeneration cycles |

| Automotive Emissions Control | Thermal degradation, poisoning (P, S, Ca) | 100-500 hours in bench tests | 150,000+ miles vehicle lifetime | 10-15 years with protected operation |

| Water Treatment | Fouling, leaching, active site oxidation | Hours in batch experiments | Weeks to months in continuous flow | Months to years with periodic chemical cleaning |

| CO2 Reduction | Copper reduction, electrolyte contamination | 10-100 hours in electrochemical cells | <1000 hours for most systems | Weeks to months in continuous operation |

Experimental Protocols for Performance Assessment

Standardized Activity and Selectivity Testing

Laboratory assessment of catalyst activity follows standardized protocols to enable cross-comparison. For solid catalysts, the most common approach involves fixed-bed reactor testing with well-defined catalyst particle sizes (typically 150-250 μm) to minimize mass transfer limitations. The experimental setup includes precise temperature control (±1°C), mass flow controllers for gaseous reactants (±1% accuracy), and liquid feed pumps for hydrocarbon introductions. Product analysis typically employs online gas chromatography with flame ionization and thermal conductivity detectors, with calibration using certified standard mixtures. Key parameters measured include conversion (X), defined as (moles of reactant consumed)/(moles of reactant fed); selectivity (S), calculated as (moles of desired product formed)/(total moles of reactant consumed); and yield (Y), determined as X × S.

Accelerated stability testing employs elevated temperatures (typically 50-100°C above normal operation), increased contaminant levels, or thermal cycling to simulate longer-term operation. For example, in Fischer-Tropsch synthesis testing, catalysts may be evaluated over 1000-hour periods with periodic intentional temperature excursions to 50°C above baseline to assess thermal stability. These protocols, while informative, cannot fully replicate the complex deactivation environment of industrial operation, particularly the slow accumulation of trace contaminants or mechanical stresses from continuous operation.

Deactivation Mechanism Analysis

Identifying specific deactivation pathways requires specialized characterization techniques. Thermo-gravimetric analysis (TGA) coupled with mass spectrometry quantifies coke deposition and composition by measuring weight loss during temperature-programmed oxidation. Temperature-programmed reduction (TPR) and oxidation (TPO) profiles reveal changes in reducibility and oxidation states of active phases. Surface area and porosity measurements via physisorption track structural changes, while electron microscopy (SEM/TEM) with elemental mapping visually identifies sintering, pore blockage, and contaminant deposition.

For metal leaching analysis, inductively coupled plasma (ICP) spectroscopy of reaction solutions quantifies dissolved metal concentrations. In water treatment catalysts, studies have demonstrated that iron oxyhalides like FeOF lose 40.7% of fluorine content after 12 hours of operation, directly correlating with a 70.7% reduction in hydroxyl radical generation efficiency [1]. Such precise measurements enable correlation between elemental leaching and activity loss, guiding catalyst formulation improvements.

The Industrial-Laboratory Divide: Root Causes of Performance Gaps

Environmental and Operational Factors

The performance gap between laboratory and industrial environments stems from fundamental differences in operational conditions. Laboratory testing typically employs purified feeds with minimal contaminants, while industrial feedstocks contain numerous impurities that act as catalyst poisons. For instance, petroleum streams may contain sulfur, nitrogen, and metal compounds that chemisorb strongly to active sites. Even at parts-per-million levels, these contaminants gradually accumulate, leading to significant activity loss over timeframes impossible to replicate in standard laboratory testing.

Industrial reactors also face significant heat and mass transfer limitations not present in laboratory-scale systems. Large catalyst beds develop thermal gradients, leading to localized hot spots that accelerate sintering, or cold zones where condensation of heavy byproducts occurs. Computational modeling of commercial-scale fixed-bed reactors has demonstrated temperature variations exceeding 50°C in highly exothermic reactions like Fischer-Tropsch synthesis, compared to nearly isothermal conditions in laboratory reactors. These thermal variations create distinct microenvironments within the catalyst bed, with different deactivation profiles that collectively determine overall system lifetime.

Mechanical and Structural Integrity

Laboratory testing often overlooks mechanical stresses that critically impact industrial catalyst longevity. Commercial operations subject catalysts to significant pressure drops, particle abrasion from gas/liquid flows, and thermal expansion/contraction cycles that cause mechanical breakdown. Fluidized bed applications like catalytic cracking impose particularly severe mechanical demands, with catalysts circulating at high velocities between reactor and regenerator vessels. These conditions lead to particle attrition, generating fines that increase pressure drop and result in catalyst loss.

The industrial handling of catalysts—including loading procedures, start-up protocols, and shutdown conditions—introduces additional stresses absent from laboratory evaluation. Improper loading can create channeling, where reactants bypass significant catalyst volumes, or create localized high-velocity zones that accelerate erosion. Start-up and shutdown procedures expose catalysts to unusual temperature and composition excursions that can cause rapid deactivation through mechanisms like metal oxidation or support structural changes.

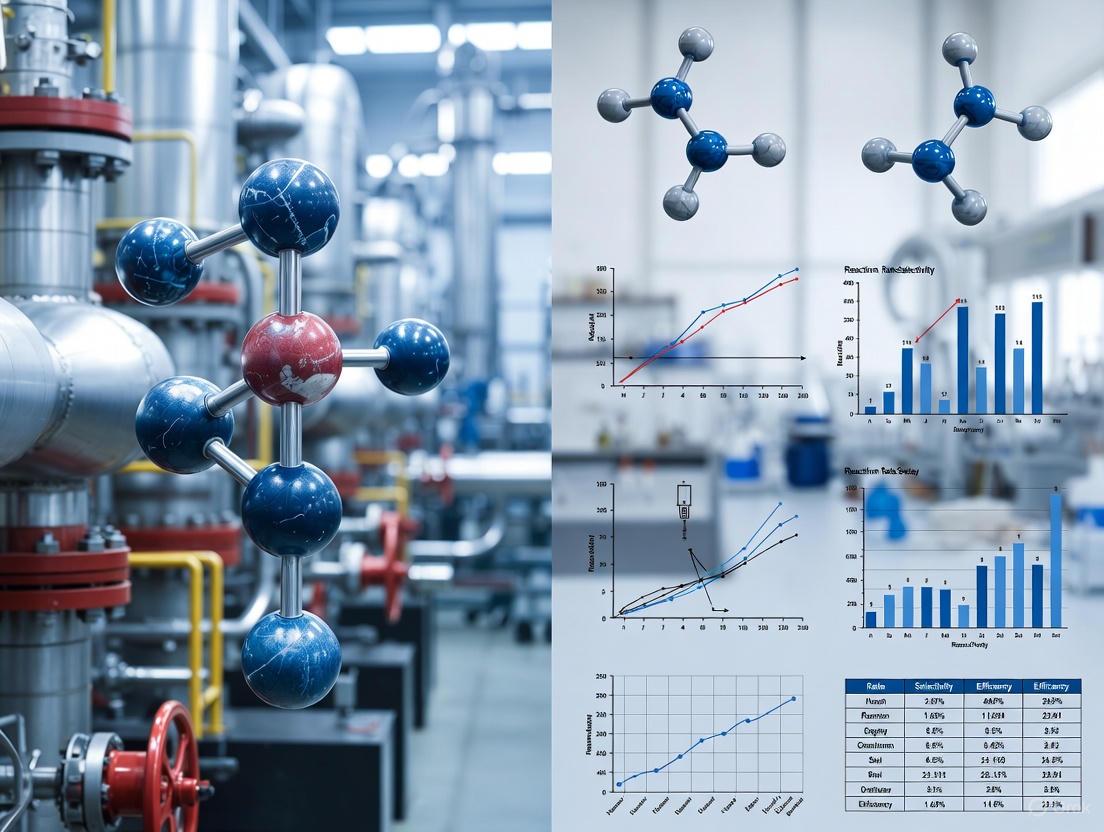

Visualization of Performance Gap Concepts

Catalyst Performance Degradation Pathways

Catalyst Performance Degradation Pathways

This diagram illustrates how ideal laboratory performance translates to industrial performance gaps through multiple degradation pathways, including activity loss from feedstock impurities, selectivity decline from transport limitations, and stability reduction from mechanical and thermal stresses.

Modern Catalyst Development Workflow

Modern Catalyst Development Workflow

This workflow diagram shows the iterative process of modern catalyst development, highlighting how performance gap analysis between laboratory and industrial scales informs catalyst reformulation through AI-assisted design, with benchmarking databases and standardized protocols enabling quantitative comparisons.

Bridging the Performance Gap: Advanced Approaches

Emerging Strategies for Enhanced Stability

Spatial confinement approaches have demonstrated remarkable success in enhancing catalyst stability while maintaining activity. Research in water treatment catalysis has shown that confining iron oxyfluoride (FeOF) catalysts between graphene oxide layers significantly reduces fluoride ion leaching—the primary deactivation mechanism—from 40.7% to minimal levels while maintaining near-complete pollutant removal for over two weeks in continuous operation [1]. This spatial restriction preserves the catalyst structure against the reactive oxygen species that normally cause rapid degradation.

Atomic-layer deposition (ALD) techniques create protective overlayers that shield active sites from poisoning while maintaining accessibility to reactant molecules. In petroleum refining applications, alumina overcoats deposited via ALD on supported metal catalysts have demonstrated reduced coking rates and enhanced resistance to sulfur poisoning, extending catalyst lifetimes by 30-50% in accelerated testing. These nanostructured protective layers represent a promising approach to bridging the stability gap without sacrificing activity.

Data-Driven Catalyst Development

The integration of artificial intelligence with high-throughput experimentation is accelerating catalyst development cycles. AI-driven methodologies enhance data analysis, automate complex decision-making processes, and optimize catalyst design for industrial applications [2]. These approaches are particularly valuable for predicting long-term stability from short-term testing data by identifying subtle performance descriptors that correlate with industrial lifetime.

Benchmarking databases like CatTestHub provide standardized reference data for comparing catalytic performance across different laboratories and conditions [3]. This community resource houses experimentally measured chemical rates of reaction, material characterization, and reactor configuration details, enabling researchers to contextualize their results against established benchmarks. Such standardized comparisons are essential for identifying genuine improvements in catalyst stability rather than incremental variations within experimental error.

The Scientist's Toolkit: Essential Research Solutions

Table 3: Key research reagents and materials for catalyst performance evaluation

| Research Solution | Primary Function | Application Examples | Industrial Relevance |

|---|---|---|---|

| Standard Reference Catalysts (EuroPt-1, Alumina standards) | Benchmarking and method validation | Cross-laboratory performance comparison; instrument calibration | Establishes baseline for commercial catalyst improvement |

| Poisoning Simulants (Thiophene, organonitrogen compounds) | Accelerated deactivation studies | Evaluating resistance to sulfur, nitrogen poisoning | Predicts performance with impurity-containing industrial feeds |

| Thermal Aging Protocols | Simulating long-term sintering | High-temperature treatment in controlled atmospheres | Assesses thermal stability under process conditions |

| Mechanical Attrition Testers | Measuring physical robustness | Fluidization endurance; crushing strength measurement | Predicts catalyst lifetime in moving-bed reactors |

| Coke Characterization Kits | Quantifying carbon deposits | Temperature-programmed oxidation; elemental analysis | Guides regeneration strategy development |

| Metal Leaching Analysis | Tracking active component loss | ICP analysis of reaction solutions; surface measurement | Identifies stability limitations in liquid-phase reactions |

The performance gap between laboratory and industrial environments remains a significant challenge in catalyst development, with differences in activity, selectivity, and stability stemming from fundamental variations in operating conditions, feedstock quality, and mechanical stresses. While standardized testing protocols and accelerated aging methods provide valuable insights, complete prediction of industrial performance from laboratory data remains elusive.

Emerging approaches including spatial confinement strategies, protective overlayers, and data-driven development methodologies show promise in bridging this gap. The continued development of benchmarking databases and standardized testing protocols will enhance the translation of laboratory discoveries to industrial applications. For researchers, acknowledging and systematically addressing these performance gaps during catalyst design represents the most viable path to developing commercially viable catalytic systems that maintain their laboratory-demonstrated performance under industrial conditions.

Catalyst deactivation presents a fundamental challenge in both industrial and laboratory settings, compromising performance, efficiency, and sustainability across numerous chemical processes [4]. While the intrinsic chemical mechanisms of deactivation remain consistent across scales, their manifestation, impact, and management differ profoundly between controlled research environments and full-scale industrial operations [5]. This guide provides a comparative analysis of three principal deactivation pathways—poisoning, sintering, and fouling—contrasting their characteristics in industrial versus laboratory contexts. By integrating mechanistic understanding with practical experimental data and protocols, this work aims to equip researchers and development professionals with the knowledge to design more durable catalytic systems and develop predictive testing methodologies that accurately mirror industrial reality.

Comparative Analysis of Deactivation Mechanisms

Table 1: Comparative Analysis of Catalyst Deactivation Mechanisms

| Mechanism | Primary Causes | Industrial Manifestation | Laboratory Manifestation | Key Differences |

|---|---|---|---|---|

| Poisoning | Strong chemisorption of impurities (e.g., S, N, P, As, alkali metals) on active sites [6] [7] [8]. | Rapid, often irreversible deactivation from trace impurities in feed; requires guard beds and feed purification [6]. | Often slower, less severe due to purified feeds; may be overlooked in short-term tests [8]. | Poison concentration, exposure time, and irreversibility are typically greater in industrial settings. |

| Sintering | Thermal degradation from high temperatures (often accelerated by water vapor), causing agglomeration of active phases [9] [7]. | Irreversible loss of surface area over long timescales; exacerbated by process upsets and exothermic reactions [10]. | Controlled temperature environments minimize risk; may not be observed in brief stability tests [9]. | Industrial sintering is driven by long-term thermal stress and transient temperature excursions. |

| Fouling (Coking) | Physical deposition of carbonaceous residues from side reactions, blocking active sites and pores [6] [4]. | Coke buildup can reach 15-20% of catalyst weight, leading to pore plugging and pressure drop issues [6]. | Coke formation mechanisms can be studied, but mass transfer limitations differ from large-scale reactors [4]. | Coke amount, location (pore blocking), and consequent fluid dynamics differ significantly. |

Table 2: Quantitative Impact of Deactivation Mechanisms on Catalyst Properties

| Mechanism | Typical Activity Loss | Impact on Surface Area | Impact on Selectivity | Typical Regeneration Method |

|---|---|---|---|---|

| Poisoning | Can be complete with very low poison concentrations (e.g., ppb levels of H₂S for methanation catalysts) [6]. | Minimal direct change | Often alters selectivity in multifunctional catalysts [6]. | Often irreversible; requires prevention via feed purification [6]. |

| Sintering | Proportional to the loss of active surface area [9]. | Can cause dramatic loss of active surface area [9]. | Can alter selectivity due to changes in active site geometry [9]. | Generally irreversible [7]. |

| Fouling (Coking) | Gradual decline correlated with coke deposition [4]. | Blocks pores and reduces accessible surface area [4]. | Can be selective, deactivating some sites more than others [6]. | Often reversible via oxidation (e.g., coke combustion) [4]. |

Experimental Protocols for Studying Deactivation

Accelerated Poisoning Tests

To simulate industrial poisoning in a laboratory setting, researchers often employ accelerated testing protocols. A representative experiment involves exposing a catalyst to a feed containing controlled concentrations of a known poison.

- Objective: To quantify the tolerance of a catalyst to a specific poison (e.g., potassium on Pt/TiO₂) and evaluate the reversibility of the poisoning effect [8].

- Materials: Fixed-bed reactor system, mass flow controllers, vapor delivery system, analytical instruments (e.g., GC, MS), catalyst sample, poison precursor.

- Procedure:

- Catalyst Pre-treatment: Activate the catalyst in situ (e.g., under H₂ flow) at specified temperature and duration.

- Baseline Activity Measurement: Establish initial conversion and selectivity under representative process conditions (e.g., temperature, pressure, GHSV) using a clean feed.

- Poisoning Phase: Introduce the poison (e.g., via a potassium salt precursor in the feed) at a controlled concentration. Monitor activity and selectivity as a function of time-on-stream.

- Characterization: Characterize the poisoned catalyst using surface-sensitive techniques (e.g., XPS, TPD) to identify the location and nature of the poison [8].

- Regeneration Test: Attempt to regenerate the catalyst (e.g., via water washing for potassium poisoning [8] or oxidative/reductive treatments) and re-measure baseline activity to assess reversibility.

- Industrial Relevance: This protocol models the gradual accumulation of poisons from biomass or other impure feedstocks in industrial reactors [8].

Constant Conversion Protocol for Catalyst Ranking

Traditional laboratory tests at fixed temperature are inadequate for predicting industrial performance where reactors are often operated to maintain constant conversion.

- Objective: To rank catalyst activity and stability under conditions mimicking industrial control schemes [5].

- Materials: Multi-reactor system (e.g., Flowrence) with individual temperature control, online GC, automated feedback control system.

- Procedure:

- Setpoint Definition: Define a target performance metric (e.g., product octane number, CO conversion) [5].

- Automated Operation: The GC analysis of each reactor's effluent is fed to a control algorithm that dynamically adjusts the individual reactor temperature to maintain the target performance.

- Data Collection: Monitor the required temperature trajectory and other key performance indicators (e.g., C5+ yield, selectivity) over an extended time-on-stream.

- Analysis: Rank catalysts based on the temperature increase required to maintain activity (indicating deactivation rate) and the stability of selectivity over time [5].

- Industrial Relevance: This approach reveals differences in catalyst lifetime and selectivity under deactivation that are impossible to identify using fixed-temperature protocols [5].

Figure 1: Generalized experimental workflow for studying catalyst deactivation.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions and Materials for Deactivation Studies

| Reagent/Material | Function in Deactivation Studies | Example Application |

|---|---|---|

| Model Poison Compounds | To simulate the effect of specific impurities found in industrial feeds [8]. | H₂S or SO₂ for sulfur poisoning; NH₃ or pyridine for basic N-poisoning; KCl for alkali metal poisoning [6] [8]. |

| Guard Bed Materials | To remove specific poisons from the feed, extending catalyst lifetime [6]. | ZnO beds for H₂S removal; aluminized alumina for HCl; sulfured charcoal for mercury [6]. |

| Regeneration Gases | To restore catalyst activity by removing deactivating species [4]. | Diluted O₂ or air for coke combustion (oxidation); H₂ for reduction of oxidized sites or sulfur removal [4]. |

| Characterization Standards | To calibrate instruments for accurate measurement of catalyst properties. | Reference catalysts with known surface area and metal dispersion for BET and chemisorption analysis. |

Visualization of Mechanism Interplay and Experimental Design

Figure 2: Interplay of deactivation mechanisms driven by process conditions and feed composition.

In the transition from laboratory research to industrial application, mass and heat transfer limitations represent the most significant barrier to maintaining catalytic performance. While catalysts may demonstrate exceptional activity and selectivity in small-scale batch reactors, their performance often degrades substantially at pilot and industrial scales due to transport limitations that become dominant under real-world flow conditions [11]. Industry data indicates that less than 20% of catalysts showing promising laboratory results successfully translate to industrial applications, primarily due to heat and mass transfer limitations that only become apparent at larger scales [11]. Understanding these limitations is crucial for researchers and drug development professionals seeking to bridge the gap between conceptual catalyst design and practical implementation.

The fundamental challenge lies in the differing dominance of kinetics versus transport phenomena across scales. In laboratory reactors, near-ideal mixing and temperature control minimize transport limitations, allowing intrinsic kinetic properties to dominate performance metrics. In contrast, industrial flow systems introduce significant concentration and temperature gradients that can reduce catalytic activity by 15-30% and selectivity by up to 25% compared to laboratory predictions [11]. These performance reductions directly impact process yield and economic viability, making the understanding of flow and diffusion principles essential for successful catalyst development.

Theoretical Framework: Transport Phenomena in Catalytic Systems

Mass Transfer Limitations in Porous Catalyst Systems

Mass transfer limitations occur when the rate of reactant transport to active sites or product transport away from these sites is slower than the intrinsic reaction rate. In porous catalyst particles, this manifests as intraparticle diffusion limitations, where reactants must navigate through complex pore networks to reach internal active sites. The effectiveness factor (η) quantifies this limitation, representing the ratio of the actual reaction rate to the rate that would occur if all interior surfaces were exposed to the same reactant concentration as the external surface [12].

Experimental studies with porous three-way catalyst (TWC) particles demonstrate how precisely controlled pore architectures can mitigate these limitations. Researchers have successfully engineered interconnected pore structures that facilitate effective diffusion of gaseous reactants to internal active sites, significantly enhancing CO oxidation performance [12]. The framework thickness (distance between pores) and macroporosity emerge as critical parameters, with thinner frameworks and higher macroporosity enabling better molecular and convective diffusion [12].

Heat Transfer Limitations in Flow Reactors

Heat transfer limitations arise from inadequate temperature control within catalytic reactors, leading to hot spots that accelerate catalyst deactivation and cold spots that reduce reaction rates. In flow systems, the high surface-to-volume ratio of microreactors provides superior heat transfer capabilities compared to traditional batch reactors [13]. This enables precise temperature control, allowing operation under conditions that would be unsafe or inefficient in batch systems.

The integration of Process Analytical Technology (PAT) tools enables real-time monitoring and control of critical temperature parameters in continuous flow systems [13]. Inline monitoring, where analytical instruments are integrated directly into the process stream, provides continuous, non-destructive data without manual sampling, allowing for immediate adjustment of process conditions to maintain optimal catalytic performance [13].

Experimental Comparisons: Laboratory vs. Industrial Performance

Quantitative Analysis of Performance Gaps

The transition from laboratory to pilot scale typically reveals significant performance degradation across key catalyst metrics. The following table summarizes typical performance reductions observed during scale-up:

Table 1: Typical Catalyst Performance Reduction During Scale-Up

| Performance Metric | Laboratory Performance | Pilot Scale Performance | Typical Reduction |

|---|---|---|---|

| Catalytic Activity | Baseline (100%) | 70-85% of laboratory | 15-30% decrease |

| Selectivity | Baseline (100%) | 75-85% of laboratory | Up to 25% decrease |

| Catalyst Lifetime | Baseline reference | 2-5x faster deactivation | 40-60% reduction |

| Mechanical Stability | Negligible attrition | 5-10% monthly attrition | Significant loss |

Porous Catalyst Architecture Optimization Study

Recent research on Three-Way Catalyst (TWC) nanoparticles for emission control provides quantitative insights into how controlled pore structures can mitigate mass transfer limitations. In this study, porous TWC particles were synthesized via a template-assisted spray process with varying poly(methyl methacrylate) (PMMA) template concentrations (0.1-3 wt%) while maintaining constant TWC nanoparticle concentration (1 wt%) [12].

Table 2: Porous TWC Particle Performance Based on Structural Properties

| Sample ID | PMMA Concentration (wt%) | Framework Thickness (nm) | Macroporosity (%) | CO Conversion Efficiency | Critical Structural Features |

|---|---|---|---|---|---|

| TP0.1 | 0.1 | 120 ± 15 | 45 ± 3 | 55% at 250°C | Isolated pores, thick framework |

| TP0.5 | 0.5 | 95 ± 10 | 58 ± 4 | 70% at 250°C | Partial interconnection |

| TP1 | 1.0 | 70 ± 8 | 72 ± 5 | 85% at 250°C | Well-interconnected pores |

| TP2 | 2.0 | 45 ± 5 | 85 ± 6 | 95% at 250°C | Optimal interconnection |

| TP3 | 3.0 | 30 ± 5 | 92 ± 7 | 88% at 250°C | Broken structures |

The experimental data demonstrates that CO oxidation performance increases with the development of an interconnected pore structure, reaching optimal performance at specific framework thickness (45 ± 5 nm) and macroporosity (85 ± 6%) values [12]. Beyond these optimal values (TP3 sample), structural integrity is compromised, leading to reduced performance despite enhanced diffusion characteristics.

Experimental Protocols for Assessing Transfer Limitations

Protocol 1: Interconnected Pore Structure Analysis

Objective: To characterize internal pore structure and its relationship to mass transfer efficiency in porous catalyst particles [12].

Materials and Equipment:

- Catalyst samples with varying template concentrations

- Plasma Focused Ion Beam (PFIB) system with Xe+ source

- Field-Emission Scanning Electron Microscope (FE-SEM)

- ImageJ software with Otsu thresholding plugin

- N₂ adsorption-desorption apparatus (BET method)

- Ultrasonic nebulizer and tubular furnace for catalyst synthesis

Methodology:

- Synthesize catalyst particles using template-assisted spray process with controlled template concentrations

- Prepare cross-sections using PFIB-SEM dual beam system

- Acquire high-resolution cross-sectional SEM images at multiple locations

- Analyze framework thickness through direct measurement from cross-sectional images

- Determine macroporosity using Otsu thresholding technique in ImageJ

- Correlate structural parameters with catalytic performance metrics

- Validate interconnected pore formation through mathematical modeling of critical formation conditions

Key Parameters:

- Precursor composition (template to active material ratio)

- Spray drying conditions (temperature zones, gas flow rate)

- Calcination protocol (temperature ramp rate, final temperature, atmosphere)

- Minimum 300 particle measurements for statistical significance

Protocol 2: Catalytic Performance Evaluation Under Flow Conditions

Objective: To quantify catalytic performance under controlled flow conditions simulating industrial reactors [12].

Materials and Equipment:

- Fixed-bed quartz tube reactor (3.8 mm inner diameter)

- Mass flow controllers for precise gas blending

- Quartz wool for catalyst bed stabilization

- Gas chromatograph with thermal conductivity detector

- Temperature-programmed furnace with precise control

- Reaction gases: H₂/Ar (5.0 vol%/95.0 vol%), CO/O₂/N₂ (0.80 vol%/0.80 vol%/98.40 vol%)

Methodology:

- Pack reactor with 15 mg catalyst sample between quartz wool layers

- Implement two-stage pretreatment:

- Stage 1: H₂/Ar at 100 mL min⁻¹ for 30 min at 200°C

- Stage 2: CO/O₂/N₂ at 100 mL min⁻¹ for 30 min at 200°C

- Perform catalytic testing with CO/O₂/N₂ mixture at 100 mL min⁻¹

- Program temperature ramp from 50°C to 300°C

- Analyze effluent composition by gas chromatography

- Calculate CO conversion using: Conversion = ([CO]₍ᵢₙ₎ - [CO]₍ₒᵤₜ₎) / [CO]₍ᵢₙ₎ × 100%

Key Parameters:

- Gas hourly space velocity (GHSV)

- Catalyst bed geometry and packing density

- Temperature ramp rate and stabilization times

- Minimum triplicate measurements for reproducibility

Flow Reactor Technologies to Overcome Transfer Limitations

Continuous Flow Systems for Enhanced Transport Properties

Continuous flow chemistry represents a paradigm shift in catalytic processing, offering significant advantages for managing mass and heat transfer in industrial applications [13]. The intrinsic properties of flow reactors address many scale-up challenges through:

- Enhanced Mass Transfer: Superior mixing efficiency in microchannels reduces diffusion path lengths and concentration gradients

- Precise Temperature Control: High surface-to-volume ratio enables rapid heat exchange and elimination of hot spots

- Process Intensification: Ability to operate under conditions unsafe for batch processes (high T, P) while maintaining control

- Scalability Predictability: Numbering-up approach (multiplying identical units) provides more reliable scale-up than traditional sizing-up

The integration of flow systems with advanced activation methods such as photocatalysis and electrocatalysis further enhances transport properties [13]. Photoreactions in flow benefit from uniform photon flux due to short light penetration distances, while electrochemical flow cells provide controlled potential application with efficient reactant delivery to electrode surfaces.

Industrial Implementation Case Study

The implementation of structured catalyst supports in hydroprocessing units demonstrates how engineered solutions can overcome transfer limitations at industrial scale [11]. Traditional catalyst designs faced performance losses of 40-60% due to pore diffusion limitations with real feedstocks containing impurities. Advanced structured supports with hierarchical pore architectures maintained performance within 15% of laboratory predictions through optimized pore networks that facilitated access to active sites while resisting fouling [11].

Research Reagent Solutions for Transfer Limitation Studies

Table 3: Essential Research Reagents and Materials for Mass/Heat Transfer Studies

| Reagent/Material | Function in Research | Application Context |

|---|---|---|

| Poly(methyl methacrylate) Templates | Creates controlled macroporous structures in catalyst particles | Template-assisted synthesis of porous catalyst architectures [12] |

| Three-Way Catalyst (TWC) Nanoparticles | Active catalytic component for oxidation/reduction reactions | Emission control catalysis, structure-performance studies [12] |

| Precision Mass Flow Controllers | Delivers exact gas compositions and flow rates | Flow reactor studies, space velocity optimization [12] |

| Process Analytical Technology (PAT) Tools | Real-time monitoring of reaction parameters | Continuous flow systems, reaction optimization [13] |

| Structured Catalyst Supports | Enhanced transport properties through engineered geometries | Industrial catalyst design, diffusion limitation mitigation [11] |

| Plasma FIB-SEM System | Cross-sectional analysis of catalyst microstructure | Pore structure characterization, diffusion path visualization [12] |

Visualization of Experimental Workflow

Catalyst Development and Scale-Up Workflow

The integration of advanced structural design with flow reactor technologies represents the most promising approach to overcoming mass and heat transfer limitations in catalytic processes. The experimental data demonstrates that precisely controlled pore architectures with optimal framework thickness (40-50 nm) and macroporosity (80-85%) can enhance catalytic performance by facilitating effective diffusion to internal active sites [12]. Meanwhile, continuous flow systems provide the thermal management and mixing efficiency necessary to maintain this performance at scale [13].

For researchers and drug development professionals, addressing transfer limitations requires a fundamental shift from purely kinetic considerations to integrated design approaches that account for transport phenomena from the earliest stages of catalyst development. The experimental protocols and analytical methods outlined provide a framework for systematically evaluating and optimizing these critical parameters, potentially increasing the success rate of laboratory-to-pilot transitions beyond the current 20% threshold [11]. As catalyst design continues to evolve with computational modeling and high-throughput experimentation, the deliberate engineering of mass and heat transport properties will remain essential for realizing laboratory performance in industrial applications.

Catalyst performance, a critical parameter meticulously optimized in laboratory settings, often faces significant challenges when translated to industrial applications. A primary source of this performance gap is the operating environment: while catalysts are typically developed and tested using pure substrates in well-defined solvents, industrial processes must frequently contend with complex, impure media. These real-world feedstocks, such as biomass-derived streams, can contain numerous inorganic and organic impurities that adsorb onto active sites, leading to catalyst deactivation and poisoning [14]. Furthermore, the solvents themselves, often chosen for optimal performance in the lab, may be toxic, difficult to handle at scale, or incompatible with impurity-laden streams. This guide objectively compares catalyst performance in traditional versus emerging sustainable solvent systems and provides detailed methodologies for evaluating their efficacy in challenging environments, framing these findings within the broader thesis of bridging the gap between laboratory and industrial catalysis.

Fundamental Solvent-Catalyst Interactions and Performance Metrics

The solvent in a catalytic system is far from an inert spectator; it directly influences reaction rate, mechanism, and selectivity through multiple physical and chemical interactions. These interactions can be rationally understood and manipulated to improve catalyst performance.

Key Solvent Parameters Influencing Catalysis

The properties of a solvent that most strongly influence catalytic outcomes are its polarity/polarizability (π*), hydrogen-bond accepting ability (basicity, β), and hydrogen-bond donating ability (proticity, α) [15]. These parameters independently affect catalytic processes. For instance:

- In the isomerization of allylic alcohol catalyzed by Fe(CO)₄, the reaction rate is strongly inhibited by solvent basicity (β) because coordinating solvents block the alkene substrate from binding to the active site [15].

- The enantioselectivity of a Rh-catalyzed cyclopropanation reaction depends on both solvent polarity (π*) and basicity (β), with the highest enantiomeric excess achieved in non-polar, non-basic solvents [15].

The effect of a single solvent property can be isolated using binary solvent mixtures, supercritical fluids, or mathematical modeling using linear free energy relationships, allowing for the rational improvement of catalysts [15].

Performance Challenges in Impure Media

In industrial contexts, especially in biomass upgrading, catalysts are exposed to a wide range of impurities that can lead to deactivation. High-throughput studies have identified that atomic impurities like S, Cl, K, and P, as well as molecular species like H₂S and HCl, exhibit strong binding energies on common transition-metal catalysts (e.g., Co, Ni, Pd, Pt, Ru) and metal-oxide supports (e.g., Al₂O₃, ZrO₂) [14]. The strong adsorption of these species blocks active sites, effectively poisoning the catalyst and reducing its lifetime and productivity. This underscores the necessity for catalyst testing and solvent selection that account for these real-world complexities.

Comparative Analysis: Traditional vs. Green Solvent Systems

The shift toward sustainable chemistry is driving the replacement of conventional toxic solvents with greener alternatives. The following section provides a data-driven comparison of their performance.

Conventional Solvents and Their Drawbacks

Traditional polar aprotic solvents such as N-methyl-2-pyrrolidone (NMP), N,N-dimethylformamide (DMF), and N,N-dimethylacetamide (DMAc) are widely used in laboratory and industrial processes for their excellent solvation power [16]. However, they pose significant environmental and health hazards, including toxicity and poor biodegradability. Their use in industrial-scale reactions, particularly with impure feedstocks, can exacerbate waste management and solvent recovery challenges.

Green solvents, derived from renewable resources, offer a promising alternative due to their biodegradability, low toxicity, and reduced environmental impact [16] [17]. The market for these solvents is projected to grow from USD 2.2 billion in 2024 to USD 5.51 billion by 2035, reflecting increasing industrial adoption [17].

Table 1: Comparison of Conventional and Green Solvent Performance Characteristics

| Solvent Category | Example Solvents | Key Performance Attributes | Limitations & Challenges |

|---|---|---|---|

| Conventional Polar Aprotic | NMP, DMF, DMAc | High solvation power, broad applicability | High toxicity, environmental persistence, hazardous waste |

| Bio-based Esters & Lactones | γ-Valerolactone (GVL), Lactate Esters | Good biodegradability, effective for polymer processing | Can have limited performance in some applications [17] |

| Dipolar Aprotic Replacements | Cyrene (dihydrolevoglucosenone), Rhodiasolv PolarClean | Low toxicity, good solvent power for polymers | Higher cost than conventional options; performance data in impure media is limited |

| Polar Protic | Bio-alcohols (e.g., from corn, sugarcane) | Low toxicity, readily available, low cost | May not be suitable for water-sensitive reactions |

| Other Renewable | Plant-derived oils, D-Limonene | High biodegradability, useful in cleaning applications | Limited applicability in high-performance catalysis |

Quantitative Performance Data in Separation Processes

In membrane separation for water purification and CO₂ capture, green solvents have demonstrated significant progress. The resulting membranes show performance that is increasingly competitive with those fabricated from traditional solvents, though challenges remain in solvent–polymer compatibility, scalability, and the trade-offs between sustainability and separation efficiency [16]. The use of Hansen Solubility Parameters (HSP) is crucial for predicting polymer-solvent compatibility and optimizing membrane fabrication [16].

Advanced Strategies for Complex Media: Magnetic Catalysts and AI

Magnetic Catalysts for Simplified Recovery in Impure Streams

Magnetic nanocatalysts represent a powerful strategy for operating in complex, impure media. These catalysts, such as manganese-doped ferrites or Mn-functionalized magnetic nanoparticles, combine high catalytic efficiency with easy separation via an external magnetic field [18]. This property is particularly advantageous in viscous or slurry-based reaction mixtures containing solid impurities, where traditional filtration is problematic.

Table 2: Magnetic vs. Conventional Heterogeneous Catalysts

| Feature | Magnetic Catalysts | Conventional Heterogeneous Catalysts |

|---|---|---|

| Recovery & Reusability | Easy separation with a magnet; highly reusable | Require filtration or centrifugation; can be damaged |

| Efficiency | High surface area; can be tailored for specific reactions | Can suffer from diffusion limitations and lower surface interaction |

| Environmental Impact | More sustainable due to easy recovery and reduced waste | Often require more energy-intensive separation processes |

| Cost-effectiveness | Lower long-term costs due to reusability and easy separation | Costs associated with catalyst loss, regeneration, and replacement |

Their intrinsic recoverability mitigates the risk of catalyst loss in processes where impurities might foul or block fixed-bed reactors, making them particularly suitable for biomass conversion and pharmaceutical synthesis in impure media [18].

AI-Guided Workflows for Solvent and Catalyst Optimization

Artificial intelligence (AI) and machine learning are transforming the development of robust catalytic systems for complex environments. These approaches can navigate vast experimental spaces with remarkable efficiency.

Active Learning for Catalyst Development: An exemplary study used an active learning framework, integrating data-driven algorithms with experimentation, to optimize a complex FeCoCuZr catalyst for higher alcohol synthesis from syngas. This approach identified an optimal catalyst (Fe₆₅Co₁₉Cu₅Zr₁₁) with a 5-fold productivity improvement over typical yields, achieving stable operation for 150 hours. Crucially, it accomplished this by performing only 86 experiments, a reduction of >90% in environmental footprint and cost compared to traditional high-throughput programs [19]. The workflow also enabled multi-objective optimization, identifying Pareto-optimal catalysts that balance high productivity with low selectivity for undesirable by-products like CO₂ and CH₄ [19].

Diagram 1: AI catalyst optimization workflow.

Machine Learning for Solvent Selection: A similar Bayesian optimization framework has been applied to the challenge of selecting green solvent mixtures for extracting valuable chemicals from plant biomass (lignin) [20]. The process starts with an initial design space of nearly infinite solvent combinations. A machine learning model is trained to predict a key performance property, and then iteratively refines its predictions by balancing exploration (testing mixtures with high predictive uncertainty) and exploitation (testing mixtures predicted to have the best performance). This approach allows researchers to identify the most promising solvent blends from a vast possibility space by testing only dozens of candidates, dramatically accelerating the development of sustainable separation processes [20].

Experimental Protocols for Performance Validation

Protocol 1: High-Throughput Impurity Adsorption Screening

This protocol, adapted from high-throughput density functional theory (DFT) studies, is used to predict catalyst poisoning in impure media [14].

- Objective: To systematically evaluate the adsorption strength of various impurities on catalyst and support surfaces to assess poisoning propensity.

- Methodology:

- Surface Modeling: Generate slab models for relevant catalyst surfaces (e.g., (111) facets for fcc metals, (0001) for hcp metals, and stable facets for metal oxides like ZrO₂(⁻111)).

- Adsorbate Placement: Identify unique high-symmetry adsorption sites (e.g., atop, bridge, hollow) on each surface model.

- DFT Calculation: Perform geometry optimization using DFT (e.g., with VASP) with a GGA-PBE functional and D3 dispersion correction. Ionic convergence is typically reached when forces on each atom are < 0.02 eV/Å.

- Energy Calculation: The adsorption energy (EB) is calculated as: EB = Etot - Eclean - Egas, where Etot is the total energy of the adsorbate-surface complex, Eclean is the energy of the clean surface, and Egas is the energy of the adsorbate in the gas phase. A more negative E_B indicates stronger adsorption and a higher poisoning potential.

- Key Outputs: A dataset of adsorption energies for atomic (S, Cl, K, P, etc.) and molecular (H₂S, HCl, NH₃, etc.) impurities on transition metals and metal oxides, identifying the most pernicious poisons for a given catalyst.

Protocol 2: Bayesian Optimization for Green Solvent Formulation

This experimental protocol details the machine-learning-guided selection of green solvent mixtures for liquid-liquid extraction [20].

- Objective: To efficiently identify an optimal blend of green solvents (e.g., alcohols, ethers, water) for separating target chemicals from complex mixtures.

- Methodology:

- Design: Identify a set of solvent mixture candidates (combinations of 8+ green solvents) for testing.

- Observe: Test the selected solvent mixtures experimentally, often using a liquid-handling robot to measure partition coefficients or other performance metrics.

- Learn: Use the experimental results to train and improve a Bayesian machine learning model.

- Iterate: The updated model suggests the next batch of solvent mixtures to test, balancing exploration of unknown compositions and exploitation of promising ones. An inner loop using a physics-based model (e.g., COSMO-RS) can generate "fantasy samples" to efficiently select batches of experiments.

- Key Outputs: A highly accurate model predicting solvent mixture performance, leading to the identification of an optimal green solvent formulation with a minimal number of experiments.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for Catalysis in Complex Media

| Research Reagent | Function & Application |

|---|---|

| Green Solvents (GVL, Cyrene, PolarClean) | Sustainable, low-toxicity alternatives to NMP/DMF for catalyst testing and material processing [16]. |

| Magnetic Nanocatalysts (e.g., Mn-ferrites) | High-activity, magnetically recoverable catalysts for reactions in impure, slurry-phase media [18]. |

| Hansen Solubility Parameters (HSP) | A computational tool for predicting polymer-solvent compatibility and optimizing membrane fabrication formulations [16]. |

| Bayesian Optimization Software | Machine learning frameworks for guiding efficient experimental design in solvent selection and catalyst optimization [20]. |

| High-Throughput DFT Workflows | Automated computational screening to predict impurity adsorption and catalyst poisoning tendencies [14]. |

| Liquid-Handling Robotics | Enables automated, high-throughput experimental validation of solvent mixtures and catalytic reactions [20]. |

Navigating the solvent and environmental challenges of complex, impure media requires a paradigm shift from traditional, trial-and-error approaches to integrated, intelligent strategies. The comparative data presented in this guide demonstrates that green solvents, while sometimes facing cost and performance hurdles, are viable and increasingly competitive alternatives to conventional toxic solvents. Furthermore, the synergistic use of magnetic catalysts for robust operation and easy recovery, combined with AI-driven active learning for accelerated optimization, provides a powerful toolkit for designing next-generation catalytic systems. By adopting these advanced materials and data-informed methodologies, researchers and drug development professionals can more effectively bridge the gap between idealized laboratory performance and the demanding realities of industrial application.

Economic and Sustainability Drivers for Improved Catalyst Longevity

Catalyst longevity is a pivotal factor influencing both the economic viability and environmental sustainability of modern industrial processes. In the broader context of research on catalyst performance in industrial versus laboratory conditions, understanding the drivers for improved catalyst durability becomes essential. Catalyst deactivation remains a fundamental challenge in heterogeneous catalysis, compromising performance, efficiency, and sustainability across numerous industrial applications [21]. The global industrial catalysts market, valued at $21.56 billion in 2024 and projected to reach $34.52 billion by 2034, reflects the substantial economic stake in catalytic technologies [22]. This article examines the key economic and sustainability drivers for enhanced catalyst longevity, comparing degradation pathways across different environments and evaluating advanced testing and regeneration methodologies that provide performance benchmarks for researchers and development professionals.

The disparity between controlled laboratory conditions and harsh industrial operational environments creates a critical research gap in accurately predicting and extending catalyst service life. Industrial catalysts operate under continuous stress from thermal, chemical, and mechanical factors that accelerate deactivation compared to idealized laboratory settings [23]. This comparison guide objectively analyzes these differential performance conditions, supported by experimental data on degradation mechanisms, durability testing protocols, and regeneration technologies that collectively aim to bridge this gap while addressing both economic and environmental imperatives.

Economic Drivers for Catalyst Longevity

Market Dynamics and Cost Considerations

The economic imperative for improved catalyst longevity stems from multiple market forces and operational cost pressures. The global catalyst aging durability test services market, valued at $1.42 billion in 2024 and projected to reach $2.62 billion by 2033 with a CAGR of 7.1%, demonstrates the significant resources dedicated to understanding and extending catalyst lifespans [24]. This growth trajectory underscores industry recognition that extended catalyst durability directly correlates with improved operational economics through reduced replacement frequency, lower material costs, and enhanced process efficiency.

Raw Material Costs: Precious metals including platinum, palladium, and rhodium represent substantial cost components in many industrial catalysts. The ability to extend functional lifespan through improved longevity directly reduces annualized precious metal consumption and associated costs [22].

Process Efficiency: Degraded catalysts diminish product yields and selectivity in critical processes such as petroleum refining and chemical synthesis. Maintaining optimal catalyst performance through extended operational life improves process economics through higher valuable product output and reduced energy consumption per unit of production [25].

Regulatory Compliance Costs: With stringent environmental regulations mandating sustained emission control performance throughout certification periods (EPA, CARB, Euro standards), premature catalyst failure can result in substantial compliance penalties and costly system replacements [23].

Table 1: Economic Impact of Catalyst Longevity Across Industries

| Industry | Economic Impact of Extended Longevity | Key Cost Factors |

|---|---|---|

| Automotive | Reduced warranty claims, compliance maintenance | Precious metal content, replacement costs, regulatory penalties |

| Petroleum Refining | Improved yield, reduced downtime | Catalyst replacement costs, process shutdown expenses |

| Chemical Synthesis | Enhanced selectivity, higher purity products | Raw material utilization, energy consumption |

| Power Generation | Sustained emission control, operational continuity | Environmental compliance costs, system replacement |

Operational Efficiency and Lifecycle Optimization

From an operational perspective, catalyst longevity directly influences process reliability and maintenance scheduling. Unplanned catalyst replacements in continuous industrial processes can necessitate complete shutdowns, resulting in substantial production losses. The North American industrial catalyst market, valued at $7.1 billion in 2024, illustrates the economic scale of catalyst consumption in just one region [25]. Industries are increasingly adopting predictive maintenance approaches based on detailed aging tests to optimize replacement cycles and minimize unplanned downtime, thereby maximizing overall equipment effectiveness.

The total cost of ownership for catalytic systems has emerged as a crucial decision metric, shifting focus from initial catalyst cost to long-term performance sustainability. This comprehensive accounting includes not only catalyst purchase price but also installation expenses, energy consumption during operation, regeneration capabilities, disposal costs, and performance degradation rates. Research indicates that even modest improvements in catalyst lifespan can yield disproportionate economic benefits by amortizing fixed replacement costs over longer operational periods [21] [24].

Sustainability Drivers for Catalyst Longevity

Environmental Regulations and Green Chemistry

Sustainability imperatives have become equally powerful drivers for improved catalyst longevity alongside economic factors. Environmental regulations continue to tighten globally, with standards such as EPA regulations, CARB requirements, and Euro 7 emissions standards mandating sustained catalytic performance over extended vehicle or system lifetimes [23]. These regulatory frameworks effectively compel manufacturers to prioritize catalyst durability alongside initial activity to ensure continuous compliance throughout certification periods.

The principles of green chemistry further reinforce the sustainability case for extended catalyst longevity. The industrial catalysts market is witnessing a pronounced shift toward sustainable and bio-based catalysts, driven by industry commitments to reduce carbon footprint and environmental impact [25]. Longer-lasting catalysts directly contribute to multiple green chemistry principles by reducing waste generation, minimizing energy consumption through maintained process efficiency, and decreasing the frequency of catalyst replacement and disposal.

Resource Conservation: Extended catalyst lifespans reduce the consumption of often scarce or energy-intensive materials, including precious metals and complex synthetic materials, supporting circular economy objectives in industrial catalysis [21].

Emission Control: Maintaining catalytic efficiency throughout operational life is crucial for continuous control of greenhouse gases and criteria pollutants, directly supporting climate goals and air quality improvements across industrial and transportation sectors [24].

Sustainable Process Intensification

The concept of process intensification through improved catalysis represents another significant sustainability driver. Advanced catalysts with enhanced longevity enable more compact, efficient chemical processes that reduce both energy and material inputs per unit of output. The emerging adoption of zeolite and metal-organic framework (MOF) catalysts exemplifies this trend, offering superior thermal stability, tailored selectivity, and extended operational life in demanding applications [25].

The growing emphasis on renewable feedstocks similarly demands more durable catalytic materials. Processes converting biomass, waste streams, or captured carbon into valuable products often involve complex, challenging feedstocks that can accelerate catalyst deactivation. Developing robust catalysts capable of maintaining performance with these alternative inputs is essential to enabling the transition toward more sustainable manufacturing paradigms and circular material flows [21] [25].

Table 2: Sustainability Benefits of Extended Catalyst Longevity

| Sustainability Dimension | Impact of Improved Longevity | Contribution to Sustainability Goals |

|---|---|---|

| Resource Efficiency | Reduced material consumption per unit of time | Conservation of scarce metals, lower embodied energy |

| Waste Reduction | Fewer spent catalyst volumes for disposal | Minimized hazardous waste generation |

| Emissions Control | Sustained pollution abatement efficiency | Continuous compliance with air quality standards |

| Energy Efficiency | Maintained process selectivity and activity | Reduced energy intensity of chemical processes |

| Renewable Integration | Enhanced stability with challenging feedstocks | Enablement of biomass and waste conversion |

Catalyst Deactivation Mechanisms

Primary Deactivation Pathways

Catalyst deactivation follows several well-characterized pathways that differ in their significance between laboratory and industrial environments. Understanding these mechanisms is essential for developing strategies to extend functional catalyst lifespan. The principal deactivation mechanisms include:

Thermal Deactivation: Prolonged exposure to high temperatures causes sintering of active metal particles, reducing available surface area, and can induce phase transformations that diminish catalytic activity. Thermal cycling can additionally cause mechanical damage through differential expansion and contraction [23].

Chemical Poisoning: Exposure to contaminants in feedstocks, such as sulfur, phosphorus, heavy metals, or halogens, leads to active site blocking or chemical modification of the catalyst surface. Poisoning mechanisms vary from reversible adsorption to permanent chemical transformation of active sites [23] [26].

Coking and Fouling: Carbon deposition through decomposition or condensation reactions forms polymeric or graphitic carbon structures on catalyst surfaces, physically blocking access to active sites. This mechanism is particularly prevalent in hydrocarbon processing applications [21].

Mechanical Damage: Physical stresses including attrition, crushing, or washcoat detachment caused by vibration, pressure drops, or thermal cycling can compromise catalyst integrity and function, especially in mobile applications or fluidized bed systems [23].

Comparative Analysis: Industrial vs. Laboratory Conditions

The progression and relative significance of deactivation mechanisms differ substantially between controlled laboratory environments and actual industrial operation, creating challenges in translating accelerated aging tests to real-world performance predictions.

Diagram 1: Deactivation mechanisms in laboratory versus industrial conditions

Laboratory studies typically investigate deactivation mechanisms in isolation under carefully controlled conditions, while industrial operation presents synergistic degradation where multiple mechanisms operate concurrently and often interact to accelerate overall deactivation [21]. For example, thermal stress may exacerbate mechanical damage, while coke deposition may trap chemical poisons against the catalyst surface, intensifying their effect. These complex interactions create challenges in extrapolating laboratory durability data to field performance predictions.

Industrial catalysts must withstand transient operations including startup/shutdown cycles, feedstock variations, and load changes that introduce additional stress factors rarely replicated in standard laboratory aging protocols. The CatTestHub database initiative seeks to address these challenges by establishing standardized benchmarking protocols and creating a shared repository of experimental data to better correlate laboratory measurements with practical catalyst performance [3].

Experimental Methodologies for Aging Assessment

Standardized Aging Protocols

Rigorous experimental methodologies are essential for accurate assessment of catalyst longevity and comparison of different catalytic materials. Standardized aging protocols have been developed to simulate various deactivation mechanisms under controlled, reproducible conditions. These methodologies enable performance benchmarking and comparative evaluation of catalyst durability across different formulations and applications.

Thermal Aging: Subjects catalysts to elevated temperatures, either constant or cycled, to simulate thermal sintering and structural degradation. Protocols specify temperature profiles, atmosphere composition, and duration to replicate specific service conditions. For automotive catalysts, thermal aging might involve exposure to 800-1050°C for 50-200 hours depending on the target equivalent mileage [23] [24].

Chemical Aging: Exposes catalysts to controlled concentrations of potential poisons (sulfur, phosphorus, heavy metals) under relevant process conditions to assess resistance to chemical deactivation. Testing may involve continuous exposure or pulsed injections to simulate transient contamination events [24].

Mechanical Aging: Evaluates physical durability through vibration testing, attrition resistance measurements, or pressure cycling to simulate the mechanical stresses encountered in industrial reactors or mobile applications [24].

Advanced Characterization Techniques

Beyond standardized aging tests, advanced characterization methods provide fundamental insights into deactivation mechanisms at the molecular level, supporting the development of more durable catalytic materials.

In Situ Spectroscopy: Techniques such as X-ray absorption spectroscopy (XAS) and infrared spectroscopy under operational conditions allow direct observation of catalyst structure and active sites during aging processes, revealing structural evolution and deactivation pathways [27].

Surface Analysis: Methods including X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), and temperature-programmed reduction (TPR) characterize changes in surface composition, morphology, and redox properties resulting from aging treatments [3].

Accelerated Testing Methodologies: Approaches such as the C-FOCAS system utilize specialized burner rigs to create accelerated aging conditions that replicate complex real-world degradation mechanisms in compressed timeframes, enabling rapid durability assessment [23].

Table 3: Standardized Catalyst Aging Test Methodologies

| Methodology | Simulated Conditions | Key Parameters | Applications |

|---|---|---|---|

| Thermal Aging | High-temperature operation | Temperature, duration, atmosphere | All high-temperature processes |

| Chemical Aging | Poison exposure | Contaminant type, concentration, duration | Refining, chemical synthesis |

| Mechanical Aging | Physical stress | Vibration frequency, pressure cycles | Fluidized beds, mobile applications |

| Hydrothermal Aging | Steam-containing environments | Temperature, steam partial pressure | Zeolite catalysts, emission control |

| Combined Stress Testing | Multiple simultaneous mechanisms | Customized stress profiles | Real-world performance prediction |

Catalyst Regeneration Technologies

Conventional Regeneration Methods

Catalyst regeneration represents a crucial strategy for extending functional lifespan and maximizing resource utilization. Conventional regeneration approaches target specific deactivation mechanisms to restore catalytic activity.

Oxidative Regeneration: Controlled combustion of carbonaceous deposits (coke) through careful temperature-programmed oxidation in dilute oxygen streams. Success depends on balancing complete carbon removal against damaging exotherms or oxidation of active components [21].

Gasification Treatments: Utilization of steam or carbon dioxide to remove carbon deposits through gasification reactions, often at lower temperatures than oxidative methods to minimize thermal stress on the catalyst structure [26].

Extraction Processes: Solvent extraction or washing to remove soluble poisons or deposits from catalyst surfaces, particularly effective for certain types of chemical fouling where the deactivating species can be dissolved and removed [21].

Emerging Regeneration Technologies

Advanced regeneration approaches leverage novel physical phenomena or chemical processes to achieve more complete activity restoration while minimizing further catalyst damage.

Supercritical Fluid Extraction (SFE): Utilizes supercritical fluids, typically carbon dioxide, with their unique solvation properties and transport characteristics to extract foulants from catalyst pores with high efficiency and minimal structural damage [21] [26].

Microwave-Assisted Regeneration (MAR): Applies microwave energy to create selective heating patterns that can more efficiently remove deposits while potentially restructing active phases, offering advantages in energy efficiency and treatment uniformity [21].

Plasma-Assisted Regeneration (PAR): Employs non-thermal plasma to generate reactive species that can remove deposits or redisperse sintered active phases through chemical and physical mechanisms not accessible thermally [26].

Atomic Layer Deposition (ALD): Uses sequential, self-limiting surface reactions to apply protective overlayers or redisperse active metals, potentially restoring and even enhancing original catalyst performance [21].

Diagram 2: Catalyst regeneration technology classification

The effectiveness of any regeneration strategy depends strongly on the specific deactivation mechanism involved and the catalyst's structural characteristics. In many cases, regeneration protocols must be tailored to specific catalyst formulations and poisoning scenarios to achieve optimal activity recovery while preserving mechanical integrity and long-term stability [21].

The Scientist's Toolkit: Research Reagent Solutions

Catalyst longevity research employs specialized materials, reagents, and reference standards to ensure reproducible, comparable results across different laboratories and studies. This toolkit enables standardized benchmarking and systematic investigation of deactivation mechanisms.

Table 4: Essential Research Reagents and Materials for Catalyst Longevity Studies

| Reagent/Material | Function | Application Examples |

|---|---|---|

| Reference Catalysts | Benchmarking material for activity comparison | EuroPt-1, EUROCAT standards, Zeolyst zeolites |

| Poisoning Compounds | Introduce specific deactivation mechanisms | Thiophene (sulfur), organophosphates (phosphorus) |

| Coke Precursors | Induce carbon deposition | Ethylene, propylene, heavy hydrocarbons |

| Standard Reaction Mixtures | Activity assessment under controlled conditions | Methanol decomposition, formic acid dehydrogenation |

| Characterization Standards | Instrument calibration and quantitative analysis | XPS reference samples, XRD standards, BET reference materials |

| Thermal Aging Materials | Controlled high-temperature exposure | High-purity gases, reactor materials |

Standard reference materials including EuroPt-1, EUROCAT standards, and standardized zeolite materials from the International Zeolite Association enable cross-laboratory comparison and benchmarking against established materials with well-characterized properties [3]. Similarly, standard reaction systems such as methanol decomposition or formic acid dehydrogenation provide reproducible probe reactions for assessing catalytic performance and its evolution during aging treatments [3].

The development of shared databases such as CatTestHub represents an important evolution in the catalyst research toolkit, creating centralized repositories for structural characterization data, reaction condition details, and catalytic performance metrics following FAIR data principles (Findability, Accessibility, Interoperability, and Reuse) [3]. These resources support more efficient research progress by reducing duplication and enabling meta-analysis of collective results across the research community.

The pursuit of improved catalyst longevity represents a critical convergence of economic and sustainability imperatives in industrial catalysis. Economic drivers include reducing total cost of ownership, optimizing operational efficiency, and complying with increasingly stringent regulatory requirements throughout certified lifetimes. Sustainability benefits encompass resource conservation, waste reduction, and maintained environmental protection performance over extended service life.

The disparity between catalyst performance in controlled laboratory environments and harsh industrial conditions remains a significant challenge, necessitating advanced aging protocols that better replicate complex real-world degradation mechanisms. Ongoing developments in regeneration technologies, standardized benchmarking through initiatives like CatTestHub, and data-driven research approaches are progressively bridging this gap [3] [21].

For researchers and development professionals, the integrated consideration of both economic and sustainability dimensions provides a comprehensive framework for catalyst development and selection. Catalyst longevity has evolved from a secondary consideration to a primary performance metric, reflecting its pivotal role in both the economic viability and environmental sustainability of catalytic processes across industries from energy and chemicals to environmental protection.

Advanced Testing and Simulation: Mimicking Industrial Realities in the Lab

In the critical field of catalyst performance research, a significant gap often exists between idealized laboratory assessments and real-world industrial longevity. Accelerated aging studies are indispensable for bridging this gap, providing vital predictive data on catalyst deactivation and performance decay. However, a fundamental challenge persists: designing accelerated protocols that do not merely speed up time, but accurately replicate the complex degradation mechanisms encountered in actual service conditions [28]. Traditional standardized tests provide a valuable baseline, but true innovation in catalyst development requires going beyond these standard protocols. This guide explores advanced methodological frameworks for designing accelerated aging studies that ensure predictive validity for both industrial and laboratory environments, with a focus on the critical principle of degradation mechanism equivalence [29].

The core dilemma in accelerated aging is that overly aggressive conditions, while saving time, can induce unrealistic failure modes not representative of natural aging. As noted in polymer aging research, which shares common principles with catalyst deactivation, the use of environmental factors "much higher than those achievable on field" can "cause unrealistic processes that would never occur in true conditions" [28]. This article compares established and emerging approaches, providing researchers with the experimental frameworks and validation tools needed to develop more reliable, predictive aging studies that serve the stringent demands of both industrial application and fundamental scientific research.

Comparative Analysis of Accelerated Aging Approaches

The table below summarizes the core characteristics, advantages, and limitations of different accelerated aging methodologies, from traditional single-stress tests to emerging advanced protocols.

Table 1: Comparison of Accelerated Aging Study Approaches for Catalysts

| Aging Approach | Core Methodology | Typical Acceleration Factor | Data Outputs | Key Limitations |

|---|---|---|---|---|

| Traditional Single-Stress (Standard Protocol) | Elevated temperature only (e.g., Arrhenius Q10=2.0) [30] [31] | Low (e.g., 2x per 10°C) | Extrapolated shelf-life; single-mechanism degradation data | Often induces non-representative degradation pathways; oversimplified [28] |

| Advanced Multi-Stress Aging | Combined thermal, chemical, and mechanical stresses applied simultaneously [32] [33] | Moderate to High | Performance decay under synergistic stresses; identification of dominant failure modes | Complex to design and calibrate; requires deep mechanistic knowledge |

| Mechanism-Equivalence Aging | Decoupling and individually accelerating specific degradation mechanisms (e.g., LLI, LAM) before recombining [29] | Very High (e.g., 39x - 62x) | High-fidelity lifetime prediction; validated degradation pathway consistency | Technically complex; requires preliminary mechanistic study |

Experimental Protocols for Advanced Aging Studies

Protocol 1: Multi-Stress Aging for Industrial Catalyst Validation

This protocol is designed to simulate the complex, synergistic degradation environments typical of industrial operations, such as those in petrochemical plants or automotive exhaust systems [32] [33].

- Objective: To assess the long-term durability of a catalyst under conditions that mimic simultaneous thermal sintering and chemical poisoning.

- Materials & Setup:

- Reactor System: High-throughput bench-scale unit (e.g., a 8-fold parallel reactor system) capable of precise temperature and gas flow control [34].

- Test Catalyst: Formulation identical to production-grade material, including all additives and supports.

- Aging Environment: Controllable atmospheric chamber with integrated gas dosing and real-time performance monitoring sensors [35] [32].

- Procedure:

- Step 1 - Thermal Stress: Subject the catalyst to elevated temperatures, typically 50-60°C, but carefully selected to remain below the material's glass-transition or melt temperature to avoid unrealistic physical changes [30] [28].

- Step 2 - Chemical Stress: Introduce specific poisoning compounds (e.g., sulfur, phosphorus, or heavy metals) relevant to the catalyst's intended application into the feedstock at controlled, elevated concentrations [33].

- Step 3 - Operational Cycling: Expose the catalyst to rapid thermal and chemical duty cycles (e.g., rich/lean oscillations, start-stop cycles) to simulate variable operational loads [32].

- Step 4 - In-Situ Analysis: Employ operando characterization methods like infrared spectroscopy or mass spectrometry to track catalyst changes in real-time under reaction conditions [32] [33].

- Data Analysis: Model the performance decay (e.g., conversion efficiency drop, selectivity change) over accelerated time and use kinetic modeling to extrapolate to real-world service life.

Protocol 2: Mechanism-Equivalence Aging for Fundamental Research

This innovative protocol, inspired by advanced battery research, focuses on equivalence in the aging path rather than just the final state of health, making it ideal for foundational studies and high-fidelity lifetime modeling [29].