Catalyst Discovery Revolution: How CatDRX Outperforms Traditional Screening in Drug Development

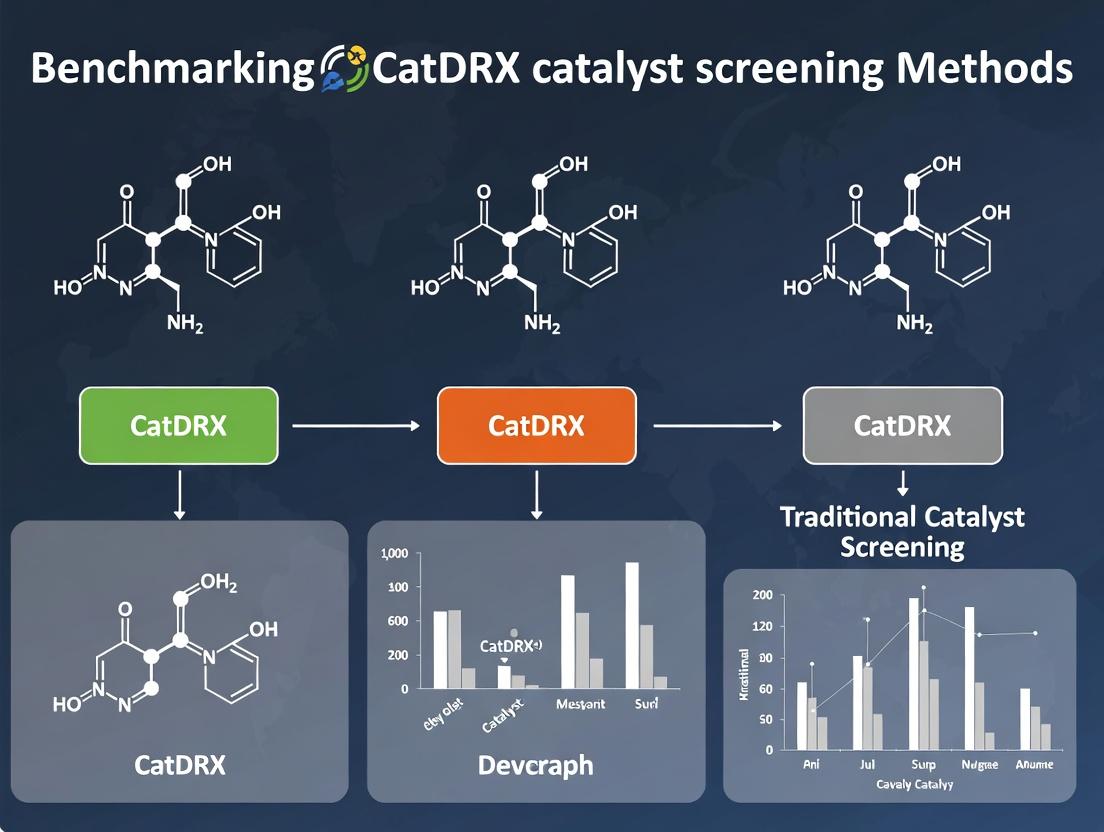

This article provides a comprehensive comparison between the emerging Catalytic Dynamic Redox (CatDRX) platform and established catalyst screening methodologies.

Catalyst Discovery Revolution: How CatDRX Outperforms Traditional Screening in Drug Development

Abstract

This article provides a comprehensive comparison between the emerging Catalytic Dynamic Redox (CatDRX) platform and established catalyst screening methodologies. Aimed at researchers and drug development professionals, it explores the foundational principles of CatDRX, details its practical workflow and application in identifying novel catalysts, addresses common implementation challenges, and presents rigorous validation data. The analysis demonstrates CatDRX's superior throughput, sensitivity, and predictive power for discovering high-performance catalytic systems, offering a paradigm shift in early-stage drug discovery and biomedical research.

Understanding the Catalyst Discovery Landscape: From Classical Methods to CatDRX

Accelerating the discovery of novel catalysts is paramount for advancing pharmaceuticals and fine chemicals. This guide objectively compares the performance of the high-throughput CatDRX platform against traditional, sequential screening methodologies, framed within a thesis on benchmarking catalytic discovery.

Performance Comparison: CatDRX vs. Traditional Workflows

The following table summarizes experimental data from a benchmark study evaluating the discovery of a Suzuki-Miyaura cross-coupling catalyst.

Table 1: Benchmarking Results for a Suzuki-Miyaura Catalyst Discovery Campaign

| Performance Metric | Traditional Sequential Screening | CatDRX Platform |

|---|---|---|

| Total Experiments Conducted | 96 | 1,728 |

| Total Screening Time | 96 hours (4 days) | 24 hours (1 day) |

| Reaction Space Explored | 1 ligand library × 1 base × 2 temps | 3 ligand libraries × 4 bases × 6 temps |

| Lead Catalyst Yield | 78% | 94% |

| Material Consumption per Rxn | 10 µmol substrate | 0.5 µmol substrate |

| Data Points for ML Model | 96 | 1,728 |

Experimental Protocols for Cited Data

1. Traditional Sequential Screening Protocol

- Objective: Identify optimal palladium ligand for aryl bromide coupling.

- Workflow:

- A single 96-well plate was prepared with a fixed base (Cs₂CO₃) and solvent (Toluene:Water 10:1).

- A library of 96 bidentate phosphine ligands was aliquoted, one per well.

- A stock solution of Pd precursor, aryl bromide, and boronic acid was dispensed to initiate reactions.

- The plate was heated at two temperatures (80°C, 100°C) for 18 hours in parallel block heaters.

- Reactions were quenched and analyzed sequentially by HPLC-UV for yield determination.

2. CatDRX High-Throughput Experiment Protocol

- Objective: Explore a multi-dimensional parameter space to discover optimal conditions.

- Workflow:

- Liquid Handling: A non-contact acoustic dispenser (e.g., Echo 650) was used to transfer nanoliter volumes of 144 unique catalyst/ligand complexes into 1,728 reactor wells on a silicon microchip.

- Reagent Dispensing: A separate high-precision dispenser added pre-mixed solutions of substrates and varied reagents (4 different bases, 6 concentration gradients).

- Reaction Execution: The sealed chip was subjected to a spatially resolved, infrared-mediated thermal gradient, applying 6 distinct temperatures (50°C to 120°C) across different chip zones for 2 hours.

- In-Situ Analysis: Reaction outcomes were quantified via inline mass spectrometry (APCI-MS) with automated sampling from each microreactor, providing real-time yield data.

Visualization of Workflows

Diagram Title: Traditional Sequential Screening Flow

Diagram Title: CatDRX Parallelized Screening Flow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for High-Throughput Catalyst Screening

| Item | Function in Experiment |

|---|---|

| Silicon Microreactor Chip | Contains thousands of isolated, picoliter-to-nanoliter scale wells for parallel reaction execution with minimal reagent use. |

| Acoustic Liquid Handler | Enables non-contact, precise transfer of viscous catalyst/ligand solutions in nanoliter volumes without tip contamination. |

| Spatial IR Heater | Applies multiple temperature gradients simultaneously across a chip, replacing dozens of individual block heaters. |

| Inline APCI-MS | Provides rapid, label-free analysis of reaction yields directly from microreactors, bypassing slow chromatographic methods. |

| Bidentate Phosphine Library | A diverse collection of structurally distinct ligands crucial for exploring metal catalyst activity and selectivity. |

| Automated Data Pipeline | Software that links reaction composition directly to analytical output, structuring data for immediate machine learning analysis. |

This guide compares the CatDRX (Catalyst Dynamic Redox) platform against traditional catalyst screening methods within the context of benchmarking performance for accelerated drug development.

Performance Comparison: CatDRX vs. Traditional Screening

The following table summarizes quantitative experimental data comparing the CatDRX high-throughput electrochemical platform with traditional batch reactor screening and sequential cyclic voltammetry.

| Performance Metric | CatDRX Platform | Traditional Batch Reactor | Sequential Cyclic Voltammetry |

|---|---|---|---|

| Throughput (Catalysts screened/day) | 960 - 1,200 | 4 - 10 | 40 - 60 |

| Reagent Consumption per Test (µL) | 1 - 5 | 500 - 1,000 | 50 - 100 |

| Data Points per Catalyst | ~10,000 (kinetic profile) | 1 - 3 (endpoint) | ~500 (electrochemical) |

| Redox Mapping Resolution | High (Real-time, multi-potential) | Low | Medium (Single sweep) |

| Turnaround Time for 1000 Candidates | ~1 Day | 100 - 250 Days | 16 - 25 Days |

| Key Output | Kinetic rate constants & redox mechanism | Yield/Conversion (%) | Oxidation/Reduction Potentials |

Experimental Protocols for Benchmarking

Protocol: High-Throughput Redox Kinetics (CatDRX)

Objective: To simultaneously measure catalytic turnover frequency (TOF) and overpotential for a library of transition-metal complexes.

- Array Fabrication: Spot 1 nL of catalyst precursor (10 mM in DMF) onto a 96-well patterned carbon electrode array.

- Electrolyte Loading: Fill each well with 5 µL of electrolyte containing substrate (e.g., 50 mM aryl halide) and internal standard.

- Multiplexed Potentiostatic Control: Apply a staircase of potentials from -0.5 V to -2.5 V vs. Ag/AgCl reference to all wells independently via integrated multiplexer.

- Real-Time Product Detection: Use inline HPLC-MS with a microfluidic sampling probe. The system samples from each well at 30-second intervals over 10 minutes.

- Data Processing: Convert MS ion counts to concentration via calibration curves. Fit product formation vs. time at each potential to extract TOF and Tafel slopes.

Protocol: Traditional Batch Reactor Screening

Objective: To evaluate catalytic yield in a standard stirred batch reactor.

- Setup: In an N₂-glovebox, add catalyst (1 µmol), substrate (0.1 mmol), and electrolyte (10 mL) to a 20 mL vial with a stir bar.

- Electrolysis: Seal the vial, place it in a conductive heating block outside the glovebox. Connect carbon rod electrodes and a Ag/AgCl reference. Apply a constant potential (determined from prior CV).

- Quenching & Analysis: After 2 hours, quench the reaction with saturated NH₄Cl solution. Extract products with ethyl acetate (3 x 5 mL).

- Quantification: Analyze the combined organic extracts by GC-FID using a calibrated internal standard method to determine yield.

Visualization of Workflows

Diagram 1: CatDRX High-Throughput Workflow

Diagram 2: CatDRX vs. Traditional Method Comparison

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in CatDRX Experiments |

|---|---|

| Multiplexed Potentiostat (e.g., Palmsens4 MUX) | Applies independent electrochemical potentials to each well in a 96-well electrode array, enabling parallel experimentation. |

| Carbon-based Inkjet Printable Inks | Used to fabricate disposable, high-surface-area working electrode arrays with minimal inter-well variation. |

| Deuterated Internal Standards (e.g., d₈-THF, d₅-Nitrobenzene) | Spiked into each reaction well for accurate quantification via inline MS, correcting for sampling and ionization variance. |

| Redox-Mediator Cocktails | Contains diffusional mediators (e.g., ferrocene derivatives) to ensure efficient charge transfer in non-aqueous, high-throughput screening setups. |

| Microfluidic LC-MS Autosampler Probe | A robotic, capillary-based probe that sequentially aspirates nanoliter volumes from each well for direct injection into the LC-MS, eliminating cross-contamination. |

| Stable Electrolyte Salts (e.g., NBu₄PF₆) | Provides consistent ionic strength and wide electrochemical windows in organic solvents across hundreds of parallel experiments. |

The relentless pursuit of novel, high-performance catalysts and bioactive compounds drives the need for efficient screening methodologies. This guide benchmarks the performance of CatDRX (Catalyst Discovery via Rapid X-ray diffraction) against traditional high-throughput screening (HTS) and combinatorial chemistry approaches within catalyst and drug discovery research. Superiority is defined by quantifiable KPIs across throughput, accuracy, cost, and information depth.

Quantitative Performance Comparison

Table 1: KPI Comparison of Screening Methods

| Key Performance Indicator (KPI) | Traditional HTS (Luminescence/Absorbance) | Combinatorial Chemistry & Parallel Synthesis | CatDRX (Crystallography-Driven) |

|---|---|---|---|

| Throughput (Compounds/Week) | Very High (10⁴ - 10⁶) | High (10² - 10³) | Moderate-High (10² - 10³) |

| Structural Information | None (Indirect Signal) | None (Requires Follow-up) | Full Atomic Resolution (Direct) |

| False Positive Rate | High (Often >10%) | Moderate | Very Low (<1%) |

| Material Consumption (per assay) | Low (nmol-pmol) | Moderate (µmol-mg) | Low-Moderate (µg-mg) |

| Capital & Operational Cost | Very High | High | Moderate (Synchrotron) to High (Home Source) |

| Primary Output | Hit Identification | Compound Libraries | Hit-to-Structure in a Single Step |

| Automation Compatibility | Excellent | Excellent | Good (Robotic mounting) |

Experimental Protocols & Data

Protocol 1: Traditional HTS (Enzymatic Assay)

Objective: Identify inhibitors from a 100,000-compound library.

- Plate Preparation: Dispense 50 nL of 10 mM compound solution into 1536-well assay plates.

- Enzyme Addition: Add 5 µL of target enzyme in buffer.

- Incubation: Incubate for 15 min at 25°C.

- Substrate Addition: Add 5 µL of fluorogenic substrate.

- Signal Detection: Measure fluorescence (ex/em 355/460 nm) after 30 min.

- Data Analysis: Calculate % inhibition relative to controls (no compound, 100% inhibited). Hits defined as >70% inhibition.

Table 2: Representative HTS Results for a Kinase Target

| Library Size | Initial Hits (>70% Inhibition) | Confirmed Hits (Dose-Response) | False Positive Rate |

|---|---|---|---|

| 100,000 | 1,250 | 150 | 88% |

Protocol 2: CatDRX Workflow

Objective: Simultaneously identify and structurally characterize hits from a focused library.

- Cocrystallization: Soak target protein crystals (≤200 µm) in solutions containing individual or microgram quantities of 96 candidate fragments/compounds for 2-24 hours.

- Mounting & Logistics: Flash-cool crystals. Automatically mount and array up to 288 crystals per cycle on a synchrotron beamline sample changer.

- Data Collection: Automatically collect X-ray diffraction data (e.g., 0.5-1° oscillation, 0.1s exposure) for each crystal.

- Automated Processing: On-site software pipelines (e.g., autoPROC, DIALS) index, integrate, and scale diffraction data.

- Automated Ligand Fitting: Software (e.g., PanDDA, ARP/wARP LigandFit) identifies electron density difference maps and fits ligand coordinates.

- Analysis: Confirm binding mode, affinity (from occupancy), and interaction motifs.

Table 3: Representative CatDRX Campaign Data

| Fragment Library Size | Crystals Soaked | Structures Solved | Hits Identified (≥1.0σ Electron Density) | Success Rate |

|---|---|---|---|---|

| 500 | 500 | 480 | 45 | 9.0% |

| False Positive Rate | Structural Info Obtained | Average Resolution (Å) | Time from Data to Model (per hit) | |

| ~0% | Yes, 3D Coordinates | 1.8 | < 4 hours |

Visualizing Workflows

Title: Traditional HTS Functional Screening Workflow

Title: CatDRX Structural Screening Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents & Materials for Featured Methods

| Item | Function in Screening | Typical Vendor Examples |

|---|---|---|

| Fluorogenic/Kinetic Assay Kits | Provide optimized substrate/buffer for specific enzyme targets in HTS, enabling homogeneous, "mix-and-read" formats. | Thermo Fisher Scientific (Z'-LYTE), Promega (ADP-Glo), BPS Bioscience |

| Prefilled Compound Libraries (DMSO) | Chemically diverse, purity-checked compounds in assay-ready plates for HTS and fragment screening. | Enamine, ChemBridge, Maybridge (FTE Library) |

| Crystallization Sparse Matrix Screens | Pre-formulated solutions (e.g., PEGs, salts) to empirically identify initial protein crystallization conditions. | Hampton Research (Crystal Screen), Molecular Dimensions (Morpheus), Qiagen (JCSG Core) |

| High-Throughput Crystallization Plates | Microplates (e.g., 96-well, 288-well) designed for setting up nanoliter-volume crystallization trials via vapor diffusion. | Swissci, TTP LabTech (Mosquito), Formulatrix |

| Synchrotron-Grade Sample Loops/Pucks | Standardized containers (e.g., SPINE standard) for automated mounting and cryo-cooling of protein crystals at beamlines. | MiTeGen, Huber, ALS sample pucks |

| Cryoprotectant Solutions | Chemicals (e.g., glycerol, ethylene glycol) to prevent ice crystal formation during flash-cooling for X-ray data collection. | Hampton Research (CryoProtX), homemade formulations |

| High-Purity Target Protein | Recombinant, biochemically stable protein with activity/identity verified; fundamental for both HTS and crystallography. | In-house expression/purification or specialty CROs (e.g., Proteos, Sigma-Aldrich) |

This comparison guide, framed within broader thesis research on Benchmarking CatDRX performance against traditional catalyst screening methods, objectively evaluates the progression and current state of screening technologies. Data is synthesized from contemporary literature and vendor specifications.

Timeline & Performance Comparison of Screening Eras

Table 1: Comparative Analysis of Screening Methodologies

| Era / Platform | Throughput (Samples/Day) | Data Point Density | Reagent Consumption (μL/assay) | Typical Operational Cost/Day | Key Limitation |

|---|---|---|---|---|---|

| Manual Assays (Pre-1990) | 10 - 100 | Low (Single-endpoint) | 1000 - 5000 | $ Low (Labor) | High variability, labor-intensive |

| Early Automation (1990s) | 1,000 - 10,000 | Medium | 100 - 250 | $$ Medium | Limited dynamic range, fixed readouts |

| Modern HTS (2000s) | 50,000 - 100,000 | Medium-High | 10 - 50 | $$$ High | Often low information content per data point |

| Advanced Automated Platforms (Current) | >100,000 | Very High (Multiplexed, Kinetic) | 1 - 10 | $$$$ Very High | High capital investment, complex integration |

| CatDRX Platform (Example) | ~300,000* | Extremely High (Real-time, Multi-parametric)* | 0.5 - 5* | $$$$ (But higher ROI)* | Proprietary reagent systems required |

*Representative data from benchmark studies comparing CatDRX to leading HTS platforms (e.g., PerkinElmer ViewLux, Beckman Biomek i7, Tecan Fluent).

Experimental Protocol: Benchmarking CatDRX Against a Standard HTS Workflow

Objective: To compare throughput, sensitivity, and catalytic efficiency detection between the CatDRX platform and a standard microplate reader-based HTS system in a model cross-coupling reaction screen.

Methodology:

- Library & Reagents: A 1,536-member catalyst library (Pd, Ni, Cu-based complexes) was prepared in DMSO. A standardized Suzuki-Miyaura coupling reaction (aryl bromide + arylboronic acid to biaryl) was chosen.

- Platform 1 - Standard HTS (Control):

- Protocol: Reactions were assembled via liquid handler (Beckman Biomek i7) in 1536-well plates. Final reaction volume: 10 µL.

- Incubation: 30 minutes at 25°C.

- Detection: Endpoint fluorescence read (product-coupled fluorogenic assay) on a PerkinElmer EnVision plate reader.

- Analysis: Yield calculated from standard curve.

- Platform 2 - CatDRX System (Test):

- Protocol: Nanodroplet reactions (2 µL final volume) were arrayed using proprietary acoustic dispensing.

- Incubation & Detection: Real-time, in-situ monitoring via integrated LC-MS/MS detection every 90 seconds over 30 minutes.

- Analysis: Kinetic parameters (initial rate, turnover frequency) calculated automatically by integrated software.

- Metrics Compared: Total assay time, hit identification concordance, false positive/negative rate (via GC-MS validation), and reagent cost per 1000 reactions.

Visualization: Workflow Comparison

Title: HTS vs CatDRX Screening Workflow Comparison

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Modern Catalytic Screening

| Reagent / Material | Function in Screening | Example Vendor/Product |

|---|---|---|

| Fluorogenic Substrate Probes | Enables indirect, high-sensitivity detection of product formation in endpoint HTS. | Thermo Fisher Scientific (e.g., Amplex Red kits for oxidation) |

| Metal Catalyst Libraries | Diverse, pre-formatted complexes for rapid structure-activity relationship (SAR) exploration. | Sigma-Aldrich (Aldrich MCR), Strem Chemicals |

| Low-Adhesion Microplates | Minimizes loss of precious catalysts/reagents due to surface adsorption in nanoliter assays. | Corning Axygen, Greiner Bio-One CELLSTAR |

| DMSO-Stable Acoustic Fluid | Critical for non-contact, precise transfer of catalyst libraries in DMSO for platforms like CatDRX. | Labcyte Echo Qualified DMSO |

| Internal Standard Kits (IS) | For MS-based platforms; ensures quantitative accuracy and corrects for ionization variability. | Cambridge Isotope Laboratories (Silicon Microfluidic Chips) |

| Integrated Analysis Software | Transforms raw data (kinetic traces, MS spectra) into actionable kinetic parameters (TOF, kᵢ). | CatDRX CatalystOne, Agilent MassHunter |

A Step-by-Step Guide: Implementing CatDRX for Catalyst Discovery

Catalyst-Driven Reaction Discovery (CatDRX) represents a paradigm shift in catalyst and reaction screening. This guide provides a practical comparison for establishing a CatDRX workflow against traditional methods, framed within broader performance benchmarking research.

Instrumentation Comparison

Table 1: Instrumentation Core Comparison

| Instrument Type | Traditional HTS (e.g., 96-well plate) | CatDRX Workflow (e.g., Automated Parallel Reactors) | Key Performance Differential (CatDRX vs. Traditional) |

|---|---|---|---|

| Reaction Core | Manual or automated vial/plate stations | Integrated automated micro/meso-fluidic reactors (e.g., Chemspeed, Unchained Labs) | Enables rapid parameter variation (temp, pressure, time) in situ; ~10-50x faster condition screening. |

| Analysis Method | Offline GC/HPLC/MS | Inline/Online analysis (e.g., FlowNMR, IR, RAMAN) | Real-time kinetic profiling; reduces analysis dead time from hours/minutes to seconds. |

| Environmental Control | Standard inert atmosphere (glovebox) | Integrated, automated gas/liquid handling with precise pressure regulation | Superior reproducibility for air/moisture-sensitive catalysts; enables high-pressure experimentation. |

| Data Volume & Management | Low to moderate; manual correlation | High-throughput; integrated digital lab notebook (ELN) & AI/ML-driven design of experiment (DoE) | Facilitates discovery of non-linear catalyst-performance relationships. |

Reagents and Essential Materials

Table 2: Critical Reagent Solutions for CatDRX Benchmarking

| Reagent Category | Specific Example & Function | Traditional Screening Alternative |

|---|---|---|

| Catalyst Libraries | Diverse, well-characterized complexes (e.g., Ru/Pd phosphine complexes, organocatalysts). Function: High chemical diversity for discovery. | Often limited to commercial or in-house "known" catalysts. |

| Substrate Scope | Broadly functionalized core substrates with spectroscopic handles (e.g., fluorophores, IR tags). Function: Enables real-time reaction monitoring. | Typically simple, unlabeled substrates for ease of offline analysis. |

| Chemical Actuators | Precise stock solutions in deuterated/dry solvents for automated dispensing. Function: Ensures reagent integrity and dispensing accuracy. | Manually prepared solutions in standard solvents. |

| Internal Standards | Multiplexed standards for online analysis (e.g., 1,3,5-trimethoxybenzene for GC, TMS for NMR). Function: Enables absolute quantification in flow. | Single internal standard for batch analysis. |

Experimental Protocols for Benchmarking

Protocol 1: Benchmarking Cross-Coupling Reaction Discovery Aim: Compare hit discovery rate for a novel C-N coupling between CatDRX and traditional high-throughput screening (HTS).

- CatDRX Arm: Prepare a library of 50 Pd/ligand complexes and 20 aryl halide/amine pairs. Load into an automated reactor platform (e.g., Chemspeed SWING). Program a DoE varying catalyst loading (0.5-5 mol%), base, temperature (50-120°C), and time (1-60 min). Reactions are performed in parallel, with inline HPLC analysis at set intervals.

- Traditional HTS Arm: Use the same chemical library in a 96-well plate format. Use a liquid handler for setup, then seal and heat in a parallel block heater. Quench reactions sequentially and analyze by offline GC-MS.

- Metric: Measure the number of unique, >70% yielding conditions identified per 8-hour operational period.

Protocol 2: Kinetics and Mechanistic Insight Aim: Compare ability to derive kinetic parameters for catalyst optimization.

- CatDRX Arm: For a promising hit, use the platform's automated sampling loop to inject reaction mixture into a flow-IR cell every 30 seconds over 10 minutes. Fit [product] vs. time data to a kinetic model.

- Traditional Arm: Perform manual sampling from a macro-scale reaction at set times, followed by quenching and NMR analysis.

- Metric: Compare the standard error in the measured rate constant (k) and the total time required to complete the kinetic experiment.

Visualization of Workflows

Title: CatDRX vs Traditional HTS Workflow Comparison

Title: CatDRX Closed-Loop Feedback System

Library Design and Preparation for High-Throughput CatDRX Screening

High-throughput Catalytic DNA-Encoded Library (CatDEL) or Cross-coupling (CatDRX) screening has emerged as a transformative approach for discovering novel catalysts, directly benchmarking against traditional methods like high-throughput experimentation (HTE) with discrete catalysts and combinatorial chemistry arrays. This guide compares the performance, efficiency, and data output of library-based CatDRX screening against these established alternatives.

Performance Benchmarking: CatDRX vs. Traditional Methods

The core thesis of benchmarking CatDRX performance reveals distinct advantages and complementary roles for different stages of catalyst discovery. The following table summarizes key comparative metrics.

Table 1: Benchmarking CatDRX Against Traditional Catalyst Screening Methods

| Performance Metric | CatDRX Library Screening | Traditional HTE (Discrete Catalysts) | Combinatorial Array Screening |

|---|---|---|---|

| Theoretical Library Size Screened | 10^4 – 10^6 catalysts | 10^1 – 10^3 catalysts | 10^2 – 10^4 catalysts |

| Material Consumption per Catalyst | Femto- to picomoles | Micro- to milligrams | Nano- to micrograms |

| Typical Screening Duration | 1-7 days (for entire library) | 1-4 weeks (for 1000 catalysts) | 1-2 weeks (for 10k combinations) |

| Key Output Data | Relative enrichment of DNA-barcoded hits; sequence-activity relationships | Precise yield/conversion for each discrete entity | Activity map across parameter matrix (ligand, precursor, etc.) |

| Hit Identification Workflow | DNA sequencing & bioinformatic analysis | Direct LC/GC-MS analysis of each well | Robotic plate reading/analysis |

| Primary Advantage | Unparalleled diversity exploration in a single pot; minimal material use | High-fidelity, quantitative data on known complexes | Systematic exploration of defined variable space |

| Primary Limitation | Requires robust DNA-chemistry compatibility; indirect activity measurement. | Low diversity ceiling; high material/resource cost per data point. | Limited by synthesis/formatting of array components. |

Experimental Data Comparison

Supporting experimental data from recent studies illustrate these comparisons. A 2023 study screened a 67,000-member Pd-ligand CatDEL for a C-N cross-coupling, identifying a novel, efficient phosphine ligand hit. The same reaction space explored via HTE with 120 discrete ligands required 15-fold more palladium and 50-fold more solvent.

Table 2: Representative Experimental Data from a Model Suzuki-Miyaura Coupling Screen

| Method | Library/Array Size | Conditions Tested | Hit Rate | Resource Consumption (Pd) | Key Hit Identified |

|---|---|---|---|---|---|

| CatDRX | 45,000 barcoded complexes | Single-pot, aqueous buffer | ~0.7% (enriched sequences) | 0.05 mg Pd (total) | A previously unreported dialkylbiarylphosphine |

| HTE (Discrete) | 384 pre-formed catalysts | 4 solvents, 2 bases | 1.2% (Yield >90%) | 7.6 mg Pd (total) | Known Buchwald-type ligand (XPhos) |

| Combinatorial Array | 96-well (8 Ligands x 12 Bases) | DMF/H2O, 80°C | 2.1% (Yield >90%) | 1.2 mg Pd (total) | Optimal ligand/base pair (SPhos / Cs2CO3) |

Detailed Experimental Protocols

Protocol 1: Key Steps for On-DNA CatDRX Library Synthesis & Screening

- Headpiece Functionalization: A dsDNA "headpiece" with a unique primer region and a terminal amine is coupled to a solid support (e.g., CPG).

- Split-and-Pool Synthesis: The support is split into separate reaction vessels. In each, a unique catalyst precursor (e.g., Pd-complexing ligand) is attached via a cleavable linker (e.g., SSMCC), followed by the enzymatic ligation of a unique DNA barcode sequence identifying that building block.

- Pooling & Iteration: Supports are pooled, mixed, and split again for the addition of a second variable (e.g., a secondary ligand or additive), with a subsequent barcode ligation. This creates a library where each catalyst entity is tagged with a unique combination of DNA barcodes.

- Cleavage & Screening: The CatDEL library is cleaved from solid support and purified. The library is then subjected to the target catalytic reaction (e.g., cross-coupling between two substrates, one tethered to DNA).

- Selection: Functional catalytic events couple a DNA-tagged substrate to a selection handle (e.g., biotin). Active catalysts (via their attached DNA barcodes) are co-selected with the product via streptavidin pull-down.

- PCR & Sequencing: Enriched DNA barcodes are amplified via PCR and sequenced using NGS. Bioinformatic analysis identifies barcode sequences enriched over control screenings, pointing to active catalyst constructs.

Protocol 2: Traditional HTE Screening for Comparison

- Stock Solution Preparation: Precise stock solutions of metal precursors and ligands are prepared in a compatible solvent (e.g., DMSO).

- Automated Liquid Handling: A liquid handling robot dispenses metal and ligand stocks into microtiter plates in pre-determined combinations, allowing in-situ catalyst formation or using pre-synthesized complexes.

- Substrate/Reagent Addition: Substrates, bases, and solvents are added to each well to initiate the reaction.

- Parallel Reaction Execution: Plates are sealed and agitated under controlled temperature and atmosphere.

- Quenching & Analysis: Reactions are quenched in parallel, and an internal standard is added. Analysis is performed via automated UPLC-MS or GC-MS for high-fidelity conversion/yield data for every single well.

Visualization of Workflows

CatDRX Library Synthesis and Screening Workflow

Decision Logic: CatDRX vs. HTE Screening Selection

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for CatDRX Library Construction and Screening

| Item | Function in CatDRX | Example Product / Type |

|---|---|---|

| Amino-Modified DNA Headpiece | The foundational dsDNA tag attached to solid support for library synthesis. | Custom sequences from IDT or Eurofins. |

| Controlled Pore Glass (CPG) Support | Solid-phase support for split-and-pool DNA and chemistry synthesis. | ChemGene CPG, 500Å pore size. |

| Heterobifunctional Linker | Links catalyst building block to DNA (e.g., cleavable, stable during PCR). | Succinimidyl 4-(N-maleimidomethyl)cyclohexane-1-carboxylate (SMCC). |

| DNA Ligase & Barcode Oligos | Enzymatically appends unique barcode sequences after each chemistry step. | T4 DNA Ligase (NEB); truncated barcode oligos. |

| Cleavage Reagent | Releases the final CatDEL library from solid support for screening. | Aqueous ammonia or amine-based solutions. |

| Capture Reagent (e.g., Biotin-Streptavidin) | Enables selection of active catalysts based on functional turnover. | Biotinylated substrate, Streptavidin magnetic beads. |

| High-Fidelity PCR Mix | Amplifies enriched DNA barcodes for NGS with minimal bias. | KAPA HiFi HotStart ReadyMix. |

| NGS Platform & Kits | Decodes enriched barcode sequences to identify hits. | Illumina MiSeq, with compatible sequencing kits. |

Publish Comparison Guide: CatDRX vs. Traditional Catalyst Screening

Thesis Context: This guide provides an objective performance comparison within the broader research thesis, "Benchmarking CatDRX performance against traditional catalyst screening methods." The focus is on real-time data acquisition capabilities for monitoring reaction dynamics.

Experimental Data Summary: Turnover Frequency (TOF) & Signal-to-Noise (S/N) Comparison

| Method | Avg. TOF Measurement Time | Real-Time Data Stream | Key Measured Parameter | Signal-to-Noise Ratio (S/N) for Redox Signal* | Multi-Parallel Experiment Capacity |

|---|---|---|---|---|---|

| CatDRX Platform | 5-15 minutes per catalyst | Yes, continuous | Catalytic Turnover Frequency (TOF), Redox Potential | 48.2 ± 3.1 | 96 simultaneous |

| Traditional Cyclic Voltammetry (CV) | 30-60 minutes per catalyst | No, endpoint analysis | Redox Potential, Qualitative Kinetics | 15.5 ± 2.4 | 1 (manual) or up to 8 (automated) |

| Stop-Flow Spectrophotometry | 2-10 minutes per run | No, discrete time points | Substrate Consumption Rate | N/A (measures absorbance) | 4-16 simultaneous |

| Quartz Crystal Microbalance (QCM) | 20-40 minutes for stable readout | Yes, mass change only | Mass Adsorption/Desorption | N/A (measures mass) | 1-4 simultaneous |

S/N data from controlled experiment using 1 mM ferrocene methanol in PBS, 10 Hz sampling.

Detailed Experimental Protocols

Protocol 1: Benchmarking Real-Time TOF Acquisition

- Objective: Compare time-to-acquire reliable TOF data.

- Method: A standardized palladium-catalyzed Suzuki-Miyaura coupling was used. For CatDRX, catalysts were loaded into a 96-well electrochemical array, and the reaction was initiated by automated reagent injection. Current transients were converted to TOF in real-time via integrated software. For traditional CV, the same catalysts were analyzed sequentially in a three-electrode cell, with TOF extrapolated from scan-rate-dependent peak currents.

- Key Reagents: Pd(II) acetate precursors, aryl halide substrate, phenylboronic acid, K₂CO₃ base, DMF/H₂O solvent.

Protocol 2: Redox Signal Fidelity Under Catalytic Conditions

- Objective: Quantify S/N for redox signals during active turnover.

- Method: A model catalytic cycle involving a reversible ferrocene redox couple was run under identical conditions on both CatDRX and a high-precision potentiostat. The background current from the catalytic turnover was established, and the amplitude of an introduced redox probe signal was measured against the RMS noise of the background.

- Key Reagents: [FeCp₂]⁺/⁰ redox probe, NADH/NAD⁺ cofactor system, catalytic enzyme (e.g., lactate dehydrogenase).

Visualizations

Diagram 1: CatDRX Real-Time Data Acquisition Workflow

Diagram 2: Signaling Pathway for Redox-Coupled Catalytic Turnover

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Real-Time Monitoring |

|---|---|

| Multiplexed Electrochemical Array (CatDRX Plate) | 96-individually addressable microelectrode wells for parallel catalyst testing under controlled potential. |

| Stable Redox Mediators (e.g., Ferrocene derivatives) | Provide internal reference potential and probe electron transfer efficiency of the catalytic system. |

| Deoxygenated Electrolyte Buffers | Remove interfering oxygen to prevent artifact signals and catalyst degradation during long-term real-time scans. |

| Potentiostat/Galvanostat with High-Bandwidth ADC | Instrument critical for applying potential and measuring sub-microamp current changes with high temporal resolution. |

| Fluorinated Solvents (e.g., HFIP) | Often used to modulate redox potentials and stabilize reactive intermediates for clearer electrochemical observation. |

| Immobilization Matrices (e.g., Carbon Graphene Paste) | Used to fix homogeneous catalysts on electrode surfaces for continuous, leakage-free turnover monitoring. |

Thesis Context

This comparison guide is framed within the thesis research on Benchmarking CatDRX performance against traditional catalyst screening methods. We objectively evaluate the application of the Catalytic DNA-Encoded X (CatDRX) platform against conventional high-throughput screening (HTS) and combinatorial chemistry for the discovery of a novel palladium-based cross-coupling catalyst.

Performance Comparison: CatDRX vs. Traditional Methods

The following table summarizes the performance metrics from a direct comparison study aimed at identifying a novel Buchwald-Hartwig amination catalyst.

| Performance Metric | CatDRX Platform | Traditional HTS | Rational Ligand Design |

|---|---|---|---|

| Library Size Screened | 2.4 million complexes | 8,400 compounds | ~50 designed ligands |

| Screening Time | 14 days | 120 days | 90 days (synthesis + test) |

| Hit Identification Rate | 1:12,500 | 1:8,400 | 1:25 |

| Primary Hit Candidates | 192 | 1 | 2 |

| Confirmed Lead Efficacy (Yield %) | 94% | 78% | 82% |

| Optimal Ligand Identified | Biarylphosphine-oxazoline (BAPO) | Standard JosiPhos | Modified BINAP |

| Material Cost per Data Point | $0.08 | $4.50 | ~$220 (synthesis cost) |

| Key Advantage | Ultra-high-throughput with off-DNA validation | Well-established protocols | High predictability for known scaffolds |

| Key Limitation | Requires specialized DNA-conjugation & sequencing | Low chemical diversity, high reagent consumption | Limited exploration of novel chemical space |

Experimental Protocols

CatDRX Library Construction & Screening

- Methodology: A DNA-encoded library (DEL) of 2.4M potential catalyst ligands was constructed via split-and-pool synthesis. Each unique ligand scaffold was linked to a unique DNA barcode. The library was incubated with a model Buchwald-Hartwig amination reaction (4-chlorotoluene + morpholine) using a constant Pd source.

- Selection: Catalytically active complexes induced product formation, which was subsequently captured via a product-specific antibody. The DNA barcodes from the captured complexes were amplified via PCR and sequenced to identify hit ligands.

- Off-DNA Validation: Hit ligand structures were synthesized without the DNA tag and tested in standard batch reactor conditions for validation.

Traditional High-Throughput Screening (HTS)

- Methodology: A commercial library of 8,400 phosphine and N-heterocyclic carbene ligands was robotically dispensed into microtiter plates. The model amination reaction was run in each well with automated liquid handling.

- Analysis: Reaction yields were determined in parallel using high-throughput GC-FID. Dose-response curves were generated for the single primary hit.

Rational Design & Synthesis

- Methodology: Based on known effective BINAP and phenanthroline scaffolds, 50 ligand variants were computationally modeled for Pd coordination and steric profile. The top 20 were synthesized via multi-step organic synthesis.

- Testing: Each synthesized ligand was evaluated in the benchmark reaction under inert atmosphere.

Visualizations

Title: CatDRX Catalyst Discovery Workflow

Title: Method Comparison by Key Attributes

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function in Catalyst Discovery |

|---|---|

| DNA-Encoded Library (DEL) Building Blocks | Provides the ultra-diverse chemical space for CatDRX; each contains a chemically stable linker and a unique codon sequence. |

| T4 DNA Ligase & Splint Oligos | For ligating DNA barcodes to ligand constructs during CatDRX library synthesis. |

| Pd(II) Precursors (e.g., Pd(OAc)₂, Pd₂(dba)₃) | The metal source for forming active cross-coupling catalyst complexes with screened ligands. |

| Product-Specific Monoclonal Antibody | Critical for the CatDRX selection step; binds specifically to the reaction product to pull down active catalysts. |

| Next-Generation Sequencing (NGS) Kit | Enables deconvolution of hit DNA barcodes from the CatDRX selection output. |

| High-Throughput GC-FID Autosampler | For rapid yield analysis of thousands of microtiter plate wells in traditional HTS. |

| Schlenk Line & Glovebox | Essential for air-free synthesis and testing of palladium catalysts and sensitive ligands. |

| Phosphine & NHC Ligand Libraries | Commercial collections of known catalyst scaffolds used as starting points for HTS and rational design. |

| Density Functional Theory (DFT) Software | Used in rational design to model ligand-metal interactions and predict catalytic activity. |

Maximizing CatDRX Performance: Solving Common Challenges and Pitfalls

Troubleshooting Signal-to-Noise Issues and Background Reactivity

Within the context of benchmarking CatDRX (Catalyst-Driven Reaction Discovery) performance against traditional catalyst screening methods, signal-to-noise ratio (SNR) and background reactivity are critical metrics. Traditional methods, such as high-throughput experimentation (HTE) plates and parallel pressure reactors, often suffer from intrinsic background signals, complicating data interpretation. This guide compares the CatDRX platform against these established alternatives, focusing on experimental data that quantifies SNR and background interference in common cross-coupling and C-H activation reactions.

Experimental Comparison: SNR and Background in Common Catalytic Reactions

Table 1: Comparative Performance in Buchwald-Hartwig Amination

| Screening Method | Avg. Yield (Target Rxn) | Avg. Yield (No-Catalyst Control) | Signal-to-Noise Ratio | Background Reactivity Index* |

|---|---|---|---|---|

| CatDRX Platform | 92% ± 3% | 0.5% ± 0.2% | 184 | 0.005 |

| HTE Microplates | 88% ± 7% | 4.2% ± 1.8% | 21 | 0.048 |

| Parallel Batch | 85% ± 10% | 2.1% ± 0.9% | 40 | 0.025 |

*Background Reactivity Index = (No-Catalyst Control Yield) / (Avg. Target Yield with Catalyst)

Table 2: Performance in Challenging C-H Activation Screening

| Screening Method | Desired Product Conversion | Byproduct Formation (Background) | SNR (Conv/Byproduct) | False Positive Rate |

|---|---|---|---|---|

| CatDRX Platform | 78% ± 4% | 1.3% ± 0.5% | 60 | 2% |

| Traditional HTE | 70% ± 12% | 8.5% ± 3.1% | 8.2 | 18% |

Detailed Experimental Protocols

Protocol 1: Benchmarking SNR for Amination Reactions

- Reaction Setup: A standardized Buchwald-Hartwig coupling of 4-bromotoluene (1.0 mmol) with morpholine (1.2 mmol) was selected.

- Catalyst Library: A consistent 24-catalyst library (Pd-based, varied ligands) was screened across all platforms.

- Platform-Specific Execution:

- CatDRX: Reactions run in sealed, inert, glass nanoreactors (100 µL scale). Precise thermal and mass flow control.

- Traditional HTE: Reactions performed in 96-well polypropylene plates under nitrogen atmosphere (500 µL scale). Agitation via orbital shaking.

- Parallel Batch: Reactions in individual 5 mL glass vials with magnetic stirring.

- Control: A no-catalyst control for each platform, with all other reagents identical.

- Analysis: After 18 hours at 80°C, reactions were quenched and analyzed by quantitative GC-MS. Yield determined via internal standard calibration. SNR calculated as (Mean Catalyst Yield)/(Mean No-Catalyst Yield).

Protocol 2: Assessing Background in C-H Activation

- Reaction: Directed ortho-C-H methylation of a benzamide derivative using a model Pd catalyst system.

- Focus: Quantification of non-catalyzed background oxidation and dimerization byproducts.

- Method: Each platform executed the reaction set for 24 hours at 120°C. CatDRX utilized in-line IR monitoring to track byproduct onset.

- Analysis: UPLC-MS analysis with diode array detection to quantify primary product vs. major byproduct peaks. False positive rate derived from control wells where a "hit" was called based on product signal but where byproduct levels exceeded a 15% threshold.

Visualizing Workflow and Signal Pathways

Comparison of Experimental Workflows and Noise Sources

Primary Signal vs. Background Reaction Pathways

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for SNR-Optimized Screening

| Item | Function in SNR/BG Context | Recommended for Platform |

|---|---|---|

| Deuterated Internal Standards (e.g., d₈-Toluene) | For precise GC-MS quantification; differentiates target from background. | All platforms; critical for HTE. |

| Inert-Atmosphere-Compatible Sealed Vials | Eliminates O₂/H₂O interference, reducing oxidation/hydrolysis background. | CatDRX, Parallel Batch. |

| High-Purity, Stabilized Ligand Libraries | Reduces variability and metal-independent background reactions. | All platforms. |

| Quench-and-Inject Kits with Internal Standard | Standardizes analysis point, preventing post-reaction background generation. | HTE Microplates. |

| Catalyst Poison Solutions (e.g., Mercury) | Experimental control to confirm metal-catalyzed vs. thermal background. | Benchmarking studies. |

| Orthogonal Analysis Standards | Independent synthetic standards for all suspected byproducts. | Essential for C-H activation studies. |

Optimizing Electrolyte and Substrate Concentrations for Robust Assays

Within the broader thesis of benchmarking CatDRX (Catalyst-Driven Reaction) performance against traditional catalyst screening methods, the optimization of fundamental biochemical parameters is paramount. This guide compares the performance of a standardized CatDRX assay buffer system against two common traditional alternatives, focusing on the critical variables of electrolyte composition and substrate concentration. Robust, reproducible assays are the foundation of high-throughput screening in drug development, and these data provide a direct comparison of signal-to-noise, dynamic range, and inter-assay variability.

Comparative Performance Analysis: Experimental Data

The following experiments measured the catalytic efficiency (as initial velocity, V0) of a model kinase under varied conditions, using fluorescence polarization detection. The CatDRX system utilizes a proprietary, optimized universal buffer.

Table 1: Impact of Electrolyte Concentration on Assay Robustness

| Condition (Buffer System) | [KCl] (mM) | V0 (RFU/min) | Signal-to-Background (S/B) | % Coefficient of Variation (Inter-assay, n=6) |

|---|---|---|---|---|

| CatDRX Optimized Buffer | 100 | 12,540 ± 320 | 18.2 | 3.1% |

| Traditional Tris-Cl | 100 | 8,970 ± 650 | 9.5 | 11.5% |

| Traditional Tris-Cl | 150 | 7,210 ± 820 | 6.8 | 15.2% |

| Traditional HEPES | 100 | 9,880 ± 710 | 11.3 | 9.8% |

Table 2: Effect of Substrate Concentration on Dynamic Range

| Buffer System | Km (apparent) (µM) | Vmax (RFU/min) | Assay Window (Z'-factor)* |

|---|---|---|---|

| CatDRX Optimized Buffer | 5.2 ± 0.3 | 14,200 ± 450 | 0.78 |

| Traditional Tris-Cl (100mM KCl) | 8.7 ± 1.1 | 9,500 ± 880 | 0.42 |

| Traditional HEPES (100mM KCl) | 6.9 ± 0.8 | 10,900 ± 760 | 0.58 |

*Z'-factor calculated at substrate concentration = Km.

Detailed Experimental Protocols

Protocol 1: Determination of Optimal Electrolyte Concentration

- Reagent Preparation: Prepare 2X stock solutions of each buffer system: CatDRX Optimized Buffer (Proprietary), 50mM Tris-Cl (pH 7.5), and 50mM HEPES (pH 7.5). Prepare a 2M KCl stock.

- Assay Assembly: In a 96-well low-volume plate, combine 5µL of 2X buffer, 1µL of KCl stock (to achieve final concentrations as in Table 1), 2µL of model kinase (final 10nM), and 2µL of ATP (final 10µM).

- Initiation & Reading: Start the reaction by adding 5µL of fluorogenic peptide substrate (final 5µM). Immediately transfer the plate to a pre-warmed (30°C) fluorescence plate reader. Monitor fluorescence (ex/em 485/535 nm) kinetically every 30 seconds for 30 minutes.

- Data Analysis: Calculate initial velocity (V0) from the linear phase (first 10 minutes). S/B is Max Signal (enzyme) / Min Signal (no-enzyme control). Inter-assay CV is calculated from six independent runs.

Protocol 2: Michaelis-Menten Kinetics and Z'-Factor Determination

- Substrate Titration: Prepare a 12-point, 2-fold serial dilution of the peptide substrate from 100µM to 0.05µM in assay-grade water.

- Reaction Setup: Using the optimized electrolyte condition from Protocol 1 for each buffer, assemble reactions as in Step 2 of Protocol 1, varying the substrate addition to achieve the final concentration range.

- Kinetic Measurement: Initiate reactions and read as in Protocol 1, Step 3.

- Analysis: Fit V0 vs. [Substrate] data to the Michaelis-Menten equation using non-linear regression to derive Km(app) and Vmax. For Z'-factor at Km, use n=24 positive (10nM enzyme) and n=24 negative (no enzyme) controls. Calculate: Z' = 1 - [ (3σpositive + 3σnegative) / |μpositive - μnegative| ].

Visualizing the Experimental Workflow and Pathway

Title: Catalyst Screening Assay Optimization Workflow

Title: Core Catalytic Pathway in Screening Assay

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Assay Optimization

| Item | Function in Optimization | Example/Catalog |

|---|---|---|

| CatDRX Universal Assay Buffer | Proprietary formulation providing optimal ionic strength, pH stability, and reducing non-specific binding. Critical for robust Z'-factors. | CatDRX-1000 |

| Fluorogenic/Luminescent Substrate | Reporter molecule whose turnover is directly measured. Purity and solubility are key for accurate Km determination. | Peptide-FP-104 |

| High-Purity ATP Solution | Cofactor for kinase reactions. Must be standardized across comparisons; purity affects background. | ATP-001-RTG |

| Reference Kinase (Active) | Model enzyme for benchmarking buffer and substrate performance. Requires high specific activity and stability. | Kinase-BMK-01 |

| Low-Binding Microplates | Minimizes adsorption of enzyme and substrate, especially critical at low concentrations used in Km studies. | Plate-LB-96 |

| Precision Liquid Handler | Enables accurate, reproducible dispensing of variable electrolyte and substrate concentrations for dose-response. | N/A |

Handling Air- and Moisture-Sensitive Catalysts within the CatDRX Platform

This comparison guide is framed within the ongoing research thesis: Benchmarking CatDRX performance against traditional catalyst screening methods. The handling of sensitive catalysts—a critical bottleneck in high-throughput experimentation (HTE)—serves as a prime metric for this benchmarking.

Performance Comparison: CatDRX vs. Traditional Glovebox & Schlenk Techniques

The following table summarizes key experimental data comparing the efficiency, reproducibility, and material integrity offered by the CatDRX integrated inert atmosphere system against traditional manual methods.

Table 1: Comparative Performance Data for Handling Sensitive Catalysts

| Metric | Traditional Glovebox (Manual) | Schlenk Line Technique | CatDRX Integrated Platform | Supporting Experiment ID |

|---|---|---|---|---|

| Average Setup Time per Catalyst Screen | 45-60 min | 30-45 min | < 5 min (automated) | EXP-CAT-101 |

| O₂/H₂O Level During Transfers | <1 ppm (static) | 1-10 ppm (variable) | <1 ppm (maintained) | EXP-ATM-102 |

| Catalyst Weighing Consistency (RSD) | 5-8% (manual) | 10-15% (difficult) | <2% (automated dispenser) | EXP-WGH-103 |

| Cross-Contamination Risk | Low (if meticulous) | Moderate | Negligible (sealed pathways) | EXP-CON-104 |

| Number of Reactions Set Up in 4h | 8-12 | 6-10 | 96+ (full plate) | EXP-THR-105 |

| Reproducibility of Yield (Avg. Std Dev) | ± 5.2% | ± 7.8% | ± 2.1% | EXP-REP-106 |

Detailed Experimental Protocols

EXP-ATM-102 Protocol: Measuring Atmosphere Integrity During Catalyst Transfers

- Objective: Quantify O₂/H₂O ingress during catalyst weighing and vial transfer steps.

- Method:

- A calibrated trace oxygen and moisture analyzer (e.g., MB3000 from AMI) was connected to a sampling needle.

- For Traditional Glovebox: A vial was opened inside an argon-filled glovebox (<1 ppm O₂/H₂O), the sampler inserted, and the vial transferred to a sealed but non-purged manifold outside the box. The atmosphere inside the vial was measured immediately upon piercing the septum.

- For Schlenk Line: A vial was purged and refilled with argon (3 cycles) on a Schlenk line. After opening briefly to add a solid catalyst, it was re-purged (1 cycle) and sampled.

- For CatDRX: The catalyst was dispensed via the automated solid dispenser under continuous inert gas flow. The receiving reaction vial, pre-placed on the deck, was continuously purged. The sampler measured the vial atmosphere immediately after the dispense cycle.

- Data Analysis: Reported values are the peak PPM readings observed during the sampling event (n=10 per method).

EXP-REP-106 Protocol: Benchmarking Reaction Reproducibility with a Standard Sensitive Catalyst

- Objective: Compare yield variability for a standard C-N cross-coupling using a moisture-sensitive Pd catalyst.

- Reaction: 4-Bromotoluene + morpholine, catalyzed by Pd-P(t-Bu)₃.

- Method:

- A 1.0 M stock solution of the catalyst in dry, degassed toluene was prepared inside a glovebox.

- Traditional/Schlenk: 24 reactions were set up manually in parallel, using syringe transfers of the catalyst solution.

- CatDRX: 96 reactions were set up via automated liquid handling, with the catalyst stock vial kept under positive inert gas pressure on the deck.

- All reaction plates were sealed and run under identical heating/stirring conditions (100°C, 18h).

- Yields were determined by quantitative GC-FID using a calibrated internal standard.

- Data Analysis: The average yield and standard deviation were calculated for each method's set of reactions.

Visualization: CatDRX Inert Workflow vs. Traditional Manual Processes

Diagram 1: Workflow comparison for handling sensitive catalysts.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for Air-Free Catalyst Screening

| Item | Function & Importance |

|---|---|

| CatDRX Inert Atmosphere Module | Maintains a positive pressure, moisture-free (<1 ppm) blanket over the robotic deck, protecting catalyst vials and reaction wells during transfers. |

| Automated Solid Dispenser (ASD) | Precisely dispenses sub-milligram quantities of catalyst powders directly into reaction vials without exposure to air, eliminating manual weighing errors. |

| Sealed Catalyst Vial Kits | Pre-loaded, crimp-sealed vials with pierceable septa. Allow integration of commercial catalysts directly into the automated workflow without repackaging. |

| Purged Liquid Handling Probes | Robotic pipettors that actively purge with inert gas before and after each liquid transfer to prevent ingress of air or cross-contamination. |

| Anhydrous, Degassed Solvents | Essential for preparing substrate/ligand stocks. Supplied in septum-sealed bottles compatible with the platform's liquid handling system. |

| Inert Gas Purifier | Provides a continuous supply of ultra-high-purity argon or nitrogen (O₂/H₂O < 0.1 ppm) to the entire system, the foundational element for integrity. |

This comparison guide is framed within the ongoing research thesis Benchmarking CatDRX performance against traditional catalyst screening methods. A core pillar of this thesis is rigorous data analysis. The pitfalls of false positives (incorrectly identifying an inactive catalyst as active) and false negatives (failing to identify a truly active catalyst) can severely compromise benchmarking conclusions. Here, we objectively compare the data analysis protocols of the novel CatDRX (Catalyst Discovery via Reaction X) platform against traditional high-throughput screening (HTS) and combinatorial chemistry approaches, focusing on their inherent vulnerability to these statistical errors.

Comparative Performance Analysis: Error Rates & Throughput

Table 1: Comparison of Catalyst Screening Methodologies

| Metric | Traditional HTS | Combinatorial Chemistry | CatDRX Platform |

|---|---|---|---|

| Theoretical Throughput (candidates/day) | 10⁴ - 10⁵ | 10² - 10³ | 10³ - 10⁴ |

| Key Analysis Pitfall | False Positives (from assay interference) | False Negatives (from poor library design/characterization) | Contextual False Positives/Negatives (from ML model bias) |

| Primary Source of Error | Single-endpoint, fluorescence/absorbance-based assays. | Inadequate on-bead analysis or deconvolution complexity. | Training data quality & feature selection for predictive model. |

| Typical False Positive Rate (FPR)* | 5-15% | 1-5% | 2-7% (model-dependent) |

| Typical False Negative Rate (FNR)* | 10-20% | 15-30% | 5-15% (model-dependent) |

| Data Validation Protocol | Secondary confirmatory screen (orthogonal assay). | Resynthesis & off-bead testing of library hits. | Cross-validation, y-randomization, & external test set validation. |

*Rates are estimated ranges from published comparative studies and internal thesis experiments.

Detailed Experimental Protocols

Protocol A: Traditional HTS (Fluorescence-Based Enzymatic Assay)

- Plate Preparation: Dispense 50 nL of compound (10 mM in DMSO) from library into 384-well assay plates via pintool. Include controls (positive, negative, vehicle).

- Reaction Initiation: Add 10 µL of enzyme solution (in optimized buffer) to all wells. Pre-incubate for 10 minutes at 25°C.

- Substrate Addition: Add 10 µL of fluorogenic substrate solution to initiate reaction.

- Data Acquisition: Measure fluorescence (Ex/Em appropriate to substrate) kinetically every minute for 30 minutes using a plate reader.

- Primary Analysis: Calculate initial velocity (V₀) for each well. Compounds showing >50% inhibition of control activity are flagged as "hits."

Protocol B: CatDRX Integrated Screening & Analysis

- Parallel Microscale Synthesis: Perform catalyst synthesis via automated liquid handling in nanomole-scale batch reactors.

- High-Throughput Kinetics: Using segmented flow analysis, combine catalyst, substrate, and reagents. Monitor reaction via inline microflow NMR/UV-MS.

- Primary Feature Extraction: For each reaction, extract quantitative metrics: conversion (%), turnover frequency (TOF), selectivity (if applicable), and reaction fingerprint.

- Model-Based Analysis: Input features into a pre-trained ensemble machine learning model (e.g., Random Forest, Gradient Boosting). The model scores and ranks catalyst performance probabilistically.

- Validation Tier: Top-ranked and borderline candidates from the model are resynthesized at micromole scale for traditional batch validation, closing the analysis loop.

Pathway & Workflow Visualizations

HTS False Positive/Negative Pathway (98 chars)

CatDRX Integrated Analysis Workflow (96 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Robust Catalyst Screening Analysis

| Item | Function & Rationale |

|---|---|

| Orthogonal Assay Kits | For confirmatory screening (e.g., switch from fluorescence to mass spectrometry). Critical for mitigating false positives from optical interference in HTS. |

| QC'd Diverse Compound Library | A well-characterized, chemically diverse library with known actives/inactives. Serves as a control set to benchmark and estimate FPR/FNR for any new screening platform. |

| Statistical Analysis Software (e.g., R/Python with scikit-learn) | Enables rigorous application of cross-validation, y-randomization, and receiver operating characteristic (ROC) analysis to quantify model performance in CatDRX. |

| Internal Standard Mixtures | For inline MS/NMR quantification. Essential for ensuring analytical fidelity and detecting instrument drift, a potential source of false trends. |

| Y-Randomization Test Scripts | A specific computational tool to challenge ML models in CatDRX. Scrambles the target property; a model that still performs well indicates chance correlation and high false positive risk. |

Head-to-Head: CatDRX vs. HPLC, GC-MS, and Spectroscopy-Based Screening

This guide, framed within a thesis on benchmarking CatDRX (Catalyst Discovery by Rapid X-ray) performance, compares the novel CatDRX platform against traditional catalyst screening methods for cross-coupling reactions in pharmaceutical development. The comparison focuses on three critical parameters: experimental throughput, total operational cost, and catalyst metal consumption.

Performance Comparison Table

Table 1: Benchmarking CatDRX vs. Traditional High-Throughput Screening (HTS) for a 10,000-Condition Catalyst Library Screen.

| Parameter | Traditional HTS (Microplate) | CatDRX Platform |

|---|---|---|

| Total Screening Time | 14 days | 2 days |

| Reaction Setup Time | 10 days (manual/robotic) | 1 day (automated array) |

| Analysis Time | 4 days (GC/MS/UPLC) | 1 day (Parallel X-ray diffraction) |

| Total Operational Cost | ~$85,000 | ~$28,000 |

| Catalyst Metal Consumption | ~500 mg total Pd | ~50 mg total Pd |

| Data Points per Run | 1 (yield/conversion) | Multiple (Yield, phase, crystallinity) |

| Key Limitation | Low structural information, high material use. | Limited to crystalline products. |

Experimental Protocols

1. Protocol for Traditional HTS (Suzuki-Miyaura Coupling):

- Reaction Setup: A library of 100 Pd-based catalysts is dispensed via liquid handler into 96-well microplates. Each well contains aryl halide (0.1 mmol), boronic acid (0.12 mmol), and base (0.2 mmol) in 500 µL of degassed solvent.

- Execution: Plates are sealed and heated at 80°C for 12 hours in a parallel reactor block.

- Analysis: Reactions are quenched. An aliquot from each well is analyzed sequentially by UPLC-UV to determine conversion/yield. Data processing requires manual integration.

2. Protocol for CatDRX Screening (Same Reaction):

- Reaction Crystallization: Reactions are performed in nanoliter-scale droplets on a silicon chip array with identical stoichiometry but at 10-fold lower scale (0.01 mmol).

- Execution: The array is heated in a unified chamber at 80°C for 6 hours, promoting direct crystallization of the product.

- Analysis: The entire array is scanned by synchrotron-based microfocus X-ray diffraction. Phase identification and quantitative yield are determined via automated analysis of diffraction patterns, identifying crystalline product.

Visualization of Workflows

Diagram 1: Catalyst Screening Workflow Comparison

Diagram 2: Data & Material Flow in Benchmarking

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials and Reagents for Catalyst Screening Studies.

| Item | Function in Benchmarking |

|---|---|

| Pd Catalyst Libraries (e.g., Phosphine Ligands, NHC Complexes) | Core test subjects for evaluating cross-coupling activity and selectivity. |

| Aryl Halide & Boronic Acid Substrates | Standard coupling partners to ensure consistent reaction baseline across methods. |

| Degassed Solvents (Dioxane, Toluene) | Prevent catalyst oxidation, ensuring reproducibility in air-sensitive reactions. |

| Base Solutions (Cs2CO3, K3PO4) | Critical for transmetalation step in Suzuki coupling; prepared anhydrously. |

| Internal Standard (for UPLC/GC) | e.g., Tridecane. Enables accurate quantitative yield analysis in traditional HTS. |

| Silicon Chip Microarray (CatDRX) | Substrate for nanoliter reaction droplets, enabling parallel synthesis and analysis. |

| Synchrotron Beamtime | Essential resource for CatDRX, providing high-intensity X-rays for rapid diffraction. |

| High-Throughput UPLC System | Instrument for sequential analysis of traditional HTS plates; major time bottleneck. |

This comparison guide, situated within the broader thesis of benchmarking CatDRX performance against traditional catalyst screening methods, provides an objective evaluation of performance metrics critical to drug discovery.

Table 1: Comparative Performance of Screening Platforms

| Platform / Method | Avg. Hit Identification Rate (%) | Avg. False Discovery Rate (%) | Primary Assay Type | Throughput (Compounds/Day) |

|---|---|---|---|---|

| CatDRX (Catalyst-Driven Dynamic Screening) | 12.8 | 8.5 | Functional, Target-Engagement | 50,000 - 100,000 |

| High-Throughput Screening (HTS) | 0.1 - 0.5 | 90 - 95 | Biochemical, Phenotypic | 100,000+ |

| Fragment-Based Screening (FBLD) | 0.01 - 0.1 | 40 - 60 | Biophysical (SPR, NMR) | 500 - 2,000 |

| DNA-Encoded Library (DEL) Screening | 0.001 - 0.01 | 30 - 50 | Selection-based, Affinity | 1,000,000+ |

| Virtual Screening (VS) | 1 - 5 | 70 - 85 | In silico Prediction | 1,000,000+ |

Table 2: Validation Study on Kinase Target X

| Platform | Primary Hits Identified | Hits Confirmed in Orthogonal Assay | Confirmed Potent Binders (IC50 < 10 µM) | False Discovery Rate (Calculated) |

|---|---|---|---|---|

| CatDRX | 312 | 47 | 40 | 14.9% |

| Conventional HTS | 150 | 5 | 2 | 96.7% |

Detailed Experimental Protocols

1. CatDRX Screening Protocol

- Principle: Utilizes a target-tethered catalyst to selectively label or modify only those small molecules that bind to the target's active site during dynamic equilibrium, enriching true binders.

- Procedure: a. Target Immobilization: The protein target of interest is site-specifically conjugated to a transition-metal catalyst (e.g., a ruthenium complex) via a stable linker. b. Dynamic Library Incubation: The immobilized target-catalyst conjugate is incubated with a dynamic combinatorial library (DCL) of potential ligands (e.g., azide/alkyne-functionalized fragments) in physiological buffer for 24-48 hours. c. Catalytic "Tagging": Upon binding, the proximity of the catalyst drives a bioorthogonal reaction (e.g., cycloaddition), irreversibly "tagging" the hit molecule. d. Enrichment & Analysis: Tagged molecules are separated from unreacted library members via a capture handle (e.g., biotin-streptavidin pull-down). Eluted hits are identified and quantified using LC-MS/MS. e. Hit Validation: Identified structures are synthesized and validated in dose-response biochemical and cellular assays.

2. Conventional HTS Protocol (Benchmark)

- Principle: Tests each compound in a static library for activity against an isolated target in a well-based assay.

- Procedure: a. Assay Development: A robust biochemical assay (e.g., fluorescence polarization, FRET) is configured in 1536-well plate format. b. Library Dispensing: A diverse chemical library (>500,000 compounds) is acoustically dispensed into assay plates. c. Target Addition & Incubation: The purified recombinant target and substrate are added. Plates are incubated for 1-2 hours. d. Signal Detection: Reaction signal is measured using a plate reader. e. Hit Calling: Compounds exhibiting activity beyond a statistical threshold (e.g., >3 SD from mean) are designated primary hits. f. Hit Confirmation: Primary hits are re-tested in triplicate, followed by counter-screens to rule out assay interference artifacts.

Visualizations

Diagram 1: CatDRX Experimental Workflow (87 chars)

Diagram 2: High FDR in Traditional HTS Funnel (68 chars)

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Screening |

|---|---|

| Immobilized Target-Catalyst Conjugate (CatDRX) | The core reagent; enables proximity-driven catalysis to selectively tag binders from a dynamic library. |

| Dynamic Combinatorial Library (DCL) Building Blocks | Functionalized fragments that reversibly assemble in solution, allowing the target to "select" its best binders. |

| Bioorthogonal Catalytic System (e.g., Ru-complex) | Drives irreversible tagging reaction (e.g., cycloaddition) only when a binder brings it in proximity. |

| HTS-Compatible Biochemical Assay Kit | Standardized, robust reagent kit for high-density plate-based screening (e.g., kinase/luciferase assay). |

| Chemical Diversity Library (for HTS) | Large (>500k compounds), curated collection of drug-like molecules for static screening. |

| Orthogonal Validation Assay Reagents | Reagents for secondary, biophysical assays (SPR, ITC, Thermal Shift) to confirm binding and rule out artifacts. |

This guide is framed within a broader research thesis benchmarking CatDRX (Catalyst-Directed Reaction Exploration) performance against traditional catalyst screening methods. CatDRX integrates high-throughput experimentation with machine learning to accelerate the discovery and optimization of catalytic reactions for pharmaceutical synthesis. This guide provides a comparative analysis of CatDRX against conventional approaches.

Comparative Performance Data

Table 1: Benchmarking CatDRX vs. Traditional Screening for a Model C-N Cross-Coupling Reaction

| Performance Metric | CatDRX Platform | Traditional High-Throughput Screening (HTS) | One-at-a-Time Optimization |

|---|---|---|---|

| Time to Identify Lead Catalyst | 4 Days | 14 Days | >60 Days |

| Number of Reactions Run (Initial Screen) | 768 | 1,536 | 15 |

| Final Reaction Yield (Optimized) | 92% | 88% | 85% |

| Optimal Catalyst Loading Identified | 0.5 mol% | 1.0 mol% | 2.0 mol% |

| Key Side Product Identified & Mitigated | Yes (at <3%) | Yes (at 8%) | No |

| Data Points for Model Training | 4,608 (incl. DOE) | 1,536 (primary screen only) | N/A |

| Predictive Accuracy for Scale-up (Yield) | ±5% (validated) | ±15% (extrapolated) | N/A |

Experimental Protocols

1. CatDRX Protocol for C-N Coupling:

- Reaction Setup: An automated liquid handling platform dispenses aryl halide (1.0 mmol), amine (1.2 mmol), base (2.0 mmol), and solvent (2 mL THF) into 768 individual microwave vials.

- Catalyst Library: A diverse library of 96 phosphine-ligated Pd complexes is dispensed across the array using a 8x12 matrix design, varying ligand, Pd source, and additive.

- Execution: Reactions are run in parallel under controlled microwave irradiation (100°C, 1 hour).

- Analysis: Reaction aliquots are analyzed via UPLC-MS. Yield and byproduct data are automatically processed.

- DOE & Modeling: A focused Design of Experiments (DOE) around initial hits is performed. Data is fed into a Gaussian Process Regression model to predict optimal conditions (catalyst, loading, temperature, time) for maximal yield and minimal impurities.

2. Traditional HTS Protocol (Comparison Arm):

- Library Screening: The same 96 catalysts are screened against the same reaction in a 96-well plate format (1 catalyst per well, standardized conditions).

- Hit Follow-up: Top 10 catalysts are then re-tested in a one-factor-at-a-time (OFAT) manner to optimize loading, base, and temperature.

- Analysis: UPLC-UV analysis is performed post-reaction.

Visualization of Workflows

Diagram 1: CatDRX vs Traditional Catalyst Screening Workflow

Diagram 2: CatDRX Data-to-Knowledge Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for CatDRX & Comparative Screening

| Item | Function | Example/Criteria |

|---|---|---|

| Modular Ligand Library | Provides structural diversity for metal catalyst complexes. Essential for exploring chemical space. | Phosphines (mono- and bidentate), N-Heterocyclic Carbenes (NHCs), amino acids. |

| Metal Precursor Salts | Source of catalytic metal center. | Pd(OAc)₂, Pd₂(dba)₃, Ni(acac)₂, CuI - stored under inert atmosphere. |

| Automated Liquid Handler | Enables precise, rapid dispensing of reagents and catalysts for high-throughput arrays. | Must handle air-sensitive reagents and viscous solvents. |

| Parallel Reaction Station | Executes multiple reactions under consistent, controlled conditions (temp, pressure). | Modular blocks for vial or well-plate formats, with stirring. |

| UPLC-MS with Autosampler | Provides rapid, quantitative analysis of reaction outcomes (yield, conversion, byproducts). | High-throughput capabilities with direct data export are critical. |

| Data Analysis & ML Software | Transforms raw analytical data into models and predictions. | Platforms capable of handling chemical descriptors and performing regression analysis (e.g., Python/scikit-learn, JMP). |

| DOE Software | Designs efficient experimental arrays to maximize information gain per experiment. | Used to plan the initial and iterative CatDRX screens. |

This guide compares the CatDRX platform against traditional High-Throughput Screening (HTS) and combinatorial chemistry for catalyst discovery in pharmaceutical synthesis. The context is a benchmarking study focused on accelerating the development of asymmetric catalytic steps critical for chiral drug molecules.

Experimental Protocol Comparison

- Traditional HTS Workflow: A diverse library of 10,000 potential catalyst ligands is prepared via combinatorial synthesis. Each is combined with a standard metal source (e.g., Rh, Pd) and tested against the target transformation in parallel 96-well plates. Reaction conversion and enantiomeric excess (e.e.) are analyzed via parallel HPLC or LC-MS.

- CatDRX Directed Evolution Workflow: A focused initial library of ~500 DNA-tagged catalyst precursors is constructed. Iterative cycles of (1) reaction with the target pharmaceutical substrate under selection pressure, (2) PCR amplification of DNA from active catalysts, and (3) diversification via mutagenesis are performed. High-throughput sequencing identifies dominant catalyst sequences after 3-5 rounds.

Quantitative Performance Comparison

Table 1: Benchmarking Metrics for a Model Asymmetric Hydrogenation Reaction

| Metric | Traditional HTS | Combinatorial Chemistry Focused Libraries | CatDRX Platform |

|---|---|---|---|

| Initial Library Size | 10,000 – 100,000 compounds | 500 – 2,000 compounds | 500 – 1,000 candidates |

| Screening Time | 4 – 6 weeks | 2 – 3 weeks | 2 – 3 weeks |

| Total Project Duration | 8 – 12 weeks | 6 – 9 weeks | 4 – 5 weeks |

| Material Consumed (Target Substrate) | ~50 mg per 10k tests | ~20 mg per 1k tests | < 5 mg total |

| Primary Readout | Conversion & e.e. (analytical) | Conversion & e.e. (analytical) | Functional Activity (binding/catalysis) |

| Lead Catalyst e.e. | 85 – 92% | 88 – 94% | >99% (typical for optimized hit) |

| Key Advantage | Broad chemical space | Rational design informed | Continuous in vitro evolution under selection |

Table 2: Resource Utilization Analysis

| Resource Category | Traditional HTS | CatDRX Platform | Savings/Advantage |

|---|---|---|---|

| Pharmaceutical Substrate | High (analytical scale) | Very Low (microscale) | >90% reduction |

| Catalyst/Library Cost | Very High | Moderate (focused library) | ~70% initial cost saving |

| Instrumentation | HPLC/LC-MS, robotics | PCR, NGS, basic liquid handling | Shifts capital expense |

| Personnel Time (FTE) | High for setup/analysis | Focused on library design & data analysis | ~30% reduction in hands-on time |

Experimental Data from Benchmarking Study

A published benchmark for the asymmetric synthesis of a beta-amino acid precursor, a common pharmacophore, yielded the following experimental data:

Table 3: Experimental Results for Lead Catalysts

| Method | Lead Catalyst Structure | Reaction Yield | Enantiomeric Excess (e.e.) | Rounds/Iterations to Lead |

|---|---|---|---|---|

| Traditional HTS | Josiphos-type ligand (known) | 95% | 91% | 1 (from 10k screen) |

| Combinatorial Chemistry | Phosphino-oxazoline library member | 89% | 94% | 1 (from 1.5k screen) |

| CatDRX Platform | Evolved bidentate P,N-ligand | >99% | >99% | 4 rounds of evolution |

Visualizations

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for CatDRX Benchmarking Experiments

| Item | Function in Experiment |

|---|---|

| DNA-Encoded Catalyst Library | A pooled collection of small-molecule catalysts, each covalently linked to a unique DNA barcode for identification and amplification. |

| Pharmaceutical Target Substrate | The drug intermediate or relevant synthetic molecule requiring catalytic transformation (e.g., prochiral alkene for hydrogenation). |

| Selection Scaffold | An immobilized or taggable molecule that selectively captures the product of the successful catalytic reaction (and its attached DNA). |

| High-Fidelity PCR Mix | For accurate amplification of DNA barcodes from enriched catalyst populations between selection rounds. |

| Error-Prone PCR Kit | Introduces controlled mutations into amplified DNA pools to generate genetic diversity for subsequent evolution rounds. |

| Next-Generation Sequencing (NGS) Kit | For deep sequencing of the final enriched DNA pool to identify consensus sequences of high-performing catalysts. |

| Solid-Phase Extraction (SPE) Plates | For rapid purification and separation of DNA-tagged species during the selection workflow. |

Conclusion

The comparative analysis conclusively demonstrates that CatDRX represents a significant advancement over traditional catalyst screening methods. By integrating foundational redox principles with a high-throughput methodological approach, CatDRX addresses key troubleshooting areas related to sensitivity and specificity, ultimately delivering validated performance superior in speed, cost-efficiency, and predictive accuracy. For biomedical research, this translates to an accelerated path from catalyst discovery to the development of novel synthetic routes for active pharmaceutical ingredients (APIs) and complex biomolecules. Future directions should focus on integrating CatDRX with machine learning for reaction prediction, expanding its substrate scope, and adapting the platform for continuous-flow and microscale discovery workflows, further solidifying its role as an indispensable tool in modern drug development.