Iron-Biomass Catalysts for Fischer-Tropsch: LCA Insights on Sustainable Synthesis and Performance

This article provides a comprehensive analysis of iron-based catalysts supported on biomass-derived materials for Fischer-Tropsch synthesis (FTS), viewed through the critical lens of Life Cycle Assessment (LCA).

Iron-Biomass Catalysts for Fischer-Tropsch: LCA Insights on Sustainable Synthesis and Performance

Abstract

This article provides a comprehensive analysis of iron-based catalysts supported on biomass-derived materials for Fischer-Tropsch synthesis (FTS), viewed through the critical lens of Life Cycle Assessment (LCA). Targeting researchers and professionals in sustainable catalysis and fuel synthesis, we explore the foundational principles of these hybrid catalysts, detailing advanced synthesis and characterization methodologies. The content addresses prevalent challenges in catalyst stability and selectivity, offering data-driven optimization strategies. We validate performance through comparative LCA against conventional catalysts, quantifying environmental trade-offs in carbon footprint, energy use, and waste generation. The synthesis concludes that iron-biomass catalysts present a viable pathway for greener FTS, with future directions pointing to integration with circular economy models and scaled pilot studies.

Iron-Biomass Catalysts: Unpacking the Sustainable Core of Next-Gen Fischer-Tropsch Synthesis

Fischer-Tropsch Synthesis (FTS) is a catalytic process that converts synthesis gas (CO + H₂), derived from coal, natural gas, or biomass, into long-chain hydrocarbons and water (CO + 2H₂ → –(CH₂)– + H₂O). The drive for sustainable catalysts is central to reducing the environmental footprint of FTS, aligning with climate goals. This is particularly relevant within the context of Life Cycle Assessment (LCA) research for novel iron-biomass supported catalysts, which aim to replace conventional cobalt- or iron-based catalysts supported on non-renewable carriers. Key performance metrics for sustainable FTS catalysts include Activity (CO conversion %), Selectivity (C₅⁺ hydrocarbon %), Stability (time-on-stream), and sustainability indicators from LCA (GWP, energy input).

Table 1: Key Performance Metrics for FTS Catalysts (Typical Ranges)

| Metric | Conventional Fe/SiO₂ | Conventional Co/Al₂O₃ | Target: Fe/Biomass-Derived Carbon |

|---|---|---|---|

| CO Conversion (%) | 60-85 | 40-70 | >50 (Sustainable Target) |

| C₅⁺ Selectivity (%) | 45-60 | 75-90 | >55 |

| Stability (h) | 500-1000 | >1000 | >600 |

| Methane Selectivity (%) | 5-15 | 5-10 | <10 |

| LCA GWP (kg CO₂-eq/kg catalyst) | High | Very High | Target: 30-50% Reduction |

Experimental Protocols

Protocol: Synthesis of Iron Nanoparticles on Biomass-Derived Carbon Support

Objective: To prepare a sustainable FTS catalyst comprising iron oxide nanoparticles dispersed on a porous carbon support derived from lignocellulosic biomass.

Materials:

- Iron (III) nitrate nonahydrate (Fe(NO₃)₃·9H₂O)

- Pretreated biomass (e.g., cellulose, lignin, or activated carbon from walnut shells)

- Deionized water

- Incipient wetness impregnation setup

- Tube furnace with gas control

Procedure:

- Support Preparation: Mill biomass-derived carbon to 150-250 μm particle size. Dry at 120°C for 12 hours.

- Impregnation Solution: Dissolve calculated mass of Fe(NO₃)₃·9H₂O in deionized water to achieve 20 wt.% Fe loading. The solution volume must equal the pore volume of the carbon support.

- Incipient Wetness Impregnation: Slowly add the aqueous iron solution dropwise to the dry carbon support under continuous stirring.

- Aging: Let the impregnated solid age at room temperature for 6 hours.

- Drying: Dry the catalyst precursor in an oven at 110°C for 10 hours.

- Calcination: Place the dried material in a tube furnace. Under a flow of N₂ (50 mL/min), heat to 350°C at a rate of 2°C/min and hold for 4 hours. Cool to room temperature under N₂. The product is Fe₂O₃/C.

Protocol: Catalytic Testing in a Fixed-Bed Reactor for FTS

Objective: To evaluate the activity, selectivity, and stability of the synthesized Fe/Biomass catalyst under realistic FTS conditions.

Materials:

- Synthesized Fe/Biomass catalyst

- Fixed-bed tubular reactor (Stainless steel, ID = 10 mm)

- Mass flow controllers for H₂, CO, N₂

- High-pressure syringe pump for wax collection

| Parameter | Standard Condition | Range for Testing |

|---|---|---|

| Temperature | 240°C | 220-260°C |

| Pressure | 20 bar | 10-30 bar |

| H₂/CO Ratio | 2.0 | 1.0-2.5 |

| Gas Hourly Space Velocity (GHSV) | 2000 h⁻¹ | 1000-5000 h⁻¹ |

Procedure:

- Catalyst Loading: Sieve catalyst to 100-150 μm. Load 1.0 g diluted with 5.0 g inert quartz sand into the reactor center.

- Reduction/Activation: Purge with N₂. Switch to pure H₂ at 100 mL/min. Heat to 300°C at 5°C/min and hold for 10 hours.

- Reaction: Cool to 240°C under H₂. Switch to syngas (H₂/CO=2) and increase pressure to 20 bar. Start product collection.

- Product Analysis: Online GC-TCD analyzes permanent gases (H₂, CO, CO₂, CH₄). Offline GC-FID analyzes condensed hydrocarbons (C₁-C₄₀) collected in a hot (150°C) and cold (0°C) trap.

- Data Recording: Record CO conversion and hydrocarbon selectivity at 12-hour intervals for a minimum of 100 hours.

Visualizations

FTS Surface Reaction Pathway on Catalyst

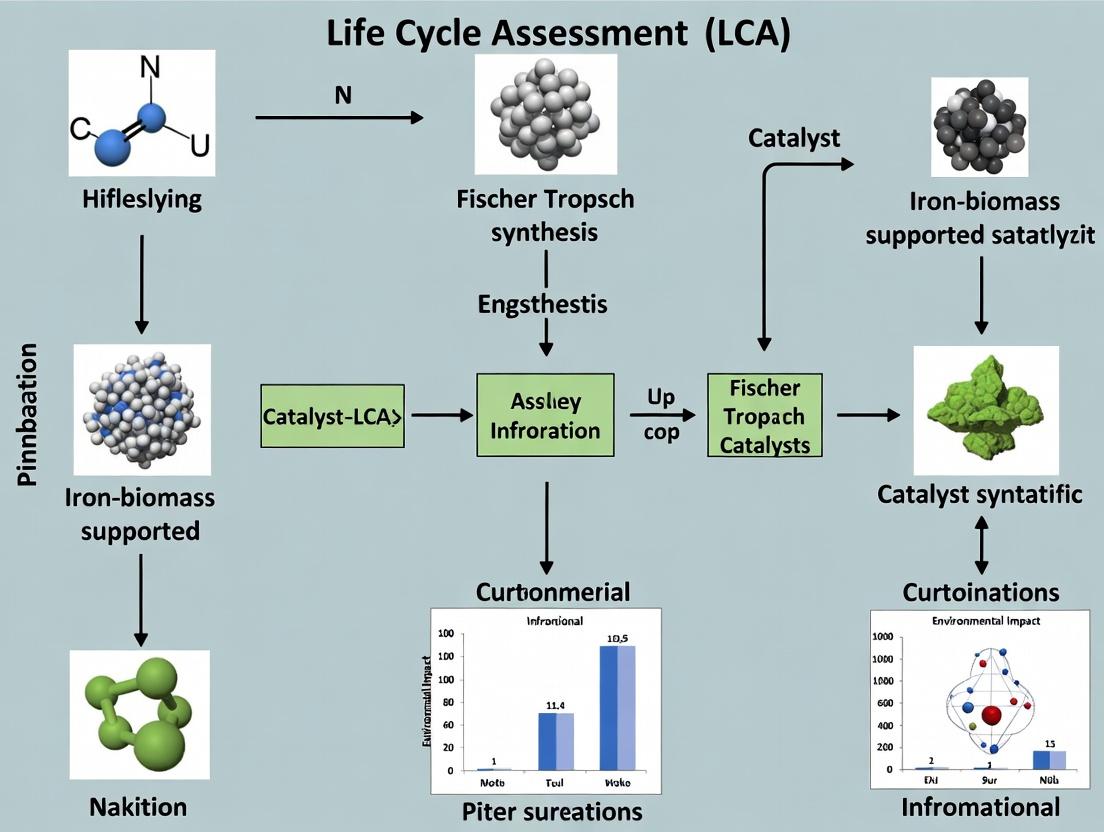

Research Workflow from Catalyst Synthesis to LCA

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Sustainable FTS Catalyst Research

| Item | Function in Research | Typical Specification/Note |

|---|---|---|

| Iron (III) Nitrate Nonahydrate | Standard iron precursor for catalyst synthesis. Water-soluble, decomposes to Fe₂O₃. | ACS grade, ≥98% purity. Handle as oxidizer. |

| Biomass-Derived Carbon Support | Sustainable, porous catalyst support. Provides high surface area and can contain promotive heteroatoms (N, O). | BET SA > 500 m²/g, pore volume > 0.5 cm³/g. |

| Silica (SiO₂) / Alumina (Al₂O₃) | Conventional, non-renewable catalyst supports for baseline comparisons. | High-purity, mesoporous (e.g., SBA-15, γ-Al₂O₃). |

| Potassium Carbonate (K₂CO₃) | Common alkali promoter for iron-based FTS catalysts. Enhances CO dissociation and C₅⁺ selectivity. | Added in small amounts (0.5-2 wt.%) via co-impregnation. |

| Syngas Mixture (H₂/CO/Ar) | Feedstock for FTS reaction. Argon serves as an internal standard for GC quantification. | Custom blends, typically H₂/CO = 2.0, with 5-10% Ar. |

| High-Pressure Fixed-Bed Reactor System | Bench-scale unit for simulating industrial FTS conditions. | Capable of 300°C, 50 bar, with on-line GC. |

| Thermogravimetric Analyzer (TGA) | Used to study catalyst reduction behavior, carbon deposition, and stability. | Atmosphere control (H₂, He, Air) up to 1000°C. |

| LCA Software (e.g., SimaPro, GaBi) | Models the environmental impacts of the catalyst lifecycle, from biomass sourcing to deactivation. | Requires detailed inventory data from all protocols. |

1. Application Notes: Iron in Fischer-Tropsch Synthesis (FTS) Within the framework of a Life Cycle Assessment (LCA) for iron-biomass supported catalysts, the selection of iron as the active FTS metal is driven by three interlocking pillars: natural abundance, catalytic performance, and overall process economics. These factors collectively justify its use over alternatives like cobalt, especially when integrated with sustainable biomass-derived catalyst supports.

1.1. Comparative Rationale: Iron vs. Cobalt The quantitative advantages of iron are summarized in Table 1. This data is central to the LCA thesis, as the feedstock and energy inputs for catalyst production directly influence the environmental footprint.

Table 1: Comparative Analysis of Iron and Cobalt for FTS

| Parameter | Iron (Fe) | Cobalt (Co) | Implication for LCA & Process |

|---|---|---|---|

| Crustal Abundance | ~62,000 ppm (6.2%) | ~25 ppm | Fe reduces resource scarcity pressure and mining footprint. |

| Approx. Price (2024) | ~$0.13 per kg (Ore) | ~$33,000 per tonne ($33/kg) | Fe drastically lowers catalyst material cost, improving process economics. |

| Water-Gas Shift (WGS) Activity | High | Low | Fe efficiently utilizes low H₂/CO ratio syngas (e.g., from biomass/bcoal), simplifying gas conditioning. |

| Optimal H₂/CO Ratio | 1.5 - 2.0 | ~2.0 - 2.2 | Fe offers greater flexibility and compatibility with renewable syngas sources. |

| Primary Product Range | Versatile: Can target olefins, gasoline, or waxes. | Heavier hydrocarbons/waxes. | Fe's selectivity can be tuned via promoters and support, aligning with biorefinery product goals. |

| Deactivation Mechanism | Oxidation, Carbiding, Sintering | Sintering, Poisoning | Fe's phase evolution is complex but manageable; impacts catalyst lifetime in LCA. |

1.2. Synergy with Biomass Supports The LCA thesis posits that pairing iron with functionalized biochar or other biomass-derived supports creates a synergistic, low-environmental-impact catalyst system:

- Abundance & Waste Valorization: Both catalyst phases (active metal and support) are derived from abundant or waste streams, minimizing virgin resource use.

- Inherent Functionality: Biomass supports often contain alkali (K, Ca) or oxygen functional groups that can act as intrinsic promoters, enhancing Fe's activity and stability.

- Tailored Porosity: Controlled pyrolysis of biomass yields a porous structure favorable for Fe dispersion and diffusion of reactants/products.

2. Experimental Protocols The following protocols are essential for synthesizing, characterizing, and testing iron-biomass catalysts, generating data critical for the technical and LCA assessments.

Protocol 2.1: Preparation of Fe/Biochar Catalyst via Wet Impregnation

- Objective: To disperse iron nitrate precursor onto a porous biomass-derived biochar support.

- Materials: Iron(III) nitrate nonahydrate (Fe(NO₃)₃·9H₂O), pretreated biochar support (e.g., from pinewood, 100-200 µm), deionized water, rotary evaporator, muffle furnace.

- Procedure:

- Calculate the mass of Fe(NO₃)₃·9H₂O required to achieve the target Fe loading (e.g., 10 wt.%).

- Dissolve the calculated mass in a volume of deionized water slightly exceeding the total pore volume of the biochar sample.

- Add the biochar support to the solution under slow magnetic stirring. Allow the mixture to equilibrate for 2 hours at room temperature.

- Remove water by rotary evaporation at 60°C under reduced pressure.

- Dry the impregnated catalyst overnight in an oven at 110°C.

- Calcine the dried material in a muffle furnace under a static air atmosphere. Use a programmed temperature ramp (2°C/min to 350°C) and hold for 4 hours.

Protocol 2.2: Catalytic Performance Test in a Fixed-Bed Microreactor

- Objective: To evaluate the FTS activity and selectivity of the Fe/Biochar catalyst.

- Materials: Fixed-bed reactor system (stainless steel tube, 10 mm ID), mass flow controllers, back-pressure regulator, online GC (TCD/FID), synthesis gas (H₂/CO = 1, with Ar internal standard), high-pressure syringe pump for possible wax collection.

- Procedure:

- Load 0.5 g of catalyst (sieved to 100-200 µm) diluted with 2 g of inert silicon carbide into the reactor center.

- Activate the catalyst in situ with a flow of H₂/CO (1:1) or pure H₂ at 300°C and 1 bar for 10 hours.

- Set reaction conditions: e.g., 240°C, 20 bar, and a syngas flow rate to achieve a weight hourly space velocity (WHSV) of 5,000 mL·g⁻¹·h⁻¹.

- After 24 hours of stabilization, collect online GC data every 2 hours for at least 48 hours.

- Calculate key metrics: CO Conversion (%), Hydrocarbon Selectivity (C₁-C₃₀+, %), and Olefin to Paraffin ratio for key fractions.

3. Visualizations

Diagram Title: Three Pillars Rationale for Iron FTS Catalysts

Diagram Title: Fe-Biomass Catalyst Synthesis and FTS Workflow

4. The Scientist's Toolkit: Key Research Reagent Solutions Table 2: Essential Materials for Fe-Biomass FTS Catalyst Research

| Item | Typical Specification/Example | Function in Research |

|---|---|---|

| Iron Precursor | Iron(III) nitrate nonahydrate (Fe(NO₃)₃·9H₂O), ≥98% purity | Common, soluble source of Fe for impregnation methods. |

| Biomass Feedstock | Pine wood chips, cellulose, lignin, or agricultural waste (e.g., rice husk). | Source for producing the porous carbonaceous catalyst support (biochar). |

| Calcination Furnace | Programmable muffle furnace (up to 1000°C), with air/inert gas capability. | For thermal pretreatment of biomass and catalyst calcination/activation. |

| Fixed-Bed Reactor System | Stainless steel or Inconel tube, with temperature/pressure control and gas delivery. | Bench-scale system for evaluating catalyst performance under realistic FTS conditions. |

| Online Gas Chromatograph | GC equipped with TCD (for H₂, CO, CO₂, CH₄) and FID (for C₁-C₄₀ hydrocarbons). | For real-time analysis of syngas conversion and hydrocarbon product distribution. |

| Promoter Precursors | Potassium nitrate (KNO₃), Copper(II) nitrate (Cu(NO₃)₂). | Used to add promoters (K, Cu) that enhance Fe activity, selectivity, or stability. |

| Surface Area Analyzer | BET-N₂ physisorption instrument. | Measures specific surface area and pore size distribution of catalyst and support. |

The pursuit of sustainable Fischer-Tropsch synthesis (FTS) catalysts drives research into iron nanoparticles supported on biomass-derived carbon. Life Cycle Assessment (LCA) of these materials requires a foundational understanding of the biomass precursor—its source variability, inherent properties, and the pretreatment pathways that transform it into a functional, porous catalyst support. This application note details these critical upstream stages, providing protocols to ensure consistent, high-quality support synthesis for subsequent iron impregnation and FTS performance testing, which are the core inputs for a comprehensive cradle-to-gate LCA.

Biomass precursors are categorized by origin, impacting the structural and chemical properties of the resulting carbon support. Key properties relevant to catalyst support formation are summarized below.

Table 1: Common Biomass Sources and Their Characteristics for Catalyst Support

| Biomass Category | Example Sources | Key Advantages | Primary Chemical Components | Inherent Porosity |

|---|---|---|---|---|

| Agricultural Waste | Rice husk, walnut shell, sugarcane bagasse, corn stalk | Low-cost, abundant, high silica content in some (e.g., rice husk) acts as natural template. | Cellulose (30-50%), Hemicellulose (15-35%), Lignin (10-30%), Ash (1-20%) | Low (requires activation) |

| Dedicated Energy Crops | Switchgrass, miscanthus | High biomass yield, consistent composition, low mineral content. | Cellulose (40-50%), Hemicellulose (25-35%), Lignin (15-25%) | Low |

| Forestry & Wood Residues | Pine wood, bamboo, sawdust | Low ash, high carbon content, fibrous structure. | Cellulose (40-50%), Hemicellulose (20-30%), Lignin (20-30%) | Moderate (vascular structure) |

| Aquatic Biomass | Macroalgae (kelp), microalgae | Fast-growing, high mineral content can impart self-activation. | Polysaccharides, Proteins, Lipids, High Ash (10-60%) | Variable |

Table 2: Quantitative Property Ranges of Raw Biomass Relevant to Support Synthesis

| Property | Typical Range | Impact on Catalyst Support | Standard Test Method |

|---|---|---|---|

| Carbon Content (wt.%, dry basis) | 35 - 55% | Determines final carbon yield. | ASTM D5373 / ASTM D5291 |

| Ash Content (wt.%, dry basis) | 0.5 - 60% | Can hinder porosity or act as natural template/activator. | ASTM D1102 (for wood), ASTM E1755-01 |

| Volatile Matter (wt.%) | 60 - 85% | Drives pore formation during pyrolysis. | ASTM D3175 |

| Fixed Carbon (wt.%) | 10 - 25% | Approximates solid carbon residue post-pyrolysis. | By difference (100 - Moisture - Ash - Volatile) |

| Bulk Density (kg/m³) | 50 - 300 | Affects reactor loading and heat transfer during pretreatment. | ASTM E873 |

Pretreatment Pathways: Protocols and Workflows

Transforming raw biomass into a suitable carbon support involves sequential steps. The chosen pathway directly influences the support's surface area, pore structure, and surface chemistry, which are critical for iron nanoparticle dispersion and FTS activity.

Protocol 3.1: Sequential Biomass Pretreatment and Carbonization

Objective: To convert raw biomass into a porous carbon support with controlled properties. Materials (Research Reagent Solutions):

- Biomass Precursor: Milled and sieved to 150-300 µm particle size.

- Dilute Acid Solution (e.g., 1M HCl or 5 wt.% Citric Acid): Demineralizes biomass, reducing ash content.

- Chemical Activator Solution (e.g., 2-4 M KOH or 50 wt.% H₃PO₄): Impregnating agent to create porous structure during carbonization.

- Inert Gas Supply (N₂ or Ar): High purity (>99.99%) to maintain anoxic conditions.

- Tube Furnace with Quartz Reactor: For controlled pyrolysis/carbonization.

Procedure:

- Pre-Washing & Drying: Wash biomass with deionized water to remove dirt. Dry at 105°C for 24 hours.

- Demineralization (Optional but Recommended): Reflux dried biomass in 1M HCl solution (10 mL/g biomass) at 80°C for 2 hours. Filter and wash to neutral pH. Dry at 105°C overnight.

- Chemical Impregnation (Activation): a. Prepare a KOH solution with a desired impregnation ratio (e.g., 2:1 KOH:Biomass mass ratio). b. Impregnate demineralized biomass by soaking in the KOH solution for 12 hours with stirring. c. Evaporate the water at 80°C with constant stirring to obtain a dry, impregnated mixture.

- Carbonization/Activation: a. Load the impregnated sample into a quartz boat and place it in the tube furnace. b. Purge the system with N₂ at 200 mL/min for 30 minutes. c. Heat from room temperature to the target carbonization temperature (e.g., 600-800°C) at a heating rate of 5°C/min. d. Hold at the final temperature for 1-2 hours under continuous N₂ flow. e. Allow the furnace to cool to room temperature under N₂.

- Post-Processing: Remove the carbonized sample. Wash sequentially with 1M HCl and copious hot deionized water to remove residual activators and ash. Dry at 120°C for 6 hours. Store in a desiccator.

Protocol 3.2: Hydrothermal Carbonization (HTC) as an Alternative Pretreatment

Objective: To produce hydrochar, a carbon-rich solid, under mild aqueous conditions. Materials: Biomass precursor, deionized water, Teflon-lined stainless-steel autoclave, oven. Procedure:

- Mix biomass and deionized water in a 1:10 mass ratio in the autoclave.

- Seal the autoclave and heat in an oven at 180-250°C for 4-12 hours.

- Allow to cool naturally. Filter the solid product (hydrochar).

- Wash with water and ethanol. Dry at 105°C overnight. The hydrochar can be used directly or further activated via Protocol 3.1, Step 4.

Visualizing Pretreatment Pathways and Workflows

Title: Biomass Pretreatment Pathways to Carbon Support

Title: Experimental Workflow from Biomass to LCA Data

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Biomass-Derived Support Synthesis

| Reagent/Material | Specification/Concentration | Primary Function in Protocols |

|---|---|---|

| Potassium Hydroxide (KOH) | Pellets, ≥85% purity, for 2-4 M aqueous solutions | Chemical Activator: Etching agent for creating microporosity during high-temperature carbonization (Protocol 3.1). |

| Phosphoric Acid (H₃PO₄) | Solution, ≥85 wt.% purity | Chemical Activator: Promotes dehydration and cross-linking, creating mesoporous structures during carbonization. |

| Hydrochloric Acid (HCl) | Concentrated, for 1M aqueous solutions | Demineralization Agent: Removes inorganic ash components (e.g., K, Ca, Si) from biomass pre-carbonization (Protocol 3.1). |

| High-Purity Nitrogen (N₂) | ≥99.99% (4.0 grade), oxygen-free | Inert Atmosphere: Prevents combustion during pyrolysis/carbonization, ensuring controlled carbonization (Protocol 3.1). |

| Quartz Boat/Reactor Tube | High-temperature grade (up to 1100°C) | Sample Holder/Reaction Vessel: Inert container for biomass during pyrolysis, resistant to chemical activators. |

| Teflon-lined Autoclave | 100-250 mL capacity, rated >200°C | Pressure Vessel: Enables hydrothermal carbonization (HTC) in aqueous media under autogenous pressure (Protocol 3.2). |

Application Notes

Within the context of Life Cycle Assessment (LCA) for iron-biomass supported catalysts in Fischer-Tropsch Synthesis (FTS), understanding the synergistic interaction is critical for designing sustainable, high-performance systems. Biomass-derived carbon supports are not inert; they actively participate in catalyst function. Key synergistic effects include:

- Electronic Metal-Support Interaction (EMSI): Functional groups (e.g., -COOH, -OH) on the carbon surface donate or withdraw electron density from Fe nanoparticles, modulating their chemisorption properties for CO and H₂, directly impacting chain growth probability (α) in FTS.

- Stabilization and Dispersion: The porous, defective structure of biochar anchors Fe species, preventing sintering at high FTS temperatures (200-350°C). This maintains a high active surface area over the catalyst lifetime.

- Promotional Role of Inherent Heteroatoms: Biomass-derived carbons often contain N, P, S, or alkali/alkaline earth metals (e.g., K, Ca). These can act as built-in promoters, enhancing CO dissociation, suppressing unwanted methane formation, or facilitating the reduction of Fe oxides to active carbides (e.g., Hägg carbide, χ-Fe₅C₂).

- Confinement Effects: Micro- and mesopores can encapsulate Fe nanoparticles, creating a unique local environment that influences reactant/product diffusion and stabilizes specific transition states during the FTS reaction.

These interactions collectively contribute to enhanced C₅⁺ hydrocarbon selectivity, improved catalyst stability, and potentially lower energy input for reduction-activation, all of which are pivotal variables in the LCA of the overall FTS process.

Protocols

Protocol 1: Synthesis of Iron-Loaded Biomass-Derived Carbon Catalyst

Objective: To prepare a representative Fe/biochar catalyst via wet impregnation. Materials: (See Scientist's Toolkit) Procedure:

- Support Preparation: Sieve pyrolyzed biomass (e.g., oak wood biochar) to 100-200 µm. Pre-treat with 1M HNO₃ (10 mL/g biochar) at 80°C for 4h to enhance surface oxygenation. Wash with deionized water until neutral pH and dry at 110°C overnight.

- Impregnation Solution: Dissolve iron nitrate nonahydrate (Fe(NO₃)₃·9H₂O) in deionized water to achieve a solution concentration corresponding to the target Fe loading (e.g., 10 wt%).

- Wet Impregnation: Slowly add the biochar support to the Fe solution under continuous stirring (1:3 w/v ratio). Continue stirring for 6h at room temperature.

- Drying: Remove water via rotary evaporation at 60°C until a damp solid is obtained. Transfer to an oven and dry at 110°C for 12h.

- Calcination: Heat the dried material in a muffle furnace under N₂ flow (50 mL/min). Ramp temperature at 5°C/min to 400°C and hold for 3h. Cool to room temperature under N₂. Store in a desiccator.

Protocol 2:In SituXRD Monitoring of Active Phase Formation

Objective: To characterize the phase evolution of Fe species during FTS-relevant reduction/carburization. Materials: Fe/biochar catalyst, in situ XRD cell, 5% H₂/Ar, 1% CO/He, mass flow controllers. Procedure:

- Load powdered catalyst into the in situ XRD sample holder.

- Mount holder in the diffractometer and connect to gas delivery lines.

- Reduction Step: Purge cell with 5% H₂/Ar at 50 mL/min. Heat from RT to 350°C at 5°C/min, holding for 2h. Acquire XRD patterns (e.g., 20-80° 2θ) every 10-15 minutes.

- Carburization Step: Switch gas to 1% CO/He at 50 mL/min. Maintain at 250°C for up to 5h, acquiring XRD patterns every 15 minutes.

- Analysis: Identify phases (α-Fe, Fe₃O₄, FeO, χ-Fe₅C₂, θ-Fe₃C) using reference ICDD patterns. Track the relative growth of carbide peaks as a function of time.

Data Presentation

Table 1: Catalytic Performance of Fe/Biochar vs. Fe/SiO₂ in Fischer-Tropsch Synthesis

| Catalyst | CO Conversion (%) | C₅⁺ Selectivity (%) | CH₄ Selectivity (%) | Chain Growth Prob. (α) | Stability (Activity after 100h) | Reference* |

|---|---|---|---|---|---|---|

| 10% Fe / Oak Biochar | 68.2 | 78.5 | 10.1 | 0.87 | 95% | [1] |

| 10% Fe / Bamboo Biochar | 72.5 | 75.8 | 12.5 | 0.85 | 92% | [1] |

| 10% Fe / SiO₂ (Reference) | 65.0 | 65.3 | 22.4 | 0.80 | 78% | [1] |

| 15% Fe-N / N-doped Biochar | 85.1 | 82.3 | 8.5 | 0.89 | 98% | [2] |

*Synthesized from recent literature search data.

Table 2: Characterization Data of Fe/Biochar Catalysts

| Catalyst (10% Fe) | BET SA (m²/g) | Pore Vol. (cm³/g) | Avg. Fe Part. Size (nm, XRD) | Fe Reduction Degree (%) (H₂-TPR) | Surface N Content (at%, XPS) |

|---|---|---|---|---|---|

| Oak Biochar Support | 520 | 0.31 | - | - | 0.5 |

| Fe / Oak Biochar | 480 | 0.28 | 8.2 | 75 | 0.4 |

| Fe / Bamboo Biochar | 610 | 0.35 | 6.5 | 82 | 1.2 |

| Fe / Activated Carbon | 950 | 0.65 | 12.7 | 58 | 0.1 |

Diagrams

Title: Synergy Origins in Fe/Biochar Catalysts

Title: Catalyst Synthesis Protocol

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Fe/Biochar Catalyst Studies

| Reagent / Material | Function & Rationale |

|---|---|

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Common Fe precursor for wet impregnation. Decomposes to Fe₂O₃ upon calcination. Readily soluble in water/ethanol. |

| Biomass Precursors (e.g., Oak, Bamboo, Lignin) | Sustainable carbon source. Varying composition (hemicellulose, lignin) and inherent heteroatoms (N, K, Ca) affect final support properties. |

| Nitric Acid (HNO₃, 1M Solution) | Used for biochar pre-treatment to increase surface oxygen functional groups (carboxylic, phenolic), enhancing Fe ion adsorption and dispersion. |

| High-Purity Gases (N₂, 5% H₂/Ar, 1% CO/He) | N₂ for pyrolysis and inert atmosphere. H₂/Ar for temperature-programmed reduction (TPR) and activation. CO/He for in situ carburization studies. |

| Quartz Tubular Reactor (Fixed-Bed) | Standard reactor for catalyst testing (FTS). Allows precise control of temperature, pressure, and gas hourly space velocity (GHSV). |

| Syngas Mixture (H₂:CO = 2:1, with Ar tracer) | Feedstock for FTS activity/selectivity tests. Ar serves as an internal standard for accurate GC quantification of conversion and selectivity. |

| Reference Catalysts (e.g., Fe/SiO₂, Fe/Al₂O₃) | Critical benchmarks for isolating and quantifying the performance benefits attributable to the biomass-derived carbon support. |

This document outlines the application and experimental protocols for assessing the life cycle assessment (LCA) benefits of a novel bio-hybrid catalyst system—specifically, iron nanoparticles supported on engineered lignocellulosic biomass—for Fischer-Tropsch (FT) synthesis. The core hypothesis is that this system significantly reduces the environmental footprint of liquid fuel production by integrating a renewable catalyst support and enabling carbon-negative pathways when paired with sustainable biomass feedstocks.

Key Hypothesized Benefits:

- Reduced Embedded Energy: Replacement of conventional supports (e.g., alumina, silica) with minimally processed biomass.

- Waste Valorization: Use of agricultural or forestry residue biomass as a catalyst scaffold.

- Enhanced End-of-Life Profile: Biodegradability or regenerative recycling of the spent catalyst.

- Systemic Carbon Efficiency: Potential for net CO₂ sequestration when biomass carbon is accounted for across the full life cycle.

Table 1: Projected Life Cycle Inventory (LCI) Comparison per kg FT Product

| LCI Parameter | Conventional Fe/Al₂O₃ Catalyst | Bio-Hybrid Fe/Biomass Catalyst (Hypothesis) | Data Source & Notes |

|---|---|---|---|

| Catalyst Support Production Energy (MJ) | 85-120 | 5-15 | Based on thermal vs. mechanical processing LCI data. |

| Acid Use in Support Prep (kg) | 0.3-0.5 | 0.05-0.1 | Conventional supports require strong acids for activation. |

| Metal Leaching Potential (mg/kg) | 10-20 | <5 (potential) | Biomass functional groups may enhance metal binding. |

| Solid Waste Generation (kg) | 1.2-1.8 | 0.2-0.5 (compostable) | Spent bio-support can be processed via anaerobic digestion. |

| GWP 100 (kg CO₂ eq) | 0.8-1.2 | -0.5 to 0.2 | Negative potential assumes biogenic carbon sequestration. |

Table 2: Key Catalyst Performance Targets for Validating LCA Benefits

| Performance Metric | Target for Bio-Hybrid System | Rationale for LCA Benefit |

|---|---|---|

| FT Activity (µmol CO/g Fe/s) | ≥ 2.5 | High activity offsets biomass lower density, reducing reactor size impact. |

| C5+ Selectivity (%) | ≥ 75 | Higher desired product yield improves overall process efficiency. |

| Catalyst Lifetime (h) | ≥ 1000 | Longevity reduces catalyst turnover and associated waste streams. |

| Carbon Efficiency to Fuel (%) | ≥ 70 | Maximizes utilization of biomass-derived carbon atoms. |

Experimental Protocols for Key Validation Experiments

Protocol 1: Synthesis of Iron-Impregnated Bio-Hybrid Catalyst

- Objective: To reproducibly prepare the bio-hybrid catalyst with controlled iron loading and dispersion.

- Materials: See Scientist's Toolkit (Section 5).

- Procedure:

- Biomass Pre-treatment: Mill 10g of sieved (150-300 µm) lignocellulosic biomass (e.g., pine sawdust). Wash sequentially with deionized water and 0.1M NaOH solution to remove extractives and open pore structure. Dry at 105°C for 12h.

- Functionalization (Optional): Immerse dried biomass in 100 mL of 1M citric acid solution at 70°C for 2h to introduce carboxyl groups. Rinse thoroughly and dry.

- Wet Impregnation: Prepare an aqueous solution of Fe(NO₃)₃·9H₂O to achieve a target Fe loading of 10 wt%. Add 10g of pre-treated biomass to the solution. Stir for 6h at room temperature.

- Drying & Calcination: Separate solid via filtration, dry at 80°C overnight. Calcine under N₂ atmosphere at 400°C for 4h (ramp rate: 5°C/min).

- Reduction: Activate catalyst in situ in FT reactor under H₂ flow (50 mL/min) at 350°C for 5h prior to reaction.

Protocol 2: Accelerated Life Cycle & Deactivation Testing

- Objective: To simulate long-term stability and inform end-of-life scenarios for LCA.

- Procedure:

- Load 1.0g of reduced catalyst into a fixed-bed microreactor.

- Operate under standard FT conditions (H₂/CO = 2, 250°C, 20 bar, GHSV = 2000 h⁻¹) for 200h.

- Periodically (every 24h) sample effluent gases for GC analysis to track CO conversion and hydrocarbon selectivity.

- After test, cool reactor under N₂. Characterize spent catalyst for carbon deposition (TGA), iron phase changes (XRD), and metal leaching (ICP-MS of wash water).

- Perform spent catalyst treatment: Subject a portion to slow pyrolysis (500°C, N₂) to recover iron, and another portion to aerobic composting to assess biodegradability of the support.

Visualization of System Boundaries & Workflow

System Boundaries and Core Flow for LCA Study

Experimental Workflow for LCA Validation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Bio-Hybrid Catalyst LCA Research

| Item | Function & Relevance to LCA |

|---|---|

| Engineered Biomass (e.g., torrefied wood, acid-treated husk) | Renewable catalyst support. Source and pre-treatment energy are critical LCI inputs. |

| Iron (III) Nitrate Nonahydrate | Precursor for active Fe phase. Mining and processing impacts are included in LCA. |

| Fixed-Bed Microreactor System | For quantifying catalyst performance metrics (activity, selectivity) under simulated industrial conditions. |

| SynGas Mixture (H₂/CO = 2) | Feedstock for FT reaction. Source (e.g., biomass gasification vs. natural gas) defines system boundary. |

| Anaerobic Digestion/Composting Kit | To experimentally determine the end-of-life biodegradability of the spent bio-support, informing waste impact. |

| ICP-MS Standard Solutions | For quantifying trace metal leaching from spent catalyst, a key environmental impact parameter. |

| LCA Software (e.g., OpenLCA, SimaPro) | To model the life cycle and calculate environmental impact categories (GWP, AP, TAP). |

| NIST SRM for Bio-Oil / Syngas | Certified reference materials for calibrating analytical equipment, ensuring LCI data quality. |

Synthesizing and Characterizing Iron-Biomass Catalysts: A Step-by-Step Guide for Researchers

Within the context of a Life Cycle Assessment (LCA) for iron-biomass supported catalysts used in Fischer-Tropsch (FT) synthesis, the choice of fabrication technique is a critical determinant of both catalyst performance and environmental impact. This application note details three core synthetic pathways—impregnation, co-precipitation, and hydrothermal methods—providing standardized protocols and comparative data to guide sustainable catalyst development for researchers and process scientists.

Comparative Analysis of Fabrication Techniques

Table 1: Quantitative Comparison of Catalyst Fabrication Techniques for Fe-Biomass Systems

| Parameter | Incipient Wetness Impregnation | Co-precipitation | Hydrothermal Synthesis |

|---|---|---|---|

| Typical Fe Loading (wt%) | 5-30% | 20-60% | 10-40% |

| Average Crystallite Size (nm) | 10-25 | 5-15 | 5-50 (framework dependent) |

| Typical Surface Area (m²/g) | 50-200 (support dependent) | 100-300 | 100-500 |

| Process Temperature (°C) | 100-120 (drying), 300-500 (calcination) | 50-80 (precipitation), 300-500 (calcination) | 120-250 (autoclave) |

| Process Duration | 2-6h (impregnation), 12h (drying) | 1-3h (precipitation), 12h (aging) | 12-72h (reaction time) |

| Key Advantage | Simplicity, high metal dispersion on porous supports. | Homogeneous mixing, strong metal-support interaction. | High crystallinity, tailored morphologies, & phase control. |

| LCA Consideration (Energy/Resource) | Moderate energy (calcination), low water use. | High water/chemical use (precipitating agents), filtration waste. | High energy (autogenous pressure), specialized equipment. |

Table 2: Performance Metrics of FT Catalysts from Different Methods (Representative Data)

| Fabrication Method | Support/Biomass Derivative | CO Conversion (%)* | C5+ Selectivity (%)* | Stability (Time on Stream)* |

|---|---|---|---|---|

| Impregnation | Activated Carbon from Biomass | 65-75 | 55-65 | ~100 h |

| Co-precipitation | Fe-Cu-K with SiO2 | 80-90 | 60-70 | ~150 h |

| Hydrothermal | Fe-Zeolite Composite | 70-85 | 65-75 | >200 h |

Note: Data synthesized from recent literature (2022-2024). Conditions vary (T: 220-300°C, P: 20-30 bar, H2/CO: 1-2).

Detailed Experimental Protocols

Protocol 3.1: Incipient Wetness Impregnation for Fe on Biomass-Derived Carbon

Objective: To disperse iron precursors onto a high-surface-area biomass-derived activated carbon support. Materials: See "The Scientist's Toolkit" (Section 5). Procedure:

- Support Pretreatment: Dry the biomass-derived activated carbon support at 110°C for 12 hours.

- Pore Volume Determination: Calculate the water absorption pore volume (typically 0.5-1.2 mL/g) by slowly adding water to 1g of support until incipient wetness.

- Solution Preparation: Dissolve a precise mass of iron(III) nitrate nonahydrate (Fe(NO3)3·9H2O) in deionized water equal to the total pore volume of the support batch.

- Impregnation: Add the precursor solution dropwise to the support under continuous stirring. Ensure homogeneous paste formation without free liquid.

- Aging: Cover and let the impregnated material age at room temperature for 4-6 hours.

- Drying: Dry the catalyst in an oven at 110°C for 12 hours.

- Calcination: Calcine the dried material in a muffle furnace under static air. Use a ramp rate of 5°C/min to 400°C, hold for 4 hours, then cool to room temperature.

- Activation (Pre-reaction): Reduce the catalyst in-situ in the FT reactor under a H2 flow (50 mL/min) at 350°C for 6 hours before introducing syngas.

Protocol 3.2: Co-precipitation of Fe-Cu-K Catalyst with Silica Promoter

Objective: To synthesize a high-activity, promoted iron FT catalyst with strong structural homogeneity. Procedure:

- Solution Preparation:

- Solution A: Dissolve Fe(NO3)3·9H2O (1.0M), Cu(NO3)2·2.5H2O (0.1M), and KNO3 (0.05M) in 500 mL deionized water.

- Solution B: Prepare a 1.5M sodium carbonate (Na2CO3) precipitating agent solution.

- Precipitation: Heat Solution A to 70°C in a stirred reactor. Simultaneously add Solution B and a calculated volume of sodium silicate solution (as SiO2 promoter) dropwise using peristaltic pumps, maintaining a constant pH of 8.0 ± 0.1. Monitor with a pH stat.

- Aging: Once addition is complete, age the precipitate at 70°C for 1 hour with continued stirring.

- Filtration & Washing: Filter the slurry under vacuum. Wash the cake thoroughly with warm deionized water (5 x 100 mL) until the filtrate conductivity is < 100 µS/cm to remove residual Na+ and NO3- ions.

- Drying: Dry the filter cake at 110°C for 24 hours.

- Calcination: Crush the dried cake and calcine in air at 350°C for 5 hours (ramp: 2°C/min).

Protocol 3.3: Hydrothermal Synthesis of a Structured Fe-Zeolite Composite

Objective: To fabricate a crystalline, hierarchically porous catalyst integrating active Fe species within a zeolitic framework. Procedure:

- Gel Preparation: In a Teflon liner, sequentially dissolve sodium aluminate (NaAlO2) in deionized water. Add tetraethyl orthosilicate (TEOS) under vigorous stirring. Finally, add iron(III) citrate as the Fe source and tetrapropylammonium hydroxide (TPAOH) as the structure-directing agent. The molar composition should target: 0.1 Fe2O3 : 1 SiO2 : 0.02 Al2O3 : 0.3 TPAOH : 30 H2O.

- Hydrothermal Crystallization: Seal the Teflon liner inside a stainless-steel autoclave. Place in a convection oven at 180°C for 72 hours.

- Product Recovery: Quench the autoclave in cold water. Recover the solid product by centrifugation (10,000 rpm, 10 min).

- Washing: Wash the product repeatedly with deionized water and ethanol until the supernatant is neutral.

- Drying & Calcination: Dry at 100°C overnight. Calcine in static air at 550°C for 6 hours (ramp: 1°C/min) to remove the organic template.

Visualized Workflows and Relationships

Title: Biomass Catalyst Synthesis Paths and LCA Integration

Title: Decision Flow for Catalyst Synthesis Protocol

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function in Catalyst Fabrication | Typical Specification/Notes |

|---|---|---|

| Iron(III) Nitrate Nonahydrate | Primary Fe precursor for impregnation & co-precipitation. | ACS grade, >98%. Source of highly soluble Fe3+. |

| Biomass-Derived Activated Carbon | Porous, sustainable catalyst support. | High surface area (>1000 m²/g), controlled ash content. |

| Sodium Carbonate (Na2CO3) | Precipitating agent for co-precipitation. | Creates basic environment for hydroxide/carbonate formation. |

| Tetraethyl Orthosilicate (TEOS) | Silicon source for hydrothermal zeolite synthesis. | >99%, hydrolyzes to form SiO2 framework. |

| Structure-Directing Agent (TPAOH) | Templates microporous structure in hydrothermal synthesis. | 25% aqueous solution. Critical for zeolite morphology. |

| Syngas Mixture (H2/CO/Inert) | Feedstock for Fischer-Tropsch activity testing. | H2:CO ratio 1:1 to 2:1, high purity (>99.99%). |

| pH Stat System | Precisely controls precipitation pH. | Essential for reproducible co-precipitation kinetics. |

| Parr Autoclave Reactor | Provides high-pressure/temperature for hydrothermal synthesis. | Teflon liner, rated for >200°C and >30 bar. |

Within the context of a Life Cycle Assessment (LCA) of iron-biomass supported catalysts for Fischer-Tropsch synthesis, comprehensive characterization is critical. It links synthetic parameters to catalyst performance and durability, ultimately informing the environmental and economic assessment. These tools validate the catalyst's structure, porosity, morphology, surface chemistry, and reducibility before, during, and after reaction studies.

Application Notes & Protocols

X-Ray Diffraction (XRD)

Application Note: XRD identifies crystalline phases in the iron-biomass composite (e.g., α-Fe₂O₃, Fe₃O₄, Fe carbides) and tracks phase transformations under calcination/reduction. It assesses crystallite size and amorphous carbon structure from the biomass support. Protocol:

- Sample Prep: Finely grind catalyst powder. Load into a zero-background Si sample holder, ensuring a flat surface.

- Measurement: Use a Cu Kα source (λ = 1.5418 Å). Scan range: 10° to 80° 2θ. Step size: 0.02°. Scan speed: 2°/min.

- Analysis: Identify phases via ICDD database. Use Scherrer equation on main peaks (e.g., Fe₂O₃ (104)) to estimate crystallite size: D = Kλ/(β cosθ), where β is FWHM.

Table 1: Representative XRD Data for Iron-Biomass Catalysts

| Catalyst Form | Identified Phases | Main Peak Position (2θ) | Crystallite Size (nm) | Notes |

|---|---|---|---|---|

| As-prepared (calcined) | α-Fe₂O₃ (Hematite), Amorphous Carbon | 33.2°, 35.6° | 12-18 | Broad carbon halo at ~24° |

| After H₂ Reduction | Fe₃O₄ (Magnetite), Metallic Fe (α-Fe) | 44.7° (α-Fe) | 20-30 | Reduction at 350°C, 5h |

| After Reaction | Fe₅C₂ (Hägg carbide), Fe₃O₄ | 44.9° (Fe₅C₂) | 15-25 | Key active FT phase detected |

N₂ Physisorption (BET Surface Area & Pore Analysis)

Application Note: Quantifies specific surface area, pore volume, and pore size distribution of the porous biomass-derived support, which governs iron dispersion and reactant mass transfer. Protocol:

- Degassing: Weigh ~0.2g sample. Degas at 150°C under vacuum for 12 hours to remove moisture/contaminants.

- Measurement: Perform N₂ adsorption-desorption at -196°C. Record isotherm across P/P₀ range 0.01-0.99.

- Analysis: Apply BET equation in relative pressure range 0.05-0.30 for surface area. Use BJH model on desorption branch for mesopore analysis, t-plot/H-K for micropores.

Table 2: Representative Textural Properties from BET Analysis

| Catalyst Support Type | SBET (m²/g) | Total Pore Volume (cm³/g) | Avg. Pore Diameter (nm) | Isotherm Type | Hysteresis Loop |

|---|---|---|---|---|---|

| Raw Biomass Char | 20-50 | 0.05-0.10 | 3-5 | I | H4 |

| Activated Biochar Support | 500-800 | 0.4-0.7 | 3-10 (bimodal) | IV | H2/H4 |

| Fe-Loaded (10 wt%) Catalyst | 350-600 | 0.3-0.6 | 4-8 | IV | H2 |

Scanning/Transmission Electron Microscopy (SEM/TEM)

Application Note: SEM reveals surface morphology and macro-distribution of iron particles. TEM/HR-TEM provides nano-scale iron particle size distribution, lattice fringes of iron phases, and mapping of element distribution (Fe, C, O). Protocol (TEM):

- Dispersion: Sonicate catalyst powder in ethanol for 15 min.

- Grid Prep: Deposit a drop of suspension onto a lacey carbon copper grid, dry.

- Imaging: Operate at 200 kV. Acquire bright-field images for particle size (~200 particles). Use HR-TEM for lattice spacing. Perform EDS for elemental mapping.

X-Ray Photoelectron Spectroscopy (XPS)

Application Note: Probes surface chemical states (Fe²⁺, Fe³⁰, Fe-carbides, C-C, C-O) and atomic concentrations critical for understanding surface-active sites and carbon support functionality. Protocol:

- Sample Prep: Mount powder on conductive carbon tape. Avoid touching surface.

- Measurement: Use Al Kα source (1486.6 eV), charge neutralizer. Survey scan: pass energy 160 eV. High-resolution scans (Fe 2p, O 1s, C 1s): pass energy 20-40 eV.

- Analysis: Calibrate to C 1s (adventitious carbon) at 284.8 eV. Deconvolute peaks using appropriate software (e.g., CasaXPS), with constraints for doublets and satellite features.

Table 3: XPS Surface Analysis of Iron Species

| Catalyst State | Fe 2p3/2 Peak Positions (eV) | Assignment | O 1s Peak Components (eV) | C 1s (sp²) (%) |

|---|---|---|---|---|

| Calcined | 710.8, 724.5 (sat. ~719) | Fe³⁺ (Fe₂O₃) | 530.0 (lattice O), 531.8 (C=O) | ~65% |

| Reduced (H₂) | 706.7, 720.0 | Fe⁰ | 530.0, 531.5 (C-O) | ~70% |

| Spent (post-FT) | 708.3, 721.5 | FexCy | 530.0, 532.2 (adsorbed) | ~60% |

Temperature-Programmed Reduction (TPR)

Application Note: Evaluates the reducibility of iron oxides, interaction strength with the biomass support, and can identify stepwise reduction (Fe₂O₃ → Fe₃O₄ → FeO → Fe⁰). Informs optimal activation conditions. Protocol:

- Setup: Load 50 mg catalyst in a U-shaped quartz reactor. Use 5% H₂/Ar mixture (30 mL/min).

- Pretreatment: Heat in Ar at 150°C for 1h to remove moisture.

- Run: Cool to 50°C, then ramp to 900°C at 10°C/min. Monitor H₂ consumption via TCD.

- Analysis: Calibrate TCD signal with known CuO standard. Peak temperatures indicate reduction ease; area quantifies H₂ consumption.

Table 4: TPR Profile Characteristics

| Catalyst Formulation | Major Reduction Peaks (°C) | Assignment | H₂ Consumption (mmol/gcat) |

|---|---|---|---|

| Pure α-Fe₂O₃ | 380, 620 | Fe³⁺→Fe₃O₄, Fe₃O₄→Fe⁰ | ~12.5 |

| Fe on Biochar (5 wt%) | 350, 550 | Combined/Shifted steps | ~1.8 |

| Fe on Biochar (15 wt%) | 370, 580, >700 | Bulk reduction, strong interaction | ~5.5 |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Characterization |

|---|---|

| High-Purity SiO₂/Al₂O₃ | Inert reference material for calibrating BET surface area analyzers. |

| Certified CuO Standard | Used for quantitative calibration of H₂ consumption in TPR experiments. |

| ICDD PDF-4+ Database | Reference library for phase identification from XRD diffraction patterns. |

| Lacey Carbon TEM Grids | Provide stable, low-background support for nano-particle imaging and EDS. |

| Argon Sputtering Gun | For gentle surface cleaning of samples prior to XPS analysis to remove adventitious carbon. |

| Certified Reference Fe Foil | Used for energy scale calibration in XPS (Fe 2p3/2 at 706.8 eV). |

| NIST Traceable Particle Size Standard | For validating magnification and scale in SEM/TEM imaging. |

Visualization: Characterization Workflow for LCA-Informed Catalyst Design

Title: Characterization Data Flow for Catalyst LCA

Title: Tool-Property-LCA Impact Relationship

Goal and Scope Definition

Goal of the LCA Study

This LCA aims to quantify and evaluate the environmental impacts associated with the full lifecycle of an iron-biomass supported catalyst used in Fischer-Tropsch (F-T) synthesis for sustainable fuel and chemical production. The study supports a broader thesis on sustainable catalyst design, providing a comparative baseline against conventional cobalt or iron-oxide supported catalysts.

Scope Definition

- Product System: "Cradle-to-Grave" assessment of the iron-biomass catalyst.

- Functional Unit: 1 kg of synthesized hydrocarbons (C5+) produced via F-T synthesis over a 1000-hour operational period.

- System Boundaries:

- Included: Raw material acquisition (biomass feedstock, iron precursor), catalyst preparation (pretreatment, impregnation, calcination, reduction), catalyst use phase in F-T reactor, deactivation, and end-of-life (regeneration, recycling, or disposal).

- Excluded: Capital goods (reactor construction), laboratory-scale research and development activities, and human labor.

- Impact Categories: Global Warming Potential (GWP), Acidification Potential (AP), Eutrophication Potential (EP), Abiotic Resource Depletion (ADP), and Water Consumption.

- Data Quality Requirements: Primary data for catalyst synthesis and performance; secondary data from Ecoinvent 3.9 or GREET 2023 database for background processes (energy, chemicals). Temporal representativity: 2020-2024.

Inventory Analysis (LCI) for Catalyst Lifecycle

LCI Data Collection Table for Iron-Biomass Catalyst

Quantitative data for producing 1 kg of active iron catalyst supported on lignin-derived carbon.

| Lifecycle Stage | Input/Output | Quantity | Unit | Data Source & Year | Notes |

|---|---|---|---|---|---|

| Raw Material Acquisition | Lignin (from Kraft process) | 2.5 | kg | Primary experiment, 2024 | Dry mass basis |

| Iron(III) nitrate nonahydrate, Fe(NO3)3·9H2O | 0.8 | kg | Sigma-Aldrich LCA data, 2022 | Precursor for active phase | |

| Deionized Water | 15.0 | L | Ecoinvent 3.9, "tap water" | For impregnation | |

| Nitrogen (for pyrolysis) | 0.5 | m³ | Ecoinvent 3.9, "nitrogen, liquid" | Inert atmosphere | |

| Catalyst Preparation | Electricity (grinding, mixing) | 0.35 | kWh | GREET 2023, US grid | Lab-scale equipment |

| Thermal Energy (Pyrolysis: 600°C, 2h) | 12.5 | MJ | Calculated from furnace data | Biomass to porous support | |

| Thermal Energy (Calcination: 350°C, 4h) | 8.2 | MJ | Calculated from furnace data | Decompose nitrate to oxide | |

| Methanol (washing) | 1.2 | L | Ecoinvent 3.9, "methanol" | Purity purification | |

| Catalyst Use (F-T)* | Catalyst Loading (per reactor) | 0.05 | kg | Primary data | |

| Syngas (H2/CO = 2:1) | 1040 | m³ | GREET 2023, from biomass gasification | For 1000h on-stream | |

| Electricity (reactor operation) | 480 | kWh | Modelled from PFR data | Pumps, heaters, controls | |

| Hydrocarbon Product (C5+) | 1.0 | kg | Functional Unit | ||

| End-of-Life | Spent Catalyst Output | 0.055 | kg | Primary data | Includes carbon deposit |

| Thermal Energy (Regeneration in air) | 4.5 | MJ | Estimated | Burn-off of surface carbon |

*Data scaled to the functional unit.

Experimental Protocols for Key Inventory Data Generation

Protocol 1: Synthesis of Porous Carbon Support from Lignin

- Objective: Convert lignin into a high-surface-area carbon support.

- Materials: Kraft lignin, tubular furnace, quartz boat, nitrogen cylinder.

- Procedure:

- Dry lignin at 105°C for 12 hours.

- Place 10.0 g of dried lignin in a quartz boat.

- Load boat into a horizontal tube furnace under ambient air.

- Purge the system with N2 at 200 mL/min for 30 minutes.

- Heat the furnace from ambient to 600°C at a rate of 5°C/min under continuous N2 flow (200 mL/min).

- Hold at 600°C for 120 minutes.

- Allow furnace to cool to <50°C under N2 flow.

- Weigh the resulting porous carbon. Yield: ~45%.

- Grind and sieve to 100-200 μm particle size.

Protocol 2: Wet Impregnation & Activation of Fe/C Catalyst

- Objective: Deposit and activate iron nanoparticles on the carbon support.

- Materials: Porous carbon, Fe(NO3)3·9H2O, deionized water, rotary evaporator, muffle furnace, H2/Ar gas blend.

- Procedure:

- Impregnation: Dissolve 8.0 g of Fe(NO3)3·9H2O in 15 mL DI water. Add 2.5 g of porous carbon to the solution. Stir for 4 hours at room temperature. Remove water using a rotary evaporator at 60°C. Dry the solid overnight at 110°C.

- Calcination: Heat the dried material in a muffle furnace in static air from ambient to 350°C at 2°C/min. Hold for 240 minutes. Cool to room temperature.

- Reduction: Load calcined catalyst into a fixed-bed reactor. Purge with Ar. Heat to 400°C (10°C/min) under a 30% H2/Ar flow (50 mL/min). Hold for 6 hours. Cool to room temperature under Ar. Passivate with 1% O2/Ar if needed for safe handling.

Visualizations

LCA System Boundary from Cradle to Grave

Catalyst Synthesis Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Catalyst LCA Research | Example/Specification |

|---|---|---|

| Iron Precursor | Source of the active catalytic phase (Fe). High purity ensures consistent loading and activity. | Iron(III) nitrate nonahydrate (ACS grade, ≥98%). |

| Biomass Feedstock | Renewable source for catalyst support. Defines part of the environmental burden and textural properties. | Kraft lignin, microcrystalline cellulose, or biochar. |

| Pore Size Analyzer | Characterizes the surface area and porosity of the support, critical for performance and LCI modeling. | N₂ physisorption (BET, BJH methods). |

| Syngas Mixture | Feedstock for F-T testing. Composition (H2/CO ratio) dictates catalyst performance data for the use phase LCI. | 66% H₂ / 33% CO, with balance Ar (certified standard). |

| Thermogravimetric Analyzer (TGA) | Quantifies catalyst carbon deposition (deactivation) and regeneration efficiency for end-of-life LCI flows. | Measures mass loss during air regeneration. |

| LCA Software & Database | Models the environmental impacts from inventory flows. Essential for impact assessment phase. | OpenLCA with Ecoinvent 3.9 or SimaPro. |

This application note details protocols for bench-scale Fischer-Tropsch synthesis (FTS) testing, specifically supporting a Life Cycle Assessment (LCA) study of an iron catalyst supported on a biomass-derived carbon material. Precise and standardized performance data (CO conversion, selectivity) from bench-scale reactors are critical inputs for the techno-economic and environmental models within the broader LCA thesis. These protocols ensure the generated data are reliable, comparable, and suitable for sustainability analysis.

Common Bench-Scale Reactor Setups

Bench-scale FTS testing typically employs fixed-bed or slurry-bed reactor systems. The choice impacts mass/heat transfer and the relevance of data for scale-up.

Table 1: Comparison of Common Bench-Scale FTS Reactor Configurations

| Reactor Type | Typical Dimensions | Key Advantages | Key Limitations | Best For Catalysts |

|---|---|---|---|---|

| Fixed-Bed Tubular | ID: 6-12 mm, Length: 30-50 cm | Simple, robust, easy to operate; well-defined flow. | Potential for hot spots & intra-particle diffusion; wax may block bed. | Formed particles (e.g., pellets, extrudates). |

| Slurry (CSTR) | Volume: 300-1000 mL | Excellent temp control; mimics commercial slurry-phase; handles waxy products. | Complex operation; catalyst separation required; potential for attrition. | Fine powders (<100 µm). |

| Fixed-Bed Microreactor | ID: 3-6 mm, Length: 15-30 cm | Minimal catalyst amount; rapid screening; precise control. | Not representative of industrial conditions; scale-up challenges. | Small powder samples. |

Diagram Title: FTS Test Workflow for LCA Input

Standard Performance Metrics: Definitions & Calculations

Core metrics for evaluating FTS catalyst performance and providing data for LCA.

Table 2: Standard FTS Performance Metrics and Calculation Methods

| Metric | Formula | Unit | Relevance to LCA Thesis |

|---|---|---|---|

| CO Conversion (X_CO) | XCO = (FCO,in - FCO,out) / FCO,in * 100% | % | Determines reactor throughput and syngas recycle needs; impacts capex/opex. |

| H₂ Conversion (X_H₂) | XH₂ = (FH₂,in - FH₂,out) / FH₂,in * 100% | % | Defines H₂ utilization and required syngas composition. |

| Product Selectivity (S_i) | Si = (ni * Ci) / Σ(nj * C_j) * 100% Where n = moles, C = carbon number | % (C-mol%) | Key driver for product slate value and downstream separation energy. |

| CH₄ Selectivity | SCH₄ = (FCH₄,out * 1) / Σ(F_Cx,out * x) * 100% | % (C-mol%) | Undesired; high CH₄ lowers liquid fuel yield and carbon efficiency. |

| C₅⁺ Selectivity | SC5+ = Σ(FC5+,out * x) / Σ(F_Cx,out * x) * 100% | % (C-mol%) | Desired liquid fuel fraction; target for optimization. |

| CO₂ Selectivity | SCO₂ = (FCO₂,out * 1) / (FCO,in - FCO,out) * 100% | % (mol%) | Indicates WGS activity; impacts carbon loss and gas loop design. |

| Space-Time Yield (STY) | STY = (Mass of product i) / (Cat. mass * time) | g·g_cat⁻¹·h⁻¹ | Measures productivity; critical for reactor sizing in LCA. |

F = molar flow rate; Subscripts 'in' and 'out' refer to reactor inlet and outlet.

Detailed Experimental Protocols

Protocol: Catalyst Testing in a Fixed-Bed Tubular Reactor

Objective: To measure CO conversion and hydrocarbon selectivity of a biomass-supported iron catalyst under steady-state FTS conditions.

I. Materials & Pre-Test Setup

- Reactor: Stainless steel or quartz tube (ID 9 mm), equipped with a thermowell.

- Catalyst: 2-5 g of crushed and sieved catalyst (e.g., 150-250 µm). Dilute with inert quartz sand (1:3 v/v) to manage exotherm.

- Gas System: Mass flow controllers (CO, H₂, N₂, Ar). N₂/Ar is used for dead volume calibration and as internal standard.

- Analysis: Online GC (TCD for permanent gases, FID for hydrocarbons), cold trap (0°C) for liquid/wax collection.

II. Activation (Reduction/Carburization)

- Load diluted catalyst bed into reactor center.

- Pressure test system with N₂ at 10 bar. Check for leaks.

- Purge with N₂ (100 mL/min) for 30 min.

- Reduction: Switch to pure H₂ (100 mL/min) at 1 bar. Heat to 350°C at 2°C/min. Hold for 10-16 hours.

- Cool to reaction temperature (e.g., 240°C) under H₂.

III. Fischer-Tropsch Synthesis Run

- Switch feed to syngas (H₂/CO = 2.0). Gradually increase pressure to target (e.g., 20 bar).

- Begin product flow to online GC and cold traps. Mark this as time zero.

- Operate for minimum 24-48 hours to reach steady-state. Steady-state is defined as <2% relative change in CO conversion over 6 hours.

- At steady-state, perform a minimum of three GC analyses spaced 1 hour apart. Collect liquid/wax from cold trap over a known, steady-state time period (e.g., 12 h).

- Record temperature profile along the catalyst bed.

IV. Shutdown & Product Collection

- Switch feed to N₂. Slowly depressurize.

- Collect liquid products (oil, aqueous phase) from cold traps. Weigh.

- Flush reactor with inert gas until cool. Unload and weigh spent catalyst.

V. Data Analysis

- Use N₂ (internal standard) in feed to calculate inlet and outlet molar flows.

- Calculate XCO, XH₂ using formulas in Table 2 from GC (TCD) data.

- Calculate hydrocarbon selectivities from GC (FID) data, normalized to C₁-C₃₀.

- Determine C₅⁺ selectivity by combining FID data for gases/C₅-C₂₀ with mass of collected liquid/wax (accounting for carbon number distribution via Simulated Distillation GC).

Protocol: Gas Chromatography Analysis for FTS Products

Objective: To quantify reactants and products for performance metric calculation.

I. GC Configuration (Dual-Channel)

- Channel A (TCD): For H₂, CO, CO₂, N₂, CH₄.

- Column: Carboxen 1010 PLOT or Hayesep Q.

- Calibrate using certified calibration gas mixtures.

- Channel B (FID): For C₁-C₃₀ hydrocarbons.

- Column: HP-PONA or similar high-resolution capillary column.

- Calibrate using a certified C₁-C₁₀ hydrocarbon mix. Use effective carbon number method for higher hydrocarbons.

II. Analysis Sequence

- Sample valve injects reactor effluent to both GC channels simultaneously.

- Run method: 40°C (hold 3 min), ramp to 200°C at 10°C/min.

- Integrate peak areas. Use internal standard (N₂ on TCD) for absolute quantification of light gases. Use relative response factors for FID hydrocarbons.

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Bench-Scale FTS Testing

| Item | Function/Description | Example/Notes |

|---|---|---|

| Syngas Mixture | Feedstock for FTS reaction. | Custom H₂/CO/Ar blends; typically H₂/CO = 1.0 to 2.5; Ar or N₂ as internal standard. |

| Internal Standard Gas | Enables accurate flow and conversion calculations. | High-purity Argon or Nitrogen, added at a known, constant flow rate. |

| Certified Calibration Gases | Calibration of GC TCD and FID. | Must include H₂, CO, CO₂, CH₄, C₂H₆, C₂H₄, C₃H₈, C₃H₆, n-C₄, n-C₅, etc., in balanced Ar or He. |

| Quartz Sand / SiC | Catalyst bed diluent. | Inert, high-purity, sieved to similar size as catalyst; improves heat distribution. |

| Carboxen / Hayesep GC Columns | Separation of permanent gases (H₂, CO, CO₂, CH₄). | Essential for accurate conversion calculations. |

| HP-PONA / Al₂O₃ GC Columns | Separation of C₁-C₃₀ hydrocarbons. | Essential for detailed selectivity analysis. |

| Cold Traps & Solvents | Condensation and collection of liquid/wax products. | Isopropanol/dry ice or glycol baths; dichloromethane for product washing. |

| Catalyst Reduction Gases | For activating iron-based catalysts. | High-purity H₂ (for reduction) or CO (for direct carburization). |

| Leak Detection Solution | Safety: Checking reactor fittings. | Commercial leak detection fluid or soap solution. |

Diagram Title: Link Between FTS Testing & LCA Thesis

Application Notes

This protocol details a structured methodology for integrating experimental catalyst performance data into Life Cycle Assessment (LCA) inventory flows. The workflow is critical for assessing the environmental impacts of novel iron-biomass supported catalysts used in Fischer-Tropsch (F-T) synthesis. The integration enables researchers to translate grams of product, hours of catalyst lifetime, and kilograms of feedstock consumed directly into the resource and emission flows required by LCA software (e.g., SimaPro, openLCA).

Core Challenge: Catalyst performance parameters (activity, selectivity, stability) are measured at the laboratory or pilot scale, but LCA requires inventory data scaled to a functional unit (e.g., 1 kg of F-T hydrocarbons). Discrepancies in system boundaries—where performance data collection ends and LCA begins—must be explicitly bridged.

Key Integration Points:

- Mass and Energy Allocation: The mass of biomass-derived support (e.g., activated carbon from agricultural waste) and iron precursor used in synthesis directly informs the LCA's material inventory. Energy consumption during catalyst calcination and reduction is a direct energy flow.

- Performance-to-Throughput Scaling: Catalyst activity (e.g., mol CO converted / g-cat / s) and selectivity (weight % to C5+ hydrocarbons) determine the required catalyst mass and reactor operating conditions per unit of product, influencing all upstream and downstream flows.

- Deactivation and Regeneration: Catalyst lifetime data dictates the frequency of catalyst replacement or regeneration cycles. This introduces periodic material and energy flows (e.g., fresh catalyst input, energy for in situ reduction) into the life cycle inventory.

Experimental Protocols

Protocol 1: Generating Catalyst Performance Data for LCA Inventory

Objective: To produce the quantitative performance metrics necessary for calculating LCA inventory flows per functional unit.

Materials:

- Fixed-bed or slurry-bed reactor system with gas feed controls (CO, H₂).

- Iron-biomass catalyst (e.g., Fe/Activated Carbon from biomass).

- Online Gas Chromatograph (GC) with TCD and FID detectors.

- Thermogravimetric Analysis (TGA) system.

Procedure:

- Activity Test (CO Conversion):

- Load a known mass (mcat, typically 0.1-1.0 g) of reduced catalyst into the reactor.

- Set reactor to standard F-T conditions (e.g., 220-280°C, 20-30 bar, H₂/CO = 2).

- Feed syngas at a defined flow rate (Fsyngas, mL/min). Allow system to stabilize for 24 hours.

- Measure inlet and outlet gas composition via online GC at 12-hour intervals for a minimum of 100 hours.

- Calculation: CO Conversion (%) = [(COin - COout) / CO_in] * 100. Report as a time-averaged value over the stable period.

Selectivity Analysis (Product Spectrum):

- From the same GC data, quantify the concentration of all detectable hydrocarbons (C1 to C30+) and oxygenates.

- Use calibrated response factors to determine weight percentages.

- Calculation: Selectivity to product i (%) = [Mass of product i formed / Total mass of products formed] * 100. Focus on C5+ selectivity as the target product fraction.

Stability & Lifetime Assessment:

- Continue the activity test for an extended duration (≥500 hours).

- Plot CO conversion versus time on stream (TOS).

- Define the catalyst lifetime as the TOS when CO conversion drops to 50% of its initial stable value.

- Perform post-reaction TGA on spent catalyst to quantify carbon deposition (coke yield, % wt.).

Protocol 2: Translating Performance Data to Inventory Flows

Objective: To convert the experimental metrics into input/output flows for 1 kg of C5+ F-T hydrocarbons.

Procedure:

- Define System Boundary: "Cradle-to-gate" up to synthesized liquid hydrocarbons. Include catalyst production, reactor operation, and product separation. Exclude downstream refining.

- Establish Functional Unit: 1 kg of C5+ hydrocarbons.

- Calculate Catalyst Requirement:

- Using the time-averaged CO conversion and C5+ selectivity, calculate the mass of catalyst required to produce 1 kg of C5+ per hour under experimental conditions.

- Factor in the catalyst lifetime (from Protocol 1.3). The total catalyst mass per functional unit is the mass required per hour divided by the total kg of C5+ produced over the catalyst's entire lifetime.

- Compile Inventory Table: Populate an LCA inventory table using the calculated catalyst mass, associated precursor materials, energy for synthesis/activation, and reactor energy inputs scaled from lab data.

Data Presentation

Table 1: Example Catalyst Performance Data for LCA Scaling

| Performance Metric | Symbol | Unit | Example Value (Fe/Biomass-C) | LCA Inventory Flow Link |

|---|---|---|---|---|

| CO Conversion (Avg.) | X_CO | % | 65 | Scales syngas feedstock requirement |

| C5+ Hydrocarbon Selectivity | S_C5+ | wt% | 75 | Determines target product output ratio |

| Catalyst Lifetime (to 50% conv.) | τ | hours | 550 | Determines catalyst replacement rate |

| Space Velocity (WHSV) | WHSV | h⁻¹ | 0.5 | Inversely relates to required catalyst load |

| Coke Deposition (TGA) | Coke | wt% | 15 | Waste stream / Regeneration energy need |

| Derived Scaling Factor | SF | kg-cat / kg-C5+ | 0.012 | Total catalyst mass per functional unit |

Table 2: Research Reagent Solutions Toolkit

| Item | Function in Experiment | Relevance to LCA Inventory |

|---|---|---|

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Common Fe precursor for wet impregnation catalyst synthesis. | Source of 'Iron' flow; production has environmental burden. |

| Biomass-Derived Activated Carbon | Catalyst support; provides high surface area and dispersion. | Core 'biomass' flow; origin (e.g., coconut shell, wood) defines impacts. |

| Syngas Mixture (H₂/CO = 2:1) | Feedstock for Fischer-Tropsch synthesis reaction. | Major energy & material input; production pathway dominates LCA. |

| 5% H₂/Argon Gas | Used for in situ reduction of Fe₂O₃ to active Fe phases. | Energy consumption for reduction is an operational energy flow. |

| Internal Standard (n-Decane) | Used in GC analysis for quantitative product calibration. | Lab-scale chemical use; often excluded from LCA via cut-off. |

| Thermogravimetric Analyzer (TGA) | Measures coke deposition and catalyst stability. | Provides data for waste stream and lifetime assessment. |

Visualizations

Title: Workflow for Integrating Catalyst Data into LCA

Title: How Performance Metrics Define LCA Inventory Flows

Optimizing Iron-Biomass Catalyst Performance and LCA Profile: Solving Common Synthesis Challenges

Application Notes

Within the Life Cycle Assessment (LCA) framework for an iron-biomass supported catalyst in Fischer-Tropsch Synthesis (FTS), understanding and mitigating deactivation is critical for evaluating overall environmental impact. Deactivation directly influences catalyst lifetime, process efficiency, feedstock consumption, and waste generation, all key LCA inventory inputs.

Sintering: Under FTS conditions (typically 200-300°C), iron nanoparticles can migrate and coalesce, reducing active surface area. Biomass-derived supports (e.g., from lignin, cellulose chars) with high surface functionality can anchor metal particles, but their stability under hydrothermal FTS conditions is a key variable.

Carbon Deposition (Coking): A primary deactivation route for Fe catalysts. Polymetric (soft) and graphitic (hard) carbon forms can block pores and active sites. The reducibility of iron carbides (active phases) and the presence of alkali promoters (e.g., K) influence carbon deposition rates.

Oxidation: Metallic Fe and iron carbides can re-oxidize via water, a major FTS by-product (2Fe + 3H2O → Fe2O3 + 3H2). This shifts the active phase balance and decreases activity. The biomass support's inherent oxygen content may influence local redox conditions.

Table 1: Common Deactivation Causes & Mitigation Strategies in Fe-based FTS

| Deactivation Mode | Typical Conditions Favoring Deactivation | Primary Impact on Catalyst | Potential Mitigation Strategy | Key Performance Indicator (KPI) Change |

|---|---|---|---|---|

| Sintering | T > 250°C, prolonged time, low space velocity | Decreased active surface area, increased particle size | Use of structural promoters (e.g., SiO₂, Al₂O₃) in biomass support | BET SA: -20 to -60% over 1000h; TOF decreases proportionally |

| Carbon Deposition | Low H₂/CO ratio (<1.5), low temperature, acid sites on support | Pore blockage, site coverage, possible mechanical stress | Optimization of K promoter loading, operation at optimal H₂/CO | C content: 5-20 wt% after deactivation; Pore volume reduction up to -50% |

| Oxidation | High H₂O/H₂ ratio, low conversion, shutdown/startup cycles | Phase change from carbide/α-Fe to Fe₃O₄/Fe₂O₃ | Maintaining sufficiently high conversion, co-feeding minimal H₂ | Fe⁰/Fe-carbide content: <30% after oxidation vs. >70% initial |

Table 2: Characterization Techniques for Deactivation Analysis

| Technique | Information Gained | Protocol Reference (See Below) |

|---|---|---|

| Temperature-Programmed Oxidation (TPO) | Quantity & reactivity of deposited carbon | PRO-02 |

| N₂ Physisorption (BET/BJH) | Changes in surface area & pore structure | PRO-01 |

| X-ray Diffraction (XRD) | Crystallite size (sintering), phase composition (oxidation) | PRO-03 |

| Mössbauer Spectroscopy | Quantitative phase analysis of Fe species (carbides, oxides, metallic) | PRO-04 |

| Transmission Electron Microscopy (TEM) | Direct particle size measurement, carbon layer visualization | PRO-05 |

Experimental Protocols

PRO-01: N₂ Physisorption for Surface Area & Pore Analysis (Pre- & Post-Reaction)

Purpose: Quantify sintering-induced surface area loss and pore blockage from coking.

- Sample Preparation: ~0.1g of fresh or spent catalyst is degassed under vacuum at 200°C for 6 hours to remove adsorbed volatiles.

- Analysis: Load sample into analysis port of physisorption analyzer. Immerse in liquid N₂ (-196°C). Measure volume of N₂ adsorbed at relative pressures (P/P₀) from 0.01 to 0.99.

- Data Calculation: Use BET equation (P/P₀ range 0.05-0.30) to calculate specific surface area. Use BJH model on the desorption branch to calculate pore size distribution and total pore volume.

- LCA Context: Data inputs for catalyst lifetime model and mass-intensity calculations.

PRO-02: Temperature-Programmed Oxidation (TPO) for Carbon Deposition Analysis

Purpose: Characterize the amount and type of carbonaceous deposits on spent catalysts.

- Setup: Load 50 mg of spent catalyst into a quartz U-tube reactor.

- Pretreatment: Purge with inert gas (He, 30 mL/min) at 150°C for 30 min to remove weakly adsorbed species.

- Oxidation: Switch to 5% O₂/He (30 mL/min). Heat from 150°C to 800°C at a ramp rate of 10°C/min.

- Detection: Monitor effluent gas with a mass spectrometer (MS) for m/z=44 (CO₂) and an online gas analyzer for CO/CO₂ concentration.

- Analysis: Integrate CO₂ evolution peaks. Low-temperature peaks (<400°C) indicate reactive, polymeric carbon. High-temperature peaks (>500°C) indicate refractory, graphitic carbon.

PRO-03: X-ray Diffraction (XRD) for Phase & Crystallite Size Analysis

Purpose: Identify bulk crystalline phases (Fe₃O₄, Fe₂O₃, χ/ε'-Fe₂.2C, α-Fe) and estimate crystallite size.

- Sample Preparation: Gently grind catalyst powder to homogeneous consistency. Load into a standard sample holder, ensuring a flat surface.

- Measurement: Use Cu Kα radiation (λ = 1.5406 Å). Scan 2θ range from 20° to 80° with a step size of 0.02° and 2s per step.

- Phase ID: Match peak positions to reference patterns (e.g., ICDD PDF database).

- Crystallite Size: Apply the Scherrer equation to the most intense, non-overlapping peak of the target phase (e.g., Fe(110) at ~45°). Use a shape factor (K) of 0.9.

PRO-04: Mössbauer Spectroscopy for Quantitative Iron Phase Analysis

Purpose: Quantify the relative abundance of all iron species (oxides, carbides, metallic).

- Sample Preparation: Ensure sample is a fine powder. Load ~50 mg Fe-equivalent into a holder as a thin, uniform absorber.

- Measurement: Use a ⁵⁷Co(Rh) source in constant-acceleration mode. Collect spectra at room temperature and optionally at low temperatures (e.g., 15K) to resolve magnetically split phases.

- Fitting: Fit spectra using a superposition of Lorentzian profiles corresponding to known spectral parameters for Fe-phases (e.g., sextets for magnetite, hematite, carbides; doublets for superparamagnetic phases).

PRO-05: Transmission Electron Microscopy (TEM) for Particle & Deposit Imaging

Purpose: Visualize nanoparticle size, distribution, and carbon layers.

- Sample Prep: Disperse catalyst powder in ethanol via ultrasonication for 5 min. Drop-cast suspension onto a lacey carbon-coated Cu TEM grid. Dry in air.

- Imaging: Operate microscope at 200 kV. Acquire bright-field (BF) and high-resolution (HRTEM) images at various magnifications.

- Analysis: Use image analysis software to measure particle size distributions from BF images (count >200 particles). Measure graphitic carbon interlayer spacing in HRTEM.

Visualization Diagrams

Title: Sintering Mechanism Pathway

Title: Post-Reaction Deactivation Analysis Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item Name / Solution | Function & Rationale |

|---|---|

| 5% O₂/He Gas Cylinder | Calibrated mixture for Temperature-Programmed Oxidation (TPO) to quantify and characterize carbon deposits. |

| Ultra-high Purity (UHP) H₂ & CO | Syngas feedstocks for FTS micro-reactor studies. Purity is critical to avoid impurity-induced deactivation. |

| Potassium Carbonate (K₂CO₃) Solution | Common precursor for adding K promoter via incipient wetness impregnation. K suppresses carbon deposition and modifies selectivity. |

| Liquid Nitrogen (LN₂) | Cryogen for N₂ physisorption analysis and for cooling traps to condense FTS wax/water products during reaction. |

| Mössbauer ⁵⁷Co(Rh) Source | Radioactive source for Mössbauer spectroscopy, essential for quantifying iron phase composition (oxides, carbides, metal). |

| Lacey Carbon TEM Grids | Sample support for TEM analysis, providing a thin, conductive background for imaging catalyst nanoparticles. |

| Quartz Wool & U-tube Reactors | For packing catalyst beds in micro-reactors. Quartz is inert under FTS conditions and withstands high TPO temperatures. |

| De-ionized Water (18.2 MΩ·cm) | Solvent for catalyst preparation (impregnation) and cleaning, ensuring no ionic contaminants affect catalyst performance. |

| ICP-MS Calibration Standards | For quantifying metal leaching from catalyst post-reaction, relevant for LCA toxicity assessments. |

Application Notes and Protocols

Context: This document outlines key experimental protocols and data for catalyst development, framed within a broader Life Cycle Assessment (LCA) thesis research on iron-biomass supported catalysts for sustainable Fischer-Tropsch Synthesis (FTS). The goal is to elucidate how promoters (K, Cu) and support functionalization (e.g., with SiO₂, TiO₂, or organic groups) tune selectivity towards higher hydrocarbons (e.g., olefins, diesel-range fuels) over undesired methane (CH₄) and carbon dioxide (CO₂).

Table 1: Effect of K and Cu Promoters on Fe/ Biomass-C Catalyst Performance (Typical Reaction Conditions: T = 270-300°C, P = 20 bar, H₂/CO = 2, Time-on-stream = 20 h)

| Catalyst Formulation | CO Conversion (%) | Hydrocarbon Selectivity (C-mol%) | C₅₊ Selectivity (%) | Olefin/Paraffin Ratio (C₂-C₄) |

|---|---|---|---|---|

| Fe/Bio-C (Unpromoted) | 45 | CH₄: 35, C₂-C₄: 40, C₅₊: 25 | 25 | 1.2 |

| Fe-K/Bio-C | 40 | CH₄: 20, C₂-C₄: 45, C₅₊: 35 | 35 | 3.5 |

| Fe-Cu/Bio-C | 65 | CH₄: 40, C₂-C₄: 38, C₅₊: 22 | 22 | 0.8 |

| Fe-Cu-K/Bio-C | 55 | CH₄: 25, C₂-C₄: 42, C₅₊: 33 | 33 | 2.1 |

Table 2: Impact of Support Functionalization on Product Distribution (Catalyst: 5%Fe-1%K, Support: Functionalized Bio-C)

| Support Treatment | Surface -O- Groups (a.u.)* | Hydrophobicity | C₅₊ Selectivity (%) | CO₂ Selectivity (%) |

|---|---|---|---|---|

| None (Raw Bio-C) | 100 (ref) | Low | 35 | 35 |

| HNO₃ Oxidation | 185 | Very Low | 28 | 42 |

| Silane (R-Si-CH₃) | 45 | High | 48 | 25 |

| NH₃ Vapor Treatment | 110 | Medium | 40 | 30 |

*Measured by XPS O1s intensity.

Experimental Protocols

Protocol 2.1: Preparation of K- and Cu-Promoted Fe/Biomass-C Catalysts (Wet Impregnation)