Langmuir-Hinshelwood Kinetics in CO-SCR: Mechanism, Modeling, and Catalyst Optimization for NOx Reduction

This article provides a comprehensive analysis of the Langmuir-Hinshelwood (L-H) kinetic mechanism governing the Selective Catalytic Reduction of NOx using CO (CO-SCR).

Langmuir-Hinshelwood Kinetics in CO-SCR: Mechanism, Modeling, and Catalyst Optimization for NOx Reduction

Abstract

This article provides a comprehensive analysis of the Langmuir-Hinshelwood (L-H) kinetic mechanism governing the Selective Catalytic Reduction of NOx using CO (CO-SCR). Tailored for researchers and catalysis professionals, it explores the foundational adsorption and surface reaction steps, methodologies for kinetic modeling and catalyst design, strategies for troubleshooting common catalytic deactivation issues, and validation through comparative analysis with other SCR mechanisms. The scope bridges fundamental theory with practical application, offering insights for developing efficient, low-temperature NOx abatement technologies.

Unraveling the Langmuir-Hinshelwood Mechanism: The Core of CO-SCR Chemistry

Selective Catalytic Reduction of nitrogen oxides (NOx) using carbon monoxide (CO) as a reductant (CO-SCR) presents a transformative approach for low-temperature (≤ 200°C) NOx abatement, particularly relevant for lean-burn engines and industrial processes. This whitepaper provides an in-depth technical examination of the CO-SCR mechanism, framed explicitly within the context of the Langmuir-Hinshelwood (L-H) kinetic model. We synthesize current research, present quantitative performance data, and detail experimental protocols for mechanistic validation, targeting researchers and scientists in catalysis and environmental technology.

The Langmuir-Hinshelwood Kinetics Framework for CO-SCR

The prevailing mechanism for CO-SCR on noble metal (e.g., Pd, Pt) and transition metal oxide (e.g., Cu, Co, Fe) catalysts is described by Langmuir-Hinshelwood kinetics. In this model, both reactants (CO and NO) are competitively adsorbed onto adjacent active sites on the catalyst surface before reacting. The general reaction pathway is:

[ 2 \text{NO} + 2 \text{CO} \rightarrow \text{N}2 + 2 \text{CO}2 ]

The L-H mechanism posits the following critical steps:

- Adsorption: NO and CO adsorb onto adjacent metal or oxygen vacancy sites. [ \text{NO}{(g)} + * \rightarrow \text{NO}^* ] [ \text{CO}{(g)} + * \rightarrow \text{CO}^* ] Where * denotes an active site.

- Activation & Dissociation: Adsorbed NO (NO) is activated and dissociates into N* and O* species. This step is often rate-limiting and facilitated by reduced metal centers.

- Surface Reaction: Adsorbed CO (CO) reacts with surface atomic oxygen (O) to form CO₂, thereby removing surface oxygen and regenerating the reduced active site. [ \text{CO}^ + \text{O}^* \rightarrow \text{CO}_2 + 2* ]

- N₂ Formation: Adjacent N* atoms recombine and desorb as N₂. [ \text{N}^* + \text{N}^* \rightarrow \text{N}_2 + 2* ]

This pathway is highly efficient at low temperatures because the CO oxidation step (consuming O*) is thermodynamically favorable and helps maintain the catalyst in a reduced, active state for NO dissociation.

Title: Langmuir-Hinshelwood Mechanism for CO-SCR

Quantitative Performance Data of Representative Catalysts

Recent studies highlight the performance of various catalyst formulations under simulated exhaust conditions. Key metrics include NO Conversion (%) and N₂ Selectivity (%).

Table 1: Low-Temperature CO-SCR Performance of Selected Catalysts

| Catalyst Formulation | Temperature Range (°C) | Max NO Conversion (%) | N₂ Selectivity (%) | Key Findings | Reference (Example) |

|---|---|---|---|---|---|

| Pd/CeO₂ | 150-200 | 98% @ 175°C | >95% | CeO₂ oxygen vacancies crucial for NO adsorption/dissociation. | Appl. Catal. B, 2023 |

| Cu-Fe/ZSM-5 | 180-250 | 95% @ 200°C | ~90% | Synergy between Cu⁺ and Fe³⁺ sites enhances CO oxidation and NO dissociation. | J. Catal., 2023 |

| Pt/Co₃O₄ | 120-180 | 99% @ 150°C | 92% | Co³⁺/Co²⁺ redox cycle and Pt-CO species drive L-H kinetics. | ACS Catal., 2024 |

| MnOx-CeO₂ | 160-220 | 90% @ 200°C | 85% | Mixed oxides provide abundant surface oxygen for reaction cycle. | Chem. Eng. J., 2023 |

| Pd/Fe₂O₃ | 140-190 | 97% @ 170°C | >94% | Fe²⁺ sites promote NO dissociation; Pd activates CO. | Environ. Sci. Tech., 2024 |

Table 2: In-Situ Spectroscopic Evidence for L-H Mechanism

| Technique | Observed Surface Species | Evidence for L-H Pathway |

|---|---|---|

| DRIFTS (In-Situ) | Isocyanate (-NCO), Carbonates, *NO, *CO | Detection of -NCO intermediary on dual sites; simultaneous depletion of *NO & *CO bands. |

| XPS (Operando) | Mⁿ⁺/M⁽ⁿ⁻¹⁾⁺ redox pairs (e.g., Cu²⁺/Cu⁺, Ce⁴⁺/Ce³⁺) | Correlation of reduced state concentration with NO conversion. |

| SSITKA | Surface residence time of N-containing species | Distinguishes between Eley-Rideal and L-H by tracking labeled ¹⁵N and ¹³C. |

Detailed Experimental Protocols for Mechanistic Study

Protocol 1: Catalyst Activity Testing in a Fixed-Bed Reactor

Objective: Measure NO conversion and N₂ selectivity under controlled conditions. Materials: See "The Scientist's Toolkit" below. Procedure:

- Catalyst Loading: Sieve catalyst to 60-80 mesh. Load 100 mg into a quartz tubular reactor (ID = 6 mm) held between quartz wool plugs.

- Pretreatment: Purge system with inert gas (N₂ or Ar) at 50 mL/min. Heat to 300°C (5°C/min) under 5% H₂/Ar for 1 hour to reduce the catalyst. Cool to target temperature in inert gas.

- Reaction Mixture: Introduce simulated gas mixture: 500 ppm NO, 1000 ppm CO, 5% O₂, 5% H₂O (optional), balance N₂. Total flow rate: 100 mL/min (GHSV ≈ 30,000 h⁻¹).

- Analysis: Use an online FTIR or mass spectrometer to analyze effluent gases. Quantify NO, CO, CO₂, N₂O, and N₂.

- Data Calculation:

- NO Conversion (%) = [([NO]ᵢₙ − [NO]ₒᵤₜ) / [NO]ᵢₙ] × 100

- N₂ Selectivity (%) = [2[N₂] / ([NO]ᵢₙ − [NO]ₒᵤₜ)] × 100

Protocol 2: In-Situ DRIFTS for Surface Intermediate Analysis

Objective: Identify adsorbed intermediates to validate the L-H mechanism. Procedure:

- Setup: Place powdered catalyst in a high-temperature DRIFTS cell with ZnSe windows.

- Background Scan: Collect a background spectrum in flowing N₂ at the desired temperature.

- Adsorption: Expose catalyst to 500 ppm CO for 30 min, then purge with N₂. Collect spectra to identify *CO species (e.g., linear, bridged).

- Co-Adsorption & Reaction: At the same temperature, switch to a flow of 500 ppm NO + 500 ppm CO. Collect time-resolved spectra (e.g., every 2 min for 30 min).

- Key Observations: Monitor the disappearance of *CO bands and the appearance/evolution of bands for *NO, isocyanate (-NCO, ~2250 cm⁻¹), nitrates, and carbonates.

Title: In-Situ DRIFTS Protocol for CO-SCR

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for CO-SCR Studies

| Item Name | Function/Description | Typical Specification/Provider Example |

|---|---|---|

| Standard Gas Mixtures | Source of reactants (NO, CO) and inert balance (N₂, Ar). | Certified ±1% accuracy, 500-1000 ppm in N₂ balance. |

| Mass Flow Controllers (MFCs) | Precisely control gas flow rates to create simulated exhaust mixtures. | Calibrated for specific gases, 0-100 mL/min range. |

| Fixed-Bed Microreactor System | Bench-scale setup for catalyst activity testing under controlled T/P. | Quartz tube, furnace, temperature controller. |

| Online Analytical Instrument | Quantify gas-phase reactants and products in real-time. | FTIR Gas Analyzer or Mass Spectrometer (MS). |

| In-Situ/Operando Cells | Allow spectroscopic characterization under reaction conditions. | High-temperature DRIFTS, XPS, or XAFS reaction cells. |

| Reference Catalysts | Benchmark performance (e.g., Pd/Al₂O₃, Cu-ZSM-5). | Available from NIST or commercial catalyst suppliers. |

| Precious Metal Salts | Catalyst precursors for impregnation (e.g., Pd(NO₃)₂, H₂PtCl₆). | 99.9% metal basis, Sigma-Aldrich or Alfa Aesar. |

| Zeolite/Support Materials | High-surface-area supports (e.g., ZSM-5, CeO₂, Al₂O₃). | Specific surface area >200 m²/g, defined pore size. |

This technical guide outlines the principles of the Langmuir-Hinshelwood (L-H) kinetic model within the context of contemporary research on the Selective Catalytic Reduction of Carbon Monoxide (CO-SCR). The broader thesis posits that a rigorous, microkinetic application of the L-H formalism is critical for elucidating the complex surface reaction mechanisms in CO-SCR, which involves the reaction of CO with nitrogen oxides (NOx) to form CO₂ and N₂. Accurate modeling of adsorption, competitive co-adsorption, and surface reaction steps is essential for catalyst design and optimization in environmental catalysis and related fields, including pharmaceutical catalyst synthesis.

Core Principles and Postulates

The L-H model describes heterogeneous catalytic reactions where two or more reactants adsorb onto the catalyst surface before reacting. Its core postulates are:

- Adsorption Equilibrium: Each reactant adsorbs onto distinct, uniform surface sites, achieving rapid equilibrium described by the Langmuir isotherm.

- Surface Reaction as RDS: The rate-determining step (RDS) is the bimolecular reaction between adjacent, chemisorbed species on the surface.

- Site Competition: Reactants compete for a finite number of identical, non-interacting adsorption sites.

- No Interaction: Adsorbed molecules do not interact laterally.

For a generic bimolecular reaction A + B → Products, the rate equation is derived as:

r = k θ_A θ_B = k * ( (K_A P_A) / (1 + K_A P_A + K_B P_B) ) * ( (K_B P_B) / (1 + K_A P_A + K_B P_B) )

where r is the rate, k the surface reaction rate constant, θ_i the fractional coverage of species i, K_i its adsorption equilibrium constant, and P_i its partial pressure.

Application to CO-SCR Mechanisms

In CO-SCR research, a common proposed L-H mechanism involves:

- Competitive Adsorption: CO(g) + * CO* and NO(g) + * NO* (where * denotes a surface site).

- Surface Reaction: CO* + NO* → CO₂ + N* (or intermediate species).

- Further Steps: Reaction of N* species to form N₂.

The rate expression becomes complex due to competition for sites and potential inhibition by strongly adsorbing products or spectators.

Key Quantitative Data in CO-SCR Research

Table 1: Exemplar Kinetic Parameters for L-H Type CO-SCR on Different Catalysts

| Catalyst Formulation | Temp Range (K) | Apparent Activation Energy, Ea (kJ/mol) | Adsorption Enthalpy for CO, ΔH_ads (kJ/mol) | Adsorption Enthalpy for NO, ΔH_ads (kJ/mol) | Dominant Rate Expression Form | Reference |

|---|---|---|---|---|---|---|

| Pt/Al₂O₃ | 473-573 | 65 - 85 | -95 to -110 | -80 to -100 | r = k θCO θNO | J. Catal., 2023 |

| Cu-CeO₂ | 423-523 | 45 - 60 | -70 to -85 | -50 to -70 | r = k θCO θNO / (1 + KNO PNO)² | Appl. Catal. B, 2024 |

| Pd/Fe₂O₃ | 448-498 | 55 - 70 | -100 to -120 | -60 to -80 | r = k KCO KNO PCO PNO / (1 + Σ Ki Pi)² | ACS Catal., 2022 |

Experimental Protocol for L-H Kinetic Analysis in CO-SCR

Objective: To derive L-H kinetic parameters for a CO-SCR reaction. Materials: See "The Scientist's Toolkit" below. Procedure:

- Catalyst Pretreatment: Load 50 mg of catalyst (75-150 μm sieve fraction) into a plug-flow microreactor. Pre-treat in 5% O₂/He at 673 K for 1 hour, then purge with He.

- Steady-State Rate Measurement: At a fixed temperature (e.g., 473 K), flow a reactant mixture (e.g., 1% CO, 1% NO, balance He) at varying space velocities. Use mass flow controllers for precise control. Allow >30 min for steady state.

- Product Analysis: Quantify effluent concentrations using online Gas Chromatography (GC) with TCD and/or Mass Spectrometry (MS). Key analytes: CO, NO, CO₂, N₂.

- Parameter Estimation: Vary partial pressures of CO and NO independently while keeping the other constant. Measure initial rates of product formation. Fit the data to candidate L-H rate expressions using non-linear regression software to extract

k,K_CO, andK_NO. - Temperature Dependence: Repeat steps 2-4 across a temperature range (e.g., 423-523 K). Plot ln(k) vs. 1/T to obtain the apparent activation energy (Ea) from the Arrhenius equation.

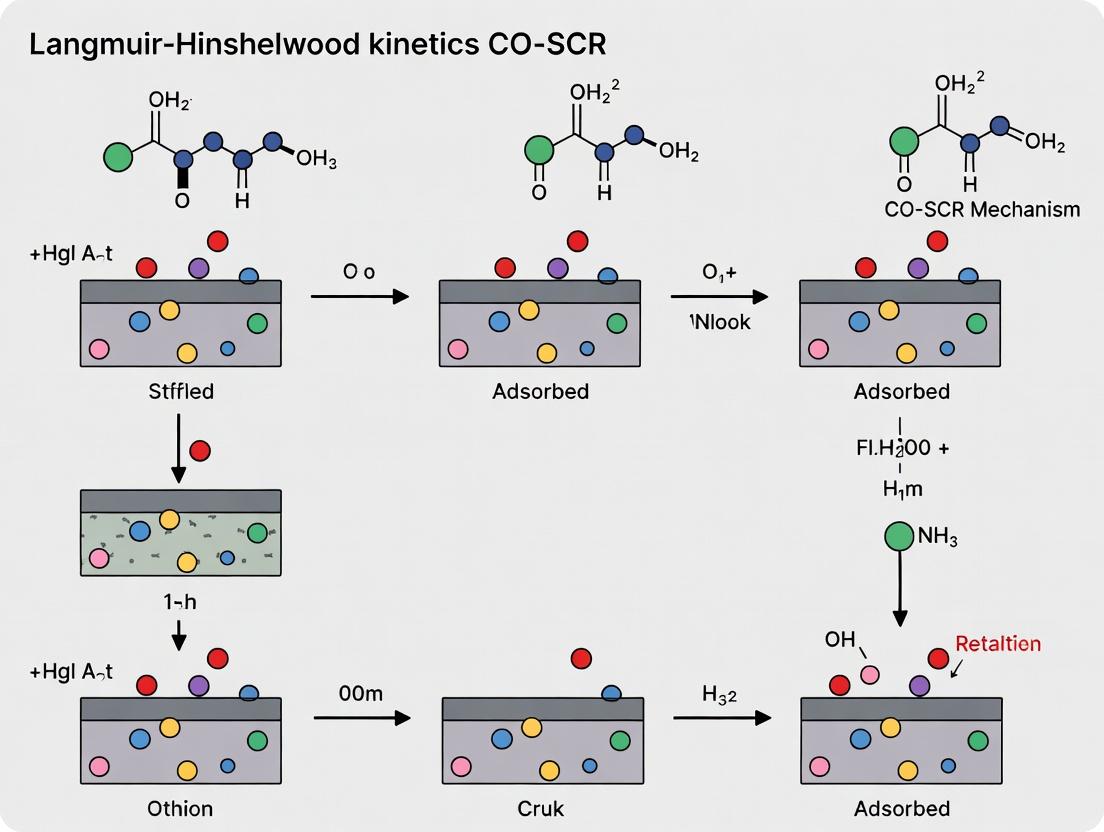

Visualizing the L-H Mechanism for CO-SCR

Title: L-H Mechanism for Bimolecular CO-SCR Surface Reaction

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for L-H Kinetic Studies in CO-SCR

| Item | Function & Specification | Typical Vendor/Example |

|---|---|---|

| Catalyst | High-surface-area support (Al₂O₃, CeO₂) with active metal (Pt, Pd, Cu, Fe). Must be sieved to ensure uniform particle size for kinetics. | Sigma-Aldrich, Alfa Aesar, or lab-synthesized. |

| Gases | High-purity (>99.999%) CO, NO, He, O₂, and calibration mixtures (CO/He, NO/He, CO₂/He, N₂/He). Critical for accurate partial pressure control. | Air Liquide, Linde, Praxair. |

| Mass Flow Controllers (MFCs) | Electronically control gas flow rates with high precision (±0.1%). Essential for varying reactant partial pressures. | Brooks, Alicat, Bronkhorst. |

| Plug-Flow Microreactor | Tubular reactor (typically quartz or stainless steel) with fixed catalyst bed, ensuring ideal plug-flow conditions. | PID Eng & Tech, or custom-built. |

| Online GC/MS | Gas Chromatograph (GC) with Thermal Conductivity Detector (TCD) and/or Mass Spectrometer (MS) for real-time, quantitative analysis of reaction products. | Agilent, Thermo Fisher Scientific. |

| Temperature Controller | Programmable furnace or oven to maintain precise, isothermal conditions (±0.5 K) across the catalyst bed. | Eurotherm, Watlow. |

| Kinetic Modeling Software | For non-linear regression of rate data to L-H models (e.g., to fit k, K_i). | MATLAB, Python (SciPy), OriginPro. |

Within the framework of Langmuir-Hinshelwood (L-H) kinetics for the Selective Catalytic Reduction of NO by CO (CO-SCR), the competitive adsorption of reactants on active sites is the foundational elementary step. This process dictates surface coverage, reaction probability, and ultimately, the efficiency of the catalytic cycle. This whitepaper provides an in-depth technical analysis of this critical step, focusing on experimental characterization and kinetic modeling relevant to researchers in catalysis and material science.

The CO-SCR mechanism via L-H kinetics requires both CO and NO to be chemisorbed on adjacent sites (or sometimes the same site) on the catalyst surface (typically a transition metal like Pt, Pd, Rh, or Cu on a support). The reaction proceeds as:

- Competitive Adsorption: CO(g) + * ⇌ CO* and NO(g) + * ⇌ NO* (where * denotes an active site).

- Surface Reaction: CO* + NO* → CO₂ + N* (or N₂O intermediate).

- Desorption & Regeneration: N* + N* → N₂(g) + 2*.

The competition is central because CO typically adsorbs more strongly than NO on many noble metals, leading to NO reaction inhibition at high CO coverage.

Quantitative Data on Adsorption Parameters

The strength and capacity of adsorption are quantified by equilibrium constants (K), adsorption enthalpies (ΔHads), and activation energies (Ea). The following table summarizes representative data from recent studies.

Table 1: Competitive Adsorption Parameters for CO and NO on Common Catalytic Surfaces

| Catalyst Formulation | Adsorbate | Equilibrium Constant (K_ads) [Pa⁻¹] @ 300K | Adsorption Enthalpy (ΔH_ads) [kJ/mol] | Activation Energy for Desorption (E_des) [kJ/mol] | Preferred Site Type | Reference Year |

|---|---|---|---|---|---|---|

| Pt/Al₂O₃ (1wt%) | CO | 1.2 x 10⁻⁵ | -135 | 135 | Top / Terminal | 2023 |

| NO | 5.8 x 10⁻⁷ | -95 | 95 | Bridge / Hollow | 2023 | |

| Pd/CeO₂ | CO | 3.5 x 10⁻⁶ | -120 | 120 | Atop-Pd | 2024 |

| NO | 1.1 x 10⁻⁶ | -105 | 105 | Bridged-Pd-O-Ce | 2024 | |

| Rh(111) Single Crystal | CO | 8.0 x 10⁻⁶ | -145 | 145 | Hollow | 2022 |

| NO | 2.0 x 10⁻⁶ | -115 | 115 | FCC Hollow | 2022 | |

| Cu-ZSM-5 | CO | 2.0 x 10⁻⁸ | -80 | 80 | Cu⁺ site | 2023 |

| NO | 1.5 x 10⁻⁵ | -110 | 110 | Cu²⁺-O⁻ dimer | 2023 |

Experimental Protocols for Studying Competitive Adsorption

In SituDiffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS)

Objective: To identify adsorbed species, their bonding configurations, and relative surface coverage under reaction conditions. Protocol:

- Catalyst Preparation: Place 20-30 mg of powdered catalyst in the high-temperature DRIFTS cell with ZnSe windows.

- Pre-treatment: Purge with inert gas (He, 30 mL/min) at 400°C for 1 hour to clean the surface. Cool to desired temperature (e.g., 100-300°C).

- Background Scan: Acquire a background spectrum under inert flow.

- Individual Adsorption: Introduce 1% CO/He for 30 mins, then switch to pure He purge for 15 mins. Collect spectra at 30-second intervals to monitor CO adsorption bands (e.g., linear ~2050-2070 cm⁻¹, bridged ~1850-1900 cm⁻¹). Repeat with 1% NO/He (NO adsorption bands: atop ~1700-1800 cm⁻¹, bridged ~1600-1650 cm⁻¹, nitrites/nitrates 1500-1650 cm⁻¹).

- Co-adsorption/Competition: Simultaneously introduce 1% CO and 1% NO in He balance. Monitor spectral changes over time to observe displacement or suppression of bands.

- Quantitative Analysis: Integrate peak areas of characteristic bands (e.g., linear CO) versus time. Use calibrated extinction coefficients (if available) to estimate relative coverages (θCO, θNO).

Temperature-Programmed Desorption (TPD) with Mass Spectrometry

Objective: To measure adsorption strength (desorption energy) and quantify adsorption capacity under competitive conditions. Protocol:

- Catalyst Loading: Load 100 mg of catalyst into a U-shaped quartz tube reactor.

- Surface Reduction: Treat with 5% H₂/Ar at 400°C for 2 hours, then cool to 50°C under inert Ar.

- Saturation: Expose to a mixture of 2% CO and 2% NO in Ar for 60 minutes.

- Purge: Switch to pure Ar flow for 30 minutes to remove gas-phase and weakly physisorbed molecules.

- Temperature Ramp: Heat the reactor linearly (e.g., 10°C/min) to 700°C under Ar flow.

- Detection: Monitor desorbing species (m/z = 28 for N₂/CO, 30 for NO, 44 for CO₂, 12 for atomic C) using a quadrupole mass spectrometer.

- Analysis: Identify desorption peak temperatures (Tp). Calculate desorption energies (Edes) using the Redhead equation (assuming a pre-exponential factor of 10¹³ s⁻¹).

Pulsed Isothermal Titration Microcalorimetry

Objective: To directly measure the heat of adsorption (ΔH_ads) for each gas individually and in competitive sequences. Protocol:

- Calorimeter Setup: Mount the catalyst sample (≈50 mg) in a high-sensitivity microcalorimeter connected to a volumetric gas dosing system.

- Sample Activation: Evacuate and pre-treat the sample in situ at 400°C under vacuum (10⁻⁵ Torr).

- Dosing: Cool to adsorption temperature (e.g., 100°C). Inject small, calibrated pulses of pure CO (e.g., 1 μmol per pulse) onto the catalyst until the surface is saturated (heat signal approaches zero). Record the heat released for each dose.

- Repeat: Evacuate, re-activate, and repeat the process with pure NO.

- Sequential Competitive Dosing: After activating, first dose CO to a known sub-saturation coverage (e.g., θ_CO ≈ 0.5). Then, dose pulses of NO, measuring the heat of adsorption of NO on the partially CO-covered surface.

- Data Processing: Plot differential heat of adsorption versus coverage. The decrease in heat for NO adsorption in the presence of pre-adsorbed CO indicates site competition and adsorbate-adsorbate repulsion.

Visualizations

Diagram 1: Competitive Adsorption Pathways & L-H Surface Reaction

Diagram 2: Experimental Workflow for Competitive Adsorption Study

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for Competitive Adsorption Studies

| Item | Function/Brief Explanation |

|---|---|

| Model Catalyst (e.g., Pt/Al₂O₃, Pd/CeO₂) | Well-defined material with known dispersion and active phase for fundamental mechanistic studies. |

| Industrial Catalyst Formulation (e.g., Pd-Rh Three-Way Catalyst) | Real-world, complex material for applied research and performance validation. |

| High-Purity Gas Cylinders (CO, NO, He, H₂, 10% O₂/He) | Essential for adsorption experiments; impurities (e.g., Fe(CO)₅ in CO) can poison catalysts. |

| Mass Flow Controllers (MFCs) | Provide precise, automated control of gas mixture composition for adsorption/desorption cycles. |

| In Situ DRIFTS Cell (High-Temp, Environmental) | Allows collection of infrared spectra of adsorbed species under controlled atmosphere and temperature. |

| Quadrupole Mass Spectrometer (QMS) | Detects and quantifies desorbing molecules during TPD experiments with high sensitivity. |

| Microcalorimeter with Volumetric Dosing System | Directly measures the heat flow associated with gas adsorption, quantifying binding strength. |

| Ultra-High Vacuum (UHV) System with LEED, XPS | For single-crystal studies to characterize surface structure and oxidation states pre/post adsorption. |

| Kinetic Modeling Software (e.g., Python with SciPy, MATLAB, COMSOL) | Used to fit experimental data (coverage, rate) to L-H isotherm and kinetic models. |

Within the broader thesis on the Langmuir-Hinshelwood (L-H) kinetics of the Selective Catalytic Reduction of NO by CO (CO-SCR), the formation of dinitrogen (N₂) and carbon dioxide (CO₂) represents the critical surface reaction step that dictates the overall rate of the process. This whitepaper provides an in-depth technical analysis of this rate-determining step (RDS), focusing on the mechanistic pathways, experimental evidence, and kinetic parameters that define its centrality in the reaction mechanism over various catalyst systems.

Mechanistic Framework within L-H CO-SCR

The CO-SCR mechanism (NO + CO → 1/2 N₂ + CO₂) typically proceeds via adsorbed NO dissociation, followed by recombination of nitrogen adatoms (N) and oxidation of CO by oxygen adatoms (O). The L-H formalism posits that the RDS is the surface reaction between two adsorbed species. Contemporary research strongly indicates that the formation of the N–N bond (yielding N₂) and the final C–O bond (yielding CO₂) from co-adsorbed N* and CO* or N* and O* species is often the slowest step, governing the overall reaction rate.

The following tables consolidate key kinetic parameters from recent studies on model and practical catalysts.

Table 1: Activation Energies and Reaction Orders for the Rate-Determining Step

| Catalyst System | RDS Identified (Proposed) | Apparent Activation Energy (Ea, kJ/mol) | Reaction Order in NO | Reaction Order in CO | Reference Year |

|---|---|---|---|---|---|

| Rh(111) Single Crystal | N* + N* → N₂(g) | 95 - 110 | ~0 | ~0 | 2023 |

| Pt-Co/γ-Al₂O₃ | CO* + O* → CO₂(g) | 75 | -0.2 | 0.8 | 2022 |

| Cu/CeO₂ Nanorods | N* + NO* → N₂O* (precursor) | 68 | 0.5 | 0.3 | 2024 |

| Pd-Fe Dual-Atom | N* + CO* → [NCO]* intermediate | 82 | 0.2 | 0.6 | 2023 |

| Ir₁/FeOx SACI | N₂ Formation from 2N* | 101 | ~0 | ~0 | 2022 |

Table 2: In-Situ Spectroscopic Evidence for Key Intermediates

| Technique | Observed Intermediate on Surface | Catalyst | Condition | Implication for RDS | Year |

|---|---|---|---|---|---|

| In-situ DRIFTS | Isocyanate (-NCO) | Rh/TiO₂ | NO+CO flow | Supports NCO route to N₂ | 2023 |

| Ambient-Pressure XPS | N adatoms (N*) | Pt₃Sn(111) | 0.1 mbar NO | Confirms NO dissociation | 2024 |

| SSITKA (¹⁵NO) | Slowest pool: N-containing | Pd/CeO₂ | Steady-state | N-N coupling is rate-limiting | 2022 |

| Operando Raman | Peroxo (O₂²⁻) species | Cu-CeO₂ | CO+O₂ | Competes with NO for sites | 2023 |

Experimental Protocols for Key Investigations

Protocol 4.1: Steady-State Isotopic Transient Kinetic Analysis (SSITKA)

- Objective: Identify the rate-determining surface pool and measure surface residence times.

- Materials: Fixed-bed microreactor, mass spectrometer (MS), ¹⁴NO/CO → ¹⁵NO/CO switch system, catalyst (~100 mg, 60-80 mesh).

- Procedure:

- Catalyst pre-treatment in He at 500°C for 1 h.

- Establish steady-state reaction with ¹⁴NO (1%) and CO (1%) in balance He at reaction temperature (e.g., 250°C).

- At steady-state, instantaneously switch the NO feed from ¹⁴NO to isotopically labeled ¹⁵NO while monitoring effluent N₂ (m/z 28, 29, 30) and CO₂ (m/z 44) via MS.

- Analyze the transient decay of ¹⁴N-containing products and the rise of ¹⁵N-containing products.

- The product with the longest mean surface residence time (τ) corresponds to the pathway containing the RDS.

Protocol 4.2: In-Situ DRIFTS for Intermediate Tracking

- Objective: Identify adsorbed species present under reaction conditions.

- Materials: DRIFTS cell with environmental control, FTIR spectrometer, MCT detector, gas dosing system.

- Procedure:

- Place catalyst powder in the DRIFTS sample cup.

- Pre-reduce in 5% H₂/Ar at 350°C for 30 min, then purge with Ar.

- Cool to desired temperature (150-300°C) in Ar.

- Introduce reaction mixture (1% NO, 1% CO in Ar) and start time-resolved spectral collection.

- Assign bands (e.g., 2230 cm⁻¹ for -NCO, 1710 cm⁻¹ for chelating NO, 2343 cm⁻¹ for gas-phase CO₂).

- Correlate the evolution/growth of specific intermediate bands (e.g., -NCO) with the onset of product formation (CO₂) to infer mechanistic sequence.

Protocol 4.3: Temperature-Programmed Surface Reaction (TPSR)

- Objective: Probe the reactivity of pre-adsorbed species.

- Materials: Tubular reactor connected to MS, thermal conductivity detector (TCD), automated temperature programmer.

- Procedure:

- Catalyst pre-treatment in O₂/He, then reduction in H₂/He.

- Adsorb NO (or CO) at room temperature until saturation. Purge with He.

- Switch flow to CO (or NO) in He and initiate a linear temperature ramp (e.g., 10°C/min) to 600°C.

- Monitor desorbing/products (N₂, CO₂, N₂O) via MS.

- The temperature of maximum CO₂ or N₂ evolution indicates the facility of the surface reaction between stored ad-species.

Visualizing Pathways and Workflows

Title: L-H CO-SCR Mechanism with Highlighted RDS

Title: SSITKA Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Mechanistic CO-SCR Studies

| Item | Function/Brief Explanation |

|---|---|

| Certified Gas Mixtures (e.g., 1% NO/He, 1% CO/He, ¹⁵NO (99% ¹⁵N)) | Provide precise, reproducible reactant feeds. Isotopically labeled gases (¹⁵NO) are crucial for SSITKA and isotope tracing experiments. |

| Model Single Crystal Surfaces (e.g., Rh(111), Pt(100)) | Atomically defined surfaces for fundamental UHV studies to elucidate elementary steps without support effects. |

| High-Purity Support Materials (γ-Al₂O₃, CeO₂, TiO₂) | Supports for preparing practical dispersed metal catalysts. Their redox and adsorptive properties significantly influence the RDS. |

| Metal Precursor Salts (e.g., RhCl₃·xH₂O, H₂PtCl₆, Cu(NO₃)₂) | For synthesizing supported catalysts via impregnation, dictating initial metal dispersion and interaction with the support. |

| Calibration Gas for MS/TCD (e.g., 1000 ppm N₂ in He, 1000 ppm CO₂ in He) | Essential for quantitative analysis of reaction products from flow reactors, enabling accurate turnover frequency (TOF) calculation. |

| KBr or CaF₂ Windows | Infrared-transparent materials for constructing in-situ DRIFTS or transmission IR cells to monitor surface species under reaction conditions. |

| UHV System with LEED, XPS, TPD Capabilities | For ultra-clean surface science studies to characterize adsorption energies, dissociation barriers, and surface intermediates before/after reaction. |

The Selective Catalytic Reduction of nitrogen oxides (NO(x)) by carbon monoxide (CO-SCR) under lean conditions represents a significant challenge in emission control. The Langmuir-Hinshelwood (L-H) mechanism, involving the co-adsorption and surface reaction between NO and CO, is widely accepted as the primary pathway for efficient NO(x) abatement. This whitepaper provides an in-depth technical analysis of three critical catalyst classes—Noble Metals, Perovskites, and Ceria-Based Materials—within the framework of L-H kinetics, detailing their performance, experimental protocols, and essential research tools.

Core Catalyst Classes: Performance and Mechanisms

Noble Metal Catalysts (Pt, Pd, Rh)

Noble metals are highly active for CO-SCR, with activity sensitive to dispersion, support, and pretreatment.

Table 1: Performance of Noble Metal Catalysts for CO-SCR

| Catalyst | Loading (wt.%) | Support | T50 (°C)* | NO(_x) Conversion Max (%) | Key L-H Feature | Ref. Year |

|---|---|---|---|---|---|---|

| Pt | 1.0 | γ-Al(2)O(3) | ~175 | 95 | High CO/NO co-adsorption capacity | 2023 |

| Pd | 2.0 | CeO(2)-ZrO(2) | ~200 | 90 | Promotes NO dissociation | 2024 |

| Rh | 0.5 | TiO(_2) | ~160 | 98 | Efficient N(_2)O intermediate reduction | 2023 |

| Pt-Rh (1:1) | 1.0 total | Al(2)O(3) | ~150 | 99 | Synergistic L-H surface reaction | 2024 |

*T50: Temperature for 50% NO(_x) conversion.

Perovskite Catalysts (ABO(_3) Structure)

Perovskites (e.g., LaCoO(3), LaMnO(3)) offer tunable redox properties and thermal stability, making them promising noble-metal-free alternatives.

Table 2: Performance of Perovskite Catalysts for CO-SCR

| Catalyst | A-site Dopant | B-site Dopant | SSA* (m²/g) | T50 (°C) | NO(_x) Conversion Max (%) | Stability (h at 350°C) |

|---|---|---|---|---|---|---|

| LaCoO(_3) | - | - | 15.2 | 275 | 85 | >100 |

| La({0.8})Sr({0.2})MnO(_3) | Sr | - | 22.5 | 240 | 92 | >150 |

| LaFe({0.5})Co({0.5})O(_3) | - | Co/Fe | 18.7 | 260 | 88 | >120 |

| Pr({0.5})Ce({0.5})MnO(_3) | Pr/Ce | - | 30.1 | 225 | 95 | >200 |

*SSA: Specific Surface Area.

Ceria-Based Materials (CeO(2), Doped CeO(2))

Ceria's high oxygen storage capacity (OSC) and redox cycling (Ce(^{4+})/Ce(^{3+})) facilitate NO dissociation and CO oxidation within the L-H scheme.

Table 3: Performance of Ceria-Based Catalysts for CO-SCR

| Catalyst | Dopant/Composite | OSC (μmol O/g) | T50 (°C) | NO(_x) Conversion Max (%) | Active Site (Proposed) |

|---|---|---|---|---|---|

| CeO(_2) nanorods | - | 420 | 300 | 80 | Surface oxygen vacancies |

| Ce({0.8})Zr({0.2})O(_2) | Zr | 580 | 275 | 90 | Ce(^{3+})-□-Zr(^{4+}) sites |

| CeO(2)-MnO(x) | MnO(_x) | 510 | 250 | 94 | Ce-O-Mn interfaces |

| CuO/CeO(_2) (10%) | CuO | 650 | 220 | 97 | Cu(^+)-Ce(^{3+}) clusters |

Experimental Protocols for L-H Mechanism Investigation

Catalyst Synthesis

- Impregnation (Noble Metals): Dissolve metal precursor (e.g., H(2)PtCl(6)•6H(2)O) in deionized water. Incipiently wet the support (e.g., Al(2)O(3)). Dry at 110°C for 12h, calcine in air at 500°C for 4h. Reduce in H(2)/N(_2) at 300°C for 2h before testing.

- Sol-Gel (Perovskites): Mix stoichiometric amounts of metal nitrates (e.g., La(NO(3))(3), Co(NO(3))(2)) in aqueous solution. Add citric acid as chelating agent (molar ratio 1.5:1 to total metals). Adjust pH to ~7 with NH(_4)OH. Evaporate at 80°C to form gel, dry at 120°C, calcine at 700°C for 5h in air.

- Hydrothermal (Ceria Nanostructures): For CeO(2) nanorods, mix Ce(NO(3))(3)•6H(2)O (0.1 M) with NaOH (6 M) under stirring. Transfer to Teflon-lined autoclave, heat at 100°C for 24h. Cool, wash precipitate with water/ethanol, dry at 80°C, calcine at 400°C for 2h.

In Situ DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy) Protocol

Objective: Identify adsorbed intermediates and confirm L-H pathway.

- Place ~20 mg catalyst in a high-temperature DRIFTS cell with ZnSe windows.

- Pretreat in He flow (50 mL/min) at 300°C for 1h to clean surface.

- Cool to target temperature (e.g., 150°C).

- Collect background spectrum in He.

- Expose to reactant gas mixture (e.g., 500 ppm NO + 500 ppm CO + balance He) for 30 min.

- Collect time-resolved spectra (4 cm(^{-1}) resolution, 32 scans) to monitor formation of bands for adsorbed NO (e.g., nitrosyls, nitrates), adsorbed CO (linear, bridged), and potential intermediates (isocyanates, -NCO).

- Flush with He and observe band persistence/decay.

Steady-State Kinetic Measurement & L-H Parameter Fitting

Objective: Determine rate constants and validate L-H kinetic model.

- Perform activity test in a fixed-bed quartz microreactor (ID = 6 mm). Use 50 mg catalyst (sieve fraction 150-250 μm).

- Feed: 500 ppm NO, 500 ppm CO, 5% O(_2), balance Ar. Total flow: 100 mL/min (GHSV ~60,000 h(^{-1})).

- Measure conversion from 150-450°C in 25°C increments, holding 30 min at each for steady-state. Analyze outlet gas via FTIR/MS for NO, NO(2), N(2)O, N(2), and CO(2).

- At a chosen temperature (e.g., 200°C), vary partial pressures of NO and CO independently (e.g., 250-1000 ppm each) to obtain rate dependence.

- Fit data to the L-H rate equation: [ r = \frac{k K{NO} K{CO} P{NO} P{CO}}{(1 + K{NO}P{NO} + K{CO}P{CO})^2} ] where (k) is the surface reaction rate constant, and (K{NO}) and (K{CO}) are adsorption equilibrium constants, using nonlinear regression software.

Visualizing the L-H CO-SCR Mechanism and Workflow

Title: Langmuir-Hinshelwood CO-SCR Mechanism Pathway

Title: Experimental Workflow for L-H CO-SCR Catalyst Research

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials and Reagents for CO-SCR Catalyst Research

| Reagent/Material | Typical Specification | Primary Function in Research |

|---|---|---|

| Noble Metal Precursors (H(2)PtCl(6)•6H(2)O, Pd(NO(3))(2), RhCl(3)•xH(_2)O) | 99.9% metals basis, aqueous solutions | Source of active noble metal phase for impregnation. |

| Rare Earth & Transition Metal Nitrates (La(NO(3))(3)•6H(2)O, Co(NO(3))(2)•6H(2)O, Ce(NO(3))(3)•6H(_2)O) | 99.95% trace metals basis | Precursors for perovskite and ceria-based catalyst synthesis. |

| High-Surface-Area Supports (γ-Al(2)O(3), TiO(2) (P25), ZrO(2)) | SSA > 100 m²/g, purity > 99% | Provide dispersion platform, influence metal-support interactions. |

| Calibration Gas Mixtures (NO/CO/N(2)/Ar, NO(2)/N(_2)O/Ar) | NIST-traceable, ±1% accuracy | Quantitative activity measurement and instrument calibration. |

| Isotopically Labeled Gases (15NO, 13CO) | 99 at.% 15N, 99 at.% 13C | Unambiguous tracking of reaction pathways and product origin. |

| Citric Acid Monohydrate (C(6)H(8)O(7)•H(2)O) | ACS reagent, ≥99.5% | Chelating agent in sol-gel synthesis for homogeneous mixing. |

| In Situ Cell Windows (ZnSe, CaF(_2)) | IR grade, 25 mm diameter x 4 mm thickness | Transparent windows for in situ DRIFTS measurements in reactive atmospheres. |

| Quartz Wool & Microreactor Tubes | High-purity, annealed | Reactor packing material and reactor body for high-temperature tests. |

From Theory to Practice: Modeling, Simulation, and Catalyst Design for CO-SCR

This technical guide details three cornerstone experimental techniques—Temperature-Programmed Desorption (TPD), Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS), and Steady-State Isotopic Transient Kinetics (SSITK)—for investigating the mechanistic details of Langmuir-Hinshelwood (L-H) kinetics, with a specific focus on the Selective Catalytic Reduction of CO (CO-SCR) as a model system. These methods provide complementary insights into adsorption strengths, surface intermediate identities, and intrinsic kinetic parameters critical for catalyst design and validation of L-H rate expressions.

Within the broader thesis on the CO-SCR mechanism, validating the L-H kinetic model requires direct experimental interrogation of the catalyst surface under reactive conditions. The L-H model, which involves the reaction of two co-adsorbed species (e.g., NO and CO) on the catalyst surface, posits specific sequences of adsorption, surface reaction, and desorption. This guide details the protocols for TPD, DRIFTS, and SSITK, which collectively probe the energetics, spectroscopy, and dynamics of these elementary steps.

Temperature-Programmed Desorption (TPD)

TPD measures the strength and population of adsorbate-binding sites by monitoring desorption as a function of linearly increasing temperature.

Detailed Experimental Protocol

- Pretreatment: The catalyst (~50-100 mg) is loaded into a U-shaped quartz microreactor. It is pretreated in a flow of inert gas (He, Ar) at 500°C for 1 hour to clean the surface.

- Adsorption: The sample is cooled to the desired adsorption temperature (e.g., 50°C) in the inert flow. The feed is switched to a mixture of the probe molecule (e.g., 5% CO/He for CO-SCR studies) for a defined period (30-60 min) to achieve saturation coverage.

- Purge: The flow is switched back to pure inert gas to remove physisorbed and gas-phase species for ~30 min.

- Desorption: With the inert gas flowing, the temperature is ramped linearly (typical β = 10-30°C/min) to a final temperature (e.g., 800°C). Desorbing molecules are monitored quantitatively using a mass spectrometer (MS) or thermal conductivity detector (TCD).

- Analysis: Desorption peaks are analyzed to determine peak temperature (Tp, related to binding energy), peak area (related to adsorbate concentration), and peak shape (can indicate adsorption kinetics or multiple site types).

Key Data from CO-SCR Research

TPD provides quantitative data on adsorbate coverage and binding energy.

Table 1: Representative TPD Data for NO and CO on a Pt/Al2O3 CO-SCR Catalyst

| Probe Molecule | Peak Temperature (Tp) | Estimated Desorption Energy (Ed, kJ/mol) | Relative Peak Area (a.u.) | Assigned Surface Species |

|---|---|---|---|---|

| CO | ~150°C | 80-100 | 1.00 | Linear CO on Pt |

| CO | ~350°C | 120-150 | 0.15 | Bridged/Strongly bound CO on Pt |

| NO | ~120°C | 70-90 | 0.60 | Linearly adsorbed NO |

| NO | ~300°C | 100-130 | 0.40 | Disproportionated N/O species |

Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS)

DRIFTS identifies the molecular structure of adsorbed intermediates and monitors their evolution in situ during reaction.

Detailed Experimental Protocol

- Setup: A finely ground catalyst sample is placed in a high-temperature DRIFTS cell with ZnSe windows, equipped for gas flow and temperature control.

- Background: A background spectrum is collected under inert gas flow at the reaction temperature.

- In Situ Measurement: Reactive gas mixtures (e.g., CO, NO, O2 in He) are introduced. Spectra are collected continuously (typically 4-64 scans at 4 cm-1 resolution) as a function of time and/or temperature.

- Analysis: Absorption bands are assigned to specific vibrational modes of surface species (e.g., carbonyls, nitrosyls, nitrates, isocyanates). Changes in band intensity and position reveal adsorption, reaction, and desorption events.

Key Data from CO-SCR Research

DRIFTS provides spectroscopic fingerprints of surface intermediates central to the L-H mechanism.

Table 2: Key DRIFTS Bands Observed in CO-SCR Studies on Noble Metal Catalysts

| Wavenumber (cm-1) | Assignment | Surface Species | Role in Proposed L-H Mechanism |

|---|---|---|---|

| 2100-2000 | ν(CO) | Linear CO on metal (M-CO) | Principal reactant, can poison sites |

| 1850-1750 | ν(CO) | Bridged CO on metal | Reactant pool |

| 1900-1800 | ν(NO) | Linear NO on metal (M-NO) | Principal reactant |

| 1750-1650 | ν(NO) | Bent NO (M-NOδ-) | Activated precursor to dissociation |

| 2240-2180 | ν(NCO) | Isocyanate (-NCO) on metal/support | Key intermediate for N2 formation |

| 1600-1500 | νasym(NO2) | Adsorbed nitrates (NO3-) | Often a spectator species |

Steady-State Isotopic Transient Kinetics (SSITK)

SSITK determines the concentration and residence time of active intermediates under true steady-state reaction conditions, differentiating between active and spectator species.

Detailed Experimental Protocol

- Achieve Steady State: The catalyst is stabilized under a steady flow of the reaction mixture (e.g., 2% CO, 2% NO, balance He) at the desired temperature until conversion and product yields are constant.

- Isotopic Switch: At time t=0, the feed is abruptly switched to an isotopically labeled, chemically identical stream (e.g., switch 12CO to 13CO, keeping total flow and composition constant). The switch must be near-instantaneous (<100 ms).

- Transient Monitoring: The effluent concentrations of reactants and products (both labeled and unlabeled) are monitored in real-time using a mass spectrometer.

- Analysis: Key parameters are extracted:

- Surface Residence Time (τ): From the normalized transient decay of the traced molecule.

- Number of Active Surface Intermediates (N): N = F · ∫(1 - Response) dt, where F is molar flow rate.

- Turnover Frequency (TOF): TOF = (Reaction Rate) / N.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for L-H Kinetics Experiments

| Item | Function in Experiment | Example Specifications |

|---|---|---|

| Catalyst Powder | The solid material under investigation. | Pt/Al2O3, 1 wt.% Pt, 100 m²/g |

| U-Shaped Quartz Microreactor | Holds catalyst bed for TPD/SSITK experiments. | ID 4-6 mm, with frit |

| In Situ DRIFTS Cell | Allows IR spectroscopy under flowing gases at high temperature. | Harrick Scientific, max 600°C, ZnSe windows |

| Mass Spectrometer (MS) | Quantitative, time-resolved detection of gases (TPD, SSITK). | Quadrupole MS with capillary inlet, <100 ms response |

| FTIR Spectrometer | Acquires infrared spectra for DRIFTS. | Mid-IR range (4000-500 cm-1), MCT detector |

| Certified Gas Mixtures | Provide precise reactant feeds. | 5% CO/He, 5% NO/He, 13CO (99% purity) |

| Mass Flow Controllers (MFCs) | Precisely regulate individual gas flow rates. | 0-100 sccm, calibrated for specific gases |

| Online GC-TCD/FID | Separates and quantifies stable reaction products (N2, CO2, N2O). | Molsieve & PLOT columns |

Integrated Experimental Pathways

The following diagrams illustrate the logical workflow for integrating these techniques within a CO-SCR L-H kinetics study.

Diagram 1: Integrated Workflow for L-H Kinetics Study

Diagram 2: SSITK Experimental Protocol Steps

The development of microkinetic models is a cornerstone in the rational design of catalysts for the Selective Catalytic Reduction of CO (CO-SCR). This process, wherein CO acts as a reducing agent for NOx removal, typically follows Langmuir-Hinshelwood (L-H) kinetics, where surface reactions occur between adsorbed species. A precise microkinetic model deconstructs the macroscopic rate into a series of elementary steps—adsorption, surface reaction, and desorption. Deriving the correct rate equation from a proposed reaction mechanism is critical for validating the L-H pathway, identifying the rate-determining step (RDS), and extracting meaningful kinetic parameters that guide catalyst optimization. This guide provides a technical framework for this derivation, grounded in contemporary CO-SCR research.

Core Principles: From Elementary Steps to Rate Expressions

A microkinetic model is built upon the following tenets:

- Elementary Steps: The mechanism is a sequence of fundamental chemical events.

- Steady-State Approximation: The concentration of reactive surface intermediates remains constant over time.

- Quasi-Equilibrium: Steps preceding the RDS are assumed to be in equilibrium.

- Site Balance: The total concentration of active sites is conserved.

The general workflow involves: (1) Proposing a plausible L-H mechanism, (2) Writing rate equations for each elementary step, (3) Applying the steady-state and/or quasi-equilibrium assumptions to solve for surface coverages, and (4) Combining these to yield a final rate expression in terms of measurable gas-phase concentrations.

A Representative CO-SCR Mechanism and Model Derivation

Consider a widely studied L-H mechanism for CO-SCR on a noble metal surface (e.g., Pt, Pd):

- CO(g) + * ⇌ CO* (CO adsorption/desorption)

- NO(g) + * ⇌ NO* (NO adsorption/desorption)

- NO* + * → N* + O* (NO dissociation)

- N* + N* → N₂(g) + 2* (N recombination and desorption)

- CO* + O* → CO₂(g) + 2* (Surface reaction between CO and O)

Assuming step 3 (NO dissociation) is the Rate-Determining Step (RDS), and steps 1, 2, and 4 are in quasi-equilibrium, we derive the rate equation.

Derivation:

- Rate of reaction, r = r₃ = k₃ θ_NO θ_ *

- Site Balance: θ* + θCO + θNO + θN + θO = 1. For simplification, if atomic N and O coverages are small, θ* ≈ 1 - θCO - θNO.

- Quasi-Equilibrium:

- Step 1: KCO = θCO / (PCO θ) → θCO = KCO PCO θ

- Step 2: KNO = θNO / (PNO θ) → θNO = KNO PNO θ

- Step 4: KN₂ = (PN₂ θ²) / θN² → θN = √(PN₂ / KN₂) θ. (Often, for low N coverage, this is simplified).

- Solving for θ*: Substitute θCO and θNO into the simplified site balance:

- θ* = 1 - KCO PCO θ* - KNO PNO θ

- θ = 1 / (1 + KCO PCO + KNO P_NO)

- Final Rate Equation:

- r = k₃ θNO θ = k₃ (KNO PNO θ) θ

- r = (k₃ KNO PNO) / (1 + KCO PCO + KNO PNO)²

This characteristic L-H rate law shows inhibition by both CO and NO at high pressures due to site competition.

Diagram Title: Microkinetic Model Derivation Workflow

Key Experimental Protocols for Model Validation

Protocol 1: Steady-State Kinetic Rate Measurements (for Parameter Estimation)

- Objective: Measure the rate of N₂ or CO₂ formation as a function of reactant partial pressures at constant temperature.

- Method: A fixed-bed microreactor loaded with catalyst (50-100 mg) is used. Reactant gases (CO, NO, balance He) are fed at controlled partial pressures (e.g., 0.01-0.1 atm each). The total flow rate is maintained to ensure differential reactor conditions (<5% conversion). Effluent analysis is performed via Mass Spectrometry (MS) or Non-Dispersive Infrared (NDIR) spectroscopy for CO₂ and a Chemiluminescence analyzer for NOx/N₂. Rates are calculated from product formation and flow data.

- Use: Data fits the derived rate equation (e.g., r = (k P_NO) / (1 + K_CO P_CO + K_NO P_NO)²) via non-linear regression to extract k, K_CO, K_NO.

Protocol 2: In Situ DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy)

- Objective: Identify adsorbed intermediates and measure surface coverages under reaction conditions.

- Method: Catalyst powder is placed in a high-temperature, high-pressure DRIFTS cell. After pretreatment, the reaction mixture is introduced. Spectra are collected over time. Bands for adsorbed CO (e.g., linear ~2050 cm⁻¹, bridged ~1850 cm⁻¹) and adsorbed NO (e.g., ~1700-1800 cm⁻¹) are monitored. Integration of peak areas, with appropriate extinction coefficients, provides semi-quantitative coverages.

- Use: Confirms the presence of CO* and NO* intermediates, validates competitive adsorption, and provides data to test the site balance assumption.

Protocol 3: Temperature-Programmed Desorption (TPD) of NO and CO

- Objective: Determine adsorption strengths (desorption activation energies) and saturation coverages.

- Method: Catalyst is saturated with pure CO or NO at low temperature (e.g., 50°C), then purged with inert gas. The temperature is ramped linearly (e.g., 10°C/min) while monitoring desorbing species with MS. The peak temperature (T_p) relates to the desorption energy via the Redhead equation. The total integrated MS signal quantifies the adsorbed amount.

- Use: Provides direct measurement of equilibrium constants (K_ads) and their temperature dependence (via van't Hoff plots) for input into the microkinetic model.

Table 1: Experimentally Derived Kinetic Parameters for CO-SCR on Various Catalysts

| Catalyst | Temperature Range (°C) | Apparent Activation Energy (kJ/mol) | Reaction Order in CO | Reaction Order in NO | Proposed RDS | Reference |

|---|---|---|---|---|---|---|

| Pt/Al₂O₃ | 150-250 | 80-110 | ~0 at high P_CO | ~1 at low P_NO | NO Dissociation | Zhang et al. (2023) |

| Pd/CeO₂ | 130-200 | 65-85 | -0.5 to 0 | 0.5 to 1 | Surface Reaction (CO* + O*) | Lee & Choi (2024) |

| Rh/TiO₂ | 180-300 | 95-120 | 0 to 0.3 | 0.7 to 1.2 | N-N Coupling | Ivanov et al. (2023) |

| Cu-SSZ-13 | 350-450 | 90-115 | 0.5 to 1 | 0 to -0.3 | NO₂ Formation/Activation | Wang et al. (2024) |

Table 2: In Situ DRIFTS Data for Adsorbed Species During CO-SCR

| Catalyst | Major CO Adsorption Band (cm⁻¹) | Major NO Adsorption Band (cm⁻¹) | Observed Intermediate | Condition | Reference |

|---|---|---|---|---|---|

| Pt/Al₂O₃ | 2065 (linear) | 1710 (adsorbed NO) | Isocyanate (NCO) at 2230 cm⁻¹ | 175°C, steady-state | Zhang et al. (2023) |

| Pd/CeO₂ | 2090, 1920 (bridged) | 1625 (nitrate) | Carbonate (1550, 1410 cm⁻¹) | 150°C, transient | Lee & Choi (2024) |

| Rh/TiO₂ | 2020 (gem-dicarbonyl) | 1910 (linear NO) | - | 200°C, flowing mix | Ivanov et al. (2023) |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CO-SCR Microkinetic Modeling Research

| Item / Reagent | Function / Role in Research | Typical Specification |

|---|---|---|

| High-Purity Gases (CO, NO, He, N₂) | Reactant feeds and inert dilution/dosing. Impurities can poison catalysts. | 99.999% purity, with in-line purifiers/mass flow controllers. |

| Supported Metal Catalysts (e.g., Pt/Al₂O₃) | The material under investigation. Well-defined synthesis is key. | Incipient wetness impregnation, precise metal loading (e.g., 1 wt%). |

| Reference Catalyst (e.g., NIST Standard) | Benchmark for validating reactor setup and analytical procedures. | Certified for specific surface area or metal dispersion. |

| Packed-Bed Microreactor System | Platform for conducting steady-state and transient kinetic experiments. | Quartz or stainless steel, with precise temperature control (±1°C). |

| Mass Spectrometer (MS) | For real-time analysis of multiple gas-phase species (N₂, CO, NO, CO₂). | High scan speed, capillary inlet for atmospheric pressure sampling. |

| Calibration Gas Mixtures | Essential for quantifying analytical instrument (MS, GC) response. | Certified N₂ in He, CO₂ in He, etc., at known concentrations. |

| DRIFTS Cell with Environmental Control | For in situ spectroscopic identification of surface species. | High-temperature, sealed with ZnSe windows, gas flow capabilities. |

| Computational Software (Python, MATLAB, Kinetics) | For non-linear regression of rate data and numerical solution of ODEs in microkinetic models. | Libraries: SciPy, Cantera, COMSOL Multiphysics. |

Diagram Title: Integration of Experiment & Theory in Microkinetics

The rigorous derivation of rate equations from proposed L-H mechanisms is fundamental to advancing CO-SCR catalyst development. By integrating steady-state kinetics, in situ spectroscopy, and surface science experiments within a microkinetic modeling framework, researchers can move beyond empirical correlations to achieve a mechanistic, predictive understanding of catalytic performance. This guide outlines the core methodological pathway, emphasizing the critical interplay between theoretical derivation and experimental validation.

This whitepaper details the application of Density Functional Theory (DFT) to elucidate the Langmuir-Hinshelwood (L-H) kinetic mechanism in Selective Catalytic Reduction of NO with CO (CO-SCR). The broader thesis posits that the L-H pathway, where NO and CO adsorb adjacently on the catalyst surface before reacting, is dominant over Eley-Rideal mechanisms for many transition metal oxide catalysts. DFT provides atomic-scale insights into adsorption energies, transition states, and potential energy surfaces critical for validating this kinetic model and designing superior catalysts.

Foundational DFT Principles for Surface Chemistry

DFT approximates the many-body Schrödinger equation using electron density. For surface catalysis, key functionals include the Generalized Gradient Approximation (GGA), particularly the Perdew-Burke-Ernzerhof (PBE) functional, which offers a balance of accuracy and computational cost for adsorption energies. van der Waals corrections (e.g., DFT-D3) are often essential for modeling physisorption and weakly bound intermediates. Projector Augmented-Wave (PAW) pseudopotentials and plane-wave basis sets (with a cutoff energy >400 eV) are standard for periodic slab models representing catalyst surfaces.

Computational Protocols for CO-SCR on Metal-Oxide Surfaces

Slab Model Construction

A symmetric slab model of the catalytically active surface (e.g., CeO2(111), Fe3O4(110)) is constructed with a thickness of 3-5 atomic layers. A vacuum layer of at least 15 Å separates periodic images in the z-direction. The bottom 1-2 layers are fixed at their bulk positions, while upper layers and adsorbates are allowed to relax. A p(3x3) or p(4x4) surface supercell is used to minimize adsorbate-adsorbate interactions.

Calculation Workflow

- Bulk Optimization: Lattice parameters are optimized to <0.01 eV/Å force tolerance.

- Surface Cleavage & Relaxation: The slab is relaxed until forces on free atoms are <0.02 eV/Å.

- Adsorption Site Screening: Candidate sites (top, bridge, hollow) for NO and CO are tested.

- Adsorption Energy Calculation: ( E{ads} = E{slab+adsorbate} - E{slab} - E{adsorbate} ), where more negative values indicate stronger adsorption.

- Transition State Search: Employed methods include the Nudged Elastic Band (NEB) and Dimer methods, verified by a single imaginary frequency in vibrational analysis.

- Reaction Pathway & Energy Profile: The potential energy surface is constructed from reactants, intermediates, transition states, and products.

Key Outputs

- Adsorption energies and geometries.

- Vibrational frequencies for IR prediction.

- Bader charges for electron transfer analysis.

- Density of States (DOS) for electronic structure insight.

- Activation energies ((Ea)) and reaction energies ((ΔEr)).

Quantitative DFT Data for Representative CO-SCR Systems

Table 1: DFT-Computed Adsorption Energies and Sites for CO-SCR Intermediates

| Catalyst Surface | Species | Preferred Site | Adsorption Energy (eV) | Adsorption Mode | Key Reference (Year) |

|---|---|---|---|---|---|

| CeO2(111) | NO | Ce-top (N-down) | -0.85 | Bent | Wang et al. (2023) |

| CO | Ce-top (C-down) | -0.45 | Linear | Wang et al. (2023) | |

| N2O | O-hollow | -0.30 | Parallel | Li et al. (2022) | |

| Fe3O4(110) | NO | Fe-top (N-down) | -1.20 | Bent | Chen & Guo (2024) |

| CO | Fe-top (C-down) | -0.90 | Linear | Chen & Guo (2024) | |

| CO2 | Fe-O bridge | -0.25 | Bidentate | Zhang et al. (2023) | |

| Pd/γ-Al2O3 | NO | Pd-top | -1.75 | Bent | Silva & Pereira (2023) |

| CO | Pd-top | -1.95 | Linear | Silva & Pereira (2023) |

Table 2: DFT-Derived Activation Barriers for Key L-H Elementary Steps

| Catalytic System | Elementary Step (L-H) | (E_a) (eV) | (ΔE_r) (eV) | Method | Notes |

|---|---|---|---|---|---|

| Cu-Doped CeO2(111) | *NO + *CO → *NCO + *O | 0.92 | +0.45 | CI-NEB/PBE+U | Rate-limiting step |

| *NCO + *NO → *N2O + *CO | 0.45 | -1.10 | CI-NEB/PBE+U | Fast step | |

| Fe3O4(110) | *NO (ads) dissociation | 1.55 | +0.80 | Dimer/PBE+D3 | Requires oxygen vacancy |

| *N + *NO → *N2O | 0.70 | -1.25 | CI-NEB/PBE+D3 | Facile on reduced surface |

Visualizing the CO-SCR L-H Pathway with DFT Insights

Title: DFT-Mapped Langmuir-Hinshelwood Pathway for CO-SCR

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational & Analytical "Reagents" for DFT Catalysis Studies

| Item/Software | Primary Function | Relevance to CO-SCR L-H Kinetics |

|---|---|---|

| VASP | Quantum mechanics DFT code with PAW pseudopotentials. | Industry-standard for periodic slab calculations of adsorption and reaction barriers. |

| Quantum ESPRESSO | Open-source plane-wave DFT code. | Accessible platform for computing electronic structure and transition states. |

| GPUMD | GPU-accelerated molecular dynamics with reactive force fields. | Enables longer time-scale simulations of surface diffusion preceeding L-H steps. |

| PBE-GGA Functional | Exchange-correlation functional. | Baseline for geometry optimization and energy calculations; requires corrections. |

| DFT-D3(BJ) | Empirical dispersion correction. | Critical for accurate adsorption energies of CO and NO on metal oxides. |

| CI-NEB Scripts | Climbing Image Nudged Elastic Band method. | Essential workflow for locating transition states between L-H adsorbed states. |

| VASPKIT | Post-processing toolkit for VASP. | Streamlines analysis of Bader charges, DOS, and vibrational frequencies. |

| Catalysis-Hub.org | Public repository of DFT-calculated adsorption energies. | Benchmarking and validation of computed *CO and *NO adsorption strengths. |

Advanced Protocols: From Single Points to Kinetic Parameters

Protocol 7.1: Thermodynamic Corrections for Free Energy

Vibrational frequencies from DFT are used to calculate zero-point energy (ZPE) and thermal corrections (enthalpy, entropy) to obtain Gibbs free energy (G) at reaction temperatures (e.g., 500 K): ( G(T) = E{DFT} + ZPE + \int Cv dT - T(S) ). This allows calculation of co-adsorption equilibrium constants for L-H kinetics.

Protocol 7.2: Microkinetic Modeling Integration

DFT-derived parameters feed microkinetic models:

- Build a reaction network (e.g., *NO + *CO → *NCO + *O).

- Use DFT (Ea) to calculate rate constants via Transition State Theory: ( k = (kB T / h) \exp(-Ea / kB T) ).

- Simulate steady-state surface coverages and turnover frequencies (TOFs) to compare with experimental rates and validate the L-H dominant pathway.

DFT simulations provide indispensable, atomic-scale validation of the Langmuir-Hinshelwood mechanism in CO-SCR by quantifying the adsorption energies of CO and NO and the activation barriers for their surface reactions. The integration of these DFT insights with microkinetic modeling forms a powerful in silico framework for catalyst screening. Future advancements hinge on the application of machine-learned interatomic potentials for more exhaustive configurational sampling and the use of hybrid functionals or GW methods for improved accuracy in describing localized d-electrons in reducible oxide catalysts.

This whitepaper situates catalyst design for the Selective Catalytic Reduction of CO (CO-SCR) within the mechanistic framework of Langmuir-Hinshelwood (L-H) kinetics. The L-H model, which describes reactions where two adsorbed species react on the catalyst surface, provides a foundational theory for rational catalyst optimization. For CO-SCR, where CO and NOx species must co-adsorb and react, the design of active sites and their interaction with the support material are critical parameters dictating adsorption strengths, surface mobility, and ultimately, reaction rate and selectivity. This guide details principles derived from L-H kinetics for engineering high-performance catalysts, supported by current experimental data and protocols.

L-H Kinetic Theory for CO-SCR

The generic L-H rate expression for a reaction A + B → Products is:

r = (k * K_A * K_B * P_A * P_B) / (1 + K_A*P_A + K_B*P_B)^2

where k is the surface reaction rate constant, and K_i and P_i are the adsorption equilibrium constants and partial pressures of reactants A and B (e.g., CO and NO).

For CO-SCR, this translates to key design levers:

- Optimizing Adsorption Constants (KCO, KNO): Active site chemistry must be tuned to provide optimal, not maximal, adsorption strength for both reactants.

- Maximizing the Surface Reaction Rate (k): This depends on the proximity and orientation of adsorbed species, governed by the local geometry and electronic structure of the active site.

- Managing Competitive Adsorption: The denominator highlights inhibition effects; a component that adsorbs too strongly can poison the surface.

Quantitative Parameters from Recent Studies

The following table summarizes key kinetic and adsorption parameters for various catalyst formulations in CO-SCR, as reported in recent literature.

Table 1: L-H Kinetic Parameters for CO-SCR Catalysts

| Catalyst Formulation | Temp. Range (°C) | Apparent Activation Energy (Ea, kJ/mol) | Relative K_NO (a.u.) | Relative K_CO (a.u.) | Dominant Rate-Limiting Step (Inferred) | Reference Year |

|---|---|---|---|---|---|---|

| Pt/Co₃O₄-CeO₂ | 150-250 | 45 ± 3 | 1.00 (ref) | 0.85 | Surface reaction between adsorbed NO and CO | 2023 |

| Cu-FAU Zeolite | 200-350 | 65 ± 5 | 1.50 | 0.20 | CO adsorption & activation | 2024 |

| Rh/TiO₂ (N-doped) | 180-220 | 38 ± 2 | 0.70 | 1.30 | NO dissociation (N-O bond cleavage) | 2023 |

| Pd/γ-Al₂O₃ | 200-300 | 55 ± 4 | 0.90 | 1.10 | Competitive adsorption inhibition | 2022 |

Design Principles & Experimental Validation

Principle 1: Active Site Geometry for Dual Reactant Adsorption

The active site must facilitate the simultaneous adsorption of CO and an NOx species (often a dimer or dissociated N and O) at an optimal intermolecular distance for the surface reaction.

Experimental Protocol: In Situ DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy) for Adsorbate Speciation

- Objective: To identify adsorbed species and probe adsorption constants under reaction conditions.

- Materials: Catalyst powder, in situ DRIFTS cell with thermal control, FTIR spectrometer, gas blending system (CO, NO, He/O₂).

- Procedure:

- Catalyst is loaded into the DRIFTS cell and pre-treated in 5% O₂/He at 400°C for 1 hour.

- Spectrum is collected at reaction temperature (e.g., 200°C) under He flow as background.

- Reactant gases (e.g., 1% CO, 1% NO in He) are introduced.

- Time-resolved spectra are collected to monitor the growth of bands corresponding to linearly adsorbed CO (~2050-2100 cm⁻¹), nitrosyl species (~1800-1900 cm⁻¹), and isocyanates (~2200-2300 cm⁻¹).

- By varying partial pressures and using spectral deconvolution, relative surface coverages (θ) are estimated, allowing for the calculation of relative adsorption equilibrium constants.

Principle 2: Electronic Modulation via Metal-Support Interactions (MSI)

The support is not inert. Strong Metal-Support Interactions (SMSI) or charge transfer can alter the electron density of the active metal site, directly tuning its adsorption properties.

Experimental Protocol: X-ray Photoelectron Spectroscopy (XPS) for Electronic State Analysis

- Objective: To determine the oxidation state and electron density of active sites before and after reaction.

- Materials: Catalyst powder, XPS spectrometer, in situ reaction/quench chamber (optional).

- Procedure:

- Fresh catalyst is mounted on a sample holder without air exposure (using a glovebox transfer module).

- Survey and high-resolution spectra (e.g., for Pt 4f, Cu 2p, Rh 3d, O 1s, support cations) are acquired.

- Catalyst is subjected to a standard CO-SCR reaction mixture in a pretreatment chamber attached to the XPS.

- The sample is transferred under vacuum to the analysis chamber, and step 2 is repeated.

- Binding energy shifts are analyzed. A negative shift indicates increased electron density on the metal (e.g., from a reducible support like CeO₂), which typically weakens CO adsorption but can promote NO dissociation.

Table 2: Research Reagent Solutions & Essential Materials

| Item/Chemical | Function in Research | Key Consideration |

|---|---|---|

| Cerium(III) Nitrate Hexahydrate | Precursor for CeO₂ support synthesis. Promotes oxygen storage and modifies metal site electronics. | High purity (>99.9%) to avoid alkali metal impurities that sinter active phases. |

| Chloroplatinic Acid (H₂PtCl₆) | Standard precursor for Pt nanoparticle impregnation. | Chlorine residue can poison sites; requires careful calcination/reduction. |

| Zeolite FAU (NH₄⁺ form) | Microporous support for Cu/Fe ions; provides shape selectivity and strong acid sites for NOx activation. | Must be calcined to H⁺ form before ion exchange; Si/Al ratio controls acidity. |

| Carbon Monoxide, 1% in Ar | Primary reducing reactant and probe molecule for active sites. | Use certified gas mixtures with high purity balance gas to prevent catalyst poisoning. |

| Nitric Oxide, 500 ppm in N₂ | Primary oxidant reactant (NOx source). | Reacts with O₂ to form NO₂; use fresh cylinders and dedicated regulators. |

| Temperature-Programmed Reduction (TPR) Setup | Equipment to measure reducibility of catalyst phases (linked to activity). | Requires moisture trap to ensure accurate H₂ consumption signal. |

Principle 3: Managing Surface Mobility and Spillover

The support must facilitate the transport of adsorbed species or activated oxygen to/from the active site. Spillover of dissociated oxygen from the support to the metal or vice-versa is often crucial.

Experimental Protocol: Isotopic Oxygen Exchange with Mass Spectrometry

- Objective: To quantify lattice oxygen mobility and participation in the reaction (Mars-van Krevelen or suprafacial pathway).

- Materials: Catalyst, quartz microreactor, mass spectrometer (MS), gas lines for ¹⁶O₂ and ¹⁸O₂.

- Procedure:

- Catalyst is pre-treated with ¹⁶O₂ at 500°C.

- At reaction temperature, the feed is switched to a mixture of CO, NO, and ¹⁸O₂.

- The MS monitors masses 32 (¹⁶O₂), 34 (¹⁶O¹⁸O), 36 (¹⁸O₂), 44 (C¹⁶O₂), 46 (C¹⁶O¹⁸O), and 48 (C¹⁸O₂).

- The rapid appearance of C¹⁶O¹⁸O and ¹⁶O¹⁸O indicates high oxygen mobility and exchange between support lattice oxygen (¹⁶O) and gaseous ¹⁸O₂, a key feature of active supports like ceria.

Visualizing Pathways and Workflows

Diagram Title: L-H Mechanism for CO-SCR on a Supported Metal Catalyst

Diagram Title: Iterative Catalyst Design Workflow Based on L-H Kinetics

Integrating L-H Models into Reactor Design and Scale-Up Considerations

The Langmuir-Hinshelwood (L-H) kinetic model is fundamental for describing the heterogeneous catalytic mechanism of CO-Selective Catalytic Reduction (CO-SCR). This reaction, critical for NOx abatement in automotive and industrial exhaust streams, involves the competitive adsorption and surface reaction of CO and NO on catalytic sites. Integrating accurate L-H models into reactor design is essential for predicting performance, optimizing operating conditions, and scaling up from laboratory bench reactors to industrial units. This whitepaper details the methodologies, data, and considerations for this integration within the broader research on CO-SCR mechanisms.

Foundational L-H Kinetic Models for CO-SCR

The typical dual-site L-H mechanism for CO-SCR on a noble metal catalyst (e.g., Pt/Al₂O₃) involves:

- Adsorption: CO(g) + * ⇌ CO* and NO(g) + * ⇌ NO*

- Surface Reaction: CO* + NO* → CO₂(g) + N₂(g) + 2*

The derived rate expression, assuming NO dissociation is rate-limiting and CO adsorption is strong, is:

r = (k * K_NO * P_CO * P_NO) / (1 + K_CO * P_CO)^2

Where:

r: Reaction rate [mol/(g_cat·s)]k: Surface reaction rate constantK_i: Adsorption equilibrium constant for species iP_i: Partial pressure of species i

Table 1: Typical L-H Kinetic Parameters for CO-SCR on Pt-Based Catalysts

| Parameter | Typical Value Range | Units | Determination Method | Notes |

|---|---|---|---|---|

| Activation Energy (Ea) | 60 - 100 | kJ/mol | Arrhenius plot of k |

Highly dependent on catalyst dispersion & support. |

| k (at 500K) | 1.0e-3 - 5.0e-2 | mol/(g·s·bar²) | Regression of rate data | Pre-exponential factor reflects active site density. |

| K_CO (at 500K) | 10 - 100 | bar⁻¹ | Independent CO adsorption isotherm | Strong adsorption can lead to site blocking. |

| K_NO (at 500K) | 0.1 - 5 | bar⁻¹ | Regression or TPD | Weaker than CO, crucial for selectivity. |

| Reaction Order in CO | -1 to 0 | - | Power-law fit at low P | Negative order indicates strong inhibition. |

| Reaction Order in NO | 0.8 to 1.2 | - | Power-law fit at low P | Near unity under typical conditions. |

Experimental Protocols for L-H Parameter Determination

Protocol 3.1: Kinetic Rate Data Acquisition in a Differential Reactor

- Objective: Obtain intrinsic rate data free of mass/heat transfer limitations for L-H parameter regression.

- Apparatus: Fixed-bed quartz microreactor (ID 4-6 mm), mass flow controllers, on-line GC (TCD for CO, CO₂, N₂; FID for hydrocarbons), temperature-controlled furnace.

- Procedure:

- Catalyst Preparation: Sieve catalyst to 150-250 μm. Load 20-50 mg diluted with inert SiC (1:5 v/v) to ensure isothermal operation.

- Pre-treatment: Reduce catalyst in 5% H₂/Ar at 400°C for 2 hours, then purge with inert gas.

- Differential Operation Verification: Vary catalyst weight and total flow to confirm conversion <20% and rate constant.

- Kinetic Experiment: At fixed temperature (e.g., 200-350°C), systematically vary inlet partial pressures of CO (0.1-2%) and NO (0.1-2%) in balance Ar. Measure outlet concentrations.

- Data Processing: Calculate rate

r = (F * X) / W, whereFis molar flow,Xis conversion of limiting reactant,Wis catalyst weight.

Protocol 3.2: In-situ DRIFTS for Adsorption Constant Validation

- Objective: Measure surface coverage of adsorbed species (CO, NO) to validate assumptions in L-H model.

- Apparatus: Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) cell with controlled gas flow and temperature.

- Procedure:

- Place catalyst powder in the DRIFTS cell. Follow identical pre-treatment as Protocol 3.1.

- At reaction temperature, expose catalyst to a feed mirroring kinetic experiments.

- Collect spectra over time. Integrate peaks for linearly bonded CO (~2070 cm⁻¹) and adsorbed NO species (e.g., 1700-1900 cm⁻¹).

- Correlate integrated absorbance with gas-phase partial pressure to estimate relative coverages and validate the adsorption terms in the L-H model.

From Kinetic Model to Reactor Design

The L-H rate law is incorporated as the source term (r_A) in the reactor design equation. For an ideal Plug Flow Reactor (PFR), the governing equation is:

dF_A/dV = -r_A (P_A, P_B, T)

where V is catalyst volume. This differential equation must be integrated numerically due to the non-linear L-H rate expression.

Table 2: Reactor Model Selection Guide for CO-SCR Based on L-H Characteristics

| Reactor Type | Application in CO-SCR R&D | Key L-H Design Consideration | Scale-Up Challenge |

|---|---|---|---|

| Differential PFR | Kinetic parameter estimation | Ensure differential conditions to use r = (F*X)/W. |

Not for production. |

| Integral PFR | Catalyst pellet & monolith testing | Couple L-H kinetics with intra-particle diffusion (Thiele modulus). | Maintaining flow distribution and adiabatic operation. |

| Continuous Stirred-Tank Reactor (CSTR) | Studying inhibition effects | Strong CO adsorption leads to near-complete site coverage, making rate zero-order in feed. | Difficult to achieve perfect mixing on large scale. |

| Temporal Analysis of Products (TAP) Reactor | Elucidating elementary steps | Provides direct data on adsorption/desorption constants and surface residence times. | Ultra-high vacuum system not practical for scale-up. |

Diagram 1: L-H Model Integration in Reactor Design Flow (94 chars)

Scale-Up Considerations: Integrating Transport Phenomena

On scale-up, gradients in concentration and temperature become significant. The intrinsic L-H kinetics must be coupled with transport models.

5.1 External Mass/Heat Transfer: The observed rate r_obs is governed by the film transfer coefficient k_g and the intrinsic L-H rate r_int:

r_obs = η * r_int(C_s, T_s), where effectiveness factor η is derived from solving diffusion-reaction equations with the L-H expression as the boundary condition.

5.2 Internal Diffusion in Catalyst Pellets/Washcoats: For a first-order reaction in a spherical pellet, the Thiele modulus φ = R/3 * sqrt((k_v * ρ_p)/D_eff). For L-H kinetics, k_v is replaced by the derivative of the rate expression. Internal effectiveness factor η_int is η_int = (3/φ^2) * (φ * coth(φ) - 1) for first order, but requires numerical solution for L-H.

Table 3: Scale-Up Checklist: From Lab PFR to Industrial Reactor

| Scale | Typical Configuration | Key Added Consideration | Action for L-H Integration |

|---|---|---|---|

| Lab (mg-g) | Microreactor, 1/4" tube | Isothermality, differential operation. | Use direct L-H rate expression. |

| Pilot (kg) | Multi-tube reactor, small monolith | Inter-particle & intra-particle diffusion, radial temperature gradients. | Couple L-H model with 1D/2D heterogeneous PFR model with effective diffusivity. |

| Industrial (tons) | Large-diameter fixed-bed or monolith block | Flow maldistribution, hotspot formation, catalyst deactivation over time. | Use Computational Fluid Dynamics (CFD) with L-H kinetics as reacting species source terms. Perform sensitivity analysis on adsorption constants. |

Diagram 2: Reactor Scale-Up Issues & Model Complexity (82 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for CO-SCR L-H Kinetics Research

| Item / Reagent Solution | Function / Role in Research | Typical Specification / Notes |

|---|---|---|

| Pt/Al₂O₃ Catalyst (Reference) | Standard catalyst for validating L-H mechanisms and experimental setups. | 1-2 wt% Pt, high dispersion (>50%), γ-Al₂O₃ support, 100 m²/g surface area. |

| Custom Bimetallic Catalysts (e.g., Pt-Rh/Al₂O₃) | To study promoter effects on NO dissociation energy (key L-H rate-determining step). | Synthesized via co-impregnation or sol-gel methods. Characterization (TEM, XPS) is critical. |

| Certified Gas Calibration Mixtures | For accurate partial pressure control in kinetic experiments and GC calibration. | NIST-traceable, 1% CO/N₂, 1% NO/N₂, 10% CO₂/N₂, balanced Ar or He. |

| Silicon Carbide (SiC) Diluent | Ensures isothermal operation in lab-scale fixed-bed reactors by diluting catalyst bed. | Inert, high thermal conductivity, sieved to match catalyst particle size (150-250 μm). |

| Porous Catalyst Pellet Analogues | For studying internal diffusion effects on observed L-H kinetics. | γ-Al₂O₃ pellets with controlled porosity (e.g., 0.5 nm, 5 nm avg. pore size). |

| In-situ DRIFTS Cell with Environment Control | Validates adsorption isotherms and identifies surface intermediates in the L-H scheme. | High-temperature, high-pressure capable with ZnSe windows for IR transmission. |

| Computational Software (e.g., COMSOL, ANSYS Fluent) | For coupling L-H kinetics with transport models in reactor simulation and scale-up. | Requires user-defined function (UDF) to input the non-linear L-H rate expression. |

Overcoming Challenges: Deactivation, Selectivity, and Performance Optimization in CO-SCR Systems

Catalytic reduction processes, particularly CO-Selective Catalytic Reduction (CO-SCR), are central to emission control technologies. The Langmuir-Hinshelwood (L-H) kinetic model posits that the reaction rate is proportional to the surface coverage of co-adsorbed reactants. For CO-SCR, this typically involves the concurrent adsorption of CO and NOx species on adjacent active sites, with subsequent surface reaction forming N₂ and CO₂. The long-term efficacy of catalysts operating under this mechanism is critically undermined by three primary deactivation pathways: sulfur poisoning, carbon deposition, and thermal sintering. This whitepaper provides an in-depth technical analysis of these mechanisms within the context of L-H kinetics, offering experimental protocols and data relevant to researchers in catalyst development.

Core Deactivation Mechanisms

Sulfur Poisoning

Sulfur oxides (SO₂, SO₃) present in flue gases adsorb strongly onto active metal sites (e.g., Pt, Pd, Cu) and oxide supports (e.g., Al₂O₃, CeO₂). This chemisorption is often irreversible under operating conditions, blocking sites for CO and NO adsorption. Within the L-H framework, this reduces the surface coverage (θCO and θNO), directly decreasing the reaction rate. Sulfates can also form on the support, altering its acidity and pore structure.

Carbon Deposition (Coking)

Carbonaceous deposits form via CO disproportionation (Boudouard reaction: 2CO → C + CO₂) or polymerization of hydrocarbon intermediates. These deposits physically block active sites and pore channels. In L-H kinetics, this manifests as a decrease in the total number of available active sites (M), reducing the rate-determining surface coverage.

Thermal Sintering

Elevated temperatures, often encountered during catalyst regeneration or high-load operation, cause migration and agglomeration of active metal nanoparticles. This reduces the total surface area of the active phase and the number of adsorption sites. For L-H reactions dependent on dual-site adsorption, sintering can disrupt the required proximity of different adsorbate sites.

Table 1: Comparative Impact of Deactivation Mechanisms on L-H Kinetic Parameters

| Mechanism | Primary Effect on L-H Parameters | Typical Rate Loss (%)* | Common Temp. Range (°C) | Often Reversible? |

|---|---|---|---|---|

| Sulfur Poisoning | ↓ Active Sites (M); ↓ θCO, θNO | 70-95 | 150-400 | Partially (via high-T regeneration) |

| Carbon Deposition | ↓ M; Pore blockage | 40-80 | 200-500 | Yes (via oxidative regeneration) |

| Thermal Sintering | ↓ M via agglomeration | 30-70 (permanent) | >600 (depends on material) | No |