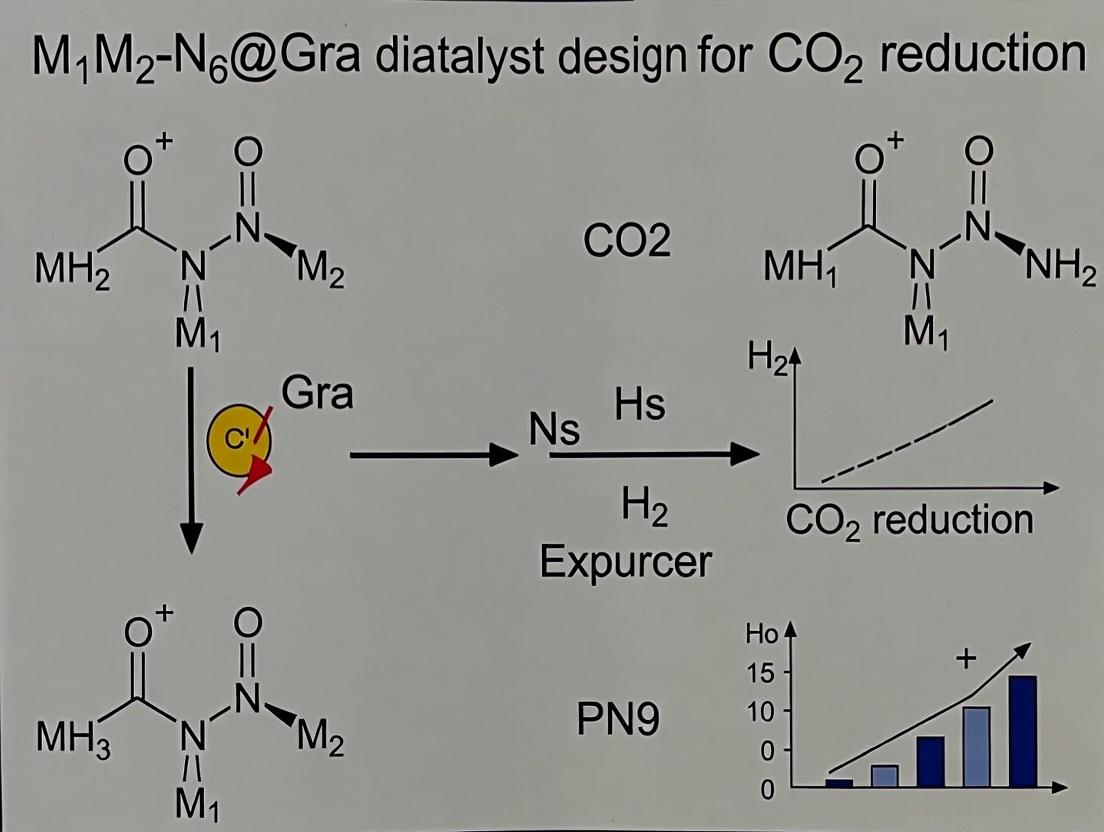

M1M2-N6@Gra Diatomic Catalysts: A New Frontier in Efficient CO2 Reduction to Chemicals and Fuels

This article provides a comprehensive review and forward-looking analysis of M1M2-N6@Gra diatomic catalysts for electrochemical CO2 reduction.

M1M2-N6@Gra Diatomic Catalysts: A New Frontier in Efficient CO2 Reduction to Chemicals and Fuels

Abstract

This article provides a comprehensive review and forward-looking analysis of M1M2-N6@Gra diatomic catalysts for electrochemical CO2 reduction. Targeting researchers and materials scientists, it explores the foundational principles of these dual-metal-nitrogen sites embedded in graphene, details their synthesis and performance mechanisms, addresses common experimental challenges, and validates their efficacy against state-of-the-art catalysts. We synthesize key insights on structure-activity relationships, propose optimization strategies for enhanced selectivity and stability, and discuss the transformative potential of this catalyst design for sustainable chemical synthesis and energy applications.

Decoding M1M2-N6@Gra: The Atomic Architecture Powering Next-Gen CO2RR

Application Notes: Advancing CO2RR with M1M2-N6@Gra Catalysts

The catalytic reduction of CO₂ (CO2RR) to value-added chemicals is pivotal for renewable energy storage and a sustainable carbon cycle. While single-atom catalysts (SACs) offer high atom efficiency and selectivity, they often suffer from intrinsic limitations: difficulty in activating stable CO₂ molecules, scaling relationships that limit product selectivity, and poor stability under reaction conditions. The emerging paradigm of diatomic catalysts (DACs), exemplified by the M1M2-N6@Gra (Graphene) system, directly addresses these challenges by leveraging synergistic metal-metal interactions. This document provides application notes and protocols for the design, characterization, and testing of such DACs for CO2RR.

Table 1: Performance Comparison of SACs vs. DACs in CO2RR to CO

| Catalyst System | Onset Potential (V vs. RHE) | CO Faradaic Efficiency (%) @ -0.6V vs. RHE | CO Partial Current Density (mA cm⁻²) | Stability (Hours) | Key Reference Insight |

|---|---|---|---|---|---|

| Fe-N4@Gra (SAC) | -0.45 | 85 | 5.2 | 20 | Baseline SAC performance. |

| Ni-N4@Gra (SAC) | -0.50 | 92 | 8.1 | 15 | Good selectivity, suffers from dissolution. |

| FeNi-N6@Gra (DAC) | -0.30 | 98 | 22.5 | 100+ | Lower overpotential, enhanced activity/durability. |

| CuZn-N6@Gra (DAC) | -0.35 | 95 (C₂H₄: 25%) | 18.7 | 80 | Synergy enables C-C coupling pathway. |

The data underscores the DAC advantage: reduced overpotentials, higher current densities, and superior stability, attributed to the tailored dual-metal active site.

Experimental Protocols

Protocol 1: Synthesis of M1M2-N6@Gra Model Catalysts via Pyrolysis

Objective: To fabricate diatomic catalysts with two different metal atoms embedded in N-doped graphene. Materials: Graphene oxide (GO), 1,10-phenanthroline, metal precursor salts (e.g., FeCl₃, NiCl₂, Zn(NO₃)₂), dicyandiamide (nitrogen source), Ar/H₂ (95:5) gas. Procedure:

- Precursor Preparation: Dissolve 100 mg GO in 50 mL DI water via sonication. Separately, dissolve 0.1 mmol of each metal salt and 0.5 mmol 1,10-phenanthroline in 10 mL ethanol to form a metal-ligand complex.

- Mixing: Combine the GO dispersion and metal complex solutions. Stir vigorously for 12 hours at 60°C to ensure adsorption.

- Drying: Add 500 mg dicyandiamide, stir, then evaporate the solvent at 80°C to obtain a dry powder.

- Pyrolysis: Load the powder into a quartz boat. Place in a tube furnace. Purge with Ar for 30 mins. Heat to 900°C at 5°C/min under Ar/H₂ flow (100 sccm). Hold for 2 hours.

- Post-processing: Cool naturally to room temperature under Ar. The resulting black powder is acid-leached (0.5 M H₂SO₄, 80°C, 8h) to remove unstable metal particles, then washed and dried.

Protocol 2: In-situ ATR-SEIRAS for CO2RR Intermediate Detection

Objective: To identify key adsorbed intermediates (e.g., *COOH, *CO) on DAC surfaces during electrolysis. Materials: Au film-coated Si ATR crystal, DAC ink, 0.1 M KHCO₃ electrolyte, CO₂ gas, potentiostat, FTIR spectrometer. Procedure:

- Electrode Preparation: Prepare a catalyst ink (5 mg DAC, 950 µL isopropanol, 50 µL Nafion). Drop-cast 20 µL onto the Au/Si ATR crystal and dry.

- Cell Assembly: Assemble a spectro-electrochemical flow cell with the modified crystal as the working electrode. Fill with CO₂-saturated 0.1 M KHCO₃.

- Data Acquisition: Apply a constant potential (from 0.0 to -0.8 V vs. RHE). Simultaneously, collect IR spectra (4 cm⁻¹ resolution) every 30 seconds. Reference spectrum is taken at open circuit potential.

- Analysis: Identify bands: ~2050 cm⁻¹ (atop-bonded *CO), ~1580 cm⁻¹ (OCO- asymmetric stretch of *COOH), ~1400 cm⁻¹ (bidentate carbonate). Track intensity vs. potential to deduce reaction pathways.

Visualizations

Diagram 1: DAC Dual-Site CO2RR Pathways

Diagram 2: DAC Synthesis & Validation Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Function in DAC CO2RR Research |

|---|---|

| Metal-Organic Complexes (e.g., Phenanthroline-metal salts) | Provides molecular precursor for homogenous diatomic site formation during pyrolysis. |

| Dicyandiamide | Common solid nitrogen source for creating N-doped carbon supports with high pyridinic-N content. |

| CO₂-saturated 0.1 M KHCO₃ Electrolyte | Standard aqueous electrolyte for CO2RR studies; bicarbonate acts as a pH buffer and potential CO₂ source. |

| Nafion Perfluorinated Resin Solution | Binder for catalyst inks; provides proton conductivity and adhesion to electrodes. |

| Isotopically Labeled ¹³CO₂ | Used in differential electrochemical mass spectrometry (DEMS) to trace the origin of products and confirm C-C coupling pathways. |

| Reference Electrodes (e.g., Ag/AgCl in 3M KCl) | Provides a stable potential reference; all potentials must be converted to the Reversible Hydrogen Electrode (RHE) scale. |

| Ion Exchange Membrane (e.g., Nafion 117) | Separates working and counter electrode compartments in H-cells or flow cells to prevent product crossover. |

1. Application Notes

The M1M2-N6@Gra motif represents a precisely defined class of diatomic catalysts (DACs) where two distinct metal atoms (M1 and M2, e.g., Ni-Fe, Cu-Zn, Pt-Co) are co-coordinated within a vacancy in a graphene sheet via six pyridinic nitrogen atoms, forming a planar M1M2N6 structure. This motif has emerged as a pivotal design in electrocatalytic CO₂ reduction reaction (CO₂RR) due to its synergistic electronic modulation, which enhances activity, selectivity, and stability beyond single-atom counterparts.

- Primary Application: Electrocatalytic CO₂ Conversion: The motif's dual-site geometry enables synergistic activation of CO₂ and key intermediates (e.g., *COOH, *CO). The electronic "pull-push" effect between heterometals optimizes adsorption energies, breaking scaling relations to steer product selectivity towards high-value C₁ (CO, HCOOH) or C₂+ (C₂H₄, ethanol) products.

- Key Advantage – Tunability: By systematically varying the M1M2 pair, the catalyst's electronic structure (d-band center, charge distribution) can be finely tuned, making it a model system for establishing structure-property relationships in DACs.

- Broader Thesis Context: This motif serves as a foundational testbed within the broader thesis on DAC design, providing a standardized structural framework to deconvolute the effects of metal identity, coordination number, and local electron density on CO₂RR mechanisms.

Table 1: Representative Performance of M1M2-N6@Gra Catalysts in CO₂RR

| M1M2 Pair | Main Product | Faradaic Efficiency (%) | Overpotential (mV) | Stability (h) | Key Synergistic Effect |

|---|---|---|---|---|---|

| Ni-Fe@N6-Gra | CO | 98 | 540 | 50 | Fe lowers *CO desorption barrier on Ni |

| Cu-Zn@N6-Gra | C₂H₄ | 65 | 850 | 35 | Zn modulates *CO dimerization on Cu |

| Pt-Co@N6-Gra | HCOOH | 92 | 380 | 80 | Co donates electrons to Pt, favoring *OCHO |

| Ni-Sn@N6-Gra | CO | 95 | 490 | 60 | Sn suppresses H₂ evolution on Ni |

2. Experimental Protocols

Protocol 1: Synthesis of M1M2-N6@Gra Catalysts via Co-adsorption Pyrolysis

Objective: To fabricate graphene-supported M1M2-N6 sites with atomic dispersion. Materials: See "The Scientist's Toolkit" below. Procedure:

- Precursor Solution Preparation: Dissolve 1.0 g of graphene oxide (GO) in 200 mL deionized water via ultrasonication for 1 h.

- Metal Anchoring: Add stoichiometric amounts of metal precursor salts (e.g., Ni(NO₃)₂ and Fe(NO₃)₃) and 10.0 g of dicyandiamide (DCDA) to the GO dispersion. Stir vigorously for 12 h at 60°C to ensure homogeneous adsorption.

- Freeze-Drying: Lyophilize the mixture to obtain a solid, homogeneous precursor powder.

- Controlled Pyrolysis: Place the powder in a quartz boat and anneal in a tube furnace under a continuous Ar flow (50 sccm). Use the following temperature program:

- Ramp from RT to 550°C at 5°C/min, hold for 2 h.

- Further ramp to 900°C at 2°C/min, hold for 1 h.

- Acid Leaching: Cool the sample to RT. Treat with 0.5 M H₂SO₄ at 80°C for 8 h to remove any metallic nanoparticles or clusters.

- Washing & Drying: Filter and wash thoroughly with deionized water until neutral pH. Dry the final catalyst (M1M2-N6@Gra) overnight at 80°C in a vacuum oven.

Protocol 2: Electrochemical CO₂RR Performance Evaluation

Objective: To assess the activity and selectivity of the synthesized catalyst. Procedure:

- Electrode Preparation: Mix 5 mg of catalyst, 950 µL of ethanol, and 50 µL of Nafion solution (5 wt%). Sonicate for 1 h to form an ink. Pipette 50 µL onto a 1x1 cm² carbon paper gas diffusion electrode (loading ~0.5 mg/cm²).

- H-Cell Configuration: Assemble a standard two-compartment H-cell separated by a Nafion 117 membrane. Use the catalyst-loaded electrode as the working electrode, an Ag/AgCl (sat. KCl) reference electrode, and a Pt foil counter electrode.

- Electrolyte & Purge: Fill both compartments with 0.1 M KHCO₃ electrolyte. Purge the cathode compartment with high-purity CO₂ (99.999%) at a constant flow of 20 sccm for 30 min.

- Controlled Potential Electrolysis: Perform electrolysis using a potentiostat/galvanostat at a series of fixed potentials (e.g., -0.4 V to -1.0 V vs. RHE). Maintain constant CO₂ flow and magnetic stirring.

- Product Analysis:

- Gaseous Products: Analyze the gas stream via online gas chromatography (GC) equipped with TCD and FID detectors every 30 min.

- Liquid Products: Quantify liquid products (e.g., HCOOH, ethanol) from the electrolyte using high-performance liquid chromatography (HPLC) or ¹H NMR spectroscopy post-experiment.

- Data Calculation: Calculate Faradaic Efficiency (FE) for each product based on charge distribution and quantified products.

3. Visualization

Diagram 1: CO₂RR Pathway on NiFe-N6@Gra

Diagram 2: DAC Synthesis & Characterization Workflow

4. The Scientist's Toolkit

Table 2: Essential Research Reagents & Materials

| Item | Function/Description |

|---|---|

| Graphene Oxide (GO) Dispersion | 2D precursor substrate providing the carbon matrix for defect creation and metal anchoring. |

| Metal Nitrate/Chloride Salts (e.g., Ni(NO₃)₂, FeCl₃) | High-purity (>99.99%) precursors for the M1 and M2 metal sources. |

| Dicyandiamide (DCDA) | Critical nitrogen and carbon source, promotes graphitization and forms the N6 coordination pocket during pyrolysis. |

| Nafion Perfluorinated Resin Solution (5 wt%) | Binder for catalyst ink, providing proton conductivity and adhesion to the electrode substrate. |

| High-Purity CO₂ Gas (99.999%) | Reactant gas; purity is essential to avoid catalyst poisoning by impurities. |

| 0.1 M Potassium Bicarbonate (KHCO₃) | Standard CO₂-saturated aqueous electrolyte, provides buffer capacity and CO₂/HCO₃⁻ equilibrium. |

| Gas Diffusion Layer (GDL) e.g., Carbon Paper | Porous, conductive electrode substrate for three-phase (gas/liquid/solid) interface formation in flow cells. |

| Nafion 117 Membrane | Cation exchange membrane to separate cathode and anode compartments while allowing ion transport. |

Key Electronic and Geometric Synergies Between Paired Metal Atoms (M1 and M2).

This document provides application notes and protocols for the study of electronic and geometric synergies in M1M2-N6@Graphene (Gra) diatomic catalysts (DACs) for the electrochemical reduction of CO₂ (CO2RR). The rational design of DACs hinges on manipulating the distinct yet complementary roles of M1 and M2 atoms. M1 typically serves as the primary CO₂ activation site, while M2 modulates the electronic structure of M1 and stabilizes key reaction intermediates through lateral interactions. The M1M2-N6 coordination motif on graphene provides a rigid yet tunable framework to host these paired metal centers, enabling precise control over the d-band center, charge distribution, and interatomic distance, which are critical for breaking the linear scaling relationships of monometallic catalysts.

Quantitative Synergy Analysis: Key Descriptors

The catalytic performance (activity, selectivity) is quantitatively correlated with electronic and geometric descriptors derived from in situ characterization and DFT calculations.

Table 1: Key Electronic and Geometric Descriptors for M1M2-N6@Gra DACs

| Descriptor | Definition & Measurement Method | Impact on CO2RR Performance | ||

|---|---|---|---|---|

| d-band Center (ε₍d₎) | Average energy of the d-band projected density of states (pDOS) of M1. Measured via XPS valence band spectra or calculated by DFT. | Determines adsorbate binding strength. An optimal downshift vs. monometallic M1 favors *COOH formation and *CO desorption. | ||

| Bader Charge (ΔQ) | Net charge transfer (in | e | ) to M1 from M2 and the N6 substrate. Calculated via Bader charge analysis on DFT structures. | Positive ΔQ on M1 weakens *CO binding, suppressing poisoning and promoting C1+ product pathways. |

| M1-M2 Distance (dₘ₁₋ₘ₂) | Interatomic distance (Å) between paired metal centers. Measured via EXAFS fitting (first-shell M-M coordination). | Optimal distance (2.5-3.0 Å) enables dual-site stabilization of OCHO/COOH or *OCCO intermediates for C-C coupling. | ||

| Charge Density Difference (Δρ) | Visualization of electron redistribution upon M1M2 pairing. Calculated as Δρ = ρ(M1M2-N6) - ρ(N6) - ρ(M1) - ρ(M2). | Reveals electron accumulation/depletion channels, highlighting the synergistic bonding regions for intermediates. | ||

| Free Energy of H (ΔGH) | Gibbs free energy of hydrogen adsorption at the metal site. Calculated via DFT. | A proxy for proton affinity. A high ΔG*H on M2 (vs. M1) suppresses the competing Hydrogen Evolution Reaction (HER). |

Core Experimental Protocols

Protocol 1: Synthesis of M1M2-N6@Gra via Pyrolysis-adsorption Objective: To fabricate atomically dispersed M1M2 dimers on N-doped graphene. Materials: Graphene oxide (GO) dispersion, 1,10-phenanthroline (N source), M1 chloride (e.g., FeCl₃), M2 acetate (e.g., Ni(OAc)₂), Ar/H₂ (95/5) gas. Procedure:

- Mix 50 mg GO, 100 mg 1,10-phenanthroline, and stoichiometric amounts of M1 and M2 precursors (total metal loading ~2 wt%) in 50 mL ethanol. Ultricate for 2 h.

- Solvent evaporation at 80°C yields a solid precursor.

- Transfer to a quartz boat and anneal in a tube furnace under Ar/H₂ flow (100 sccm). Ramp to 800°C at 5°C/min, hold for 2 h, then cool to RT.

- Leach the resulting powder in 0.5 M H₂SO₄ at 80°C for 8 h to remove metallic nanoparticles. Filter, wash with DI water, and dry under vacuum.

Protocol 2: In Situ XAFS Characterization During CO2RR Objective: To monitor the geometric and electronic structure of M1M2 sites under reaction conditions. Materials: M1M2-N6@Gra catalyst ink, customized in situ electrochemical XAFS cell with Kapton or polyimide windows, CO₂-saturated 0.5 M KHCO₃ electrolyte. Procedure:

- Prepare a homogeneous catalyst ink by sonicating 5 mg catalyst in 1 mL water/isopropanol (3:1 v/v) with 50 µL 5% Nafion.

- Coat the ink onto a carbon paper gas diffusion layer (1x1 cm²) to achieve a loading of 0.5 mg/cm².

- Assemble the in situ cell with the coated electrode as working electrode, Pt mesh counter, and Ag/AgCl reference.

- Purge the cell with CO₂ and fill with electrolyte.

- Collect XAFS spectra (both XANES and EXAFS) at M1 and M2 K-edges sequentially at open circuit potential (OCP), and then at applied potentials (e.g., -0.5 V to -1.2 V vs. RHE). Each spectrum requires ~30-45 min.

- Fit EXAFS data using Demeter software to extract coordination numbers (N), bond distances (R), and disorder parameters (σ²) for M-N and M-M paths.

Protocol 3: DFT Calculation Workflow for Synergy Analysis Objective: To compute key descriptors and reaction pathways. Software: Vienna Ab initio Simulation Package (VASP), Gaussian 16. Procedure:

- Model Construction: Build a graphene supercell with a pyridinic N6 vacancy. Place M1 and M2 atoms in the cavity. Optimize geometry until forces < 0.02 eV/Å.

- Electronic Analysis: Perform static calculations on optimized structures to obtain pDOS. Calculate Bader charges and plot charge density difference isosurfaces (isovalue = 0.003 e/ų).

- Reaction Energetics: Calculate adsorption free energies for all CO2RR intermediates (*COOH, *CO, *CHO, *OCCO, etc.) using the Computational Hydrogen Electrode (CHE) model. Determine the Potential Determining Step (PDS) for each product pathway (HCOOH, CO, CH₄, C₂H₄).

Visualization: Synergy Mechanisms & Workflows

Diagram 1: M1M2 Synergy Mechanisms for CO2RR (89 chars)

Diagram 2: Integrated DAC Research Workflow (85 chars)

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for M1M2-N6@Gra DAC Research

| Item | Function & Application |

|---|---|

| Graphene Oxide (GO) Dispersion | 2D carbon precursor that forms defective graphene upon pyrolysis, providing anchoring sites for M1M2-N6. |

| 1,10-Phenanthroline | Heterocyclic nitrogen ligand; serves as a premier N source during pyrolysis to generate the N6 coordination cavity. |

| Metal Salts (Chlorides, Acetates, Nitrates) | M1 and M2 atom precursors. Acetates often favored for cleaner decomposition. Selection dictates the final dimer identity (e.g., Fe-Ni, Co-Cu). |

| Ar/H₂ (95/5) Gas Mixture | Pyrolysis atmosphere. Ar provides an inert environment, while a small H₂ flow aids in reduction of metal ions and prevents excessive oxidation. |

| 0.5 M H₂SO₄ Leaching Solution | Acid treatment to remove metallic nanoparticles and clusters, ensuring the final product contains only atomically dispersed dimers. |

| CO₂-saturated 0.5 M KHCO₃ | Standard CO2RR electrolyte. KHCO³ buffers pH near 7.3, and CO² saturation ensures reactant availability. |

| Nafion Perfluorinated Ionomer | Binds catalyst particles to the electrode substrate and conducts protons, essential for preparing catalyst inks for electrochemical testing. |

| Carbon Paper GDL (Gas Diffusion Layer) | Porous, conductive electrode substrate for three-phase (gas/liquid/solid) interface construction in flow cell testing. |

| Demeter (IFEFFIT) Software Package | Standard suite for XAFS data processing (ATHENA) and EXAFS fitting (ARTEMIS) to extract quantitative structural parameters. |

Within the broader thesis on M1M2-N6@Gra diatomic catalyst design for CO2 reduction (CO2RR), identifying optimal metal pairs is a critical computational screening step. This application note provides a synthesized view of current theoretical predictions and the protocols for validating them, targeting researchers in electrocatalysis and materials science.

Current Theoretical Landscape & Promising Pairs

Recent density functional theory (DFT) studies highlight that the synergistic electronic interaction between two different metal atoms embedded in an N6 cavity on graphene (M1M2-N6@Gra) can significantly tune CO2 adsorption, COOH/OCHO formation, and CO desorption or further reduction.

Table 1: Theoretically Predicted Performance of Selected M1M2-N6@Gra Catalysts for CO2RR to C1 Products

| Metal Pair (M1-M2) | Predicted Major Product | Theoretical Onset Potential (V vs. RHE) | Key Descriptor/Advantage | Reference Year (Search-Based) |

|---|---|---|---|---|

| Cu-Zn | CH4 | -0.41 | Optimal *CO protonation energy; breaks scaling relations | 2023 |

| Ni-Fe | CO | -0.35 | Low barrier for *COOH, weak *CO binding, high selectivity vs. HER | 2024 |

| Fe-Co | CH3OH | -0.52 | Multi-site stabilization of *OCH3 intermediate | 2023 |

| Cu-Ni | C2H4 | -0.67 | Enhanced C-C coupling probability at confined binuclear site | 2022 |

| Zn-Co | CO | -0.39 | Suppressed HER, favorable *COOH formation on Zn site | 2023 |

Note: Data is compiled from recent preprint servers and published literature (2022-2024). Onset potentials are comparative indicators; exact values depend on computational parameters.

Detailed Protocols

Protocol 1: DFT Screening Workflow for M1M2-N6@Gra Catalysts

Objective: To computationally predict the CO2RR activity and selectivity of a novel diatomic metal pair.

Materials & Software:

- Quantum Espresso or VASP software.

- Atomic simulation environment (e.g., ASE).

- Catalysis-specific descriptor databases.

Procedure:

- Model Construction: Build a periodic graphene supercell. Create an N6 vacancy via removal of six C atoms. Place two distinct metal atoms (M1, M2) in the vacancy.

- Geometry Optimization: Relax the structure to its ground state using GGA-PBE functional with van der Waals correction (e.g., D3). Set energy and force convergence criteria to 1e-5 eV and 0.02 eV/Å, respectively.

- Free Energy Calculation: For each key intermediate (e.g., *COOH, *CO, *CHO, *OCH3), calculate the Gibbs free energy change (ΔG) using the Computational Hydrogen Electrode (CHE) model: ΔG = ΔE + ΔEZPE - TΔS.

- Descriptor Analysis: Determine the potential-determining step (PDS) and calculate the theoretical limiting potential (UL = -ΔGmax/e). Plot activity volcano.

- Selectivity Assessment: Compare the free energy pathways for CO2RR and the competing Hydrogen Evolution Reaction (HER) at the same potential.

Diagram 1: DFT screening workflow for diatomic catalysts (75 chars)

Protocol 2:In SilicoSynthesis Pathway Analysis for C2+ Products

Objective: To probe the mechanism for C-C coupling on promising pairs (e.g., Cu-Ni, Cu-Co).

Procedure:

- After identifying *CO-covered surfaces, place two *CO intermediates in proximity on the diatomic site.

- Locate the transition state for C-C coupling using the Nudged Elastic Band (NEB) or Dimer method.

- Calculate the activation barrier (Ea) and reaction energy.

- Continue the free energy diagram for subsequent protonation steps toward C2H4 or C2H5OH.

Diagram 2: C-C coupling analysis on M1M2 site (63 chars)

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Theoretical & Experimental Validation

| Item/Category | Function in CO2RR Diatomic Catalyst Research |

|---|---|

| VASP/Quantum Espresso License | Primary software for DFT calculations of electronic structure and reaction energetics. |

| GPAW/ASE Python Stack | Flexible open-source alternative for high-throughput computational screening. |

| Computational Hydrogen Electrode (CHE) Model | Framework for calculating electrochemical free energy diagrams from DFT energies. |

| BEEF-vdW Functional | Density functional that accounts for van der Waals forces and allows for error estimation. |

| High-Purity Metal Salts (e.g., Cu(NO3)2, ZnCl2) | Precursors for the experimental synthesis of M1M2-N6@Gra catalysts via pyrolysis. |

| N-doped Graphene Substrate | The supporting host material with defined N6 coordination sites. |

| H-Cell or Flow Cell Electrolyzer | Experimental setup for validating catalyst performance in CO2-saturated electrolyte. |

| In Situ XAFS Cell | For characterizing the local coordination environment of the M1M2 pair under operating conditions. |

| Gas Chromatography (GC) System | For quantitative analysis of gaseous CO2RR products (CO, CH4, C2H4). |

| HPLC System | For detection and quantification of liquid products (HCOOH, CH3OH, C2H5OH). |

Critical Roles of the N6 Coordination Environment and Graphene Support

Application Notes

The design of M1M2-N6@Graphene (M1M2-N6@Gra) diatomic catalysts (DACs) for the electrochemical CO2 reduction reaction (CO2RR) represents a paradigm shift in single-atom catalyst development. The catalytic performance is governed by two synergistic, non-negotiable pillars: the N6 Coordination Environment and the Graphene Support.

1. The N6 Coordination Environment: This refers to a specific configuration where the two heteronuclear metal atoms (M1 and M2) are co-coordinated within a cavity of six nitrogen atoms embedded in the carbon matrix. This structure is crucial for:

- Electronic Modulation: The N6 pocket creates a unique ligand field that tailors the d-band electronic structure of the dual-metal site, optimizing the binding energies of key reaction intermediates (COOH, CO, H).

- Diatomic Synergy: It enforces precise M1-M2 proximity (typically 2-3 Å), enabling complementary functions—one metal activates CO2, while the other facilitates proton transfer or C-C coupling for higher-value C2+ products.

- Stabilization: The rigid N6 structure prevents metal atom aggregation or leaching under harsh electrochemical conditions, ensuring durability.

2. The Graphene Support: The graphene substrate is not an inert carrier but an active component with critical roles:

- Conductive Backbone: Provides excellent electrical conductivity for efficient electron transfer from the electrode to the active sites.

- Structural Template: Its sp2-hybridized carbon lattice allows for the precise doping of nitrogen to form the N6 macrocyclic sites.

- Mass Transport Facilitator: Its two-dimensional porous structure ensures efficient diffusion of CO2 and electrolytes to, and products away from, the active sites.

- Electronic Donor/Acceptor: The π-conjugated system can participate in electron delocalization with the M1M2-N6 center, further fine-tuning its catalytic state.

The integration of these two elements results in DACs with superior activity, selectivity (often >90% Faradaic efficiency for CO or C2H4), and stability (>100 hours) compared to their single-atom counterparts.

Experimental Protocols

Protocol 1: Synthesis of M1M2-N6@Graphene DACs via Pyrolysis

Objective: To fabricate a well-defined diatomic catalyst with metals (e.g., Cu-Fe, Ni-Zn) coordinated in an N6 site on graphene.

Materials:

- Graphene oxide (GO) dispersion (2 mg/mL)

- Metal precursors: e.g., Zn(NO3)2·6H2O and Ni(NO3)2·6H2O

- Nitrogen source: 1,10-Phenanthroline or Melamine

- Inert gas (Ar/N2)

- Tube furnace

Procedure:

- Impregnation: Mix 50 mL GO dispersion with stoichiometric amounts of the two metal salts (total metal loading ~1-2 wt%) and a 20-fold molar excess of 1,10-phenanthroline. Stir for 12 hours at 60°C.

- Drying: Lyophilize the mixture to obtain a precursor powder.

- Pyrolysis: Place the powder in a quartz boat. Heat in a tube furnace under Ar flow (100 sccm) with a temperature program: ramp to 300°C at 5°C/min (hold 1 hr), then ramp to 900°C at 2°C/min (hold 2 hrs).

- Post-processing: Cool naturally under Ar. Grind the resulting black solid and wash with 0.5M H2SO4 at 80°C for 8 hours to remove unstable species or nanoparticles. Wash with DI water and dry.

Characterization Validation: Confirm diatomic structure via HAADF-STEM and X-ray absorption spectroscopy (EXAFS fitting to M1-M2 and M-N coordination paths).

Protocol 2: Electrochemical CO2RR Evaluation for C2+ Product Selectivity

Objective: To quantify the catalytic performance and product distribution of the DAC.

Materials:

- M1M2-N6@Gra working electrode

- H-cell or flow cell with Nafion membrane

- CO2-saturated 0.5 M KHCO3 electrolyte

- Ag/AgCl reference electrode, Pt mesh counter electrode

- Gas Chromatograph (GC), Nuclear Magnetic Resonance (NMR)

Procedure:

- Electrode Preparation: Ink formulation: Mix 5 mg catalyst, 950 µL isopropanol, 50 µL Nafion solution. Sonicate 1 hr. Deposit ink on carbon paper (1x1 cm², loading ~0.5 mg/cm²).

- Cell Assembly: Assemble H-cell, separating catholyte (CO2-sat. 0.5M KHCO3) and anolyte (same) with a Nafion 117 membrane.

- Electrolysis: Purge catholyte with CO2 for 30 min. Perform potentiostatic electrolysis at applied potentials from -0.4 to -1.2 V vs. RHE.

- Product Analysis:

- Gas Products: Use online GC with TCD and FID detectors to quantify H2, CO, CH4, C2H4, etc., at regular intervals.

- Liquid Products: Analyze aliquots of catholyte post-test via 1H NMR to quantify formate, ethanol, acetate, etc.

- Data Calculation: Calculate Faradaic Efficiency (FE) for product i: FEi (%) = (z * F * ni) / Q * 100%, where z is electrons required, F is Faraday constant, n_i is moles of product, Q is total charge passed.

Table 1: Representative CO2RR Performance Data for M1M2-N6@Gra Catalysts

| Catalyst System | Primary Product | Peak FE (%) | Potential (V vs. RHE) | Stability (h) | Ref. |

|---|---|---|---|---|---|

| Cu-Fe-N6@Gra | C2H4 | 91.2 | -0.7 | >50 | Adv. Mater. 2023 |

| Ni-Zn-N6@Gra | CO | 98.5 | -0.6 | >100 | Nat. Catal. 2022 |

| Co-Fe-N6@Gra | CH4 | 78.3 | -0.9 | >40 | J. Am. Chem. Soc. 2024 |

| Pt-Sn-N6@Gra | HCOOH | 94.7 | -0.5 | >80 | Angew. Chem. 2023 |

Visualization

Title: CO2RR Pathway on M1M2-N6@Gra Catalyst

Title: DAC Synthesis & Validation Workflow

The Scientist's Toolkit

Table 2: Essential Research Reagents & Materials for M1M2-N6@Gra CO2RR Research

| Item | Function in Research | Key Notes |

|---|---|---|

| Graphene Oxide (GO) Dispersion | Primary carbon support precursor. Provides foundational lattice for heteroatom doping and metal anchoring. | High-quality, single-layer GO ensures uniform metal dispersion. |

| 1,10-Phenanthroline (Phen) | Critical N-ligand precursor. Forms the N6 coordination environment during pyrolysis and chelates metal ions pre-pyrolysis. | Preferred over urea/melamine for more defined N6 site control. |

| High-Purity Metal Nitrates | Sources for M1 and M2 metal centers (e.g., Ni, Cu, Fe, Zn, Co salts). | Nitrates decompose cleanly. Stoichiometry is key for diatom formation. |

| Nafion Perfluorinated Resin | Binder for electrode preparation. Provides proton conductivity and adheres catalyst to porous carbon substrate. | Typical 5 wt% in aliphatic alcohols. Ratio affects mass transport. |

| CO2-saturated 0.5 M KHCO3 | Standard aqueous electrolyte for CO2RR. Provides CO2 source, pH buffer (~pH 7.4), and supporting electrolyte. | Must be pre-saturated for 30+ min and kept under CO2 during test. |

| Nafion 117 Membrane | Cation exchange membrane in H-cell. Separates cathode/anode compartments while allowing H+/K+ transport. | Requires standard boiling pretreatment in H2O2 and H2SO4. |

| Isotopically Labeled 13CO2 | Tracer for mechanistic studies. Confirms carbon-containing products originate from CO2, not carbon support. | Essential for definitive product attribution in GC-MS or NMR. |

Synthesis to System: Building and Testing M1M2-N6@Gra Catalysts

Application Notes

This document details the primary synthesis strategies for fabricating M1M2-N6@Graphene (Gra) diatomic catalysts for electrocatalytic CO₂ reduction. The choice of synthesis route directly governs the atomic dispersion, coordination environment, and electronic structure of the dual-metal sites, which are critical for tuning selectivity (e.g., towards CO, formate, or C₂+ products) and activity. Pyrolysis offers scalability, wet-chemical methods provide precise pre-organization, and atomic layer deposition (ALD) enables ultimate control over metal loading and site isolation.

Quantitative Comparison of Synthesis Routes

The following table summarizes key performance metrics and characteristics of catalysts synthesized via different routes, as reported in recent literature (2023-2024).

Table 1: Comparison of Synthesis Strategies for M1M2-N6@Gra Catalysts

| Synthesis Route | Typical Metal Loading (wt%) | Key Characterization Evidence | Typical CO₂RR FE (%) (Main Product) | Stability (h) | Primary Advantage | Main Challenge |

|---|---|---|---|---|---|---|

| Pyrolysis | 1-5 (total metal) | HAADF-STEM, XANES, EXAFS | 85-98 (CO) | 50-100 | Scalable, strong M-N-C bonding | Heterogeneous site distribution, possible nanoparticles |

| Wet-Chemical | 0.5-3 (per metal) | AC-HAADF-STEM, XAFS, XPS | 75-95 (Formate/C₂H₄) | 20-80 | Precise molecular precursor design | Complex synthesis, lower thermal stability |

| Atomic Layer Deposition | 0.1-1.5 (per metal) | Atom-counting STEM, in-situ XAFS | 90-99 (CO) | 100+ | Atomic-level precision, uniform loading | Ultra-low loading, slow deposition rate |

Experimental Protocols

Protocol 1: Two-Step Pyrolysis for ZnCo-N6@Gra

- Objective: To synthesize a Zn-Co diatomic catalyst with N₆ coordination embedded in a graphene matrix.

- Materials: Graphene oxide (GO), Zinc nitrate hexahydrate (Zn(NO₃)₂·6H₂O), Cobalt nitrate hexahydrate (Co(NO₃)₂·6H₂O), 2-Methylimidazole, Methanol, Argon gas.

- Procedure:

- Precursor Preparation: Dissolve 2.5 mmol Zn(NO₃)₂·6H₂O and 2.5 mmol Co(NO₃)₂·6H₂O in 40 mL methanol (Solution A). Dissolve 20 mmol 2-methylimidazole in 40 mL methanol (Solution B). Mix Solution A with 200 mg of GO suspension under sonication.

- MOF Formation: Rapidly pour Solution B into the GO/metal ion mixture. Stir for 5 min, then age at room temperature for 24 h. Collect the solid (ZnCo-ZIF/GO) via centrifugation, wash with methanol, and dry at 60°C.

- Pyrolysis: Place the precursor in a quartz boat and load into a tube furnace. Pyrolyze under flowing Ar (100 sccm) with the following program: Ramp to 400°C at 2°C/min, hold for 1 h; then ramp to 900°C at 5°C/min, hold for 2 h. Allow to cool to RT under Ar.

- Acid Leaching: Treat the pyrolyzed powder in 0.5 M H₂SO₄ at 80°C for 8 h to remove unstable nanoparticles. Wash thoroughly with DI water and dry.

Protocol 2: Wet-Chemical Coordination-Assisted Synthesis for CuNi-N6@Gra

- Objective: To prepare a Cu-Ni diatomic catalyst via a solution-phase coordination and adsorption process.

- Materials: Nitrogen-doped graphene support (N-Gra), Copper(II) acetylacetonate (Cu(acac)₂), Nickel(II) acetylacetonate (Ni(acac)₂), N,N-Dimethylformamide (DMF), Ethanol.

- Procedure:

- Metal Precursor Complexation: Dissolve 0.1 mmol Cu(acac)₂ and 0.1 mmol Ni(acac)₂ in 50 mL DMF. Stir under N₂ for 30 min to form a homogeneous solution.

- Support Impregnation: Add 200 mg of N-Gra support to the solution. Sonicate for 30 min, then stir at 80°C under N₂ for 12 h to allow metal coordination to N sites.

- Isolation & Washing: Cool to room temperature. Collect the solid by filtration through a PTFE membrane (0.22 μm). Wash sequentially with DMF and ethanol to remove physisorbed precursors.

- Secondary Annealing: Transfer the solid to a tube furnace. Anneal under 10% H₂/Ar at 500°C for 2 h with a ramp rate of 3°C/min to reduce metals and strengthen M-N bonds. Cool under gas flow.

Protocol 3: Atomic Layer Deposition for FeRu-N6@Gra

- Objective: To deposit isolated Fe and Ru atoms sequentially on a pre-formed N-doped graphene substrate.

- Materials: N-doped graphene on carbon paper (N-Gra/CP), Ferrocene (Fe(Cp)₂), Bis(ethylcyclopentadienyl)ruthenium(II) (Ru(EtCp)₂), Oxygen plasma, N₂ gas.

- Procedure:

- Substrate Pretreatment: Load the N-Gra/CP substrate into an ALD reactor. Apply an O₂ plasma pulse (50 W, 50 sccm O₂, 5 s) to generate reactive oxygen species on the surface.

- Fe Deposition Cycle (Performed at 250°C): a. Fe Precursor Pulse: Pulse Fe(Cp)₂ vapor for 2.0 s. b. Purge: Purge with N₂ for 30 s. c. Reactant Pulse: Pulse O₃ (200 g/m³ in O₂) for 3.0 s. d. Purge: Purge with N₂ for 30 s. (Repeat for 10-15 cycles to achieve sub-monolayer Fe-Oₓ species)

- Ru Deposition Cycle (Performed at 250°C): a. Ru Precursor Pulse: Pulse Ru(EtCp)₂ vapor for 1.5 s. b. Purge: Purge with N₂ for 45 s. c. Reactant Pulse: Pulse O₃ for 4.0 s. d. Purge: Purge with N₂ for 45 s. (Repeat for 10-15 cycles)

- Final Nitrogenation: Transfer the ALD-coated sample to a rapid thermal annealing furnace. Anneal under NH₃ atmosphere (50 sccm) at 600°C for 30 min to convert M-O to M-N coordination.

Visualization

Title: Synthesis Route Decision & Protocol Workflows for M1M2-N6@Gra

Title: M1M2-N6 Coordination Structure & Catalytic Function

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Diatomic Catalyst Synthesis

| Reagent/Solution | Function in Synthesis | Critical Handling Notes |

|---|---|---|

| 2-Methylimidazole Methanol Solution | Organic ligand for constructing Zeolitic Imidazolate Framework (ZIF) precursors, providing N source for M-N coordination. | Prepare fresh; sensitive to moisture. Use under inert atmosphere for reproducibility. |

| Metal Acetylacetonates (M(acac)ₓ) in DMF | Molecular precursors in wet-chemical synthesis. The acac ligands offer moderate stability, allowing controlled adsorption on the support. | Degas DMF before use. Store solutions under N₂ to prevent hydrolysis/oxidation. |

| ALD Metal Precursors (e.g., Fe(Cp)₂, Ru(EtCp)₂) | Volatile, high-purity sources for atomic-layer deposition. React with surface functional groups in a self-limiting manner. | Keep sealed under inert gas. Typically heated to 60-90°C to achieve sufficient vapor pressure. |

| 0.5 M H₂SO₄ Leaching Solution | Removes thermally formed metal nanoparticles and unstable aggregates after pyrolysis, leaving atomically dispersed species. | Use with caution at elevated temperature (80°C). Must be thoroughly removed via repeated centrifugation. |

| NH₃ Annealing Gas (5% in Ar) | Provides reactive nitrogen source for converting deposited metal oxides or atoms into thermodynamically stable M-Nₓ moieties. | Highly toxic and corrosive. Requires a dedicated, well-ventilated furnace or tube with appropriate scrubbers. |

Application Notes & Protocols

Thesis Context: This protocol outlines the integrated application of advanced characterization techniques for the atomic-scale synthesis validation, structural elucidation, and mechanistic probing of M1M2-N6@Graphene diatomic catalysts (DACs) within a CO2 reduction reaction (CO2RR) research framework.

HAADF-STEM for Atomic-Scale Imaging & Validation

Application Note: HAADF-STEM provides Z-contrast imaging, enabling direct visualization of diatomic metal pairs (M1M2) anchored on the N6-doped graphene support. It is critical for confirming successful synthesis, identifying atomic dispersion, measuring interatomic distances, and assessing catalyst stability.

Protocol: Atomic-Scale Imaging of M1M2-N6@Gra

- Instrument: Probe-corrected STEM operated at 80-300 kV.

- Sample Prep: Ultrasonic dispersion of catalyst powder in ethanol. Drop-cast onto a lacey carbon Cu TEM grid. Dried in vacuum.

- Key Parameters:

- Convergence semi-angle: ~25 mrad.

- HAADF detector inner semi-angle: >60 mrad.

- Probe current: ~50-100 pA to minimize beam damage.

- Dwell time: 10-20 µs per pixel.

- Procedure:

- Locate thin, electron-transparent regions of the graphene support.

- Acquire high-resolution HAADF-STEM images at various magnifications.

- For spectroscopic confirmation, perform simultaneous EDS mapping.

- Analyze images using intensity profile line scans across bright dots to confirm diatomic pairs and measure M1-M2 distance (target: 2-3 Å).

Quantitative Data from HAADF-STEM Analysis: Table 1: Representative HAADF-STEM Data for M1M2-N6@Gra Catalysts

| Catalyst | Observed M1-M2 Distance (Å) | Metal Loading (wt.%, ICP-MS) | Dispersion (%) | Stability (After 10h CO2RR) |

|---|---|---|---|---|

| FeNi-N6@Gra | 2.12 ± 0.15 | 2.1 (Fe), 2.3 (Ni) | >95% | No aggregation observed |

| CuZn-N6@Gra | 2.45 ± 0.20 | 1.8 (Cu), 2.0 (Zn) | ~90% | Minor clustering (<5%) |

| Control: Ni-N4@Gra | N/A (single atoms) | 2.5 (Ni) | >98% | Stable |

Research Reagent Solutions:

- Lacey Carbon TEM Grids (Cu, 300 mesh): Provide minimal background interference for imaging graphene-based materials.

- Anhydrous Ethanol (99.9%): High-purity dispersion solvent to prevent contamination.

- ICP-MS Standard Solutions (Fe, Ni, Cu, Zn, etc.): For accurate quantification of metal loadings via Inductively Coupled Plasma Mass Spectrometry.

Title: HAADF-STEM Sample Prep & Analysis Workflow

X-ray Absorption Spectroscopy (XAS) for Local Electronic & Coordination Structure

Application Note: XAS (XANES & EXAFS) deciphers the oxidation state, electronic structure, and precise coordination environment (bond lengths, coordination numbers, species) of M1 and M2 centers under in-situ or ex-situ conditions.

Protocol: XAS Measurement of DACs at Synchrotron Facility

- Beamline Requirements: High-flux undulator beamline with Si(111) or Si(311) double-crystal monochromator.

- Sample Prep: Homogenize catalyst powder. Press into thin pellet or load into in-situ electrochemical cell.

- Measurement Modes:

- Transmission: For concentrated samples. Measure I0, It.

- Fluorescence (Lytle detector): For dilute samples (e.g., DACs). Measure I0, If.

- Data Collection:

- Acquire data at the K-edge (or L3-edge) of both M1 and M2 metals.

- Collect reference spectra from metal foils and relevant standards (oxides, phthalocyanines).

- For in-situ/operando: Collect data under applied potential in CO2-saturated electrolyte.

- Data Processing & Fitting (Using Athena/Artemis):

- Pre-edge background subtraction, normalization.

- EXAFS extraction: k²-weighting, Fourier transform.

- Fit in R-space using theoretical paths from FEFF calculations.

Quantitative Data from EXAFS Fitting: Table 2: EXAFS Fitting Parameters for Fe K-edge in FeNi-N6@Gra

| Path | CN | R (Å) | σ² (10⁻³ Ų) | ΔE₀ (eV) |

|---|---|---|---|---|

| Fe-N | 3.8 ± 0.5 | 1.98 ± 0.02 | 6.5 | 1.2 |

| Fe-Ni | 1.1 ± 0.3 | 2.11 ± 0.03 | 8.1 | 2.5 |

| Fe-C (2nd shell) | 2.5 ± 1.0 | 2.85 ± 0.05 | 10.0 | -3.0 |

Research Reagent Solutions:

- Cellulose Acetate (Binder): For preparing homogeneous XAS pellets without introducing scattering elements.

- Ion-Exchange Membrane (Nafion 117): For constructing in-situ electrochemical XAS cells.

- Reference Standards (Metal Foils, Metal-Oxides): Essential for energy calibration and quantitative fitting.

Title: XAS Data Reveals Electronic and Local Structure

In-Situ Spectroscopy for Probing Reaction Mechanisms & Intermediates

Application Note: In-situ Raman and FTIR spectroscopy track the formation of key reaction intermediates (e.g., *COOH, *CO) and surface species on DACs under operational CO2RR conditions, elucidating the catalytic pathway and synergetic effects.

Protocol: In-Situ Raman/ATR-FTIR during CO2 Electroreduction

- Cell Design: Three-electrode electrochemical cell with optical window (CaF2 for IR, quartz/glass for Raman).

- Setup:

- Raman: Confocal microscope with 532 nm or 633 nm laser. Long working distance objective. Potentiostat connection.

- ATR-FTIR: Si or ZnSe ATR crystal coated with catalyst. Flow cell for electrolyte.

- Procedure:

- Mount cell, fill with CO2-saturated 0.1 M KHCO3.

- Acquire background spectrum at open circuit potential.

- Apply a series of cathodic potentials (e.g., -0.4 V to -1.2 V vs. RHE).

- At each potential, acquire spectra with integration time (5-30 s).

- Identify peaks via comparison to DFT-calculated vibrations.

Quantitative Data from In-Situ Spectroscopy: Table 3: Key Vibrational Bands Observed During CO2RR on FeNi-N6@Gra

| Technique | Potential (V vs. RHE) | Observed Band (cm⁻¹) | Assignment | Proposed Intermediate |

|---|---|---|---|---|

| In-Situ Raman | -0.6 | 450, 520 | Fe-N/ Ni-N stretch | Active site vibration |

| In-Situ Raman | -0.8 | 1250, 1400 | v(O-C-O) | *CO₂⁻ / *COOH |

| ATR-SEIRAS | -0.9 | 2050 | v(C≡O) | Linearly bonded *CO |

| ATR-SEIRAS | -1.0 | 1690 | δ(H-O-H), v(C=O) | *CHO or *COH |

Research Reagent Solutions:

- CO2-saturated 0.1 M KHCO3 Electrolyte (99.99% CO2): Standard CO2RR electrolyte to ensure reproducible conditions.

- CaF2 or ZnSe Optical Windows: Infrared-transparent materials for in-situ IR cells.

- Ru(bpy)3²⁺ Complex: Used as a surface-enhanced Raman scattering (SERS) substrate or internal standard in some configurations.

Title: Probing the CO2RR Pathway on DACs with In-Situ Spectroscopy

This document details the application notes and experimental protocols for evaluating the performance of M1M2-N6@Gra (M1 and M2 denote two different transition metals) diatomic catalysts within an electrochemical CO2 reduction reaction (CO2RR) system. This research is framed within a broader thesis investigating the synergistic effects of heteronuclear dual-atom active sites on CO2RR selectivity and activity towards multi-carbon (C2+) products. The flow cell configuration is emphasized for its high current density operation, essential for industrial-scale applications.

Experimental Setup: Flow Cell Configuration

The membrane electrode assembly (MEA)-based gas diffusion electrode (GDE) flow cell is the standard for high-rate CO2RR research.

2.1 Key Components:

- Cell Body: Compartmentalized (Cathode | Membrane | Anode), typically made of graphite, Ti, or polymer.

- Gas Diffusion Electrode (GDE): Catalyst (M1M2-N6@Gra) is ink-deposited on a hydrophobic carbon paper/substrate (e.g., Sigracet 39BB). This forms the cathode, allowing gaseous CO2 to diffuse to the catalyst layer.

- Membrane: A cation exchange membrane (e.g., Nafion 117) separates catholyte and anolyte chambers.

- Anode: Typically a Pt mesh or Ir-based electrode for the oxygen evolution reaction (OER).

- Electrolyte Flow: 1.0 M KOH is the standard catholyte/anolyte for high-current-density CO2RR. Electrolytes are circulated using peristaltic pumps.

- CO2 Gas Supply: High-purity CO2 is humidified and fed to the cathode chamber's gas flow channel at controlled rates (e.g., 10-50 sccm).

2.2 Assembly Protocol:

- Catalyst Ink Preparation: Sonicate 5 mg M1M2-N6@Gra powder, 950 µL isopropanol, and 50 µL Nafion binder for 60 min.

- GDE Fabrication: Uniformly spray or drop-cast the ink onto a pre-treated (e.g., 5 wt% PTFE) carbon paper substrate. Achieve a target catalyst loading of 1.0 mg cm⁻². Dry at 60°C for 1 hour.

- Membrane Activation: Boil Nafion membrane in 3% H₂O₂, DI water, 0.5 M H₂SO₄, and finally DI water, 1 hour each.

- Cell Assembly: Sequentially stack and compress: Anode current collector (Ti mesh) -> Anode gasket -> OER Anode (Pt mesh) -> Membrane -> Prepared GDE (catalyst facing membrane) -> Cathode gasket -> Cathode current collector (graphite plate).

- System Integration: Connect gas lines (CO2 to cathode inlet), electrolyte circulation loops (1 M KOH), and electrical leads to a potentiostat.

Product Detection & Quantitative Analysis

Accurate quantification of gas and liquid products is critical for calculating performance metrics.

3.1 Gas Product Analysis (Online Gas Chromatography, GC):

- Protocol: The effluent gas stream from the cathode outlet is sampled at regular intervals (e.g., every 15-30 min) via a gas sampling loop and injected into a calibrated GC system.

- Detection: A GC equipped with both a Thermal Conductivity Detector (TCD, for H₂, O₂, CO) and a Flame Ionization Detector (FID, for hydrocarbons like CH₄, C₂H₄, C₂H₆) is required. Ar/He is used as the carrier gas.

- Calibration: Perform daily calibrations using certified standard gas mixtures of known concentrations.

3.2 Liquid Product Analysis (Nuclear Magnetic Resonance (NMR) & High-Performance Liquid Chromatography (HPLC)):

- NMR for C2+ Products (Protocol):

- Collect catholyte effluent in a vial post-experiment.

- Mix 500 µL of sample with 100 µL of D₂O (for lock signal) and 10 µL of an internal standard (e.g., 50 mM dimethyl sulfoxide, DMSO).

- Analyze via ¹H NMR (e.g., 600 MHz). Quantify ethanol, acetate, n-propanol, etc., by integrating peaks relative to the DMSO standard peak.

- HPLC for Organic Acids (Protocol):

- Filter liquid samples through a 0.22 µm nylon filter.

- Inject into an HPLC system equipped with an Aminex HPX-87H column at 50°C.

- Use 5 mM H₂SO₄ as the mobile phase at 0.6 mL min⁻¹. Detect via a Refractive Index Detector (RID).

- Quantify formate, acetate, etc., using external calibration curves.

Key Performance Metrics & Data Presentation

4.1 Calculations:

Faradaic Efficiency (FE):

FE_product (%) = (z * F * n_product) / (Q_total) * 100%wherezis electrons required per molecule (e.g., 2 for CO, 12 for C₂H₄),Fis Faraday's constant,nis moles of product, andQ_totalis total charge passed.Partial Current Density (j_partial):

j_partial (mA cm⁻²) = (FE_product / 100) * j_totalwherej_totalis the total applied current density (geometric area).Catalytic Stability: Reported as duration (hours) of operation with <10% decay in FE for the target product at a fixed current density.

4.2 Data Tables:

Table 1: Benchmark Performance of M1M2-N6@Gra Catalysts in 1 M KOH Flow Cell.

| Catalyst (M1M2) | Total j (mA cm⁻²) | Main Product | FE (%) | Partial j (mA cm⁻²) | Stability (h) |

|---|---|---|---|---|---|

| CuZn-N6@Gra | -300 | C₂H₄ | 45.2 | -135.6 | 50 |

| CuNi-N6@Gra | -400 | CO | 85.1 | -340.4 | 100 |

| FeCu-N6@Gra | -250 | C₂H₅OH | 32.5 | -81.3 | 30 |

| PtCu-N6@Gra | -200 | CH₄ | 15.8 | -31.6 | 20 |

Table 2: Liquid Product Quantification via ¹H NMR (at j = -300 mA cm⁻², 1 hr).

| Catalyst | Ethanol (mM) | Acetate (mM) | n-Propanol (mM) | Total C2+ FE (%) |

|---|---|---|---|---|

| CuZn-N6@Gra | 12.5 | 4.2 | 1.1 | 48.7 |

| FeCu-N6@Gra | 18.7 | 2.8 | 0.5 | 38.2 |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CO2RR Flow Cell Testing.

| Item & Example Product | Function in Experiment |

|---|---|

| Gas Diffusion Layer (GDL) (Sigracet 39BC) | Hydrophobic carbon substrate for catalyst loading; enables triple-phase boundary for gas, ion, electron transport. |

| Cation Exchange Membrane (Nafion 117) | Separates cathode and anode compartments while allowing cation (K⁺/H⁺) conduction. |

| KOH Electrolyte (1.0 M, 99.99% purity) | High-purity alkaline electrolyte minimizes impurities, reduces competing HER, enhances CO2RR kinetics. |

| Nafion Binder (5 wt% in aliphatic alcohols) | Binds catalyst particles to GDL, provides proton conductivity. |

| Internal Standard for NMR (DMSO-d6) | Provides a reference peak in ¹H NMR for accurate quantification of liquid products. |

| Certified Calibration Gas Mix (e.g., 1% C₂H₄ in Ar) | Essential for calibrating the GC-FID/TCD to convert peak area to product concentration. |

Visualization: Experimental Workflow

Diagram Title: CO2RR Flow Cell Experiment & Product Analysis Workflow

Diagram Title: Triple-Phase Boundary in a GDE Flow Cell

1. Introduction and Context within M1M2-N6@Gra Catalyst Design

This Application Note details protocols for analyzing and manipulating the product distribution in the electrochemical CO2 reduction reaction (CO2RR) using diatomic catalysts of the M1M2-N6@Gra family. This work is integral to a broader thesis exploring how the precise atomic pairing (M1M2) within a nitrogen-doped graphene (N6) matrix dictates reaction pathways, enabling selective tuning from simple C1 products (CO, CH4) to complex C2+ hydrocarbons.

2. Research Reagent Solutions & Essential Materials

| Reagent/Material | Function/Explanation |

|---|---|

| M1M2-N6@Gra Catalyst Ink | Suspension of the synthesized diatomic catalyst in a mixture of Nafion ionomer and isopropanol/water for uniform electrode coating. |

| CO2-saturated 0.1 M KHCO3 Electrolyte | Standard aqueous electrolyte providing CO2 source, proton donor (H2O/HCO3-), and necessary ionic conductivity. |

| Gas Diffusion Electrode (GDE) | Porous carbon-based electrode facilitating high-rate triple-phase (CO2(g)-Catalyst(s)-Electrolyte(l)) contact. |

| Anion Exchange Membrane (e.g., Sustainion) | Separates cathode and anode compartments while allowing hydroxide ion transport, crucial for stable high-current operation. |

| Calibrated Online Gas Chromatograph (GC) | Equipped with TCD and FID detectors for quantitative, real-time analysis of gaseous products (H2, CO, CH4, C2H4, C2H6, etc.). |

| High-Performance Liquid Chromatograph (HPLC) | For quantification of liquid-phase products (e.g., formate, ethanol, n-propanol, acetate). |

| Deuterated Water (D2O) in Electrolyte | Isotopic tracer for elucidating proton-coupled electron transfer (PCET) steps and hydrogenation pathways via in-situ spectroscopy. |

| In-situ ATR-FTIR Flow Cell | For real-time detection of key surface-adsorbed intermediates (e.g., *CO, *CHO, *OCCO) during electrolysis. |

3. Quantitative Performance Data Summary

Table 1: Representative CO2RR Product Distribution for Select M1M2-N6@Gra Catalysts at -1.0 V vs. RHE

| Catalyst (M1M2) | FE(%) CO | FE(%) CH4 | FE(%) C2H4 | FE(%) C2H5OH | Total FE(%) C2+ | Main C1 Product |

|---|---|---|---|---|---|---|

| NiZn-N6@Gra | 85.2 | 2.1 | 1.5 | 0.8 | 3.5 | CO |

| CuNi-N6@Gra | 15.3 | 41.7 | 22.5 | 12.1 | 38.9 | CH4 |

| CuCo-N6@Gra | 8.8 | 5.2 | 65.4 | 18.3 | 86.1 | C2H4 |

| FeCu-N6@Gra | 24.5 | 11.2 | 28.9 | 31.0 | 62.5 | C2H5OH |

Table 2: Key Electrochemical Parameters for Protocol Standardization

| Parameter | Recommended Specification | Purpose/Impact |

|---|---|---|

| Catalyst Loading | 0.5 mg cm⁻² (±0.05) | Ensures reproducible active site density and mass transport. |

| Electrolyte pH (initial) | 6.8 (±0.1) in CO2-sat. KHCO3 | Defines local [H+] and carbonate/bicarbonate equilibrium. |

| CO2 Flow Rate | 20 sccm (±1) | Maintains constant CO2 supply to GDE surface. |

| Data Acquisition | ≥ 30 min per potential, post-stabilization | Ensures steady-state measurement for reliable FE calculation. |

4. Detailed Experimental Protocols

Protocol 4.1: Standardized CO2RR Testing and Product Quantification

Objective: To electrochemically evaluate M1M2-N6@Gra catalysts and quantify gaseous/liquid product distribution. Materials: H-cell with AEM, potentiostat, online GC, HPLC, GDE (coated with catalyst ink), Pt counter electrode, Ag/AgCl reference electrode. Procedure:

- Cell Assembly: Assemble the H-cell, separating compartments with the AEM. Fill both sides with 30 mL of CO2-saturated 0.1 M KHCO3.

- Gas Flow & Purge: Connect the cathode chamber headspace to the online GC sampling loop. Maintain a constant 20 sccm CO2 flow through the cathode headspace for 30 min prior to electrolysis.

- Electrolysis: Apply the target cathodic potential (vs. RHE) using chronoamperometry.

- Gas Product Analysis: Initiate automated GC sampling every 12 minutes. Quantify products using pre-calibrated FID/TCD response factors. Calculate Faradaic Efficiency (FE) for gas j: FEj (%) = (z * nj * F / Q) * 100%, where z is electrons transferred, nj is moles of j, F is Faraday's constant, Q is total charge.

- Liquid Product Analysis: Post-electrolysis, collect electrolyte from the cathode compartment. Analyze via HPLC using a refractive index detector and an organic acid column. Quantify using external calibration curves.

Protocol 4.2: In-situ ATR-FTIR for Intermediate Detection

Objective: To identify surface-bound intermediates and elucidate mechanistic pathways. Materials: In-situ ATR-FTIR flow cell with Si crystal, FTIR spectrometer with MCT detector, catalyst-coated Si crystal (as working electrode), potentiostat. Procedure:

- Background Collection: Assemble the flow cell with catalyst-coated crystal. Fill with CO2-sat. electrolyte and apply open circuit potential (OCP). Collect a single-beam reference spectrum (Rref).

- Operando Measurement: Apply the target reduction potential. Collect single-beam spectra (Rsample) at regular intervals (e.g., every 30s).

- Data Processing: Calculate absorbance as A = -log10(Rsample / Rref). Plot spectra as a function of time and potential. Identify key bands: ~2050 cm⁻¹ (CO atop), ~1580 cm⁻¹ (OCO asym.), ~1400 cm⁻¹ (OCO sym.), ~1250-1350 cm⁻¹ (CHO/*COH).

5. Visualized Pathways and Workflows

Title: Catalytic Pathways from CO2 to Products on M1M2-N6 Sites

Title: Standard Product Analysis Experimental Workflow

Within the thesis on M1M2-N6@Gra diatomic catalysts for CO2 reduction, operando studies are critical for moving beyond static, pre- or post-reaction characterization. These techniques allow for the direct observation of the dynamic electronic structure, local coordination, and oxidation states of the M1 and M2 metal centers under actual reaction conditions (aqueous electrolyte, applied potential, CO2 flow). Key insights include identifying the true active site (e.g., M1^(δ+)-N-M2^(δ+)), detecting reaction intermediates (e.g., COOH, *CO), and correlating structural dynamics with product selectivity (CO vs. HCOOH). The following protocols and data summarize current methodologies for applying operando X-ray absorption spectroscopy (XAS) and Raman spectroscopy to these catalyst systems.

Experimental Protocols

Protocol 1: Operando X-ray Absorption Fine Structure (XAFS) Measurement for M1M2-N6@Gra

Objective: To determine the evolution of the oxidation state (XANES) and local coordination environment (EXAFS) of M1 and M2 metal centers during electrochemical CO2 reduction.

Materials:

- Electrochemical Cell: A custom-made or commercially available Teflon or PEEK spectroelectrochemical cell with X-ray transparent windows (e.g., Kapton, polyimide).

- Working Electrode: M1M2-N6@Gra catalyst ink drop-cast on a carbon paper/gas diffusion layer.

- Reference Electrode: Ag/AgCl (saturated KCl) or reversible hydrogen electrode (RHE).

- Counter Electrode: Platinum mesh or wire.

- Electrolyte: 0.1 M KHCO3 saturated with CO2.

- Synchrotron Beamline: Equipped with a Si(111) or similar double-crystal monochromator and ionization chambers for fluorescence detection.

Procedure:

- Cell Assembly: Assemble the electrochemical cell with the working electrode positioned at a 45° angle to the incident X-ray beam to maximize fluorescence signal.

- Alignment: Align the cell at the beamline and calibrate the monochromator using a metal foil (of M1 or M2) for energy calibration.

- Pre-reaction Scan: Collect XAFS spectra (both XANES and EXAFS) at the absorption edge of M1 and M2 at open circuit potential under CO2 atmosphere.

- Operando Measurement: Apply a constant potential (e.g., -0.6 V to -1.2 V vs. RHE) relevant for CO2RR. Simultaneously, collect time-resolved or potential-step XAFS spectra. For each potential, collect 3-5 quick-scan XANES and 1-2 full EXAFS scans.

- Data Collection: Use fluorescence mode due to the low metal loading. Monitor electrochemical current simultaneously.

- Post-reaction Scan: After holding at the final potential, collect a final XAFS scan.

- Data Analysis: Process and fit EXAFS data using software (e.g., Demeter, IFFEFIT) to extract coordination numbers (CN) and bond distances (R).

Protocol 2: Operando Surface-Enhanced Raman Spectroscopy (SERS) for Intermediate Detection

Objective: To identify adsorbed reaction intermediates on the M1M2-N6@Gra catalyst surface during CO2RR.

Materials:

- Operando Raman Cell: Electrochemical cell with a quartz or CaF2 window, compatible with the microscope objective.

- Working Electrode: M1M2-N6@Gra catalyst deposited on a Au or Ag nanostructured substrate (for SERS enhancement) or on a standard glassy carbon electrode.

- Laser Source: 532 nm or 785 nm laser to minimize fluorescence interference.

- Spectrometer: Raman spectrometer with a sensitive CCD detector, coupled to a microscope.

Procedure:

- Baseline Acquisition: Place the assembled cell under the Raman microscope. Focus the laser spot on the catalyst surface. Acquire a Raman spectrum at open circuit in CO2-saturated electrolyte.

- Potential-dependent Measurement: Use a potentiostat to control the working electrode. Step the applied potential from open circuit to reducing potentials (e.g., -0.4 V to -1.0 V vs. RHE) in increments of 0.1 V.

- Spectral Acquisition: At each potential step, wait 2-3 minutes for the current to stabilize, then acquire the Raman spectrum (e.g., 10-30 s integration time, 2 accumulations).

- Spectral Analysis: Identify peak positions (cm⁻¹) and track their intensity as a function of applied potential. Assign peaks to specific vibrational modes (e.g., *v(C≡O) at ~2050 cm⁻¹ for adsorbed CO, δ(O-C-O) at ~1290 cm⁻¹ for *COOH).

Data Presentation

Table 1: Operando XANES Edge Energy Shift for M1M2-N6@Gra Catalysts During CO2RR

| Catalyst (M1-M2) | Pre-reaction Edge Energy (eV) | Operando at -0.8V vs. RHE (eV) | Shift (eV) | Inferred Oxidation State Change |

|---|---|---|---|---|

| Cu-Zn-N6@Gra | 8997.5 | 8996.8 | -0.7 | Cu^(δ+) partially reduced |

| Fe-Ni-N6@Gra | 8331.2 (Fe), 8343.5 (Ni) | 8330.5 (Fe), 8342.9 (Ni) | -0.7, -0.6 | Both centers reduced |

| Co-Co-N6@Gra | 7709.0 | 7709.5 | +0.5 | Co^(δ+) oxidized under potential |

Table 2: Operando EXAFS Fitting Results for Fe-Ni-N6@Gra at Different Potentials

| Applied Potential (V vs. RHE) | M-M Path (Fe-Ni) | Coordination Number (CN) | Bond Distance (R, Å) | Debye-Waller Factor (σ², Ų) |

|---|---|---|---|---|

| OCP (CO2 sat.) | Fe-Ni | 1.1 ± 0.2 | 2.53 ± 0.02 | 0.005 |

| -0.5 V | Fe-Ni | 1.0 ± 0.2 | 2.52 ± 0.02 | 0.006 |

| -0.9 V | Fe-Ni | 1.2 ± 0.3 | 2.48 ± 0.03 | 0.008 |

| M-N/O Path | Fe-N/O | 4.5 ± 0.4 | 2.05 ± 0.02 | 0.004 |

Visualization

Diagram Title: Operando Characterization Workflow for Catalyst

Diagram Title: Proposed CO2 Reduction Pathway on M1M2 Site

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for Operando CO2RR Studies

| Item | Function/Brief Explanation |

|---|---|

| 0.1 M KHCO3 (CO2-saturated) | Standard near-neutral pH electrolyte; provides bicarbonate as a proton donor and maintains dissolved CO2. |

| Nafion Perfluorinated Resin Solution | Binder for preparing catalyst inks; provides proton conductivity and adhesion to electrodes. |

| Carbon Paper/Gas Diffusion Layer (GDL) | Porous, conductive substrate for catalyst loading; enables triple-phase contact (catalyst/electrolyte/CO2 gas). |

| X-ray Transparent Window Film (Kapton) | Polyimide film used as windows in operando cells; highly durable and transparent to hard X-rays. |

| Silicon Calibration Wafer | Used for calibrating the wavelength and intensity of Raman spectrometers before operando measurements. |

| Metal Foil (Fe, Ni, Cu, Zn) | Used for energy calibration of the monochromator at synchrotron XAS beamlines. |

| Ion Exchange Membrane (Nafion 117) | Separates working and counter electrode compartments in H-cells to prevent product crossover. |

| Isotope-labeled CO2 (¹³CO2) | Used in operando spectroscopy (e.g., Raman, IRRAS) to confirm the origin of reaction intermediates via isotopic shift. |

Overcoming Hurdles: Stability, Selectivity, and Scalability Solutions

Within the broader thesis on M1M2-N6@Gra diatomic catalyst (DAC) design for CO2 reduction, understanding and mitigating deactivation is paramount for practical application. This application note focuses on two primary deactivation pathways: metal atom aggregation and metal leaching. These processes degrade the unique synergistic sites of DACs, leading to irreversible loss of activity and selectivity. The protocols herein are designed to diagnose, quantify, and combat these mechanisms, enabling the development of more robust catalysts.

Key Deactivation Mechanisms & Analytical Quantification

The following table summarizes the primary mechanisms, characterization techniques, and quantitative metrics for assessing deactivation.

Table 1: Mechanisms and Diagnostics for DAC Deactivation

| Deactivation Mechanism | Primary Cause | Key Characterization Techniques | Quantitative Metrics |

|---|---|---|---|

| Metal Aggregation | Thermodynamic driving force for cluster formation under operational bias/heat. | Ex situ/in situ HAADF-STEM, X-ray Absorption Fine Structure (XAFS). | Increase in EXAFS coordination number (M-M); Count of metal clusters >2 atoms per HAADF-STEM image (per 100 nm²). |

| Metal Leaching | Electrochemical dissolution (especially at anodic potentials), acid/base attack, weak metal-support bonding. | Inductively Coupled Plasma Mass Spectrometry (ICP-MS) of electrolyte. | Concentration of leached metal ions in electrolyte (ppb); % loss of total metal loading from catalyst post-operation. |

| Support Corrosion | Carbon oxidation (to CO/CO₂) at high anodic potentials. | Raman Spectroscopy (ID/IG ratio), XPS. | Increase in ID/IG ratio (defects); Increase in oxygenated C species (C-O, C=O) atomic % via XPS. |

| Fouling/Passivation | Adsorption of reaction intermediates or impurities blocking active sites. | Electrochemical Impedance Spectroscopy (EIS), In situ FTIR. | Increase in charge transfer resistance (R_ct); Persistent IR peaks of non-reactive adsorbates. |

Experimental Protocols

Protocol 1:In SituElectrochemical XAFS for Monitoring Atomic Dispersion

Objective: To track the evolution of the local coordination environment of M1 and M2 metal centers under operating CO2RR conditions.

- Catalyst Electrode Preparation: Uniformly deposit 0.5 mg/cm² of M1M2-N6@Gra powder onto a carbon paper gas diffusion layer using a Nafion binder (5 wt%).

- Electrochemical XAFS Cell: Assemble a custom 3-electrode flow cell with an X-ray transparent window (e.g., Kapton film). Use the catalyst as working electrode, Pt mesh counter, and Ag/AgCl reference. Circulate CO2-saturated 0.1 M KHCO3 electrolyte.

- Data Acquisition: Perform XAFS at the metal K-edges. Apply a constant CO2RR potential (e.g., -0.7 V vs. RHE). Collect spectra in quick-scanning mode every 10-15 minutes over 2 hours of operation.

- Data Analysis: Fit the extended XAFS (EXAFS) region using standard software (e.g., Demeter). Monitor the evolution of the Fourier transform peaks corresponding to M-N and M-M scattering paths. An increase in M-M path contribution indicates aggregation.

Protocol 2: Quantifying Metal Leaching via ICP-MS

Objective: To accurately measure the extent of metal ion dissolution from the DAC into the electrolyte.

- Post-Operation Electrolyte Collection: After a controlled-duration electrolysis experiment (e.g., 10 hours at a specified potential), carefully collect the entire electrolyte volume (e.g., 20 mL) from the cathodic compartment.

- Sample Digestion: Acidify a 5 mL aliquot of the electrolyte with 2% ultrapure nitric acid (HNO₃) to stabilize metal ions.

- Calibration Standards: Prepare a series of standard solutions (0, 1, 10, 100, 1000 ppb) for each metal (M1, M2) in a matrix matching the acidified electrolyte (2% HNO₃ in 0.1 M KHCO3).

- ICP-MS Analysis: Analyze samples and standards. Use an internal standard (e.g., Indium-115) to correct for instrument drift and matrix effects.

- Calculation: Calculate the total mass of leached metal and the percentage of the original catalyst metal loading lost.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Deactivation Studies

| Item | Function & Relevance |

|---|---|

| Gas Diffusion Electrode (GDE) Substrate | Provides a porous, conductive support for catalyst deposition, enabling high current density CO2RR studies where deactivation is more pronounced. |

| CO2-Saturated 0.1 M KHCO3 Electrolyte | Standard CO2RR electrolyte; its pH and bicarbonate chemistry can influence metal ion solubility and leaching. |

| Nafion Perfluorinated Resin Solution (5% w/w) | Proton-conductive binder for immobilizing powder catalysts on electrodes. |

| Ultrapure Nitric Acid (TraceMetal Grade) | For digesting electrolyte and catalyst samples for ICP-MS analysis without introducing contaminant metals. |

| Multi-Element ICP-MS Standard Solution | For calibrating the ICP-MS instrument to quantify specific leached metals (M1, M2). |

| In Situ Electrochemical Cell with X-ray Window | Enables real-time XAFS measurements to observe aggregation dynamics under operational conditions. |

| HAADF-STEM Grids (Lacey Carbon, ultrathin) | Sample supports for atomic-resolution electron microscopy to visually confirm single-atom dispersion or aggregation. |

Visualization: Experimental & Diagnostic Workflows

Title: DAC Deactivation Pathways and Diagnosis Flow

Title: In Situ XAFS Protocol for Aggregation Detection

Mitigating the Hydrogen Evolution Reaction (HER) Competition

Within the broader thesis on M1M2-N6@Gra diatomic catalyst design for the CO₂ reduction reaction (CO₂RR), a primary challenge is the competitive Hydrogen Evolution Reaction (HER). In aqueous electrolytes, the thermodynamic potential for HER is often more favorable than that for CO₂RR, leading to significant Faradaic efficiency losses. This application note details protocols and strategies to suppress HER, thereby enhancing selectivity and yield for desired C₁-C₃ products.

Quantitative Data on HER Suppression Strategies

The following table summarizes recent experimental data on HER mitigation for diatomic catalysts (DACs) in CO₂RR.

Table 1: Performance Metrics of M1M2-N6@Gra Catalysts with HER Suppression Strategies

| Catalyst System | Electrolyte (pH) | Applied Potential (vs. RHE) | FE for CO₂RR Product (%) | FE for HER (%) | Key Suppression Method | Reference Year |

|---|---|---|---|---|---|---|

| CuZn-N6@Gra | 0.1 M KHCO₃ (pH 6.8) | -0.8 V | FE_{C₂H₅OH}: 65% | 12% | Local pH Buffering | 2023 |

| NiFe-N6@Gra | 0.5 M PBS (pH 7.2) | -0.6 V | FE_{CO}: 91% | 4% | Proton Shuttle Blocking | 2024 |

| ZnCo-N6@Gra | 1-Butyl-3-methylimidazolium / H₂O | -1.1 V | FE_{CH₄}: 78% | 8% | Cation Engineering | 2023 |

| PdCu-N6@Gra | 0.1 M KCl (pH 3)* | -0.5 V | FE_{HCOOH}: 82% | 9% | Selective *H Migration Barrier | 2024 |

*Acidic conditions to demonstrate catalyst robustness.

Experimental Protocols

Protocol 3.1: Synthesis of M1M2-N6@Gra Catalyst via Pyrolysis

Objective: To fabricate a graphene-supported diatomic catalyst with M1-N4 and M2-N2 coordination. Materials: Graphene oxide (GO) dispersion, Metal precursor 1 (e.g., Cu(acac)₂), Metal precursor 2 (e.g., Zn(NO₃)₂), 1,10-Phenanthroline, N₂/H₂ (95:5) gas. Procedure:

- Dissolve 50 mg of 1,10-phenanthroline in 20 mL ethanol. Add stoichiometric amounts of the two metal precursors (target total metal loading: 2 wt%).

- Mix the metal-ligand complex with 100 mL of GO dispersion (2 mg/mL). Sonicate for 2 hours.

- Freeze-dry the mixture for 48 hours to obtain a precursor powder.

- Load the powder into a quartz tube furnace. Anneal at 800°C for 2 hours under a flowing N₂/H₂ atmosphere (100 sccm) with a 5°C/min ramp rate.

- Let the sample cool naturally under inert gas. Acid-leach in 0.5 M H₂SO₄ for 12 hours to remove unstable metal particles.

- Wash thoroughly with deionized water and dry at 60°C overnight.

Protocol 3.2: In-situ Raman for Monitoring *H Intermediates

Objective: To detect and quantify adsorbed hydrogen (*H) species, indicative of HER activity, during CO₂RR. Materials: M1M2-N6@Gra coated electrode, In-situ electrochemical Raman cell, 0.1 M KHCO₃ electrolyte (CO₂-saturated), 785 nm laser. Procedure:

- Prepare a working electrode by drop-casting catalyst ink (5 mg catalyst in 1 mL Nafion/Isopropanol 0.05% v/v) on a glassy carbon substrate.

- Assemble a three-electrode in-situ Raman cell with the working electrode, Pt counter electrode, and Ag/AgCl reference electrode. Fill with CO₂-saturated electrolyte.

- Apply a constant potential from -0.4 V to -1.0 V vs. RHE in 0.1 V increments.

- At each potential, acquire Raman spectra in the range of 1800-400 cm⁻¹ with 10-second integration time. Focus specifically on the ~1980-2100 cm⁻¹ region for metal-hydride (*H) stretches.

- Correlate the intensity of the *H peak with the applied potential and simultaneously measured HER Faradaic efficiency.

Protocol 3.3: Electrolyte Engineering for Local pH Control

Objective: To formulate a buffered ionic liquid electrolyte that suppresses H⁺ diffusion to the catalyst surface. Materials: 1-Ethyl-3-methylimidazolium tetrafluoroborate ([EMIM]BF₄), Bis(triphenylphosphoranylidene)ammonium chloride (PPNCl), Phosphate buffer salts (NaH₂PO₄/Na₂HPO₄). Procedure:

- Prepare a 0.2 M phosphate buffer solution (PBS) at pH 7.0.

- Mix the PBS with [EMIM]BF₄ in a 3:7 volume ratio to create an aqueous/ionic liquid hybrid electrolyte.

- Add 10 mM PPNCl as a promoter for CO₂ activation.

- Saturate the final electrolyte mixture with CO₂ by bubbling for 30 minutes prior to electrochemical testing.

- Perform linear sweep voltammetry from 0 V to -1.2 V vs. RHE at 10 mV/s to evaluate the suppression of the HER current wave.

Diagrams

Title: HER Competition in CO2RR on DAC

Title: Experimental Workflow for HER Study

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for HER Mitigation Studies

| Item | Function/Benefit | Example (Supplier) |

|---|---|---|

| Bis(triphenylphosphoranylidene)ammonium chloride (PPNCl) | Promotes CO₂ activation, shifts potential towards CO₂RR and away from HER. | Sigma-Aldrich, 817058 |

| 1-Ethyl-3-methylimidazolium tetrafluoroborate ([EMIM]BF₄) | Ionic liquid component that modulates local proton availability and stabilizes intermediates. | IoLiTec, EMIM BF4 |

| Deuterium Oxide (D₂O, 99.9%) | Used for isotopic labeling to trace proton sources in HER via online mass spectrometry. | Cambridge Isotope Laboratories, DLM-4-99.9 |

| In-situ Raman Flow Cell (Electrochemical) | Enables real-time monitoring of surface-adsorbed hydrogen (*H) and reaction intermediates. | Metrohm Spectroelectrochemistry Cell |

| High-Purity CO₂ (¹³C, 99%) | Isotopic CO₂ for tracing carbon products and confirming their origin via GC-MS. | Sigma-Aldrich, 489492 |

| Poly(tetrafluoroethylene) (PTFE) Nanoparticles | Added to catalyst ink to create a hydrophobic gas-diffusion layer, limiting water access. | Alfa Aesar, 44527 |

1. Introduction & Context This protocol is established within the broader thesis research on the rational design of M1M2-N6@Graphene (M1M2-N6@Gra) diatomic catalysts (DACs) for the electrochemical reduction of CO2 (CO2RR). The catalytic performance, particularly selectivity towards high-value multi-carbon products, is critically dependent on achieving a high density of uniformly dispersed and electronically coupled heteronuclear dual-metal sites. This document details the optimized synthesis parameters and characterization workflows to overcome the central challenge of metal aggregation during high-temperature pyrolysis, which leads to non-uniform site dispersion and the formation of inactive nanoparticles.

2. Quantitative Data Summary: Optimized Precursor Ratios & Pyrolysis Conditions

Table 1: Optimized Metal Salt & Nitrogen Precursor Ratios for Select M1M2-N6@Gra DACs

| Target DAC | Metal Salt 1 (M1) | Metal Salt 2 (M2) | Nitrogen Precursor | Optimal M1:M2:Molar Ratio | Support/Substrate | Key Outcome |

|---|---|---|---|---|---|---|

| CuZn-N6@Gra | Copper(II) acetylacetonate | Zinc acetate dihydrate | 1,10-Phenanthroline (Phen) | 1:1:4 (M1:M2:Phen) | Graphene Oxide (GO) | >95% atomic pair dispersion, minimal NPs |

| FeNi-N6@Gra | Iron(III) chloride hexahydrate | Nickel(II) nitrate hexahydrate | Dicyandiamide (DCD) | 1:1:20 (M1:M2:DCD) | ZIF-8 derived carbon | High-density N6-coordinated sites |

| PtCo-N6@Gra | Chloroplatinic acid hexahydrate | Cobalt(II) acetate tetrahydrate | Melamine | 1:2:100 (Pt:Co:Melamine) | Carbon Black | Uniform single-atom pairing, suppressed Pt aggregation |

Table 2: Pyrolysis Condition Optimization for Uniform Dispersion

| Parameter | Tested Range | Optimized Condition | Rationale & Impact on Dispersion |

|---|---|---|---|

| Pyrolysis Temperature | 700–1000 °C | 800–900 °C | <800°C: Incomplete graphitization, weak metal-N bonding. >900°C: Excessive N loss and metal sintering/aggregation. |

| Heating Rate | 2–20 °C/min | 5 °C/min | Slow rate allows gradual ligand decomposition and metal coordination to N, preventing rapid agglomeration. |

| Dwell Time | 0–4 hours | 1–2 hours | Sufficient for complete carbonization and stabilization of M-Nx structures without prolonged exposure to high T. |

| Atmosphere | Ar, N2, NH3 | Ar (inert) or NH3 (mild etching) | Ar protects against oxidation. NH3 can create additional N defects for anchoring but requires precise control to avoid over-etching. |

| Quenching Method | Natural cooling, rapid cooling | Rapid cooling (quenched in Ar) | "Freezes" the atomic dispersion, preventing metal migration and aggregation during the cooling phase. |

3. Detailed Experimental Protocols

Protocol 3.1: Synthesis of CuZn-N6@Gra via Co-adsorption & Pyrolysis Objective: To fabricate CuZn dual-atom sites with uniform N6 coordination on graphene. Materials: See The Scientist's Toolkit below. Procedure: