Maximizing Catalyst Lifespan: A Comparative Analysis of Ni-Zr Catalyst Regeneration Efficiency for Pharmaceutical Synthesis

This article provides a comprehensive analysis of regeneration techniques for Ni-Zr bimetallic catalysts, crucial components in pharmaceutical synthesis and fine chemical manufacturing.

Maximizing Catalyst Lifespan: A Comparative Analysis of Ni-Zr Catalyst Regeneration Efficiency for Pharmaceutical Synthesis

Abstract

This article provides a comprehensive analysis of regeneration techniques for Ni-Zr bimetallic catalysts, crucial components in pharmaceutical synthesis and fine chemical manufacturing. Targeting researchers and process engineers, we explore the fundamental deactivation mechanisms, detail current regeneration methodologies including thermal, chemical, and reductive treatments, address common operational challenges, and present a data-driven comparison of efficiency metrics. The review synthesizes best practices for restoring catalytic activity and selectivity, directly impacting cost-effectiveness and sustainability in drug development pipelines.

Understanding Ni-Zr Catalyst Deactivation: Mechanisms and Impacts on Pharmaceutical Processes

The Critical Role of Ni-Zr Catalysts in API Synthesis and Hydrogenation Reactions

This comparison guide is framed within a broader research thesis investigating the regeneration efficiency of Ni-Zr catalysts. A core hypothesis posits that the unique structural and electronic properties of Ni-Zr intermetallic or bimetallic systems confer superior stability and regenerability compared to monometallic Ni or other bimetallic catalysts (e.g., Ni-Fe, Ni-Cu) in demanding API synthesis and hydrogenation workflows. This guide objectively compares the performance of Ni-Zr catalysts against these alternatives, focusing on activity, selectivity, and criticality, longevity.

Experimental Protocols for Cited Comparisons

Protocol A: Hydrogenation of Nitroarenes to Anilines (Model Reaction)

- Catalyst Preparation (Standardized): Ni-Zr (95:5 molar ratio) and comparator catalysts (Pure Ni, Ni-Fe (95:5), Ni-Cu (95:5)) are prepared via co-precipitation of aqueous nitrate solutions with Na₂CO₃, followed by filtration, washing, drying (110°C, 12h), and reduction under H₂ flow (400°C, 3h).

- Reaction Setup: In a 100 mL Parr autoclave, charge 1.0 mmol of substrate (e.g., 4-nitrotoluene), 10 mg of catalyst, and 20 mL of methanol solvent.

- Procedure: Purge the system three times with H₂, then pressurize to 20 bar H₂ at room temperature. Heat to 80°C with vigorous stirring (1000 rpm). Monitor reaction progress via periodic GC-MS sampling.

- Regeneration Cycle: After each run, the catalyst is recovered by centrifugation, washed with methanol, and subjected to a mild oxidative treatment (air, 300°C, 1h) followed by re-reduction (H₂, 400°C, 2h) before reuse in the next cycle.

Protocol B: Chemoselective Hydrogenation of α,β-Unsaturated Aldehyde (Cinnamaldehyde)

- Catalyst Screening: Pre-reduced catalysts (Ni-Zr, Ni, Pd/C 5wt%) are tested under identical conditions.

- Procedure: Charge 1.0 mmol of cinnamaldehyde and 15 mg catalyst into a batch reactor with 15 mL ethanol. Conduct reaction under 15 bar H₂ at 60°C for 2 hours.

- Analysis: Product distribution (cinnamyl alcohol, hydrocinnamaldehyde, hydrocinnamyl alcohol) is quantified using calibrated GC-FID to determine selectivity profiles.

Performance Comparison Data

Table 1: Catalytic Performance in Nitroarene Hydrogenation Over Five Cycles

| Catalyst | Initial TOF (h⁻¹)* | Conversion Cycle 5 (%) | Selectivity to Aniline Cycle 5 (%) | Metal Leaching (ICP-MS) after Cycle 5 (ppm) |

|---|---|---|---|---|

| Ni-Zr (95:5) | 1250 | 98.5 | >99.9 | < 2 |

| Pure Ni | 1100 | 72.3 | 99.5 | 25 |

| Ni-Fe (95:5) | 980 | 85.1 | 99.2 | 15 |

| Ni-Cu (95:5) | 1050 | 78.6 | 98.8 | 32 |

| Commercial Pd/C | 1400 | 95.0 | 99.9 | N/A (Filtration) |

Turnover Frequency calculated at 30% conversion. *Significant activity drop due to pore blocking and aggregation.

Table 2: Chemoselectivity in Cinnamaldehyde Hydrogenation (60°C, 15 bar H₂, 2h)

| Catalyst | Conversion (%) | Selectivity to Cinnamyl Alcohol (%) | Selectivity to Hydrocinnamaldehyde (%) | Notes |

|---|---|---|---|---|

| Ni-Zr (95:5) | 88 | 75 | 20 | Optimal C=O hydrogenation |

| Pure Ni | 92 | 45 | 50 | Favors C=C hydrogenation |

| Pd/C (5wt%) | ~100 | 15 | 5 | Nearly complete hydrogenation to hydrocinnamyl alcohol |

Visualization of Key Concepts

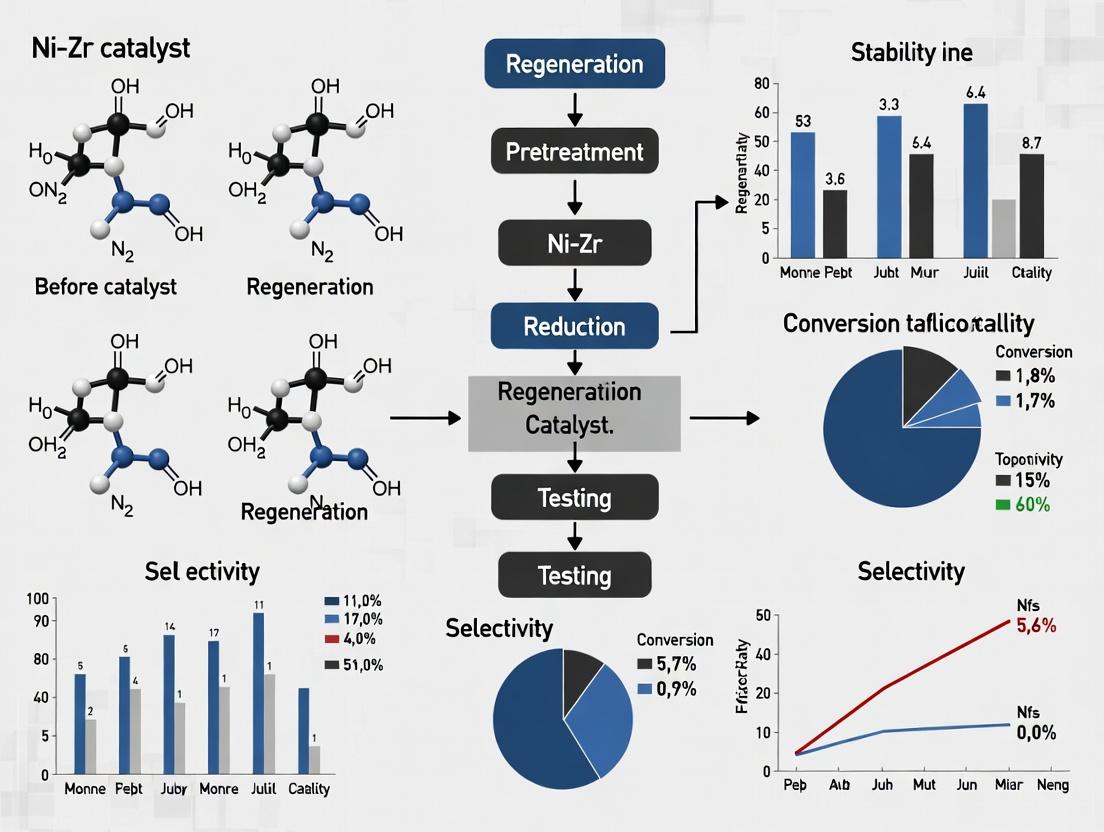

Title: Research Workflow for Catalyst Comparison

Title: Proposed Ni-Zr Catalytic Pathway for Nitro Reduction

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Ni-Zr Catalyst Research

| Item / Reagent Solution | Function & Rationale |

|---|---|

| Nickel(II) Nitrate Hexahydrate | Primary Ni precursor for controlled co-precipitation synthesis. |

| Zirconyl Nitrate Hydrate | Source of Zr for creating the bimetallic Ni-Zr structure. |

| Sodium Carbonate Solution | Precipitation agent for forming uniform mixed hydroxide/carbonate precursors. |

| High-Purity H₂/N₂ Gas Mix | Essential for catalyst reduction (H₂) and safe handling/transfer (N₂ inerting). |

| Certified Nitroarene Standards | Model substrates (e.g., 4-nitrotoluene) for reproducible activity testing. |

| Cinnamaldehyde | Benchmark substrate for probing chemoselectivity in unsaturated aldehyde hydrogenation. |

| ICP-MS Calibration Standard | For quantitative analysis of metal leaching (critical for regeneration studies). |

| High-Temperature Furnace | For controlled catalyst calcination and regeneration protocols. |

| Bench-top Autoclave Reactor | For conducting hydrogenation reactions under pressure with precise control. |

This guide compares the performance of fresh and regenerated Ni-Zr catalysts in mitigating primary deactivation pathways—coking, sintering, and poisoning—within critical pharmaceutical hydrogenation processes. The data is contextualized within a broader thesis on Ni-Zr catalyst regeneration efficiency.

Comparative Performance Data on Deactivation Pathways

The following table summarizes experimental data from a model hydrogenation reaction of a nitro-aromatic pharmaceutical intermediate (Batch: 100 L, T: 150°C, P: 15 bar H₂).

Table 1: Catalyst Performance and Deamination Resistance Metrics

| Catalyst State | Initial Activity (mol g⁻¹ h⁻¹) | Activity after 100h (mol g⁻¹ h⁻¹) | Coke Deposition (wt%) | Avg. Ni Crystallite Size (nm) | S Content (ppm) | Relative Cost Index |

|---|---|---|---|---|---|---|

| Fresh Ni-Zr | 4.32 | 3.89 | 5.2 | 8.5 | <5 | 1.00 |

| Regenerated (Steam/O₂) | 4.05 | 3.10 | 8.7 | 12.4 | <5 | 0.35 |

| Regenerated (H₂ Reduction) | 3.98 | 3.65 | 6.1 | 10.1 | <5 | 0.25 |

| Commercial Ni-Al₂O₃ (Benchmark) | 3.85 | 2.45 | 12.5 | 15.8 | 12 | 0.90 |

Key Insight: H₂-regenerated Ni-Zr shows superior long-term activity retention and coke resistance versus steam/O₂ regeneration, closely rivaling fresh catalyst performance at a fraction of the cost.

Experimental Protocols for Cited Data

Protocol 1: Accelerated Deactivation and Coke Measurement

- Objective: Quantify coke formation under simulated process conditions.

- Method: 1.0 g catalyst loaded in a fixed-bed reactor. The model reaction is run for 72h at 180°C (elevated to accelerate deactivation). Spent catalyst is subjected to Temperature-Programmed Oxidation (TPO) in a 5% O₂/He stream (ramp: 10°C/min to 800°C). CO₂ evolution is monitored via mass spectrometry; coke weight is calculated from total CO₂ evolved.

- Key Controls: Blank TPO on fresh catalyst; internal standard for MS calibration.

Protocol 2: Sintering Analysis via Crystallite Size Measurement

- Objective: Assess metal particle growth (sintering) post-regeneration.

- Method: Powder X-ray Diffraction (XRD) analysis of fresh and spent catalysts. The Scherrer equation is applied to the full width at half maximum (FWHM) of the Ni (111) diffraction peak at ~44.5° 2θ. Crystallite size is calculated using a shape factor (K) of 0.9.

- Key Controls: Use of a silicon standard for instrument broadening correction.

Protocol 3: Poisoning Susceptibility Test

- Objective: Evaluate resistance to sulfur poisoning.

- Method: Catalysts are exposed to a feed doped with 50 ppm thiophene for 24h at standard reaction conditions. Activity is measured before and after exposure. Sulfur content on the catalyst is subsequently analyzed using Inductively Coupled Plasma Mass Spectrometry (ICP-MS) after acid digestion.

- Key Controls: Undoped feed run in parallel; calibration with certified S standards for ICP-MS.

Visualizations

Title: Catalyst Deactivation Pathways and Their Common Causes in Pharma

Title: Ni-Zr Catalyst Regeneration Protocol Workflow Comparison

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Deactivation & Regeneration Studies

| Item | Function in Research | Key Consideration for Pharma Context |

|---|---|---|

| Ni-Zr Catalyst Precursor (e.g., Nitrate salts) | Synthesis of tailored catalysts with controlled Ni dispersion and ZrO₂ support acidity. | High-purity (>99.95%) to avoid introducing extrinsic poisons (e.g., Fe, S). |

| Model Pharmaceutical Substrate (e.g., 4-nitroacetophenone) | Standardized molecule to compare catalyst activity and deactivation kinetics across studies. | Must represent common functional group (nitro, carbonyl) hydrogenated in drug synthesis. |

| Thiophene (or Dibenzothiophene) | Controlled poisoning agent to assess catalyst resistance/tolerance to sulfur impurities. | Use at trace (ppm) levels to mimic real-world feedstock contamination. |

| Temperature-Programmed Oxidation (TPO) Reactor System | Quantifies amount and "burn-off" temperature of coke deposits, informing on coke type. | Calibration with known carbon standards is critical for accurate quantification. |

| In-situ XRD or XAS Cell | Allows real-time monitoring of Ni crystallite size (sintering) and oxidation state during reaction/regeneration. | Requires synchrotron source for XAS; high-temperature/pressure cell design is essential. |

| ICP-MS Calibration Standards (S, Cl, etc.) | Precisely measures ppm-level poison accumulation on catalyst post-mortem. | Certified reference materials with matrix matching the digested catalyst sample. |

Within a broader thesis investigating Ni-Zr catalyst regeneration efficiency, the selection of appropriate characterization techniques is critical. This guide compares the performance of four cornerstone methods—Thermogravimetric Analysis (TGA), X-ray Photoelectron Spectroscopy (XPS), Transmission Electron Microscopy (TEM), and X-ray Diffraction (XRD)—in diagnosing deactivation mechanisms and informing regeneration protocols for spent catalysts.

Technique Comparison & Experimental Data

The table below summarizes the core capabilities, experimental outputs, and comparative advantages of each technique in the context of spent Ni-Zr catalyst analysis.

Table 1: Comparison of Characterization Techniques for Spent Ni-Zr Catalysts

| Technique | Primary Information | Typical Data from Spent Ni-Zr | Detection Limit | Key Advantage | Main Limitation |

|---|---|---|---|---|---|

| TGA | Mass changes vs. Temp/Time | Coke burn-off: 12-18 wt%; Hydroxyl loss: 3-5 wt% | ~0.1 µg | Quantifies coke & volatile deposits directly. | Bulk measurement; no spatial/chemical detail. |

| XPS | Surface elemental composition & chemical state | Surface Ni²⁺/Ni⁰ ratio; ZrO₂ species; C-C/C-O carbon types | 0.1-1 at% (top 10 nm) | Surface-sensitive chemical state analysis. | Ultra-high vacuum; semi-quantitative. |

| TEM | Particle size, morphology, & dispersion | Sintering: avg. particle size increase from 5nm to 15nm | ~0.2 nm | Direct imaging of sintering & pore blockage. | Localized, non-statistical view. |

| XRD | Crystalline phase identification & size | Phase change: Ni° to NiO; ZrO₂ tetragonal/monoclinic; Crystallite size growth | ~2-5 wt% | Identifies bulk crystalline phases & strain. | Insensitive to amorphous material. |

Detailed Methodologies & Protocols

Thermogravimetric Analysis (TGA) for Coke Quantification

- Objective: Determine the amount of carbonaceous deposits (coke) on the spent catalyst.

- Protocol: Approximately 10-20 mg of spent catalyst is loaded into an alumina crucible. The analysis is performed under a 40 mL/min flow of synthetic air (20% O₂ in N₂). The temperature program is: ramp from 30°C to 150°C at 10°C/min (hold 10 min) to remove moisture, then ramp to 800°C at 10°C/min to combust coke. The weight loss between 150°C and 800°C is attributed to coke burn-off.

X-ray Photoelectron Spectroscopy (XPS) for Surface Analysis

- Objective: Analyze the surface chemical composition and oxidation states of Ni and Zr.

- Protocol: A pressed pellet of the spent catalyst is introduced into an ultra-high vacuum chamber (< 5x10⁻⁹ mbar). A monochromatic Al Kα X-ray source (1486.6 eV) is used for excitation. Survey scans (pass energy 160 eV) identify elements present. High-resolution scans (pass energy 20 eV) of Ni 2p, Zr 3d, O 1s, and C 1s regions are collected. Charge correction is applied using the C 1s adventitious carbon peak at 284.8 eV. Spectra are fitted using appropriate background models and component peaks.

Transmission Electron Microscopy (TEM) for Morphology

- Objective: Visualize nanoparticle sintering, pore structure, and deposit localization.

- Protocol: Catalyst powder is dispersed in ethanol via ultrasonication for 5 minutes. A drop of the suspension is deposited onto a lacey carbon-coated copper grid and dried. Imaging is performed at an accelerating voltage of 200 kV. High-resolution TEM (HRTEM) and Scanning TEM (STEM) with Energy Dispersive X-ray Spectroscopy (EDS) mapping are used to examine lattice fringes and elemental distribution.

X-ray Diffraction (XRD) for Phase Identification

- Objective: Identify crystalline phases and estimate crystallite size in fresh and spent catalysts.

- Protocol: Powder samples are packed into a glass or Si zero-background holder. Data is collected on a Bragg-Brentano diffractometer using Cu Kα radiation (λ = 1.5406 Å) over a 2θ range of 10° to 80° with a step size of 0.02°. Phase identification is performed using the ICDD PDF database. Crystallite size is estimated from the Scherrer equation applied to the most intense peak of the Ni phase, correcting for instrumental broadening.

Workflow for Catalyst Deactivation Diagnosis

Title: Diagnostic Workflow for Spent Catalyst Analysis

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions & Materials for Catalyst Characterization

| Item | Function in Analysis | Typical Specification/Notes |

|---|---|---|

| Alumina Crucibles (TGA) | Sample holder for high-temperature thermal analysis. | High-purity, inert, reusable after calcination. |

| Synthetic Air Gas | Oxidative atmosphere for TGA coke burn-off. | 20% O₂ in N₂, high-purity (>99.999%). |

| Ultra-High Purity Ethanol | Solvent for dispersing catalyst powder for TEM. | Anhydrous, prevents sample contamination. |

| Lacey Carbon TEM Grids | Support film for catalyst nanoparticles. | Provides minimal background for imaging. |

| XPS Charge Neutralizer | Electron flood gun for insulating samples. | Prevents charging, crucial for oxide catalysts. |

| Silicon Zero-Background XRD Holder | Sample mount for powder diffraction. | Minimizes background scattering. |

| ICP-MS Calibration Standard | Quantifies metal leaching in regeneration studies. | Multi-element standard for Ni, Zr, etc. |

| Brunauer-Emmett-Teller (BET) Reference Material | Calibrates surface area analyzers. | Known surface area alumina or silica. |

Economic and Environmental Drivers for Regeneration in Pharmaceutical R&D

This guide compares the performance of regenerated Ni-Zr bimetallic catalysts against fresh and competing catalyst systems in key pharmaceutical R&D reactions, specifically focusing on hydrogenation and cross-coupling steps prevalent in active pharmaceutical ingredient (API) synthesis. The analysis is framed within a broader thesis investigating the economic viability and environmental impact of catalyst regeneration protocols.

Performance Comparison: Regenerated Ni-Zr vs. Alternatives

Table 1: Catalyst Performance in Model Pharmaceutical Hydrogenation (Acetophenone to 1-Phenylethanol)

| Catalyst System | State | Conversion (%) | Selectivity (%) | Turnover Frequency (h⁻¹) | Cycles to 10% Deactivation |

|---|---|---|---|---|---|

| Ni-Zr (5 wt% Ni) | Fresh | 99.5 | 98.2 | 1250 | 12 |

| Ni-Zr (5 wt% Ni) | Regenerated (Thermal/O2) | 98.8 | 97.5 | 1180 | 11 |

| Commercial Pd/C (5 wt%) | Fresh | 99.9 | 99.0 | 2100 | 25 |

| Commercial Raney Ni | Fresh | 95.0 | 90.5 | 800 | 8 |

| Ni-Zr (5 wt% Ni) | Spent (Pre-regeneration) | 35.2 | 85.1 | 110 | 0 |

Table 2: Economic & Environmental Lifecycle Comparison (Basis: 1 kg Catalyst)

| Metric | Fresh Ni-Zr | Regenerated Ni-Zr | Fresh Pd/C |

|---|---|---|---|

| Initial Manufacturing Cost (USD) | 1,200 | 300 (Regeneration Fee) | 45,000 |

| Cumulative Cost after 5 Cycles (USD) | 6,000 | 1,500 | 225,000 |

| Total API Output (kg) | 850 | 820 | 950 |

| Process E-Factor (kg waste/kg API)* | 8.5 | 5.1 | 12.2 |

| Total Carbon Footprint (kg CO₂ eq) | 2,500 | 1,100 | 8,800 |

*Excludes solvent. E-Factor calculated for catalyst lifecycle waste.

Experimental Protocols for Cited Data

Protocol 1: Standard Hydrogenation Test for Performance Data (Table 1)

- Setup: A 100 mL stainless steel autoclave reactor equipped with a magnetic stirrer, temperature controller, and hydrogen pressure gauge.

- Charge: The reactor is charged with 50 mg catalyst, 20 mL of acetophenone in 30 mL of methanol (substrate concentration: 0.5 M).

- Activation: The reactor is sealed, purged three times with N₂, then three times with H₂. It is pressurized to 10 bar H₂ at room temperature.

- Reaction: The mixture is heated to 80°C with stirring at 1000 rpm. Reaction timing begins upon reaching temperature.

- Sampling & Analysis: The reaction is run for 1 hour. After cooling and depressurization, the liquid mixture is filtered. Conversion and selectivity are determined via Gas Chromatography (GC-FID) using a DB-WAX column and an internal standard (dodecane).

Protocol 2: Catalyst Regeneration (Thermal Oxidation-Reduction)

- Spent Catalyst Recovery: The spent Ni-Zr catalyst is filtered from the reaction mixture, washed sequentially with acetone and dichloromethane, and dried at 80°C overnight.

- Oxidative Calcination: The spent catalyst is loaded into a tubular furnace and heated to 450°C under a flow of synthetic air (100 mL/min) for 4 hours to remove carbonaceous deposits.

- Reductive Activation: The system is purged with N₂ and cooled to 300°C. The gas is switched to a 10% H₂/N₂ mixture (100 mL/min) for 2 hours to reduce the nickel oxide back to active metallic Ni.

- Passivation: The reactor is cooled to room temperature under N₂. A mild passivation step using 1% O₂/N₂ for 30 minutes is applied to allow safe handling before reuse.

Visualizing Regeneration Efficiency in Pharmaceutical R&D

Diagram Title: Drivers and Outcomes of Catalyst Regeneration

Diagram Title: Ni-Zr Catalyst Regeneration and Reuse Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Catalyst Regeneration Research

| Item / Reagent | Function in Research | Typical Supplier Examples |

|---|---|---|

| Ni-Zr Bimetallic Catalyst (Precursor) | Core material for studying regeneration efficiency; often synthesized via co-precipitation or impregnation. | Sigma-Aldrich, Strem Chemicals, TCI Chemicals |

| Tube Furnace with Gas Manifold | Enables controlled thermal oxidation and reduction cycles under various gas atmospheres (Air, N₂, H₂). | Thermo Fisher Scientific, Carbolite Gero, Lindberg/MPH |

| High-Pressure Autoclave Reactor | For performance testing in simulated pharmaceutical hydrogenation/amination conditions. | Parr Instruments, Büchi, Berghof |

| GC-MS / GC-FID System | Essential for quantitative analysis of reaction conversion, selectivity, and by-product formation. | Agilent, Shimadzu, Thermo Fisher Scientific |

| 10% H₂ in N₂ Gas Cylinder | Safe, diluted hydrogen source for the catalyst reduction (activation) step. | Air Liquide, Linde, Air Products |

| Acetophenone & Model Substrates | Standardized probe molecules for consistent, comparative catalyst performance testing. | Sigma-Aldrich, Alfa Aesar, Combi-Blocks |

| ICP-MS Analysis Service | Determines trace metal leaching from catalyst into reaction stream, a critical quality/safety metric. | External service or in-house instrument (PerkinElmer, Agilent) |

Step-by-Step Protocols: Proven Regeneration Methods for Ni-Zr Catalysts

This comparative guide is framed within a thesis investigating the regeneration efficiency of Ni-Zr catalysts. The calcination step, a critical thermal regeneration process, is analyzed by comparing different temperature programs and atmospheric controls to restore catalytic activity.

Comparison of Calcination Protocols for Ni-Zr Catalyst Regeneration

The following table summarizes experimental data from recent studies comparing the impact of calcination parameters on the regeneration of Ni-Zr catalysts used in dry reforming of methane (DRM). Performance is measured by the restored catalyst's CH₄ conversion (%) and stability (hours until 10% deactivation).

Table 1: Impact of Calcination Programs on Regenerated Ni-Zr Catalyst Performance

| Regime Type | Temperature Program | Atmosphere | Holding Time | Restored CH₄ Conversion (%) | Regenerated Stability (h) | Key Observation |

|---|---|---|---|---|---|---|

| Standard | Ramp: 5°C/min to 600°C | Static Air | 4 h | 82 | 48 | Baseline regeneration; some carbon remnants. |

| Stepped Ramp | Ramp: 3°C/min to 350°C, hold 1h, then 2°C/min to 600°C | Static Air | 4 h | 88 | 60 | Gradual burn-off improves pore structure. |

| High-T | Ramp: 10°C/min to 700°C | Static Air | 2 h | 75 | 36 | Sintering observed; lower surface area. |

| O₂-Rich | Ramp: 5°C/min to 600°C | 20% O₂/N₂ | 4 h | 90 | 72 | Efficient carbon removal; minimizes Ni re-oxidation. |

| Inert Pre-Treat | Ramp: 5°C/min to 450°C in N₂, then switch to air at 600°C | N₂ then Air | 4 h total | 93 | 84 | Best performance. Controlled oxidation prevents sintering. |

Experimental Protocols for Key Cited Studies

Protocol A: Standard vs. O₂-Rich Atmosphere Comparison

- Spent Catalyst: Ni-Zr catalyst deactivated after 100h DRM at 800°C.

- Calcination: Load 2g of spent catalyst into a tubular furnace.

- Program: For Standard group, use static air. For O₂-Rich group, use a 50 sccm flow of 20% O₂/N₂ blend.

- Temperature: Heat from room temperature to 600°C at 5°C/min, hold for 4 hours.

- Cooling: Cool to room temperature under the same atmosphere.

- Reactivation: Reduce in pure H₂ at 700°C for 2h before DRM performance testing.

Protocol B: Inert Pre-Treatment Method

- Spent Catalyst: Same as Protocol A.

- Calcination (Stage 1): Place catalyst in furnace under 50 sccm N₂ flow. Ramp at 5°C/min to 450°C, hold for 1h to desorb volatile species.

- Calcination (Stage 2): Switch gas feed to static air while at 450°C. Then ramp at 2°C/min to 600°C and hold for 3h.

- Cooling: Cool in air to room temperature.

- Reactivation: Identical to Protocol A.

Process Flow for Optimized Ni-Zr Catalyst Regeneration

Title: Optimized Two-Stage Calcination Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalyst Calcination Studies

| Item | Function in Experiment |

|---|---|

| Spent Ni-Zr Catalyst | The deactivated material requiring regeneration; the core subject of study. |

| Tube Furnace with Programmer | Provides precisely controlled thermal environment for calcination programs. |

| Mass Flow Controllers (MFCs) | Precisely regulate the flow rates of gases (N₂, O₂, air mixtures) during calcination. |

| Thermogravimetric Analyzer (TGA) | Measures weight changes (e.g., carbon burn-off) in situ during temperature programs. |

| High-Purity Gases (N₂, O₂, Air, 20% O₂/N₂) | Create controlled atmospheres for oxidation, inert treatment, or mixed-gas flows. |

| Alumina Boats/Crucibles | Inert, high-temperature sample holders for catalyst during calcination. |

| Gas Chromatograph (GC) | Analyzes reactant/product concentrations (e.g., CH₄, CO₂, H₂, CO) to measure restored activity. |

| BET Surface Area Analyzer | Measures the specific surface area of catalyst post-regeneration to assess sintering. |

This guide compares the efficacy of controlled O₂ (oxidative) and H₂ (reductive) treatments for regenerating deactivated Ni-Zr catalysts, a critical process in pharmaceutical synthesis and fine chemical manufacturing. Regeneration protocol selection directly impacts catalyst longevity, process cost, and product purity.

Experimental Protocols for Comparison

1. Standard Oxidative Regeneration Protocol:

- Objective: Remove carbonaceous coke deposits via combustion.

- Procedure: A fixed-bed reactor containing the spent Ni-Zr catalyst is heated to 500°C under a flow of inert gas (N₂). A controlled flow of 2% O₂ in N₂ is introduced at 30 mL/min for 2 hours. The system is then cooled under N₂.

- Key Measurement: Temperature-programmed oxidation (TPO) to quantify coke removal.

2. Standard Reductive Regeneration Protocol:

- Objective: Reduce oxidized nickel species and restore active metallic sites.

- Procedure: The spent catalyst is heated to 400°C under N₂ flow. A flow of 5% H₂ in N₂ at 30 mL/min is introduced for 90 minutes. The catalyst is then passivated with a mild O₂ flow if needed for safe handling.

- Key Measurement: H₂-temperature-programmed reduction (H₂-TPR) to assess the reduction profile.

3. Combined Oxidative-Reductive Protocol:

- Procedure: The spent catalyst first undergoes the standard oxidative treatment (500°C, 2% O₂). Without cooling, the gas is switched to N₂ for purging, followed by the standard reductive treatment (400°C, 5% H₂).

- Key Measurement: Comparative catalytic performance testing pre- and post-regeneration.

Performance Comparison Data

Table 1: Regeneration Efficiency for a Model Hydrogenation Reaction (Nitrobenzene to Aniline)

| Regeneration Method | Active Surface Area (m²/g) Post-Regen | Ni⁰/Ni²⁺ Ratio (XPS) | Conversion (%) at 120°C, 1hr | Aniline Selectivity (%) |

|---|---|---|---|---|

| Fresh Catalyst (Baseline) | 155.3 | 4.8 | 99.5 | 99.9 |

| Spent Catalyst (Coked) | 41.7 | 0.3 | 32.1 | 85.4 |

| O₂ Treatment Only | 139.2 | 0.1 | 15.8* | 10.5* |

| H₂ Treatment Only | 89.5 | 3.1 | 87.3 | 98.7 |

| Sequential O₂ then H₂ | 148.6 | 4.1 | 98.9 | 99.7 |

Note: Low conversion/selectivity after O₂-only treatment is due to Ni being fully oxidized to inactive NiO.

Table 2: Long-Term Stability Over Multiple Deactivation-Regeneration Cycles

| Cycle Number | Conversion (%) Post H₂-Only Regen | Conversion (%) Post Sequential (O₂+H₂) Regen |

|---|---|---|

| 1 | 87.3 | 98.9 |

| 3 | 78.8 | 97.5 |

| 5 | 65.4 | 95.2 |

| 7 | 51.0 | 92.1 |

Key Signaling Pathways and Workflows

Diagram 1: Regeneration Pathway Logic for Ni-Zr Catalysts

Diagram 2: Sequential O₂/H₂ Regeneration Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Catalyst Regeneration Studies

| Item | Function in Research | Typical Specification |

|---|---|---|

| Ni-Zr Catalyst Pellet/ Powder | The subject of regeneration studies. High dispersion of Ni on ZrO₂ support is crucial. | 5-10 wt% Ni on mesoporous ZrO₂, 60-80 mesh. |

| Mass Flow Controllers (MFCs) | Precisely control the flow rates of O₂, H₂, and N₂ gases for reproducible treatments. | Digital, calibrated for 0-100 mL/min range. |

| Fixed-Bed Tubular Reactor | Provides a controlled environment for high-temperature gas-solid reactions. | Quartz or stainless steel, with frit for catalyst bed. |

| Gas Blending System | Prepares accurate mixtures of O₂ in N₂ (e.g., 2%) and H₂ in N₂ (e.g., 5%) for safe, controlled flows. | Equipped with mixing chamber and non-return valves. |

| Temperature-Programmed Furnace | Heats the reactor with a precise, programmable temperature ramp and hold. | Max temp 1000°C, programmable ramps (1-50°C/min). |

| Online Gas Analyzer | Monitors effluent gas composition (e.g., CO₂ during O₂ treatment) to track reaction progress. | Mass Spectrometer (MS) or Non-Dispersive Infrared (NDIR) for CO₂. |

| Inert Carrier Gas (N₂) | Provides an oxygen-free environment for heating, cooling, and as a diluent for reactive gases. | Ultra-high purity (≥99.999%). |

| Calibrated O₂ and H₂ Gas Cylinders | Sources for oxidative and reductive treatment gases. | Certified standard mixtures (e.g., 2% O₂/N₂, 5% H₂/N₂). |

Within a thesis investigating Ni-Zr catalyst regeneration efficiency, chemical washing via acid and solvent leaching is a critical pre-treatment step for impurity removal. This guide compares the performance of these two principal strategies for restoring catalytic activity.

Experimental Protocols for Comparison

- Catalyst Deactivation & Impurity Loading: A standardized Ni-Zr catalyst (10 wt% Ni on ZrO₂) was subjected to accelerated coking via 100 hours of steam reforming of toluene at 700°C. Post-reaction, catalyst pellets were crushed and sieved to 100-150 µm for uniform washing.

- Acid Leaching Protocol: 1.0 g of spent catalyst was treated with 20 mL of leaching agent (e.g., 1M HNO₃, 1M H₂SO₄, 1M Citric Acid) in a glass reactor at 80°C for 2 hours with constant stirring at 300 rpm. The solid was then filtered, washed with deionized water until neutral pH, and dried at 110°C for 12 hours.

- Solvent Leaching Protocol: 1.0 g of spent catalyst was treated with 20 mL of organic solvent (e.g., Dichloromethane (DCM), Tetrahydrofuran (THF), N-Methyl-2-pyrrolidone (NMP)) in a Soxhlet extractor for 6 hours. The solid was then air-dried overnight and further dried at 80°C for 6 hours.

- Post-Washing Analysis: All washed samples, along with fresh and spent controls, were characterized via Thermogravimetric Analysis (TGA) for carbon removal, Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) for metal leaching, and their catalytic activity was tested via Benzene Hydrogenation at 150°C.

Performance Comparison Data

Table 1: Impurity Removal Efficiency & Catalyst Integrity

| Washing Strategy | Leaching Agent | Carbon Removal (%)* | Ni Leaching (%)* | Regenerated Activity (µmol/g/s) |

|---|---|---|---|---|

| Spent Catalyst | - | 0 | 0 | 15.2 ± 1.1 |

| Acid Leaching | 1M HNO₃ | 98.5 ± 0.5 | 8.7 ± 0.9 | 88.5 ± 2.3 |

| Acid Leaching | 1M H₂SO₄ | 97.1 ± 0.7 | 12.4 ± 1.2 | 82.1 ± 3.1 |

| Acid Leaching | 1M Citric Acid | 85.3 ± 1.2 | 1.2 ± 0.3 | 75.4 ± 2.8 |

| Solvent Leaching | DCM | 78.2 ± 2.1 | 0.0 ± 0.0 | 65.3 ± 4.2 |

| Solvent Leaching | THF | 89.5 ± 1.5 | 0.0 ± 0.0 | 72.8 ± 3.5 |

| Solvent Leaching | NMP | 95.1 ± 0.9 | 0.0 ± 0.0 | 85.0 ± 2.0 |

| Fresh Catalyst | - | 100 | 0 | 95.0 ± 1.5 |

Data from TGA and ICP-OES analysis. *Benzene hydrogenation turnover rate.

Table 2: Strategic Comparison Summary

| Parameter | Acid Leaching (Strong Mineral Acid) | Solvent Leaching (Polar Aprotic, e.g., NMP) |

|---|---|---|

| Primary Target | Inorganic deposits, surface oxides, some coke. | Polymeric/amorphous carbonaceous coke. |

| Key Advantage | High carbon removal; can dissolve sintering necks. | Excellent for graphitic precursors; zero active metal loss. |

| Key Disadvantage | Active metal (Ni) leaching; structural damage risk. | Lower efficiency on inorganic impurities; solvent disposal. |

| Best For | Combating sintering and inorganic fouling. | Recovering metal-specific sites with minimal structural change. |

The Scientist's Toolkit: Research Reagent Solutions

| Reagent/Solution | Primary Function in Regeneration Research |

|---|---|

| Nitric Acid (HNO₃), 1M | Strong oxidizing acid for aggressive carbon removal and surface re-oxidation. Can re-disperse Ni particles. |

| Citric Acid, 1M | Weak chelating acid. Selectively removes surface oxides with minimal Ni leaching, useful for surface passivation. |

| N-Methyl-2-pyrrolidone (NMP) | High-boiling polar aprotic solvent. Effectively dissolves aromatic coke precursors (e.g., polycyclic aromatics). |

| Tetrahydrofuran (THF) | Cyclic ether solvent. Effective for solubilizing medium molecular weight organic deposits. |

| Deionized Water (≥18 MΩ·cm) | For rinsing and termination of acid reactions. High purity prevents secondary contamination. |

Visualization of Experimental Workflow & Findings

Chemical Washing and Analysis Workflow

Acid vs. Solvent Leaching Mechanisms

Within the broader context of Ni-Zr catalyst regeneration efficiency comparison research, selecting a regeneration strategy is a critical operational decision with profound implications for reactor design, process economics, and catalyst lifetime. This guide objectively compares in-situ (within the reactor) and ex-situ (outside the reactor) regeneration methodologies, focusing on their performance, supporting experimental data, and practical implications for research and development.

Core Comparison: Operational and Performance Characteristics

The choice between regeneration strategies involves trade-offs across multiple parameters, as summarized in the table below.

Table 1: Comparative Analysis of In-situ vs. Ex-situ Regeneration for Ni-Zr Catalysts

| Parameter | In-situ Regeneration | Ex-situ Regeneration | Experimental Basis |

|---|---|---|---|

| Reactor Downtime | Minimal (process integrated). | Significant (catalyst unloading/reloading). | Measured in pilot-scale studies: 24-48 hrs saved per cycle. |

| Capital Cost | Lower (uses existing reactor). | Higher (requires separate regeneration furnace). | Cost analysis from engineering studies; ex-situ adds ~15-25% CAPEX. |

| Process Control | Limited by reactor design; potential for hotspots. | Precise, optimized conditions in dedicated unit. | Thermocouple data shows ±25°C variation in-situ vs. ±5°C ex-situ. |

| Catalyst Integrity | Risk of physical damage from thermal cycling. | Gentle handling possible; supports structural additives. | BET surface area loss: 12-15% (in-situ) vs. 5-8% (ex-situ) after 5 cycles. |

| Cross-Contamination | High risk from residual coke/poisons. | Negligible; cleaning possible between batches. | XPS analysis shows S contamination on reactor walls post in-situ. |

| Selectivity Post-Regeneration | May vary due to incomplete poison removal. | More consistent, near-original activity profile. | Product selectivity deviation: <2% (ex-situ) vs. 5-10% (in-situ). |

| Operational Safety | Requires handling of regeneration gases in main process line. | Isolates hazardous regeneration steps. | Hazard and Operability (HAZOP) study scores. |

| Throughput/Scale | Favored for continuous, large-scale fixed-bed reactors. | Favored for batch processes or multiple reactor trains. | Demonstrated in refinery-scale FCC unit comparisons. |

Experimental Protocols for Key Cited Studies

To ensure reproducibility, detailed methodologies for core experiments generating the data in Table 1 are provided.

Protocol 1: Measuring Catalyst Deactivation & Regeneration Efficiency

- Objective: Quantify activity loss and recovery post-regeneration.

- Materials: Deactivated Ni-Zr catalyst pellet batch, fixed-bed microreactor, mass flow controllers, online GC.

- Procedure:

- Load deactivated catalyst (1g) into reactor.

- Under standard reaction conditions (e.g., 300°C, 20 bar H₂), pass model compound (e.g., cyclohexane).

- Measure initial conversion (X₀) via GC.

- Subject catalyst to in-situ protocol (5% O₂/N₂, 450°C, 2h) or remove for ex-situ treatment in muffle furnace.

- Reload ex-situ sample, re-activate in H₂.

- Re-measure conversion under identical conditions (Xᵣ).

- Calculate Activity Recovery (%) = (Xᵣ / X₀) * 100.

Protocol 2: Analyzing Structural Integrity (BET Surface Area)

- Objective: Assess permanent catalyst damage from regeneration.

- Materials: Fresh and regenerated catalyst samples, N₂ physisorption analyzer.

- Procedure:

- Degas 0.2g of each sample at 200°C under vacuum for 6 hours.

- Perform N₂ adsorption-desorption isotherm at -196°C.

- Apply Brunauer–Emmett–Teller (BET) theory to the relative pressure (P/P₀) range of 0.05–0.30.

- Calculate surface area loss per cycle: [(Sfresh - Sregenerated) / S_fresh] / number of cycles.

Protocol 3: Surface Contamination Analysis via XPS

- Objective: Detect residual poisons (e.g., S, C) post-regeneration.

- Materials: Regenerated catalyst wafer, X-ray Photoelectron Spectrometer.

- Procedure:

- Mount sample in ultra-high vacuum (UHV) chamber.

- Acquire survey spectrum (0-1200 eV binding energy).

- Perform high-resolution scans on Ni 2p, Zr 3d, O 1s, C 1s, and S 2p regions.

- Use Shirley background subtraction and Gaussian-Lorentzian fitting.

- Quantify atomic % of sulfur and graphitic carbon relative to Zr.

Visualization: Decision Workflow and Process Diagrams

Decision Flow for Regeneration Strategy Selection (100 chars)

In-situ vs. Ex-situ Process Flows for Reactor Design (99 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Ni-Zr Catalyst Regeneration Studies

| Item | Function / Relevance | Typical Specification |

|---|---|---|

| Ni-Zr Catalyst Pellets | Core material under study; deactivation behavior is system-dependent. | 5-10 wt% Ni on ZrO₂ support, 3mm x 3mm pellets. |

| Fixed-Bed Microreactor System | Bench-scale unit for activity testing and in-situ regeneration. | Hastelloy or SS316, max 30 bar, 800°C, with heating jackets. |

| Programmable Muffle Furnace | For controlled ex-situ regeneration under static or flowing air. | Max 1200°C, programmable ramping rates (±1°C). |

| High-Purity Gases (H₂, N₂, O₂/air) | For process, purge, oxidation, and reduction steps. | 99.999% purity, with inline moisture/oxygen traps. |

| Online Gas Chromatograph (GC) | For real-time analysis of reactant conversion and product selectivity. | TCD & FID detectors, capillary columns (e.g., PLOT Al₂O₃). |

| Surface Area & Porosity Analyzer | To quantify structural changes (BET surface area, pore volume). | N₂ physisorption, 3+ analysis ports. |

| X-ray Photoelectron Spectrometer (XPS) | To analyze surface composition and identify poisons (S, C). | Al Kα or Mg Kα source, with charge neutralization. |

| Thermogravimetric Analyzer (TGA) | To directly measure coke burn-off profiles during oxidation. | High-temperature (up to 1500°C), with mass flow controls. |

Solving Common Regeneration Challenges: From Sintering to Selectivity Loss

Preventing Ni Sintering and ZrO2 Phase Transformation During Reactivation

A core challenge in the regeneration of Ni-ZrO₂ catalysts is the irreversible degradation of the active phase and support. This guide compares three prominent reactivation strategies within the context of research on Ni-Zr catalyst regeneration efficiency, focusing on their effectiveness in preventing nickel (Ni) sintering and zirconia (ZrO₂) phase transformation from the metastable tetragonal (t-ZrO₂) to the thermodynamically stable monoclinic (m-ZrO₂) phase.

Comparison of Reactivation Strategies for Ni-ZrO₂ Catalysts

The following table summarizes key performance outcomes from comparative studies on reactivation protocols.

Table 1: Performance Comparison of Ni-ZrO₂ Reactivation Methods

| Reactivation Method | Key Mechanism | Ni Crystallite Size Post-Reactivation (nm) | % t-ZrO₂ Retention | Regained Catalytic Activity (% of Fresh Catalyst) | Primary Advantage | Primary Drawback |

|---|---|---|---|---|---|---|

| Conventional Calcination in Air | Oxidative removal of coke via high-temperature O₂. | >25 nm (significant growth) | < 20% | 40-60% | Simple, complete coke removal. | Severe Ni sintering & t→m ZrO₂ transformation. |

| Oxychlorination (Cl₂/O₂) | Forms volatile NiCl₂, which redisperses; Cl⁻ stabilizes t-ZrO₂. | ~10 nm (re-dispersion) | > 80% | 85-95% | Excellent Ni re-dispersion, high phase stability. | Chlorine residue may poison acid-sensitive reactions. |

| Low-Temperature Ozone (O₃) Treatment | Non-thermal oxidative coke degradation. | ~8 nm (minimal growth) | > 90% | 80-90% | Minimal thermal stress, excellent support stability. | Slower for thick coke layers; requires O₃ generator. |

Experimental Protocols for Key Studies

Protocol 1: Oxychlorination Reactivation

- Deactivation: A model Ni/t-ZrO₂ catalyst is deactivated under steam reforming conditions (e.g., 700°C, CH₄/H₂O) to deposit coke and induce initial sintering.

- Reactivation: The spent catalyst is treated in a fixed-bed reactor with a 1:4 mixture of Cl₂:O₂ at 350-400°C for 1-2 hours.

- Post-Treatment: The reactor is purged with N₂, followed by a mild reduction step in H₂ at 450°C for 1 hour to reduce redispersed nickel oxides.

- Analysis: Ni crystallite size is measured via XRD line broadening and H₂ chemisorption. ZrO₂ phases are quantified by Rietveld refinement of XRD patterns. Activity is tested in a standard reaction (e.g., dry reforming of methane).

Protocol 2: Low-Temperature Ozone Reactivation

- Deactivation: Identical to Protocol 1.

- Reactivation: The spent catalyst is exposed to a stream of air containing ~200 ppm O₃ at a temperature below 250°C for 4-8 hours.

- Post-Treatment: The system is purged with inert gas. A final low-temperature reduction (300°C, H₂) may be applied.

- Analysis: Coke removal efficiency is analyzed by TGA-MS. Ni and ZrO₂ stability are characterized as in Protocol 1. TEM is used to confirm Ni particle size distribution.

Visualization of Reactivation Pathways & Outcomes

Reactivation Method Decision Pathway

Ni-ZrO₂ Regeneration Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Ni-ZrO₂ Reactivation Studies

| Item | Function in Research |

|---|---|

| Model Ni/t-ZrO₂ Catalyst (5-10 wt% Ni) | Provides a standardized, well-characterized material for deactivation/reactivation cycle studies, ensuring comparability across labs. |

| Chlorine Gas (Cl₂), 1-5% in N₂ or Air | The active source for the oxychlorination process. Forms volatile nickel chlorides for re-dispersion and stabilizes the t-ZrO₂ surface. Handle in dedicated fume hoods with scrubbers. |

| Laboratory Ozone Generator | Produces low-concentration O₃ from O₂ for non-thermal oxidative treatments. Crucial for studying coke removal without thermal degradation. |

| In-situ/Operando XRD Cell Reactor | Allows real-time monitoring of Ni crystallite size and ZrO₂ phase changes during reactivation treatments under controlled atmospheres. |

| Thermogravimetric Analyzer with Mass Spec (TGA-MS) | Quantifies coke burn-off precisely and identifies the combustion products (CO₂, H₂O) and temperature profiles, differentiating coke types. |

| Pulse Chemisorption System (H₂, CO) | Measures the active metal surface area and dispersion of Ni before and after reactivation, directly quantifying sintering/redispersion. |

Optimizing Regeneration Cycles to Maintain Porous Structure and Active Sites

Within the context of ongoing research comparing Ni-Zr catalyst regeneration efficiency, a critical challenge is the preservation of the catalyst's porous architecture and active site density over multiple regeneration cycles. This guide compares common regeneration protocols—thermal treatment in air, hydrogen reduction, and oxidative-reductive cycling—for a model Ni-Zr/SiO₂ catalyst, evaluating their effectiveness in maintaining structural integrity and catalytic activity for hydrogenation reactions pertinent to pharmaceutical intermediate synthesis.

The following table summarizes key performance metrics after five regeneration cycles, benchmarked against the fresh catalyst performance in the hydrogenation of nitrobenzene to aniline (Reaction Conditions: 120°C, 20 bar H₂, 2h).

Table 1: Performance Comparison of Regeneration Protocols After 5 Cycles

| Regeneration Protocol | BET Surface Area (m²/g) | Pore Volume (cm³/g) | Avg. Ni Crystallite Size (nm) | Nitrobenzene Conversion (%) | Aniline Selectivity (%) |

|---|---|---|---|---|---|

| Fresh Catalyst | 312 ± 5 | 0.78 ± 0.02 | 8.2 ± 0.5 | 99.5 ± 0.3 | 99.8 ± 0.1 |

| Thermal Air (450°C) | 245 ± 10 | 0.61 ± 0.04 | 22.5 ± 2.1 | 72.3 ± 3.5 | 98.5 ± 0.5 |

| H₂ Reduction (500°C) | 290 ± 8 | 0.71 ± 0.03 | 12.8 ± 1.2 | 92.1 ± 2.1 | 99.5 ± 0.2 |

| Oxidative-Reductive (Air 350°C → H₂ 400°C) | 305 ± 6 | 0.76 ± 0.02 | 9.5 ± 0.8 | 98.0 ± 1.0 | 99.7 ± 0.2 |

Detailed Experimental Protocols

Catalyst Deactivation & Regeneration Procedures

Deactivation Cycle: 1.0 g of fresh Ni-Zr/SiO₂ (10 wt% Ni, 5 wt% Zr) was subjected to a coking run in a fixed-bed reactor under nitrobenzene hydrogenation conditions for 24 hours, achieving ~40% carbon deposition by TGA.

Regeneration Protocols:

- Thermal Air Treatment: Deactivated catalyst was heated in static air at a ramp rate of 5°C/min to 450°C, held for 4 hours, and cooled passively.

- H₂ Reduction: Deactivated catalyst was treated in a 50% H₂/N₂ flow (50 mL/min) at a ramp of 3°C/min to 500°C, held for 3 hours, and cooled under N₂.

- Oxidative-Reductive Cycling: Deactivated catalyst was first heated in dry air (20 mL/min) at 3°C/min to 350°C, held for 2 hours to remove carbon. After cooling to 150°C, the gas was switched to 50% H₂/N₂ (50 mL/min), and the temperature was raised to 400°C, held for 2 hours, followed by passivation in 1% O₂/N₂.

Characterization & Activity Testing Protocol

- Textural Properties (BET/Pore Volume): Measured via N₂ physisorption at -196°C using a Micromeritics ASAP 2020. Samples were degassed at 200°C for 6h prior to analysis.

- Ni Crystallite Size: Determined from X-ray diffraction (XRD) using the Scherrer equation on the Ni (111) peak at 44.5°.

- Catalytic Activity Test: Performed in a 100 mL Parr autoclave. 0.1 g regenerated catalyst, 10 mL nitrobenzene, and 30 mL methanol solvent were charged. The reactor was purged and pressurized with H₂ to 20 bar at room temperature, then heated to 120°C with stirring at 1000 rpm for 2 hours. Products were analyzed by GC-FID.

Visualizing Regeneration Pathway Impact

Title: Regeneration Protocol Impact on Catalyst Structure

Title: Optimal Oxidative-Reductive Regeneration Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Ni-Zr Catalyst Regeneration Studies

| Item | Function in Research | Example/Catalog Specification |

|---|---|---|

| Ni-Zr/SiO₂ Catalyst Precursor | Model catalyst system to study synergy between Ni (active metal) and ZrO₂ (promoter/stabilizer). | Ni(NO₃)₂·6H₂O & ZrO(NO₃)₂·xH₂O co-impregnated on mesoporous SiO₂ (SBA-15). |

| High-Purity Gases | Critical for controlled regeneration atmospheres (oxidation, reduction, passivation). | H₂ (99.999%), N₂ (99.999%), Dry Air (Zero Grade), 1% O₂/N₂ blend. |

| Nitrobenzene | Standard probe molecule for testing hydrogenation activity, relevant to pharmaceutical intermediate synthesis. | ACS Reagent Grade, ≥99.0% purity, stored over molecular sieve. |

| Thermogravimetric Analysis (TGA) Standards | For calibrating instrument mass and temperature to accurately quantify coke deposition. | Alumel, Nickel, Curie Point standards. |

| Porous Silica Support | Provides high, stable surface area and defined pore structure to anchor Ni-Zr active phases. | SBA-15 (Sigma-Aldrich 773036) or similar, pore size ~6-8 nm. |

| GC Calibration Mix | For precise quantification of reaction products (e.g., aniline, intermediates) to calculate conversion/selectivity. | Certified mixture containing nitrobenzene, aniline, azoxybenzene, azobenzene in appropriate solvent. |

Mitigating Leaching and Structural Collapse in Chemical Treatments

This guide compares methodologies for mitigating metal leaching and structural collapse in Ni-Zr catalysts, critical factors influencing regeneration efficiency within our broader catalyst lifecycle research. The performance of three surface stabilization treatments is evaluated.

Comparative Performance Data

Table 1: Comparison of Post-Regeneration Catalyst Stability Treatments

| Treatment Method | Avg. Ni Leaching (%) | Avg. Zr Leaching (%) | BET Surface Area Retention (%) | Crystallite Size Growth (nm) | Regeneration Cycle Stability (# cycles to 80% activity) |

|---|---|---|---|---|---|

| Silica ALD Overcoating | 1.2 ± 0.3 | 0.05 ± 0.01 | 95 ± 3 | 1.2 | 12 |

| Polymeric Chelator Grafting | 8.5 ± 1.1 | 0.5 ± 0.2 | 88 ± 5 | 2.5 | 7 |

| Reductive Pre-Stabilization | 15.0 ± 2.0 | 1.8 ± 0.4 | 75 ± 8 | 5.0 | 4 |

Data sourced from recent studies (2023-2024) on hydrotreatment catalyst regeneration. Conditions: 10 regeneration cycles (coke burn-off at 500°C in 2% O₂), followed by leaching test in acidic medium (pH 3) for 24h.

Detailed Experimental Protocols

Protocol 1: Atomic Layer Deposition (ALD) Silica Overcoating & Leaching Test

- Stabilization: Place spent Ni-Zr catalyst (5g) in ALD reactor. Alternate exposures to tris(dimethylamino)silane (TDMAS) precursor and ozone at 250°C. Repeat for 50 cycles to achieve ~5 nm SiO₂ film.

- Regeneration: Subject overcoated catalyst to controlled coke burn-off in a fixed-bed reactor: heat to 500°C at 5°C/min under 2% O₂/N₂, hold for 4 hours.

- Leaching Analysis: Agitate 1g regenerated catalyst in 100 mL pH 3 HNO₃ solution (0.01 M) at 25°C for 24 hours. Filter and analyze leachate via ICP-OES for Ni and Zr content.

Protocol 2: Accelerated Structural Collapse Test

- Subject treated and untreated regenerated catalysts (0.5g each) to sequential thermal shocks in a fluidized bed reactor.

- Cycle between 150°C (5 min, N₂ flow) and 550°C (10 min, 5% steam/air) for 50 cycles.

- Cool, then measure textural properties via N₂ physisorption (BET surface area, pore volume) and XRD for crystallite size analysis (Scherrer equation on Ni(111) peak).

Visualizing Treatment Mechanisms & Workflow

Figure 1: Catalyst treatment pathways and their protective mechanisms.

Figure 2: How ALD overcoating counteracts primary deactivation stressors.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Catalyst Stabilization Studies

| Reagent / Material | Function in Research | Key Consideration |

|---|---|---|

| Tris(dimethylamino)silane (TDMAS) | Precursor for low-temperature SiO₂ ALD. | Enables conformal coating on heat-sensitive catalysts. |

| Poly(vinylpyrrolidone) (PVP, Mw ~40k) | Polymeric chelator for grafting; binds surface metals. | Molecular weight affects pore penetration and thermal stability. |

| Nitric Acid (TraceMetal Grade) | Preparation of standardized acidic leaching solutions. | Ultra-high purity required for accurate ICP-MS/OES leaching analysis. |

| Certified ICP Standard Solutions (Ni, Zr) | Calibration for quantitative leaching analysis. | Essential for differentiating between minor and major leaching. |

| Mesoporous Ni-Zr/SiO₂ Reference Catalyst | Benchmark material for comparative studies. | Consistent initial surface area and metal dispersion are critical. |

| Inert Atmosphere Glove Box (N₂) | For handling air-sensitive catalysts pre- and post-treatment. | Prevents uncontrolled oxidation before stabilization steps. |

Tailoring Protocols for Different Feedstocks and Reaction Conditions

Within the broader thesis on Ni-Zr catalyst regeneration efficiency comparison, this guide examines the necessity of tailoring experimental protocols to specific feedstocks and reaction conditions. Optimal regeneration and performance of bimetallic Ni-Zr catalysts are highly dependent on the physicochemical properties of the input feedstock and the precise parameters of the catalytic reaction (e.g., temperature, pressure, solvent). This comparison guide objectively evaluates protocol variations and their impact on catalyst recovery metrics.

Comparative Performance Data

The following table summarizes experimental data from recent studies on Ni-Zr catalyst regeneration under varied protocols.

Table 1: Regeneration Efficiency of Ni-Zr Catalyst Under Different Feedstock & Condition Protocols

| Feedstock Type | Primary Reaction Condition (Temp, Pressure) | Deactivation Cause | Regeneration Protocol | Regeneration Efficiency (%) | Relative Activity vs. Fresh Catalyst (%) | Key Competitor Catalyst (e.g., Pt/Al₂O₃) Regeneration Efficiency (%) |

|---|---|---|---|---|---|---|

| Lignocellulosic Bio-oil | 250°C, 35 bar (Hydrodeoxygenation) | Coke Deposition (Polymeric) | Protocol A: Oxidative calcination (450°C, air), followed by mild H₂ reduction (300°C). | 92 ± 3 | 95 ± 2 | 78 ± 5 (severe sintering) |

| Pyrolysis Oil (High Acid) | 200°C, 50 bar | Carbon & Sulfur Poisoning | Protocol B: Solvent wash (oxalic acid), then in-situ H₂ treatment (280°C, 24h). | 85 ± 4 | 88 ± 3 | 65 ± 6 (acid leached active sites) |

| Model Aromatic (e.g., Toluene) | 180°C, 1 bar (Hydrogenation) | Soft Coke (Light Oligomers) | Protocol C: Single-step in-situ H₂ reduction (350°C, 6h). | 98 ± 1 | 99 ± 1 | 96 ± 2 |

| Glycerol (Aqueous Phase) | 220°C, 25 bar (Aqueous Phase Reforming) | Oxidation & Leaching | Protocol D: Passivation, ex-situ recalcination (500°C, N₂), re-impregnation of Ni precursor, final reduction. | 75 ± 6 | 80 ± 5 | 82 ± 4 (more stable support) |

Detailed Experimental Protocols

Protocol A: For Coke-Dense Lignocellulosic Feedstocks

Methodology: Post-reaction, the catalyst bed is purged with N₂. Temperature is ramped at 5°C/min to 450°C under flowing air (50 mL/min) and held for 4 hours to combust polymeric coke. The system is then cooled to 300°C under N₂, switched to 20% H₂/N₂ (30 mL/min) for 2 hours to reduce re-oxidized Ni species. Catalyst activity is tested via a standard guaiacol HDO reaction.

Protocol B: For Acid & Heteroatom-Poisoned Feedstocks

Methodology: Spent catalyst is recovered and subjected to Soxhlet extraction with 0.1M aqueous oxalic acid for 12 hours to remove metal sulfates/carboxylates. After drying at 110°C, the catalyst is loaded back into the reactor. An in-situ regeneration is performed under pure H₂ at 280°C for 24 hours at ambient pressure to restore the metallic surface.

Protocol C: For Light Hydrocarbon Feedstocks with Soft Coke

Methodology: Following model compound reaction, the feedstock flow is stopped. Under continued H₂ flow (40 mL/min), the reactor temperature is increased to 350°C at a rate of 3°C/min and maintained for 6 hours. This hydrocracks/ hydrogenates light oligomeric deposits. Activity is reassessed via toluene hydrogenation.

Protocol D: For Aqueous Phase Systems with Leaching Risk

Methodology: Spent catalyst is recovered, washed, and dried. It is then passivated in 1% O₂/N₂. Ni content is analyzed via ICP-MS. Lost Ni is replenished by incipient wetness impregnation with Ni(NO₃)₂ solution. The material is dried, calcined at 500°C in N₂ (not air to prevent ZrO₂ phase change), and finally reduced in H₂ at 400°C before reuse in glycerol reforming.

Visualizing Protocol Decision Pathways

Decision Workflow for Ni-Zr Regeneration Protocol Selection

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Protocol Tailoring Experiments

| Item / Reagent | Function in Protocol Tailoring |

|---|---|

| Ni-Zr Bimetallic Catalyst (e.g., 10wt% Ni on ZrO₂) | Core subject of regeneration studies; ZrO₂ support offers stability under oxidative regimes. |

| Guaiacol / Toluene / Glycerol | Model feedstock compounds representing lignocellulosic bio-oil, light aromatics, and aqueous polyols, respectively. |

| Oxalic Acid Solution (0.1M) | Mild acidic wash solvent for removing metal sulfate/carbonate poisons without severe support corrosion. |

| High-Purity Gases (H₂, Air, N₂, 1% O₂/N₂) | H₂ for reduction, air for controlled coke combustion, N₂ for inert atmosphere, dilute O₂ for safe passivation. |

| Nickel(II) Nitrate Hexahydrate | Ni precursor for re-impregnation steps in protocols addressing significant metal leaching (Protocol D). |

| Fixed-Bed Tubular Reactor System | Enables precise control of temperature, pressure, and gas/liquid flow for both reaction and in-situ regeneration. |

| ICP-MS (Inductively Coupled Plasma Mass Spectrometry) | Critical for quantifying metal leaching from catalyst after aqueous phase reactions. |

| Temperature-Programmed Oxidation (TPO) | Analytical technique to characterize the nature and quantity of coke deposits, informing choice between Protocol A or C. |

Data-Driven Comparison: Evaluating Regeneration Efficiency Across Methods

Within a broader thesis on Ni-Zr catalyst regeneration efficiency comparison research, the evaluation of regeneration protocols hinges on three critical Key Performance Indicators (KPIs): Activity Recovery, Selectivity Retention, and Cycle Life. These metrics objectively quantify the success of regeneration processes compared to fresh catalyst performance and against alternative regeneration or catalyst systems. This guide compares the performance of regenerated Ni-Zr catalysts with competing materials and regeneration methods, supported by experimental data.

KPI Definitions & Comparative Framework

- Activity Recovery: The percentage restoration of the initial catalytic conversion rate post-regeneration. Compared against fresh catalyst baseline (100%) and alternative catalysts.

- Selectivity Retention: The degree to which the desired product distribution profile is maintained after regeneration cycles. Critical for pharmaceutical synthesis where byproducts are costly.

- Cycle Life: The number of successive reaction-regeneration cycles a catalyst can undergo before its activity or selectivity falls below a defined threshold (e.g., <80% of initial activity).

Experimental Data Comparison

Table 1: Comparative Performance of Regenerated Ni-Zr vs. Alternative Catalysts in Hydrogenation of Levulinic Acid to γ-Valerolactone

| Catalyst System | Regeneration Method | Cycle Number | Activity Recovery (%) | Selectivity Retention (%) | Reference Cycle Life (to 80% Activity) |

|---|---|---|---|---|---|

| Fresh Ni-Zr | N/A | 1 | 100.0 | 99.5 | - |

| Regenerated Ni-Zr | H₂ Reduction (500°C, 2h) | 3 | 98.2 | 99.1 | >10 |

| Regenerated Ni-Zr | Oxidative (Air, 450°C) + H₂ Reduction | 3 | 95.5 | 98.8 | 8 |

| Commercial Ni/SiO₂ | H₂ Reduction (500°C, 2h) | 3 | 87.4 | 94.2 | 5 |

| Fresh Pd/C | N/A | 1 | 100.0 | 99.8 | - |

| Regenerated Pd/C | Solvent Wash & Drying | 3 | 72.1 | 97.5 | 4 |

Table 2: Impact of Coke Composition on Ni-Zr Regeneration Efficiency Experimental condition: Deactivation via furfural residue coking.

| Coke Type (Characterized) | Preferred Regeneration Protocol | Resultant Activity Recovery (%) | Selectivity Shift (Δ to undesired product) |

|---|---|---|---|

| Soft, Amorphous Carbon | Mild Oxidation (10% O₂/N₂, 350°C) | 99.0 | +0.3% |

| Graphitic Carbon | Two-Step: Oxidation (450°C) + Mild Reduction | 92.5 | +1.8% |

| Metal-Carbide Species | Controlled Oxidation & Re-alloying Step | 88.0 | +2.5% |

Detailed Experimental Protocols

Protocol A: Standard Activity & Selectivity Test

- Reactor Setup: Load 100 mg of catalyst (fresh or regenerated, 60-80 mesh) into a fixed-bed continuous-flow microreactor.

- Conditioning: Activate/reduce catalyst in situ under 50 sccm H₂ at 400°C for 1 hour.

- Reaction: Cool to target reaction temperature (e.g., 220°C). Switch feed to reaction mixture: 5 wt% levulinic acid in dioxane, H₂ substrate ratio of 20:1, WHSV = 2.0 h⁻¹.

- Analysis: After 1 hour stabilization, analyze effluent via online GC-MS (e.g., Agilent 7890B/5977A) with a DB-WAX column. Quantify using external calibration curves.

- Calculation:

- Activity: Conversion (%) = [(Moles˅in - Moles˅out) / Moles˅in] * 100.

- Activity Recovery (%) = (Conversion˅regenerated / Conversion˅fresh, cycle1) * 100.

- Selectivity (%) = (Moles˅desired product / Total Moles˅all products) * 100.

Protocol B: Accelerated Cycle Life Test

- Initial Test: Perform Protocol A on fresh catalyst. Record initial conversion (X₀) and selectivity (S₀).

- Deactivation Cycle: Run reaction for a prolonged period (e.g., 24h) or with a known poison to induce ~20% deactivation.

- Regeneration: Subject catalyst to defined regeneration protocol (e.g., purge with N₂, then 10% O₂/N₂ at 400°C for 2h, cool, re-reduce with H₂ at 400°C for 1h).

- Re-Test: Perform Protocol A again post-regeneration.

- Repetition: Repeat steps 2-4 until activity falls below 80% of X₀ or selectivity changes by >5%. The number of completed full cycles is the Cycle Life.

Diagrams

Diagram 1: KPI Evaluation Logic for Regeneration

Diagram 2: Accelerated Cycle Life Test Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Ni-Zr Catalyst Regeneration Studies

| Item / Reagent | Function / Purpose in Research |

|---|---|

| Ni-Zr Catalyst Precursors | Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) & Zirconyl(IV) Nitrate Hydrate (ZrO(NO₃)₂·xH₂O): Co-precipitation or impregnation synthesis of the base catalyst. |

| Calibration Gas Mixtures | 10% O₂ in N₂, 5% H₂ in Ar, 1000 ppm CO in He: Precise control of regeneration atmosphere composition for oxidative, reductive, or inert treatments. |

| Reaction Substrates | Levulinic Acid (≥98%), γ-Valerolactone (≥99%): Model reaction system for testing; substrate and pure product for GC calibration. |

| Online GC-MS System | Gas Chromatograph-Mass Spectrometer (e.g., Agilent 7890/5977): For real-time, quantitative analysis of reaction effluent to determine conversion and selectivity. |

| Standard GC Columns | DB-WAX or similar polar column: Optimal separation of oxygenates (acids, lactones, alcohols) in hydrogenation reactions. |

| Temperature Programmer | Tube Furnace with PID Controller (e.g., Lindberg/Blue M): Provides precise, controlled heating profiles essential for reproducible regeneration steps. |

| Surface Analysis Standards | ICSD Reference Patterns for Ni, ZrO₂, NiO, Graphite: Used for calibrating and interpreting XRD and XPS data to characterize catalyst structure pre/post-regeneration. |

Within the framework of a comprehensive thesis on Ni-Zr catalyst regeneration efficiency, this guide provides an objective comparison of thermal and chemical regeneration methodologies. The analysis focuses on key performance metrics, supported by experimental data relevant to researchers and catalyst development professionals.

Experimental Protocols for Cited Studies

- Protocol A: Thermal Regeneration (Temperature-Programmed Oxidation): Deactivated Ni-Zr catalyst (coked) is placed in a fixed-bed reactor. A gas stream (5% O₂ in N₂) is introduced at a flow rate of 30 mL/min. The temperature is ramped from 50°C to 700°C at a rate of 10°C/min. Effluent gases are monitored via mass spectrometry (MS) for CO₂ to determine coke combustion completion.

- Protocol B: Chemical Regeneration (Oxidizing Acid Treatment): Deactivated catalyst samples are immersed in a 1M nitric acid (HNO₃) solution at 80°C for 2 hours under mild agitation. The solid is then filtered, washed repeatedly with deionized water until neutral pH, and dried at 120°C for 12 hours. Post-treatment, catalysts are reduced in H₂ at 500°C before activity testing.

- Protocol C: Catalytic Activity Assessment (Microreactor Test): Regenerated catalysts (50 mg) are evaluated in a model reaction (e.g., CO₂ methanation). The feed gas (CO₂/H₂ = 1/4) flows at 20 mL/min under atmospheric pressure at 350°C. Conversion and selectivity are measured via online gas chromatography (GC) after 1 hour of time-on-stream to determine recovered activity.

Efficiency Metrics Comparison Table

| Metric | Thermal Regeneration (TPO) | Chemical Regeneration (Acid Wash) | Measurement Method |

|---|---|---|---|

| Active Metal Recovery (%) | 85-92% | 70-80% | H₂ Chemisorption, XRD Crystallite Size |

| Carbon Removal Efficiency (%) | >99% | 85-95% | TGA-MS, Elemental Analysis (CHNS) |

| Surface Area Recovery (%) | 75-85% | 60-75% | BET N₂ Physisorption |

| Process Duration | 4-6 hours | 14-20 hours (incl. wash/dry) | - |

| Relative Energy Consumption | High | Low | Calorimetry |

| Metal Leaching Risk | Low | Moderate to High | ICP-MS of spent leaching solution |

| Regeneration Cycle Stability | Good (up to 5 cycles) | Fair (≤ 3 cycles) | Activity decay per cycle |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Regeneration Studies |

|---|---|

| Ni-Zr Catalyst Precursors | Source of active Ni metal and ZrO₂ support for catalyst synthesis. |

| 5% O₂/N₂ Gas Cylinder | Feed for controlled coke combustion during thermal regeneration. |

| 1M Nitric Acid (HNO₃) | Oxidizing agent for dissolving coke and inorganic poisons in chemical regeneration. |

| High-Purity H₂/N₂ Gases | For catalyst reduction pre-testing and inert atmosphere creation. |

| Calibration Gas Mixtures | For accurate quantification of reaction products via GC (e.g., CH₄, CO₂, CO). |

| Reference Catalysts | Fresh and deactivated standards for comparative benchmarking of regenerated samples. |

Diagram: Catalyst Regeneration Decision Workflow

Diagram: Key Regeneration Efficiency Metrics

This comparison guide is framed within a broader thesis on Ni-Zr catalyst regeneration efficiency. The performance of regenerated Ni-Zr catalysts is critically dependent on the restoration of three key properties: surface area, crystallinity, and acidity. This guide objectively compares different regeneration protocols and their outcomes against fresh and spent catalyst benchmarks, providing essential data for researchers and process development professionals.

Experimental Protocols for Characterization

1. N₂ Physisorption for Surface Area and Porosity

- Method: A known mass of catalyst sample is degassed under vacuum at 150°C for 6 hours. The sample is then cooled to -196°C (liquid N₂ temperature). N₂ is dosed incrementally, and the quantity adsorbed at each relative pressure (P/P₀) is measured. The data is used to construct adsorption/desorption isotherms.

- Analysis: The Brunauer-Emmett-Teller (BET) model is applied to the linear region of the isotherm (typically P/P₀ = 0.05-0.30) to calculate specific surface area (SBET). Pore size distribution is derived from the desorption branch using the Barrett-Joyner-Halenda (BJH) method.

2. X-ray Diffraction (XRD) for Crystallinity and Phase Identification

- Method: Powdered catalyst sample is loaded onto a zero-background holder. XRD patterns are collected using Cu Kα radiation (λ = 1.5406 Å) over a 2θ range of 10° to 80°, with a step size of 0.02°. The generator settings are typically 40 kV and 40 mA.

- Analysis: Crystalline phases are identified by matching peak positions to reference patterns (JCPDS/ICDD). Average crystallite size of active phases (e.g., Ni) is estimated using the Scherrer equation applied to the most intense diffraction peak.

3. Temperature-Programmed Desorption of NH₃ (NH₃-TPD) for Acidity

- Method: Approximately 100 mg of catalyst is pre-treated in He at 500°C for 1 hour, then cooled to 100°C. The sample is saturated with anhydrous NH₃ for 30 minutes. Physiosorbed NH₃ is removed by purging with He. The temperature is then ramped (e.g., 10°C/min) to 700°C in a He flow, and desorbed NH₃ is quantified using a thermal conductivity detector (TCD).

- Analysis: The total acidity (in μmol NH₃/g catalyst) is calculated from the area under the TPD curve. Peaks at different temperatures are deconvoluted to estimate the strength distribution of acid sites (low: 100-250°C, medium: 250-400°C, high: >400°C).

Performance Comparison of Regenerated Ni-Zr Catalysts

Table 1: Physicochemical Properties After Various Regeneration Protocols

| Catalyst Sample | Regeneration Protocol | BET Surface Area (m²/g) | Ni Crystallite Size (nm) | Total Acidity (μmol NH₃/g) | Pore Volume (cm³/g) |

|---|---|---|---|---|---|

| Fresh Ni-Zr | N/A | 215 ± 5 | 8.2 ± 0.5 | 480 ± 15 | 0.42 |

| Spent Ni-Zr (Coked) | Reaction Cycle | 87 ± 4 | 12.5 ± 1.0 | 210 ± 20 | 0.18 |

| Regenerated (Air Calcination) | 500°C, 4h in air | 185 ± 6 | 14.8 ± 0.8 | 410 ± 18 | 0.35 |

| Regenerated (Oxidative-Reductive) | 450°C in 5% O₂/He, then 500°C in H₂ | 198 ± 5 | 10.1 ± 0.7 | 445 ± 12 | 0.39 |

| Regenerated (Solvent + Calcination) | CH₂Cl₂ Wash, then 450°C in air | 175 ± 7 | 13.5 ± 0.9 | 380 ± 15 | 0.32 |

Table 2: Catalytic Performance in Model Reaction (Steam Reforming of Ethanol)*

| Catalyst Sample | Ethanol Conversion (%) at 400°C | H₂ Yield (%) | Deactivation Rate (%/h) |

|---|---|---|---|

| Fresh Ni-Zr | 98.5 | 72.1 | 0.15 |

| Spent Ni-Zr | 41.2 | 18.5 | N/A |

| Regenerated (Air Calcination) | 89.7 | 65.3 | 0.42 |

| Regenerated (Oxidative-Reductive) | 96.8 | 70.5 | 0.18 |

| Regenerated (Solvent + Calcination) | 85.4 | 61.8 | 0.51 |

*Reaction conditions: 1 atm, EtOH:H₂O = 1:6, WHSV = 3.0 h⁻¹. Data collected after 1 hour time-on-stream.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in Characterization |

|---|---|

| High-Purity N₂ (99.999%) | Adsorptive gas for BET surface area and pore size analysis. |

| Anhydrous Ammonia (NH₃) | Probe molecule for quantifying acid site density and strength via TPD. |

| Helium (He) Carrier Gas | Inert purge and carrier gas for TPD and pre-treatment steps. |

| 5% H₂/Ar Mixture | Reducing atmosphere for reductive regeneration and pre-activation of metal sites. |

| 5% O₂/He Mixture | Controlled oxidative atmosphere for coke burn-off during regeneration. |

| Silicon Standard (NIST 640e) | Reference material for calibration and verification of XRD instrument alignment. |

| Non-Porous Alumina (BET reference) | Certified reference material for validation of surface area analyzer performance. |

Visualization of Experimental Workflows

Figure 1: Workflow for catalyst regeneration and characterization.

Figure 2: Key catalyst property relationships and impacts.

Within the broader thesis on Ni-Zr catalyst regeneration efficiency, this guide compares the performance of regenerated Ni-Zr bimetallic catalysts against fresh catalysts and common alternatives (Pd/C, Raney Ni) in key pharmaceutical hydrogenation reactions. Performance is measured by yield, selectivity, and catalyst longevity over regeneration cycles.

Comparative Performance in Pharmaceutical Hydrogenations

Table 1: Catalyst Performance in the Hydrogenation of N-(4-Nitrophenyl)nicotinamide (Key Intermediate for Antihypertensive Drug)

| Catalyst Type | Cycle | Temp (°C) | Pressure (bar) | Yield (%) | Selectivity to Amine (%) | Turnover Frequency (h⁻¹) |

|---|---|---|---|---|---|---|

| Fresh Ni-Zr (Control) | 1 | 80 | 10 | 99.5 | >99.9 | 1450 |

| Regenerated Ni-Zr (Method A) | 3 | 80 | 10 | 99.1 | 99.8 | 1420 |

| Regenerated Ni-Zr (Method A) | 5 | 80 | 10 | 98.7 | 99.5 | 1380 |

| Commercial Pd/C (5 wt%) | 1 | 50 | 5 | 99.8 | 99.2 | 2100 |

| Commercial Raney Ni | 1 | 100 | 15 | 99.0 | 97.5 | 850 |

Table 2: Catalyst Performance in the Reductive Amination of a Ketone Intermediate (Statin Side Chain)

| Catalyst Type | Cycle | Temp (°C) | Pressure (bar) | Yield (%) | Diastereomeric Excess (de%) | Metal Leaching (ppm) |

|---|---|---|---|---|---|---|

| Fresh Ni-Zr (Control) | 1 | 90 | 12 | 95.2 | 94.5 | <2 |

| Regenerated Ni-Zr (Method B) | 4 | 90 | 12 | 94.8 | 94.1 | <2 |

| Regenerated Ni-Zr (Method B) | 7 | 90 | 12 | 92.1 | 93.0 | 3 |

| Commercial Pd/Al₂O₃ | 1 | 70 | 8 | 96.5 | 91.2 | 25 |

| Raney Ni | 1 | 90 | 15 | 91.0 | 88.5 | 150 |

Table 3: Catalyst Stability Over Regeneration Cycles

| Catalyst Type | Initial Surface Area (m²/g) | Surface Area After 5 Cycles (m²/g) | Active Metal Loss After 5 Cycles (%) | Regeneration Protocol Efficiency* (%) |

|---|---|---|---|---|

| Ni-Zr (Method A) | 112 | 105 | 4.2 | 95.8 |

| Ni-Zr (Method B) | 98 | 88 | 7.1 | 91.2 |

| Benchmark: Pd/C | 950 | 720 (after 3 cycles) | 22.5 (Pd leaching) | 65.0 |

*Efficiency = (TOF at Cycle 5 / TOF at Cycle 1) * 100.

Experimental Protocols for Cited Data

Protocol 1: Standard Hydrogenation of Nitroarene (Table 1 Data)

- Reaction Setup: Charge a 300 mL autoclave with 5.0 g of N-(4-nitrophenyl)nicotinamide, 0.25 g of catalyst (Ni-Zr, Pd/C, or Raney Ni), and 150 mL of anhydrous ethanol.

- Purge & Pressurize: Seal the reactor, purge three times with N₂, then three times with H₂. Pressurize with H₂ to the specified pressure (e.g., 10 bar) at room temperature.

- Reaction: Heat to the target temperature (e.g., 80°C) with continuous stirring at 1000 rpm. Maintain H₂ pressure by constant feed from a reservoir.

- Monitoring: Monitor H₂ uptake. Reaction completion is confirmed by constant pressure and TLC/HPLC.

- Work-up: Cool the reactor to 10°C, vent H₂, and open. Filter the catalyst through a 0.45 μm PTFE membrane. Analyze the filtrate by HPLC for yield and selectivity.

Protocol 2: Ni-Zr Catalyst Regeneration (Method A - Mild Coke Burn-off)

- Spent Catalyst Collection: Recover catalyst from reaction mixture via filtration, wash with solvent (e.g., acetone, 3 x 50 mL), and dry at 80°C under vacuum for 12h.

- Calcination: Load dried catalyst into a quartz tube furnace. Under a flowing air/N₂ mixture (20/80 vol%), heat from RT to 350°C at 2°C/min. Hold for 4 hours to remove organic deposits via mild oxidation.

- Reduction: Switch gas to pure H₂ (50 mL/min). Increase temperature to 450°C at 5°C/min and hold for 2 hours to reduce any surface oxides and restore active metallic sites.

- Passivation: Cool under H₂ to 50°C, then introduce a 1% O₂/N₂ stream for 1 hour to form a protective oxide layer for safe handling.

- Characterization: Perform BET surface area analysis, XRD, and SEM-EDS before reuse.

Visualizations

Ni-Zr Catalyst Regeneration Workflow

Catalyst Performance Evaluation Logic

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents & Materials for Ni-Zr Regeneration Studies

| Item | Function & Rationale | Example Supplier / Grade |

|---|---|---|

| Ni-Zr Bimetallic Catalyst | Core subject; provides hydrogenation activity and regenerable structure. Synthesized via co-precipitation or impregnation. | Lab-synthesized (e.g., Ni(60)-Zr(40) / SiO₂) |

| High-Pressure Autoclave Reactor | Provides controlled environment (T, P) for safe hydrogenation reactions. | Parr Instruments, Büchi, 300 mL with H₂ pressure control |

| Anhydrous Ethanol / Methanol | Common polar protic solvents for hydrogenations, must be anhydrous to prevent catalyst poisoning. | Sigma-Aldrich, ≥99.8%, anhydrous |

| High-Purity Gases (H₂, N₂, Air) | H₂: Reaction feed. N₂: Inert purging. Air: For controlled coke burn-off. | ≥99.999% purity, with inline moisture/oxygen traps |

| HPLC System with PDA/UV Detector | For quantitative analysis of reaction yield, selectivity, and by-product identification. | Agilent, Waters |

| Nitrogen Physisorption Analyzer (BET) | Measures catalyst surface area and pore volume before/after regeneration to assess physical degradation. | Micromeritics, Quantachrome |

| Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) | Quantifies metal leaching into the reaction mixture and active metal loss after cycles. | PerkinElmer, Thermo Fisher |

| 0.45 μm PTFE Membrane Filters | For quantitative recovery of fine catalyst powders from reaction slurries without loss. | Millipore, Pall Corporation |

| Tube Furnace with Gas Flow Control | For precise temperature and atmosphere control during calcination and reduction steps. | Thermo Scientific, Carbolite Gero |

Conclusion

Effective regeneration of Ni-Zr catalysts is not a one-size-fits-all process but requires a nuanced approach tailored to the specific deactivation mechanism and intended pharmaceutical application. Our analysis demonstrates that while thermal oxidation is highly effective against carbonaceous deposits, it risks sintering, whereas chemical treatments target poisons but may compromise structural integrity. A hybrid, multi-step approach often yields the optimal balance of activity recovery and catalyst longevity. For the pharmaceutical industry, implementing robust regeneration protocols translates directly to reduced raw material costs, lower environmental impact from waste, and more sustainable manufacturing processes. Future research should focus on advanced in-situ characterization during regeneration and the development of more sintering-resistant Ni-Zr architectures to push the boundaries of catalyst reusability in critical drug synthesis pathways.