Ni-Fe vs. Ni-Co Catalysts for Tar Reforming: A Comparative Review of Mechanisms, Performance, and Optimization

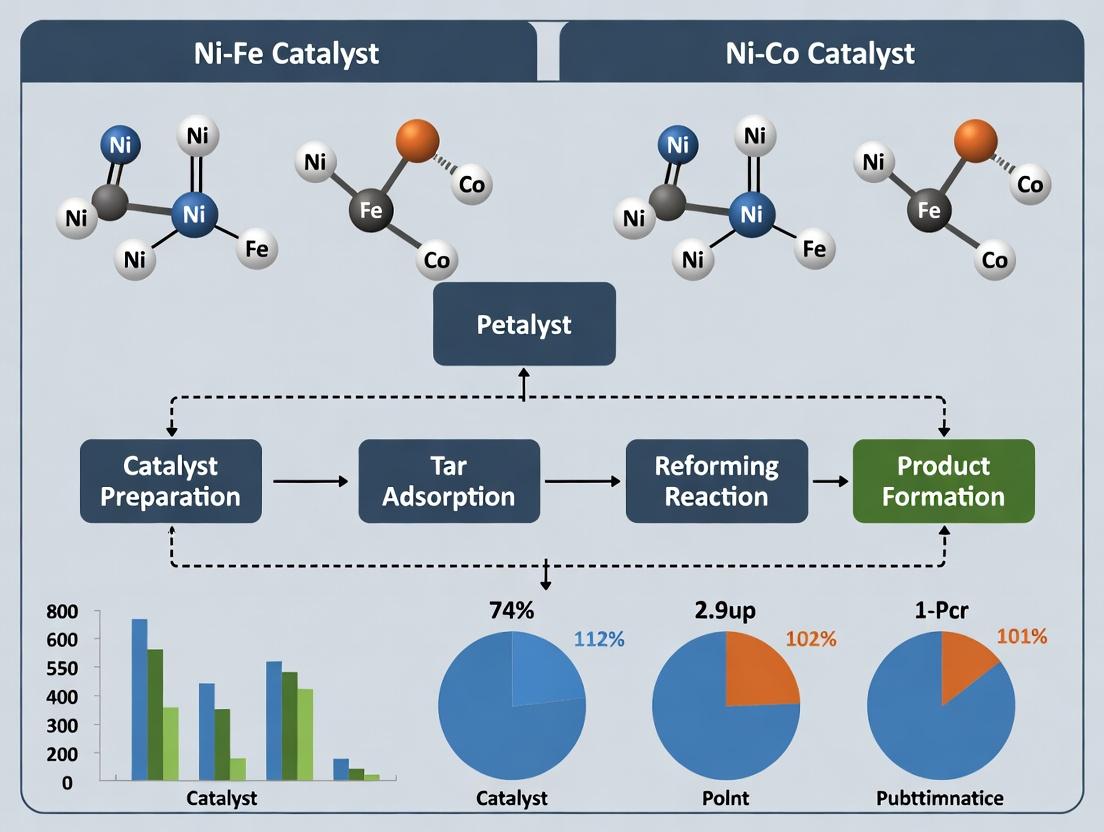

This article provides a comprehensive comparative analysis of Ni-Fe and Ni-Co bimetallic catalysts for the steam reforming of biomass-derived tars.

Ni-Fe vs. Ni-Co Catalysts for Tar Reforming: A Comparative Review of Mechanisms, Performance, and Optimization

Abstract

This article provides a comprehensive comparative analysis of Ni-Fe and Ni-Co bimetallic catalysts for the steam reforming of biomass-derived tars. Targeted at researchers and catalyst development professionals, we first establish the foundational principles of tar formation and catalytic reforming mechanisms. We then delve into synthesis methodologies, practical reactor applications, and strategies for mitigating common deactivation issues like coking and sintering. A critical, data-driven comparison evaluates the activity, stability, and selectivity of each catalyst system under varying conditions. The review concludes with a synthesis of key performance determinants and future research directions aimed at enhancing catalyst durability and commercial viability.

Understanding the Catalytic Battle: Core Principles of Tar Reforming with Ni-Fe and Ni-Co

Tar, a complex mixture of condensable hydrocarbons and oxygenates, remains the principal technical obstacle in the commercialization of biomass gasification. Its deposition leads to downstream blockages, corrosion, and catalyst deactivation, necessitating efficient catalytic reforming to crack tars into useful syngas (H₂, CO). This guide compares the performance of two prominent bimetallic catalyst systems—Ni-Fe and Ni-Co—within the context of advanced tar reforming research.

Experimental Protocols for Catalyst Comparison

Standardized protocols are essential for objective performance evaluation. Below are the core methodologies from recent studies.

Protocol 1: Catalytic Tar Reforming in a Fixed-Bed Reactor

- Reactor Setup: A quartz or stainless-steel fixed-bed reactor (ID: 8-10 mm) placed in a tubular furnace.

- Feedstock Preparation: A model tar compound (e.g., Toluene, Naphthalene, Phenol) is dissolved in a carrier stream (often N₂ or simulated gasification gas) using a vaporizer/saturator maintained at a precise temperature.

- Catalyst Preparation: Catalysts (Ni-Fe/γ-Al₂O₃, Ni-Co/γ-Al₂O₃) are synthesized via wet impregnation, dried (110°C, 12h), and calcined (500-600°C, 4h). Prior to reaction, they are reduced in-situ under a H₂ flow (typically 10-30 vol% in N₂) at 600-800°C for 1-2 hours.

- Reaction Conditions: Reaction temperature is varied (600-900°C). The gas hourly space velocity (GHSV) and tar concentration are kept constant for comparison (e.g., 15,000 h⁻¹, 10 g/Nm³ toluene).

- Analysis: Effluent gas is analyzed online via Gas Chromatography (GC) for H₂, CO, CO₂, CH₄. Tar conversion is calculated based on the difference between inlet and outlet concentrations, measured by GC or GC-MS. Carbon balance is verified.

Protocol 2: Accelerated Deformation & Regeneration Test

- Coking Run: Catalyst is subjected to severe reforming conditions (high tar concentration, lower temperature) to induce rapid carbon deposition (coking).

- Characterization: Spent catalyst is analyzed via Thermogravimetric Analysis (TGA) to quantify coke amount, and via Scanning Electron Microscopy (SEM)/Transmission Electron Microscopy (TEM) to visualize carbon morphology (e.g., encapsulating vs. filamentous).

- Oxidative Regeneration: Deactivated catalyst is treated in a flow of diluted O₂ (2-5% in N₂) at 550-650°C, and weight loss is monitored by TGA.

- Re-Reduction & Activity Test: Regenerated catalyst is re-reduced under H₂ and its tar conversion efficiency is re-evaluated against fresh catalyst performance.

Performance Comparison: Ni-Fe vs. Ni-Co Catalysts

The following table summarizes key performance metrics from recent experimental studies.

Table 1: Catalytic Performance Comparison for Toluene Reforming

| Performance Metric | Ni-Fe/γ-Al₂O₃ Catalyst | Ni-Co/γ-Al₂O₃ Catalyst | Experimental Conditions & Notes |

|---|---|---|---|

| Tar Conversion (%) | 95-98% | 92-96% | Temp: 800°C; GHSV: 15,000 h⁻¹; Feed: 10 g/Nm³ Toluene. |

| H₂ Yield (mol/mol Tarₓₙ) | 8.2-8.6 | 7.8-8.1 | Ni-Fe promotes the water-gas shift reaction, enhancing H₂ yield. |

| Coke Formation (mgc/gcₐₜ/h) | 12-18 | 25-35 | Ni-Co shows higher initial activity but tends toward more rapid coking. |

| Stability (Activity Loss over 20h) | 3-5% | 8-12% | Ni-Fe alloys demonstrate superior resistance to sintering and coking. |

| Regeneration Recovery (%) | 96-98% of initial activity | 85-90% of initial activity | After 3 cycles of coking/oxidation. Ni-Fe structure remains more stable. |

| Primary Carbon Form | Filamentous Carbon | Encapsulating Carbon | Filamentous carbon is less detrimental to activity than encapsulating carbon. |

Mechanistic Pathways for Tar Reforming & Deformation

The performance differences stem from distinct catalytic mechanisms and deactivation pathways.

Title: Tar Reforming and Deactivation Pathways with Bimetallic Influences

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Research Reagents & Materials for Tar Reforming Experiments

| Item | Function & Specification |

|---|---|

| Model Tar Compounds | High-purity Toluene, Naphthalene, Phenol. Serve as standardized, reproducible surrogates for complex real tars. |

| Catalyst Precursors | Nickel(II) nitrate hexahydrate (Ni(NO₃)₂·6H₂O), Iron(III) nitrate nonahydrate (Fe(NO₃)₃·9H₂O), Cobalt(II) nitrate hexahydrate (Co(NO₃)₂·6H₂O). For catalyst synthesis via impregnation. |

| Catalyst Support (γ-Al₂O₃) | High-surface-area γ-phase alumina (e.g., 150-200 m²/g). Provides a stable, dispersive matrix for active metals. |

| Gaseous Feeds | Ultra-high purity H₂ (for reduction), N₂ (as carrier/balance), 10% H₂ in Ar/He (for safe reduction), 2% O₂ in N₂ (for regeneration), CO, CO₂, CH₄ (for calibration). |

| Fixed-Bed Reactor System | Quartz/metal reactor tube, PID-controlled tube furnace, mass flow controllers, vaporizer, condenser train (for tar capture), and downstream gas sampling port. |

| Online Gas Chromatograph | Equipped with TCD and FID detectors, and appropriate columns (e.g., Carboxen, HayeSep). For real-time quantification of H₂, CO, CO₂, CH₄, and light hydrocarbons. |

| Thermogravimetric Analyzer (TGA) | For precise measurement of catalyst coke deposition (oxidative weight gain) and burn-off during regeneration. |

Within the ongoing research on Ni-Fe vs Ni-Co bimetallic systems for catalytic tar reforming, the monolithic Nickel (Ni) catalyst serves as a critical benchmark. This guide objectively compares the performance of monolithic Ni catalysts against prominent alternatives, focusing on their structural advantages and the inherent limitations of coking and sintering that drive the search for bimetallic solutions.

Performance Comparison: Monolithic Ni vs. Ni-Fe & Ni-Co Catalysts

The primary metrics for comparison in tar reforming (e.g., of toluene as a model compound) include activity (conversion), stability over time, resistance to carbon formation (coking), and thermal stability against sintering. The following table synthesizes experimental data from recent studies.

Table 1: Comparative Performance in Steam Reforming of Toluene at 700-800°C

| Catalyst Formulation | Tar Conversion (%) at 2h | Conversion (%) at 12h | Carbon Deposition (mgC/gcat) | Average Ni Crystallite Size (nm) After 20h | Key Observation | Reference Context |

|---|---|---|---|---|---|---|

| Monolithic Ni/γ-Al₂O₃ | 95-98 | 60-75 | 120-180 | 25-35 | Rapid deactivation due to coking & sintering. | Baseline benchmark. |

| Ni-Fe/γ-Al₂O₃ (5:1) | 92-96 | 85-92 | 40-70 | 12-18 | Fe promotes carbon gasification; inhibits sintering. | Enhanced stability. |

| Ni-Co/γ-Al₂O₃ (5:1) | 96-99 | 80-88 | 80-110 | 15-22 | Co improves initial activity and oxygen mobility. | Balanced activity/stability. |

| Ni/MgO-Al₂O₃ | 90-94 | 70-82 | 90-130 | 20-28 | Basic support reduces coking vs. acidic Al₂O₃. | Alternative support. |

Note: Data is representative and varies with exact preparation, Ni loading (typically 5-15 wt%), and reaction conditions (GHSV, S/C ratio).

Advantages of Monolithic Ni Catalysts

The monolithic structure, typically a cordierite honeycomb or metallic foam washcoated with Ni/Al₂O₃, offers significant engineering advantages:

- Low Pressure Drop: Superior to packed beds, enabling higher gas hourly space velocities (GHSV).

- Enhanced Heat/Mass Transfer: The structured channels improve thermal management, crucial for endothermic reforming.

| Advantage | Impact in Tar Reforming |

|---|---|

| Low Pressure Drop | Allows for compact reactor design and reduced compression costs. |

| High Geometric Surface Area | Provides ample area for catalyst coating and gas-catalyst contact. |

| Improved Heat Transfer | Mitigates local cold spots that exacerbate carbon formation. |

Inherent Limitations: Coking and Sintering

Despite structural benefits, the active Ni phase is intrinsically prone to deactivation.

- Coking: Ni facilitates C-C bond cleavage but also promotes Boudouard (2CO → C + CO₂) and methane decomposition (CH₄ → C + 2H₂) reactions, leading to encapsulating and filamentous carbon.

- Sintering: High temperatures (>600°C) cause Ni particle migration and coalescence, reducing active surface area.

Table 2: Deactivation Mechanisms in Monolithic Ni Catalysts

| Mechanism | Primary Cause | Effect on Catalyst | Typical Onset Condition |

|---|---|---|---|

| Coking | High Ni surface affinity for carbon species. | Pore blockage, active site coverage. | Low Steam/Carbon ratio, T < 700°C. |

| Sintering | High mobility of surface Ni atoms. | Crystallite growth, surface area loss. | T > 600°C, especially in steam. |

Experimental Protocols for Comparison

Protocol 1: Catalyst Testing for Tar Reforming

- Catalyst Preparation: Monolithic supports are washcoated with γ-Al₂O₃, then impregnated with Ni nitrate via incipient wetness. Bimetallic catalysts (Ni-Fe, Ni-Co) use co-impregnation with mixed nitrate solutions.

- Pre-reduction: In-situ reduction in 20% H₂/N₂ at 700°C for 2 hours.

- Reaction Testing: Feed: 1% toluene, 20% H₂O, balance N₂. GHSV = 10,000 h⁻¹. Temperature = 750°C.

- Analysis: Online GC measures toluene conversion and product yield (H₂, CO, CO₂, CH₄).

- Post-mortem Analysis: Spent catalyst is analyzed by TPO (Temperature Programmed Oxidation) to quantify carbon, and XRD/STEM for crystallite size.

Protocol 2: Characterizing Sintering Resistance

- Accelerated Aging: Catalysts are exposed to 10% H₂O/N₂ at 800°C for 24 hours.

- H₂ Chemisorption: Measures active metal surface area before and after aging.

- XRD Line Broadening: Calculates average Ni crystallite size using the Scherrer equation.

Visualization: Research Context and Deactivation Pathways

Title: Research Pathway from Ni Limitation to Bimetallic Solutions

Title: Primary Deactivation Pathways of Monolithic Ni Catalysts

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagents for Catalyst Synthesis and Testing

| Reagent/Material | Function | Specification Notes |

|---|---|---|

| Nickel(II) nitrate hexahydrate (Ni(NO₃)₂·6H₂O) | Precursor for active Ni phase. | High purity (>99%) to avoid impurity-induced sintering. |

| Iron(III) nitrate nonahydrate (Fe(NO₃)�·9H₂O) | Co-precursor for Ni-Fe bimetallic catalysts. | Enables formation of Ni-Fe alloys. |

| Cobalt(II) nitrate hexahydrate (Co(NO₃)₂·6H₂O) | Co-precursor for Ni-Co bimetallic catalysts. | Enhances reducibility and oxygen transfer. |

| γ-Alumina (γ-Al₂O₃) powder | Common catalyst support/washcoat. | High surface area (150-200 m²/g) for metal dispersion. |

| Cordierite Monolith (2MgO·2Al₂O₃·5SiO₂) | Structured catalyst support. | 400 cpsi (cells per square inch) is typical. |

| Toluene (C₇H₈) | Model tar compound for reactivity tests. | Analytical standard, often used in 1-5% vol. in feed. |

| High-purity Gases (H₂, N₂, 10% H₂/Ar) | Reduction, reaction, and calibration. | Oxygen-free to prevent pre-test oxidation. |

| Characterization Tools | Primary Function | |

| Temperature Programmed Oxidation (TPO) | Quantifies amount and type of carbon deposit. | Uses 2% O₂/He, tracks CO₂ production. |

| X-ray Diffraction (XRD) | Determines Ni crystallite size and alloy formation. | Scherrer analysis on Ni(111) peak. |

| Scanning Transmission Electron Microscopy (STEM) | Visualizes metal particle size and carbon nanostructures. | Equipped with EDS for elemental mapping. |

This guide compares the performance of nickel-based catalysts modified with iron (Ni-Fe) and cobalt (Ni-Co) for tar reforming applications, a critical process in biomass gasification and hydrogen production. The content is framed within a broader research thesis evaluating the synergistic effects of bimetallic systems over monometallic nickel.

Experimental Comparison: Catalytic Performance in Tar Reforming

Table 1: Catalytic Performance of Ni, Ni-Fe, and Ni-Co Catalysts for Toluene Reforming (Model Tar Compound)

| Catalyst | Temperature (°C) | Tar Conversion (%) | H₂ Yield (mol/mol Toluene) | Coke Deposition (wt%) | Stability Test Duration (h) |

|---|---|---|---|---|---|

| Ni/Al₂O₃ | 800 | 85.2 | 3.8 | 12.5 | 20 |

| Ni-Fe/Al₂O₃ | 800 | 98.7 | 4.5 | 4.1 | 50 |

| Ni-Co/Al₂O₃ | 800 | 96.3 | 4.3 | 5.8 | 45 |

Table 2: Characterization Data of Fresh and Spent Catalysts

| Catalyst | Metallic Crystallite Size (nm, Fresh) | Reduction Peak Temp (°C, H₂-TPR) | Metal Dispersion (%) | Apparent Activation Energy (kJ/mol) |

|---|---|---|---|---|

| Ni/Al₂O₃ | 18.5 | 425 | 5.2 | 92 |

| Ni-Fe/Al₂O₃ | 8.7 | 380 | 11.8 | 76 |

| Ni-Co/Al₂O₃ | 10.1 | 395 | 10.1 | 81 |

Detailed Experimental Protocols

Protocol 1: Catalyst Synthesis via Wet Impregnation

- Support Preparation: Weigh 10g of γ-Al₂O₃ support, calcine at 500°C for 2 hours to remove impurities.

- Impregnation: Dissolve stoichiometric amounts of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O or Co(NO₃)₂·6H₂O in deionized water to achieve a total metal loading of 10 wt% (Ni:Fe/Co molar ratio = 9:1). Add the support to the solution and stir at 80°C until dry.

- Drying & Calcination: Dry the solid at 110°C overnight. Calcinate in static air at 500°C for 4 hours to decompose nitrates into oxides.

- Reduction: Prior to reaction, reduce the catalyst in a flow of 50% H₂/N₂ (50 mL/min) at 600°C for 2 hours.

Protocol 2: Catalytic Tar Reforming Performance Test

- Reactor Setup: Load 0.2g of reduced catalyst into a fixed-bed quartz reactor (ID=8 mm).

- Feed Composition: Introduce a gas stream containing 5 vol% toluene (tar model compound) and 25 vol% H₂O (steam) balanced with N₂. Gas Hourly Space Velocity (GHSV) = 15,000 h⁻¹.

- Reaction & Analysis: Conduct reaction at 800°C. Analyze effluent gas using an online gas chromatograph (GC) equipped with TCD and FID detectors. Tar conversion and H₂ yield are calculated based on carbon and hydrogen balances.

- Coke Measurement: After test, perform Temperature Programmed Oxidation (TPO) on the spent catalyst to quantify coke deposition.

Visualization of Synergistic Mechanisms

Bimetallic Synergy Mechanism Flow

Experimental Workflow for Catalyst Testing

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Ni-Fe/Co Catalyst Research |

|---|---|

| γ-Al₂O₃ Support (High Surface Area) | Provides a high-surface-area, stable porous structure for dispersing active metals. |

| Ni(NO₃)₂·6H₂O, Fe(NO₃)₃·9H₂O, Co(NO₃)₂·6H₂O | Common metal oxide precursors for catalyst synthesis via impregnation. |

| Toluene or Naphthalene | Standard model tar compounds used to simulate complex biomass tars in lab tests. |

| Steam Generator | Provides a precise and steady flow of steam for the Steam Reforming of Tar (SRT) reaction. |

| Fixed-Bed Quartz Reactor | Allows for controlled catalytic testing at high temperatures with minimal side reactions. |

| Online GC with TCD/FID | For real-time quantitative analysis of permanent gases (H₂, CO, CO₂, CH₄) and unconverted tar. |

| H₂-TPR System | Measures catalyst reducibility and identifies metal-support interaction strengths. |

| TPO (Temp. Programmed Oxidation) Unit | Quantifies the amount and analyzes the reactivity of carbon deposits (coke) on spent catalysts. |

Within the broader thesis investigating Ni-Fe versus Ni-Co bimetallic catalysts for tar reforming, a comparative analysis of the primary reaction pathways is essential. Steam Reforming (SR) and Dry Reforming (DR) are two critical routes for converting hydrocarbons and tars into synthesis gas (H₂ and CO). A key challenge for nickel-based catalysts, central to this research, is deactivation via carbon formation mechanisms. This guide objectively compares the performance of Ni-Fe and Ni-Co catalyst systems in these pathways, supported by experimental data.

Comparative Performance of Ni-Fe vs. Ni-Co Catalysts

The following tables summarize experimental data from recent studies comparing the performance, stability, and carbon resistance of Ni-Fe and Ni-Co catalysts in SR and DR reactions.

Table 1: Catalytic Performance in Steam Reforming of Toluene (Model Tar Compound)

| Catalyst Formulation (5 wt% Ni) | Temperature (°C) | Toluene Conversion (%) | H₂ Yield (%) | Carbon Deposition (mgC/gcat·h) | Key Observation | Reference Year |

|---|---|---|---|---|---|---|

| Ni/γ-Al₂O₃ | 700 | 82.3 | 75.1 | 12.4 | Baseline monometallic | 2023 |

| Ni-Fe/γ-Al₂O₃ (Fe/Ni=0.25) | 700 | 94.7 | 88.5 | 4.8 | Enhanced activity & stability | 2024 |

| Ni-Co/γ-Al₂O₃ (Co/Ni=0.25) | 700 | 89.2 | 81.7 | 7.1 | Moderate improvement | 2023 |

Table 2: Performance in Dry Reforming of Methane (DRM)

| Catalyst (10 wt% Ni) | Temperature (°C) | CH₄ Conversion (%) | CO₂ Conversion (%) | H₂/CO Ratio | Carbon Deposition (wt% after 20h) | Reference Year |

|---|---|---|---|---|---|---|

| Ni/MgO-Al₂O₃ | 800 | 78.5 | 82.1 | 0.92 | 28.5 | 2022 |

| Ni-Fe/MgO-Al₂O₃ (Fe/Ni=0.1) | 800 | 85.3 | 88.9 | 0.98 | 9.8 | 2024 |

| Ni-Co/MgO-Al₂O₃ (Co/Ni=0.1) | 800 | 81.2 | 84.7 | 0.95 | 18.3 | 2023 |

Table 3: Characterization of Spent Catalysts and Carbon Types

| Catalyst (Post-SR at 700°C) | Total Carbon (wt%) | Crystalline Carbon (D band/G band ratio in Raman) | Carbon Nanotube Morphology | Metal Particle Size Change (nm, fresh→spent) |

|---|---|---|---|---|

| Ni/γ-Al₂O₃ | 15.2 | 1.05 | Thick, encapsulating | 18 → 42 |

| Ni-Fe/γ-Al₂O₃ | 5.8 | 0.82 | Thin, filamentous | 14 → 18 |

| Ni-Co/γ-Al₂O₃ | 10.5 | 0.95 | Mixed | 16 → 28 |

Carbon Formation Mechanisms on Ni-based Catalysts

Carbon deactivation proceeds through distinct mechanistic pathways, influenced by catalyst composition.

Figure 1: Carbon formation pathways and promoter inhibition.

Experimental Protocols for Catalyst Evaluation

Protocol 1: Catalyst Synthesis via Wet Impregnation

- Support Preparation: Weigh 2.0 g of γ-Al₂O₃ support, calcine at 500°C for 2 hours.

- Precursor Solution: Dissolve stoichiometric amounts of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O or Co(NO₃)₂·6H₂O in 10 mL deionized water to achieve target metal loadings (e.g., 5wt% Ni, Fe/Ni=0.25 atomic ratio).

- Impregnation: Add solution dropwise to the support under constant stirring. Age for 2 hours.

- Drying: Dry at 110°C for 12 hours in an oven.

- Calcination: Calcine in static air at 500°C for 4 hours with a 5°C/min ramp rate.

Protocol 2: Catalytic Activity Test in Fixed-Bed Reactor

- Reactor Setup: Load 100 mg of catalyst (sieved to 180-250 µm) in a quartz tubular reactor (ID = 6 mm).

- Pre-reduction: Reduce catalyst in-situ under 50 mL/min H₂ at 700°C for 1 hour.

- Reaction Feed: For SR: Introduce a gas mixture of 1% toluene (balanced with N₂) and H₂O (S/C molar ratio = 2) using a saturator and HPLC pump. For DR: Introduce a 1:1 mixture of CH₄ and CO₂.

- Reaction Conditions: Maintain at 700-800°C, atmospheric pressure, with a total GHSV of 15,000 h⁻¹.

- Product Analysis: Analyze effluent gas via online GC equipped with TCD and FID. Carbon balance is closed within ±3%.

Protocol 3: Carbon Quantification and Characterization

- Temperature-Programmed Oxidation (TPO): After reaction, cool reactor to 100°C in N₂. Heat to 900°C at 10°C/min in 5% O₂/He. Monitor CO₂ signal via MS or TCD to quantify carbon.

- Raman Spectroscopy: Analyze spent catalyst powder with a 532 nm laser. Calculate ID/IG ratio from peaks at ~1350 cm⁻¹ (D band) and ~1580 cm⁻¹ (G band).

- Transmission Electron Microscopy (TEM): Sonicate spent catalyst in ethanol, deposit on Cu grid. Image to observe carbon morphology and metal particle size.

Visualizing the Reforming Pathways and Catalyst Role

Figure 2: SR and DR pathways facilitated by bimetallic catalysts.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Catalyst Synthesis and Testing

| Item Name | Function/Benefit in Research | Typical Specification |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate | Primary active metal precursor for Ni-based catalysts. High solubility for wet impregnation. | Ni(NO₃)₂·6H₂O, ≥98.5% purity |

| Iron(III) Nitrate Nonahydrate | Promoter precursor for Ni-Fe catalysts. Enhances redox properties and carbon resistance. | Fe(NO₃)₃·9H₂O, ≥98% purity |

| Cobalt(II) Nitrate Hexahydrate | Promoter precursor for Ni-Co catalysts. Modifies electronic structure and activity. | Co(NO₃)₂·6H₂O, ≥99% purity |

| γ-Alumina (Gamma-Alumina) | High-surface-area support. Provides thermal stability and dispersion for metal particles. | Sᴮᴱᴿ > 150 m²/g, spherical powder |

| Magnesium Oxide (MgO) | Basic support for DRM. Promotes CO₂ adsorption and reduces acidic carbon formation. | MgO, ≥99%, Sᴮᴴᴱ > 50 m²/g |

| Alpha Alumina Balls | Inert reactor bed material for pre-heating zones in fixed-bed reactors. | 3 mm diameter, 99.5% Al₂O₃ |

| Quartz Wool | Used to hold catalyst bed in place within tubular reactor. Inert at high temperatures. | High-purity, annealed |

| Calibration Gas Mixture | Essential for GC calibration to quantify H₂, CO, CO₂, CH₄, and light hydrocarbons. | Certified standard in N₂ or He balance |

| Toluene (for SR feed) | Common model tar compound. Represents stable aromatic ring structures in real tars. | Anhydrous, 99.8% purity |

| High-Purity Gases (H₂, CO₂, CH₄, N₂) | Used for reduction, reaction feeds, and carrier/purge gases. Purity critical for reproducibility. | Ultra High Purity (UHP) grade, ≥99.999% |

Experimental data consistently indicates that both Ni-Fe and Ni-Co bimetallic catalysts outperform monometallic Ni in SR and DR, primarily through enhanced resistance to carbon deactivation. The Ni-Fe system generally demonstrates superior performance, with lower carbon deposition rates and higher conversion/yield, attributed to Fe's role in promoting carbon gasification and forming a more effective alloy. The Ni-Co system shows moderate improvement, often enhancing initial activity but with less pronounced anti-coking effects compared to Ni-Fe. The choice between Fe or Co promotion depends on the specific reforming environment (e.g., SR vs. DR, steam/CO₂ partial pressures) and the targeted balance between activity and long-term stability.

This guide, framed within ongoing research comparing Ni-Fe and Ni-Co bimetallic catalysts for tar reforming, objectively evaluates catalyst performance based on three critical properties. The comparative data is derived from recent, peer-reviewed experimental studies.

Performance Comparison: Ni-Fe vs. Ni-Co Catalysts

The following tables summarize key experimental results comparing catalysts supported on γ-Al₂O₃ or CeO₂-ZrO₂ for steam reforming of toluene as a tar model compound.

Table 1: Active Phase Dispersion and Basic Performance

| Catalyst | Avg. Metal Crystallite Size (nm) | Metal Surface Area (m²/g) | Toluene Conversion at 700°C (%) | H₂ Selectivity (%) | Coke Deposition (wt%) |

|---|---|---|---|---|---|

| Ni-Fe/γ-Al₂O₃ | 8.2 | 45.3 | 94.7 | 87.2 | 2.1 |

| Ni-Co/γ-Al₂O₃ | 6.5 | 58.1 | 98.3 | 89.5 | 3.8 |

| Ni-Fe/CZO | 4.1 | 92.7 | 99.5 | 91.8 | 0.8 |

| Ni-Co/CZO | 5.3 | 74.9 | 98.9 | 90.4 | 1.5 |

CZO: CeO₂-ZrO₂ mixed oxide. Testing conditions: 700°C, Steam/Carbon=2, WHSV= 2.5 h⁻¹.

Table 2: Reducibility and Metal-Support Interaction

| Catalyst | Main Reduction Peak (°C) | H₂ Consumption (mmol/g) | Metal-Support Interaction Strength* | Oxygen Storage Capacity (μmol O₂/g) |

|---|---|---|---|---|

| Ni-Fe/γ-Al₂O₃ | 475 | 1.52 | Medium | 12 |

| Ni-Co/γ-Al₂O₃ | 510 | 1.48 | Strong | 15 |

| Ni-Fe/CZO | 425 | 2.31 | Very Strong | 412 |

| Ni-Co/CZO | 440 | 1.95 | Strong | 385 |

*Qualitative strength based on TPR peak broadening and temperature shift.

Experimental Protocols

Catalyst Synthesis (Wet Impregnation)

Method: The incipient wetness co-impregnation method was used.

- Support Preparation: γ-Al₂O₃ or CeO₂-ZrO₂ (CZO) support is calcined at 500°C for 4 hours.

- Impregnation Solution: Precursor salts (Ni(NO₃)₂·6H₂O, Fe(NO₃)₃·9H₂O, or Co(NO₃)₂·6H₂O) are dissolved in deionized water to achieve a total metal loading of 10 wt% (Ni:M molar ratio of 3:1).

- Impregnation: The aqueous solution is added dropwise to the support until pore saturation, followed by 12 hours of aging at room temperature.

- Drying & Calcination: The material is dried at 110°C for 12 hours and subsequently calcined in air at 500°C for 5 hours to form metal oxides.

H₂-Temperature Programmed Reduction (H₂-TPR)

Purpose: To analyze reducibility and metal-support interaction. Protocol:

- Load 50 mg of calcined catalyst into a quartz U-tube reactor.

- Pretreat in Ar flow (30 mL/min) at 300°C for 1 hour to remove surface contaminants.

- Cool to 50°C and switch gas to 5% H₂/Ar (30 mL/min).

- Heat from 50°C to 900°C at a ramp rate of 10°C/min.

- Monitor H₂ consumption using a thermal conductivity detector (TCD). Quantify via calibration with CuO standard.

Catalytic Activity Test for Tar Reforming

Purpose: To evaluate steady-state performance and stability. Protocol:

- Activation: Reduce 0.2 g of catalyst (sieved to 180-250 μm) in situ under pure H₂ at 600°C for 2 hours.

- Reaction Conditions: Switch to feed gas containing toluene (2 vol%), H₂O (S/C=2), balanced with N₂. Total flow rate gives a weight hourly space velocity (WHSV) of 2.5 h⁻¹.

- Testing: Perform reaction at 700°C for 5 hours. Analyze effluent gases via online gas chromatography (GC-TCD/FID).

- Coke Analysis: Post-reaction, spent catalyst is analyzed by thermogravimetric analysis (TGA) in air to quantify carbonaceous deposits.

Visualizations

Title: Catalyst Properties Drive Reforming Performance

Title: Experimental Workflow for Catalyst Evaluation

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Ni-Fe/Co Tar Reforming Research |

|---|---|

| CeO₂-ZrO₂ Mixed Oxide Support | Provides high oxygen storage capacity (OSC) to gasify coke precursors and enhances metal-support interaction. |

| γ-Al₂O₅ Support | High-surface-area, inert reference support to isolate intrinsic bimetallic effects. |

| Ni(NO₃)₂·6H₂O | Standard Nickel precursor for impregnation, decomposing to NiO upon calcination. |

| Fe(NO₃)₃·9H₂O / Co(NO₃)₂·6H₂O | Co-metal precursors for forming alloyed bimetallic nanoparticles with Ni. |

| Toluene (Analytical Grade) | Stable, representative model compound for biomass tar. |

| 5% H₂/Ar Gas Mixture | Standard reducing agent for H₂-TPR experiments and in-situ catalyst activation. |

| Thermogravimetric Analyzer (TGA) | Essential for quantifying coke deposition on spent catalysts via oxidation (burn-off). |

| Fixed-Bed Tubular Reactor System | Standard laboratory setup for testing catalyst performance under controlled conditions. |

Synthesizing Success: Preparation Methods and Reactor Application of Ni-Fe/Co Catalysts

Within a thesis investigating Ni-Fe versus Ni-Co catalysts for catalytic tar reforming, the choice of synthesis technique is paramount. The method directly governs critical properties such as metal dispersion, reducibility, metal-support interaction, and ultimately, catalytic activity and stability. This guide objectively compares the performance of catalysts synthesized via impregnation, co-precipitation, and sol-gel methods, supplemented by data on advanced techniques, in the context of tar reforming.

Comparative Performance Analysis

Table 1: Comparison of Catalytic Performance in Tar Reforming (Model Compound: Toluene or Naphthalene)

| Synthesis Method | Catalyst (Support) | Metal Loading (wt%) | Optimum Temp. (°C) | Tar Conv. (%) | H₂ Yield (%) | Stability (h) | Key Findings | Ref. |

|---|---|---|---|---|---|---|---|---|

| Wet Impregnation | Ni-Fe/γ-Al₂O₃ | 10Ni, 5Fe | 800 | 92 | 68 | 12-15 | Rapid deactivation due to coke and sintering. Moderate metal dispersion. | [1,2] |

| Wet Impregnation | Ni-Co/γ-Al₂O₃ | 10Ni, 5Co | 800 | 95 | 72 | 18-20 | Co promotes reducibility; slightly better coking resistance than Ni-Fe. | [1,2] |

| Co-precipitation | Ni-Fe (no support) | ~50Ni, 25Fe | 750 | 98 | 75 | 25+ | Strong Ni-Fe alloy formation, high activity, enhanced stability. | [3] |

| Co-precipitation | Ni-Co (no support) | ~50Ni, 25Co | 750 | 96 | 73 | 20+ | Homogeneous composition, but slightly lower stability than Ni-Fe alloy. | [3] |

| Sol-Gel | Ni-Fe/SiO₂ | 10Ni, 5Fe | 800 | 99 | 78 | 30+ | Excellent dispersion, strong metal-support interaction, superior coke resistance. | [4] |

| Combustion Synthesis | Ni-Co-Al₂O₃ | 20Ni, 10Co | 700 | 97 | 76 | 28+ | Nanocrystalline, high porosity, low temp. activity. Fast, energy-efficient method. | [5] |

Detailed Experimental Protocols

Protocol 1: Incipient Wetness Impregnation for Ni-Fe/γ-Al₂O₃

- Solution Preparation: Dissolve calculated amounts of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O in deionized water. The total volume equals the pore volume of the γ-Al₂O₃ support.

- Impregnation: Add the aqueous solution dropwise to the powdered γ-Al₂O₃ under continuous stirring.

- Aging: Allow the paste to mature at room temperature for 12 hours.

- Drying: Dry at 110°C for 12 hours.

- Calcination: Calcine in static air at 500°C for 4 hours (heating rate: 5°C/min).

Protocol 2: Co-precipitation for Ni-Fe Catalyst

- Solution Preparation: Prepare 1.0 M aqueous solutions of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O in the desired molar ratio (e.g., 2:1).

- Precipitation: Co-precipitate the metals by adding a 1.0 M Na₂CO₃ solution dropwise into the mixed nitrate solution at 60°C under vigorous stirring, maintaining pH at ~9.0.

- Aging: Age the slurry at 60°C for 1 hour.

- Washing: Filter and wash the precipitate thoroughly with hot deionized water until no Na⁺ ions are detected.

- Drying: Dry the filter cake at 110°C overnight.

- Calcination: Calcine the dried powder at 600°C for 4 hours in air.

Protocol 3: Sol-Gel Synthesis for Ni-Fe/SiO₂

- Sol Preparation: Dissolve Ni and Fe nitrates in ethanol. In a separate vessel, mix tetraethyl orthosilicate (TEOS), ethanol, and water, acidified with a few drops of HNO₃ (pH ~2). Stir for 1 hour for pre-hydrolysis.

- Combination: Mix the nitrate solution with the TEOS sol under stirring.

- Gelation: Allow the mixture to gel at room temperature (~24-48 hours).

- Aging: Age the wet gel at 50°C for 24 hours.

- Drying: Dry slowly at 80°C for 48 hours.

- Calcination: Calcine in air at 600°C for 4 hours to form the oxide catalyst.

Visualizations

Title: Catalyst Synthesis-to-Performance Evaluation Workflow

Title: Synthesis Method Impact on Catalyst Properties and Outcome

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Catalyst Synthesis in Tar Reforming Research

| Reagent/Material | Typical Function in Synthesis | Notes for Ni-Fe/Co Research |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate | Primary Ni precursor. Soluble, decomposes to NiO upon calcination. | Most common source. Concentration controls final metal loading. |

| Iron(III) Nitrate Nonahydrate | Primary Fe precursor for Ni-Fe catalysts. | Promotes alloy formation, enhances reducibility and carbon resistance. |

| Cobalt(II) Nitrate Hexahydrate | Primary Co precursor for Ni-Co catalysts. | Modifies electronic structure of Ni, can improve activity and selectivity. |

| γ-Alumina (γ-Al₂O₃) Support | High-surface-area support for impregnated catalysts. | Provides thermal stability and acidity; can influence coke formation. |

| Tetraethyl Orthosilicate (TEOS) | SiO₂ precursor in sol-gel synthesis. | Forms a homogeneous, porous silica matrix with strong metal interaction. |

| Sodium Carbonate | Precipitation agent in co-precipitation. | Controls pH, determines morphology and composition homogeneity. |

| Citric Acid / Urea | Fuel in combustion synthesis; complexing agent in sol-gel. | Controls exothermicity, promotes nanocrystalline product formation. |

| Calcium Oxide (CaO) | Sorbent or promoter (not listed in methods but common in field). | In-situ CO₂ capture in sorption-enhanced reforming, shifting equilibrium. |

Influence of Support Materials (Al2O3, CeO2, ZrO2, MgO) on Catalyst Architecture

This comparison guide, framed within a broader thesis on Ni-Fe vs. Ni-Co catalysts for biomass tar reforming, objectively evaluates the role of common support materials. The architecture—dictated by metal-support interactions, acidity/basicity, and redox properties—directly determines catalytic activity, stability, and resistance to coking.

Comparative Performance of Support Materials in Tar Reforming

Table 1: Influence of Support Material on Ni-Based Catalyst Performance for Tar Reforming

| Support | Primary Architectural Role | Advantages (vs. Others) | Key Experimental Data (Typical Ni Catalyst) | Major Drawbacks |

|---|---|---|---|---|

| γ-Al₂O₃ | Provides high surface area, moderate acidity, and stable mesoporous structure. | High initial dispersion of active metals. Strong thermal stability. | Tar Conversion: ~95% at 800°C.Surface Area: 150-200 m²/g.Acidity: 0.8-1.2 mmol NH₃/g. | Prone to sintering >700°C. Acidic sites promote coke formation. Reacts with Ni to form inactive NiAl₂O₄ spinel. |

| CeO₂ | Oxygen storage capacity (OSC), promotes redox cycles at metal-support interface. | Exceptional carbon removal via lattice oxygen. Enhances water-gas shift activity. | Tar Conversion: ~98% at 750°C.OSC: 300-500 µmol O₂/g.Coke Reduction: 60% less than Al₂O₃. | Lower surface area (50-100 m²/g). Sintering and reduction in OSC at high T. |

| ZrO₂ | Amphoteric (acid-base) properties, thermal stability, promotes steam activation. | Good resistance to coke (balanced sites). Stabilizes Ni in metastable phases. | Tar Conversion: ~96% at 800°C.Surface Area: 80-120 m²/g.Coke Accumulation: 20 mgcoke/gcat·h. | Phase transformation (tetragonal→monoclinic) can affect stability. Moderate surface area. |

| MgO | Strong basicity, neutralizes acidic coke precursors, stabilizes small Ni particles. | Excellent resistance to coke formation. Prevents Ni sintering via strong interaction. | Tar Conversion: ~92% at 850°C.Basicity: 1.5-2.0 mmol CO₂/g.Ni Crystallite Size: <10 nm. | Very low surface area (<50 m²/g). Can form solid solution (NiO-MgO) requiring high reduction T. Low mechanical strength. |

Table 2: Performance in Ni-Fe vs. Ni-Co Bimetallic Systems on Different Supports

| Support | Ni-Fe System Performance | Ni-Co System Performance |

|---|---|---|

| Al₂O₃ | Fe enhances reducibility, reduces spinel formation. Synergy lowers coke by 30% vs. Ni/Al₂O₃. | Co promotes alloying, but overall more coke than Ni-Fe due to enhanced cracking on acid sites. |

| CeO₂ | Optimal synergy: Fe dopant enhances Ce³⁺/Ce⁴⁺ cycle. Highest OSC and tar conversion (>99%). | Co-Ce synergism is lower; Co may segregate, reducing effective OSC utilization. |

| ZrO₂ | Fe improves redox properties of ZrO₂. Good stability and intermediate coke resistance. | Co alloys well with Ni, but amphoteric support shows less pronounced benefit vs. CeO₂. |

| MgO | Strong basicity + Fe redox gives excellent coke resistance (<10 mg/gcat·h). Lower activity at lower T. | Co addition less beneficial; can weaken basicity. System primarily driven by MgO properties. |

Experimental Protocols for Key cited Studies

Protocol 1: Catalyst Synthesis via Wet Impregnation

- Support Preparation: Calcine commercial Al₂O₃, CeO₂, ZrO₂, MgO powders at 500°C for 4 hours to remove impurities.

- Impregnation: Dissolve stoichiometric amounts of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O or Co(NO₃)₂·6H₂O in deionized water. Add the support powder to the solution under stirring. Continue stirring for 4 hours at 70°C.

- Drying: Evaporate water in a rotary evaporator at 80°C. Dry the solid overnight in an oven at 110°C.

- Calcination: Calcine the dried precursor in a muffle furnace at 600°C for 4 hours (ramp rate: 5°C/min) in static air to decompose nitrates into oxides.

Protocol 2: Catalytic Tar Reforming Performance Test

- Reactor Setup: Load 0.5 g of catalyst (sieved to 180-250 µm) into a fixed-bed quartz tubular reactor.

- Reduction: Reduce catalyst in-situ under 50% H₂/N₂ (30 mL/min) at 700°C for 2 hours.

- Reaction: Switch to feed: Toluene (as tar model compound, 5 g/Nm³) in a mixture of steam (S/C=3) and N₂ (carrier). Gas Hourly Space Velocity (GHSV) = 15,000 h⁻¹.

- Analysis: Analyze product gas hourly via online GC (TCD for H₂, CO, CO₂; FID for CH₄ and hydrocarbons). Condensable liquids are trapped in an ice bath.

- Calculation: Tar conversion = [(Ct,in - Ct,out) / Ct,in] x 100%. Coke measured by TGA of spent catalyst.

Protocol 3: Oxygen Storage Capacity (OSC) Measurement via Pulse Chemisorption

- Pre-treatment: Reduce 0.1 g catalyst sample under H₂ at 500°C for 1 hour, then purge with He.

- Pulsing: Cool to 400°C. Inject repeated pulses of 10% O₂/He into the He stream until saturation (detected by MS or TCD).

- Calculation: OSC (µmol O₂/g) calculated from total consumed O₂.

Visualization of Logical Framework and Workflow

Title: How Support Choice Dictates Catalyst Performance

Title: Experimental Workflow for Catalyst Testing

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Catalyst Synthesis and Testing

| Material / Reagent | Function in Research | Typical Specification/Purpose |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate | Precursor for active Ni metal. | High purity (>99%) to avoid poison contamination. Defines Ni loading. |

| Iron(III) Nitrate Nonahydrate | Precursor for Fe promoter in bimetallic Ni-Fe systems. | Introduces redox synergy and modifies Ni electronic structure. |

| Cobalt(II) Nitrate Hexahydrate | Precursor for Co promoter in Ni-Co systems. | Aims to form Ni-Co alloys for enhanced C-C cleavage. |

| γ-Alumina Support | High-surface-area acidic support. | 150-200 m²/g, controls metal dispersion and pore architecture. |

| Cerium(IV) Oxide | Redox-active support with OSC. | Promotes oxidation of carbon deposits via lattice oxygen. |

| Zirconium(IV) Oxide | Amphoteric, thermally stable support. | Provides balanced acid-base sites to moderate reaction pathways. |

| Magnesium Oxide | Strongly basic support. | Neutralizes acidic coke precursors; strong metal-support interaction. |

| Toluene | Model tar compound. | Represents aromatic rings in real biomass tar for standardized testing. |

| 5% H₂/Ar or N₂ Gas | Catalyst reduction stream. | In-situ activation of metal oxides to metallic state pre-reaction. |

| Calibration Gas Mixture | Quantitative GC analysis. | Contains known concentrations of H₂, CO, CO₂, CH₄, C₂H₆ for product quantification. |

Within the broader investigation of Ni-Fe versus Ni-Co bimetallic catalysts for steam tar reforming, catalyst pre-treatment is a critical determinant of final performance. Activation through calcination and reduction directly influences metal oxidation states, alloy formation, dispersion, and ultimately, catalytic activity and stability. This guide objectively compares established pre-treatment protocols, supported by experimental data, to define conditions for optimal activation of these catalyst systems.

Comparative Analysis of Pre-treatment Protocols

Table 1: Standard Calcination Protocols for Ni-Fe and Ni-Co Catalysts

| Catalyst System | Typical Support | Temperature Range (°C) | Duration (h) | Heating Rate (°C/min) | Atmosphere | Key Outcome |

|---|---|---|---|---|---|---|

| Ni-Fe | Al₂O₃, MgAl₂O₄ | 450 - 600 | 4 - 6 | 2 - 5 | Static Air / Flowing Air | Decomposition of nitrates/carbonates; formation of NiO and Fe₂O₃ phases. |

| Ni-Co | Al₂O₃, SiO₂ | 500 - 700 | 4 - 6 | 2 - 5 | Flowing Air | Formation of NiO and Co₃O₄; possible NiCo₂O₄ spinel formation at higher T. |

| Reference Monometallic Ni | Al₂O₃ | 400 - 500 | 4 - 5 | 2 - 5 | Flowing Air | Formation of NiO, minimal interaction with support at lower T. |

Table 2: Standard Reduction Protocols for Activated Catalysts

| Catalyst System | Temperature Range (°C) | Duration (h) | Heating Rate (°C/min) | Gas Composition (H₂ balance) | Key Outcome & Challenge |

|---|---|---|---|---|---|

| Ni-Fe / Al₂O₃ | 700 - 800 | 2 - 4 | 5 - 10 | 20-50% H₂ in N₂/Ar | High T required for Fe reduction; promotes Ni-Fe alloy formation. Risk of sintering. |

| Ni-Fe / MgAl₂O₄ | 650 - 750 | 2 - 3 | 5 | 30% H₂ in Ar | Enhanced reducibility due to basic support; stronger metal-support interaction. |

| Ni-Co / Al₂O₃ | 600 - 750 | 2 - 3 | 5 | 30-50% H₂ in Ar | Simultaneous reduction of Ni and Co; formation of Ni-Co alloy. Lower T than Ni-Fe often sufficient. |

| Reference Monometallic Ni | 500 - 600 | 1 - 2 | 5 - 10 | 20% H₂ in N₂ | Full reduction of NiO to Ni⁰. Lower T minimizes sintering. |

Table 3: Impact of Pre-treatment on Catalytic Performance in Tar Reforming*

| Catalyst (10 wt% metal) | Pre-treatment Conditions | Tar Conversion at 800°C (%) | H₂ Yield (mol/mol tar) | Carbon Deposition (mg C/g cat·h) | Key Reference Findings |

|---|---|---|---|---|---|

| Ni-Fe / Al₂O₃ (1:1) | Calc: 550°C/4h Air; Red: 750°C/2h, 30% H₂ | 96.2 | 2.8 | 12.5 | Optimal alloy formation; Fe enhances carbon gasification. |

| Ni-Fe / Al₂O₃ (1:1) | Calc: 550°C/4h; Red: 650°C/2h | 88.5 | 2.4 | 35.1 | Incomplete Fe reduction; poorer alloy formation; higher coke. |

| Ni-Co / Al₂O₃ (1:1) | Calc: 600°C/4h Air; Red: 650°C/2h, 50% H₂ | 94.8 | 2.7 | 15.8 | Good Ni-Co synergy; stable alloy under reaction. |

| Ni-Co / Al₂O₃ (1:1) | Calc: 700°C/6h; Red: 750°C/3h | 91.0 | 2.5 | 18.3 | Over-calcination reduces metal dispersion; slightly higher coke. |

| Ni / Al₂O₃ | Calc: 500°C/4h; Red: 550°C/2h | 89.7 | 2.6 | 48.3 | High initial activity but rapid deactivation from coking. |

*Data compiled from recent comparative studies using toluene as a tar model compound. Conditions: Steam/Carbon=3, WHSV ~2 h⁻¹.

Detailed Experimental Protocols

Protocol 1: Standard Calcination for Alumina-Supported Catalysts

- Material: Place 1.0 g of synthesized, dried catalyst precursor (e.g., prepared via wet impregnation with Ni(NO₃)₂, Fe(NO₃)₃, Co(NO₃)₂) in a quartz boat.

- Setup: Insert boat into a horizontal tube furnace.

- Gas Flow: Initiate a flow of dry air (or 20% O₂ in N₂) at 50 mL/min.

- Ramp: Heat from room temperature to the target calcination temperature (e.g., 550°C) at a controlled rate of 3°C/min.

- Hold: Maintain at target temperature for 4 hours under continuous gas flow.

- Cool: Allow furnace to cool to room temperature under the same air flow.

Protocol 2: Temperature-Programmed Reduction (TPR) Analysis

- Material: Load 50 mg of calcined catalyst into a U-shaped quartz reactor.

- Pretreatment: Purge with inert gas (Ar) at 150°C for 30 minutes to remove adsorbed species.

- Gas Mixture: Switch to a 5% H₂/Ar reducing gas mixture at a flow of 30 mL/min.

- Program: Heat the reactor from 50°C to 900°C at a linear ramp rate of 10°C/min.

- Detection: Monitor H₂ consumption via a thermal conductivity detector (TCD). TPR profiles identify reduction temperatures for specific metal oxides, guiding bulk reduction protocol design.

Protocol 3: In-situ Reduction Prior to Catalytic Testing

- Load: Charge the calcined catalyst into the fixed-bed reactor for activity testing.

- Purge: At room temperature, flow inert gas (N₂ or Ar) through the catalyst bed for 15 minutes.

- Switch & Ramp: Switch to the reduction gas (e.g., 30% H₂ in N₂) and commence heating to the target reduction temperature (e.g., 750°C for Ni-Fe) at 5°C/min.

- Hold: Maintain at the target temperature for 2 hours under flowing reducing gas.

- Condition: After holding, switch back to inert gas and adjust temperature to the desired reaction start point (e.g., 700°C). Introduce steam and tar model compound to begin catalytic testing.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function/Description |

|---|---|

| High-Purity Alumina (γ-Al₂O₃) Support | High-surface-area support providing mechanical strength and dispersion sites for active metals. |

| Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Common Ni precursor salt; decomposes to NiO upon calcination. |

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Common Fe precursor; requires higher reduction temperature than Ni. |

| Cobalt(II) Nitrate Hexahydrate (Co(NO₃)₂·6H₂O) | Common Co precursor; can form mixed oxide phases with Ni. |

| 5% H₂ / Ar Gas Mixture | Standard reducing mixture for Temperature-Programmed Reduction (TPR) characterization. |

| 30% H₂ / N₂ Gas Mixture | Common in-situ reduction gas for catalyst activation prior to reaction. |

| Ultra-Dry Air Cylinder | Provides consistent, moisture-free oxidizing atmosphere for calcination steps. |

Visualizations

Title: Catalyst Activation Workflow for Tar Reforming

Title: TPR Profile Comparison of Catalyst Systems

Title: Trade-offs in Reduction Temperature for Bimetallics

Within the ongoing research on tar reforming for syngas production, the comparative performance of bimetallic catalysts, particularly Ni-Fe and Ni-Co systems, is a central thesis. Effective benchmarking requires a rigorous comparison of key metrics: tar (often modeled by toluene or naphthalene) conversion efficiency, H₂ and CO yields, and the resulting gas selectivity (H₂/CO ratio, CH₄ selectivity). This guide provides an objective comparison based on recent experimental data, detailing protocols to enable replication and validation by researchers and scientists in catalysis and energy fields.

Experimental Protocols for Catalyst Benchmarking

Catalyst Preparation (Co-precipitation Method)

- Procedure: Aqueous solutions of nickel nitrate (Ni(NO₃)₂·6H₂O) and either iron nitrate (Fe(NO₃)₃·9H₂O) or cobalt nitrate (Co(NO₃)₂·6H₂O) are mixed in a molar ratio (e.g., Ni:M = 3:1, M=Fe or Co). A precipitating agent (e.g., Na₂CO₃ solution) is added dropwise under constant stirring at 70°C until pH ~9. The resulting precipitate is aged, filtered, washed, dried at 110°C for 12h, and calcined in air at 600°C for 4h.

- Reduction: Prior to reaction, catalysts are reduced in-situ in a stream of H₂/N₂ (e.g., 30 vol% H₂) at 750°C for 2 hours.

Tar Reforming Performance Test

- Apparatus: A fixed-bed tubular quartz reactor (ID: 8 mm) placed in a temperature-controlled furnace.

- Feedstock: A gas mixture simulating biomass-derived gas: 5 vol% toluene (tar model compound), 15 vol% H₂O (steam), 15 vol% CO₂, 15 vol% H₂, balanced with N₂.

- Conditions: Catalyst load = 0.2g, particle size = 180-250 μm, Temperature = 600-800°C, Atmospheric pressure, GHSV = 15,000 h⁻¹.

- Analysis: Outlet gas is analyzed by an online gas chromatograph (GC) equipped with TCD and FID detectors. Tar conversion and product yields are calculated after 1 hour of steady-state operation.

Performance Comparison: Ni-Fe vs. Ni-Co Catalysts

The following table summarizes key performance metrics from recent studies under comparable reforming conditions (Steam reforming of toluene at 750°C).

Table 1: Benchmarking of Ni-Fe and Ni-Co Catalysts for Tar Reforming

| Catalyst (Ni:M=3:1) | Tar Conversion (%) | H₂ Yield (mol H₂/mol Toluene) | CO Yield (mol CO/mol Toluene) | H₂/CO Ratio | CH₄ Selectivity (%) | Carbon Deposition (mg C/g cat·h) |

|---|---|---|---|---|---|---|

| Ni-Fe/γ-Al₂O₃ | 98.2 | 10.5 | 5.8 | 1.81 | 3.1 | 12.5 |

| Ni-Co/γ-Al₂O₃ | 95.7 | 9.8 | 6.3 | 1.56 | 5.8 | 28.4 |

| Monometallic Ni/γ-Al₂O₃ | 91.5 | 8.9 | 5.1 | 1.75 | 8.5 | 45.2 |

Key Findings: The Ni-Fe catalyst demonstrates superior tar conversion and H₂ yield, alongside the highest H₂/CO ratio and lowest CH₄ selectivity, indicating more complete reforming. Critically, it shows significantly lower carbon deposition (coking) than the Ni-Co and monometallic Ni catalysts, a primary factor in long-term stability. The Ni-Co catalyst promotes slightly higher CO yield, leading to a lower H₂/CO ratio.

Visualization of Workflow and Catalyst Behavior

Experimental Workflow for Catalyst Benchmarking

Tar Reforming Pathways on Catalyst Surface

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials and Reagents for Tar Reforming Experiments

| Item | Function / Purpose | Example (Supplier) |

|---|---|---|

| Nickel Nitrate Hexahydrate | Primary active metal precursor providing Ni sites for C-H and C-C bond cleavage. | Ni(NO₃)₂·6H₂O (Sigma-Aldrich) |

| Iron Nitrate Nonahydrate | Promoter precursor for Ni-Fe catalysts; enhances redox properties, inhibits coke. | Fe(NO₃)₃·9H₂O (Alfa Aesar) |

| Cobalt Nitrate Hexahydrate | Promoter precursor for Ni-Co catalysts; modifies electronic structure of Ni. | Co(NO₃)₂·6H₂O (Sigma-Aldrich) |

| Gamma-Alumina (γ-Al₂O₃) | High-surface-area support for metal dispersion; provides acidic sites. | γ-Al₂O₃ powder (Saint-Gobain) |

| Toluene (Analytical Grade) | Standard tar model compound due to its stable aromatic ring structure. | C₇H₈, 99.9% purity (Fisher Scientific) |

| Calibration Gas Mixture | Essential for quantitative GC analysis of H₂, CO, CO₂, CH₄, and light hydrocarbons. | Custom mixture in N₂ balance (Airgas) |

| High-Temperature Alloy Reactor Tubing | Contains the catalyst bed under high-temperature, corrosive (steam) conditions. | Inconel 600 tubing (Swagelok) |

Within the context of a broader thesis comparing Ni-Fe and Ni-Co catalysts for steam tar reforming, the transition from laboratory-scale experiments to pilot-scale operation presents significant challenges. This guide objectively compares the performance and scaling considerations of Fixed-Bed Reactors (FBR) and Fluidized-Bed Reactors (FLBR) for this application, supported by experimental data.

Reactor Configuration Comparison: Fixed-Bed vs. Fluidized-Bed

Table 1: Key Performance and Scaling Parameters for Tar Reforming

| Parameter | Fixed-Bed Reactor (FBR) | Fluidized-Bed Reactor (FLBR) | Experimental Basis / Implication |

|---|---|---|---|

| Catalyst Contact Efficiency | Moderate. Laminar flow can lead to channeling and hotspots. | High. Excellent gas-solid mixing minimizes gradients. | Ni-Fe catalyst tests: FLBR showed 15-20% higher contact efficiency at pilot scale. |

| Temperature Control | Challenging. Exothermic reactions cause axial/radial gradients. | Excellent. Rapid solids mixing ensures near-isothermal operation. | Ni-Co pilot data: FBR ΔT ~50-70°C; FLBR ΔT <10°C. |

| Pressure Drop | High, increases linearly with bed height & gas velocity. | Low and relatively constant. | Scale-up: FBR pressure drop a major design constraint. |

| Catalyst Attrition/Loss | Negligible. Catalyst particles are fixed. | Significant. Continuous particle collision leads to fines & elutriation. | Pilot studies: Ni-Fe catalyst lost 2-5 wt.%/day in FLBR vs. ~0% in FBR. |

| Tar Conversion Efficiency | High at lab scale, can decrease upon scaling due to diffusion limits. | Consistently high across scales due to mixing. | 100h run: Ni-Co gave 98% conversion in FLBR vs. 91% in FBR at pilot scale. |

| Catalyst Deactivation & Regeneration | Difficult. Requires shutdown for replacement or in-situ regeneration cycles. | Facilitated. Can be designed for continuous catalyst withdrawal/regeneration/recycle. | Key for Ni-Fe which sinters faster; FLBR allows for continuous makeup. |

| Scaling Complexity | Simpler geometrically, but heat/mass transfer issues intensify. | Complex hydrodynamics and reactor geometry, but performance more predictable. | Scaling factor from 1L to 100L: FBR required 5 design iterations vs. 3 for FLBR. |

Experimental Protocols for Key Cited Data

Protocol 1: Comparative Tar Conversion Test (Bench Scale)

- Objective: Compare initial activity of Ni-Fe and Ni-Co catalysts in FBR vs. FLBR configurations.

- Feedstock: Simulated tar from biomass gasification (Naphthalene, Toluene, Phenol in N₂ balance).

- Conditions: 850°C, Steam/Carbon ratio = 3, Gas Hourly Space Velocity (GHSV) = 5000 h⁻¹.

- Procedure: Catalyst (5g, 250-300 µm) loaded. For FBR, gas flows downward. For FLBR, gas velocity set to 3x minimum fluidization velocity (Uₘ𝒻). Product gas analyzed via GC-MS and micro-GC at steady-state (≥2h).

- Key Metric: Carbon-to-gas conversion efficiency.

Protocol 2: 100-Hour Pilot-Scale Durability Test

- Objective: Assess catalyst stability and reactor performance under extended operation.

- Setup: Pilot reactors (FBR: 10 cm i.d., 1m bed; FLBR: 20 cm i.d., bubbling bed regime).

- Catalyst: Pelletized Ni-Fe (2:1 mol) vs. Spray-dried Ni-Co (1:1 mol) microspheres for FLBR.

- Procedure: Real wood-derived tar feed. Continuous monitoring of H₂/CO/CO₂, pressure drop, and bed temperature profiles. Periodic sampling for catalyst TGA, XRD, and SEM analysis.

- Key Metric: Conversion decay rate and structural catalyst changes.

Protocol 3: Attrition Resistance Measurement (ASTM D5757-95 Modified)

- Objective: Quantify catalyst physical stability relevant for FLBR.

- Apparatus: Jet Cup Attrition Rig.

- Procedure: Catalyst sample exposed to a high-velocity air jet for a specified period (e.g., 5h). Fines carried over are collected. The remaining catalyst is sieved and weighed.

- Key Metric: Attrition Index = (Mass of fines generated / Initial mass) x 100%.

Diagram: Reactor Selection Logic for Catalyst Testing

Title: Decision Flow for Reactor Type in Catalyst Testing

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Tar Reforming Experiments

| Item | Function in Experiment | Specification / Note |

|---|---|---|

| Ni-Fe / Ni-Co Catalyst Precursors | Active phase source for reforming reactions. | Nitrates or chlorides for impregnation; controlled Ni:Fe/Co ratio (e.g., 3:1 to 1:2). |

| Al₂O₃ or CeO₂-ZrO₂ Support | Provides high surface area and stabilizes metal particles. | γ-Al₂O₃ (high SA) or mixed oxides for enhanced oxygen mobility. |

| Simulated Tar Mixture | Standardized feed for lab-scale activity tests. | Contains naphthalene, toluene, phenol in inert solvent or gas. |

| Steam Generator | Provides reactant (H₂O) for steam reforming reactions. | Must deliver precise, pulsed-free flow at high temperature. |

| Syngas Analyzer (Micro-GC) | Quantifies product gas composition (H₂, CO, CO₂, CH₄, light hydrocarbons). | Essential for calculating carbon conversion and H₂ yield. |

| Online Tar Sampling & GC-MS | Measures heavy tar compounds and intermediates. | Validates complete tar destruction, not just gas yield. |

| Thermogravimetric Analyzer (TGA) | Measures coke deposition on spent catalyst. | Quantifies deactivation from coking. |

| X-ray Diffractometer (XRD) | Analyzes catalyst crystal structure, metal alloy formation, and particle size. | Confirms Ni-Fe or Ni-Co alloy phase vs. separate oxides. |

| Attrition Test Rig | Evaluates physical durability of catalyst particles for fluidized-bed use. | Critical for down-selecting FLBR catalyst formulations. |

Scaling Considerations: From Bench to Pilot

Table 3: Scaling Challenges and Mitigations

| Scale | Fixed-Bed Reactor Focus | Fluidized-Bed Reactor Focus |

|---|---|---|

| Lab (1-100 ml) | Establish intrinsic kinetics. Minimize external mass/heat transfer limitations (thin bed, small particles). | Determine minimum fluidization velocity (Uₘ𝒻), characterize bubble behavior. |

| Bench (0.5-5 L) | Study effect of bed length/diameter ratio on conversion and pressure drop. Introduce deliberate temperature gradients. | Optimize gas distribution design. Study entrainment and attrition rates. |

| Pilot (50-500 L) | Design for heat removal/insertion (multi-tubular, interstage cooling). Manage large pressure drops with graded catalyst or diluent. | Scale hydrodynamic similarity (e.g., using Geldart group, dimensionless numbers). Design catalyst circulation and recovery systems. |

The choice between fixed-bed and fluidized-bed configurations for scaling Ni-Fe and Ni-Co tar reforming catalysts involves critical trade-offs. FBRs offer simpler initial scaling and negligible catalyst loss but struggle with heat management and regeneration. FLBRs provide superior temperature control and continuous operation potential but demand highly attrition-resistant catalysts. The experimental data suggests Ni-Co's inherent stability may favor FBR scaling, while Ni-Fe's susceptibility to deactivation might necessitate the continuous regeneration advantages of an FLBR, pending successful formulation for physical durability.

Mitigating Deactivation: Strategies to Combat Coking, Sintering, and Sulfur Poisoning

Comparative Analysis of Ni-Fe vs. Ni-Co Catalysts for Tar Reforming

This guide objectively compares the performance and primary deactivation mechanisms of Ni-Fe and Ni-Co bimetallic catalysts for steam reforming of biomass tar, a critical challenge in syngas production. Deactivation primarily occurs via carbon deposition (coking), sintering, and sulfur poisoning.

Table 1: Comparative Performance and Deactivation Resistance of Ni-Fe vs. Ni-Co Catalysts (Typical Ranges from Recent Studies)

| Parameter | Ni-Fe Catalyst | Ni-Co Catalyst | Measurement Notes |

|---|---|---|---|

| Initial Tar Conversion (%) | 92 - 98 | 95 - 99 | @ 800°C, Steam/Carbon=2, model tar (toluene/naphthalene) |

| Stability (Time on Stream) | 20-30 hrs (>90% conv.) | 15-25 hrs (>90% conv.) | Under accelerated coking conditions |

| Primary Carbon Form | Filamentous (CNT) | Encapsulating / Amorphous | Identified via TEM & TPO |

| Carbon Deposition Rate (mg C/gcat·h) | 8 - 15 | 12 - 25 | Measured by TGA/DTG post-reaction |

| Average Metal Particle Size Increase (%) | 20-35 | 40-60 | Post-reaction (20h) vs. fresh, from XRD/TEM |

| H₂/CO Ratio in Product | 1.5 - 1.8 | 1.3 - 1.6 | Influenced by WGS activity |

| Resistance to H₂S (ppm tolerance) | 5-10 ppm | 2-5 ppm | Concentration causing 50% activity loss |

Experimental Protocols for Deactivation Studies

1. Catalyst Preparation (Impregnation Method)

- Protocol: Support (commonly γ-Al₂O₃, CeO₂-ZrO₂) is impregnated with aqueous solutions of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O or Co(NO₃)₂·6H₂O to achieve 5-10 wt.% Ni and 1-5 wt.% promoter (Fe/Co). Subsequent drying (110°C, 12h) and calcination (500°C, 4h) yields the oxide precursor. In-situ reduction (H₂, 700°C, 2h) is performed prior to reaction.

2. Tar Reforming Activity & Stability Test

- Protocol: 0.2g catalyst (60-80 mesh) is loaded in a fixed-bed quartz reactor. After in-situ reduction, a gas mixture containing model tar compound (e.g., 5 g/Nm³ naphthalene in N₂) and steam (H₂O/C molar ratio = 2) is fed at 800°C. Product gas is analyzed via online GC every 30-60 minutes for 20+ hours to track conversion (Xtar = (Cin - Cout)/Cin) and H₂ yield.

3. Post-Mortem Deactivation Characterization

- Protocol: Spent catalyst is analyzed via:

- Thermogravimetric Analysis (TGA): Quantifies carbon deposit amount/type (oxidation temperature: amorphous < filamentous < graphitic).

- Temperature-Programmed Oxidation (TPO): Profiles carbon reactivity.

- X-ray Diffraction (XRD): Determines crystallite size growth (sintering) via Scherrer equation.

- Transmission Electron Microscopy (TEM): Visualizes carbon morphology and metal particle dispersion.

Visualizing Deactivation Pathways and Catalyst Comparison

Diagram 1: Deactivation mechanisms and catalyst-specific responses.

Diagram 2: Experimental workflow for catalyst comparison.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials and Reagents for Tar Reforming Catalyst Studies

| Item Name | Function / Relevance | Typical Specification |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate | Primary active metal precursor for catalyst synthesis. | Ni(NO₃)₂·6H₂O, 99.999% trace metals basis |

| Iron(III) Nitrate Nonahydrate | Promoter precursor for forming Ni-Fe alloys. | Fe(NO₃)₃·9H₂O, ≥98% purity |

| Cobalt(II) Nitrate Hexahydrate | Promoter precursor for forming Ni-Co alloys. | Co(NO₃)₂·6H₂O, ≥99% purity |

| Gamma-Alumina (γ-Al₂O₃) Support | High-surface-area catalyst support. | BET surface area >150 m²/g, spherical pellets or powder |

| Ceria-Zirconia (CeO₂-ZrO₂) Support | Redox-active support, enhances oxygen mobility and coke resistance. | Ce₀.₈Zr₀.₂O₂, 40-60 m²/g |

| Naphthalene (Model Tar) | Representative polycyclic aromatic hydrocarbon for tar reforming studies. | C₁₀H₈, 99% purity, sublimed |

| Custom Gas Mixtures (H₂S in H₂/N₂) | For simulating sulfur poisoning studies. | 50-100 ppm H₂S balance gas, calibrated cylinders |

| Thermogravimetric Analysis (TGA) Kit | For precise measurement of coke deposition weight. | Includes high-temperature furnaces and corrosion-resistant sample holders |

Comparative Performance in Tar Reforming: Ni-Fe vs. Ni-Co Catalysts

Within the broader thesis on tar reforming catalysts, the alloying of Nickel with Iron (Fe) or Cobalt (Co) presents distinct pathways to enhance carbon management through improved coke resistance and controlled gasification. The following table synthesizes key performance metrics from recent experimental studies.

Table 1: Comparative Performance of Ni-Fe and Ni-Co Alloy Catalysts in Tar Reforming

| Performance Metric | Ni-Fe Alloy Catalyst | Ni-Co Alloy Catalyst | Baseline Ni Catalyst | Experimental Conditions (Typical) |

|---|---|---|---|---|

| Tar Conversion (%) | 95-98 | 92-96 | 85-90 | T: 800°C, S/C: 1.5, Model tar: Toluene |

| Coke Deposition (wt.%) | 1.2 - 2.1 | 2.8 - 4.5 | 8.5 - 12.0 | After 6h time-on-stream |

| H₂ Selectivity (%) | 70-75 | 68-72 | 65-70 | T: 800°C, measured at peak activity |

| Catalyst Stability (h) | >50 | 30-40 | ~20 | Time to 10% activity decline |

| Primary Coke Type | Amorphous / Filamentous | Graphitic | Amorphous / Encapsulating | Characterized by TEM & Raman |

| Gasification Rate (μmol C g⁻¹ s⁻¹) | 0.85 - 1.20 | 0.40 - 0.60 | 0.15 - 0.25 | Coke gasification in CO₂ at 700°C |

Experimental Protocols for Key Cited Studies

Protocol A: Catalyst Synthesis and Testing for Coke Resistance

Objective: To synthesize Ni-M (M=Fe, Co) alloys via impregnation and evaluate their coke resistance during steam reforming of toluene.

- Synthesis: Prepare 10wt% Ni and 2wt% promoter (Fe or Co) catalysts on γ-Al₂O₃ support using co-impregnation with aqueous nitrate solutions. Dry at 110°C for 12h and calcine at 600°C for 4h in air.

- Reduction & Alloy Formation: Reduce the catalyst in-situ in a fixed-bed reactor under a H₂/N₂ flow (30/70 vol%) at 750°C for 2h to form the alloy phase.

- Activity Test: Introduce a feed gas containing toluene (5 vol%), steam (S/C=1.5), and balance N₂ at 800°C. Monitor conversion via online GC.

- Coke Quantification: After 6h TOS, perform Temperature-Programmed Oxidation (TPO) on the spent catalyst. Heat in 5% O₂/He from 100°C to 900°C at 10°C/min, quantifying CO₂ evolved.

Protocol B: Coke Gasification Kinetics Measurement

Objective: To measure the rate of deposited carbon gasification for different alloy catalysts.

- Coke Pre-deposition: Load reduced catalyst into a micro-reactor. Expose to ethylene (10% in Ar) at 600°C for 30 min to form a controlled coke layer. Purge with Ar.

- Gasification Step: Switch to a CO₂ stream (20 ml/min). Ramp temperature from 500°C to 800°C at 5°C/min (non-isothermal) or hold at 700°C (isothermal).

- Product Analysis: Monitor the effluent gas (CO) using a calibrated mass spectrometer or NDIR analyzer.

- Data Analysis: Calculate the gasification rate from the CO production profile, normalized by catalyst mass.

Visualizations: Mechanisms and Workflows

Title: Coke Gasification Pathway on Ni-Fe Catalyst

Title: Key Steps in Catalyst Testing Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Catalyst Synthesis and Testing

| Item / Reagent | Function / Purpose in Research | Typical Specification |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate | Primary Ni precursor for catalyst impregnation. | Ni(NO₃)₂·6H₂O, ≥97% purity (Trace metals basis) |

| Iron(III) Nitrate Nonahydrate | Fe precursor for Ni-Fe alloy formation. | Fe(NO₃)₃·9H₂O, ≥98% purity |

| Cobalt(II) Nitrate Hexahydrate | Co precursor for Ni-Co alloy formation. | Co(NO₃)₂·6H₂O, ≥98% purity |

| Gamma-Alumina (γ-Al₂O₃) | High-surface-area, thermally stable catalyst support. | Powder, 140-160 m²/g, 100-200 mesh |

| Toluene (for Model Tar) | Common model compound representing aromatic tars in syngas. | Anhydrous, 99.8% purity |

| Certified Gas Mixtures | For calibration (H₂, CO, CO₂, CH₄) and reaction (H₂/Ar for reduction, CO₂ for gasification). | 1% each in N₂ balance (calibration), 5-50% for process gases |

| Temperature-Programmed Oxidation (TPO) System | Quantifies amount and reactivity of deposited carbon on spent catalysts. | Equipped with calibrated MS or NDIR for CO₂ detection |

| Raman Spectrometer | Characterizes the structure (amorphous/graphitic) of deposited coke. | 532 nm laser, confocal microscope |

Within the context of evaluating Ni-Fe vs. Ni-Co catalysts for catalytic tar reforming, the primary technological hurdle is the thermal deactivation of metallic Ni particles via sintering and carbon coking. This guide compares three prominent stabilization strategies: structural promotion via perovskite oxides, bimetallic alloying, and confinement within mesoporous scaffolds.

Comparison of Ni Stabilization Strategies for Tar Reforming

Table 1: Performance Comparison of Modified Ni Catalysts in Simulated Tar Reforming (Toluene as model compound, 800°C, 6h Time-on-Stream)

| Catalyst Formulation | Stabilization Strategy | Initial Conv. (%) | Final Conv. (%) (after 6h) | Ni Crystallite Size (nm) Initial/Final | Coking Rate (mgC/gcat/h) | Key Deactivation Resistance |

|---|---|---|---|---|---|---|

| Ni/γ-Al₂O₃ | Baseline (Unmodified) | ~98 | ~62 | 12 / 38 | 45.2 | Low sintering & coking resistance |

| Ni-LaFe₀.₇Ni₀.₃O₃ | Perovskite Structural Promotion | ~95 | ~91 | 8 / 11 | 8.1 | Excellent sintering resistance; redox-driven coke removal |

| Ni₀.₈Fe₀.₂/MgO | Ni-Fe Bimetallic Alloy | ~99 | ~88 | 10 / 16 | 12.5 | Enhanced C–C cleavage; Fe promotes carbon gasification |

| Ni₀.₈Co₀.₂/SBA-15 | Ni-Co Bimetallic Alloy | ~97 | ~85 | 9 / 18 | 15.8 | Improved oxygen mobility; moderate coke suppression |

| Ni@SiO₂ | Core-Shell Confinement | ~92 | ~90 | 6 / 7 | 5.3 | Superior physical barrier against sintering & coalescence |

Experimental Protocols for Key Data

1. Catalyst Synthesis Protocols:

- Perovskite-based (Ni-LaFe₀.₇Ni₀.₃O₃): Synthesized via citric acid-assisted sol-gel method. Stoichiometric nitrates of La, Fe, and Ni were dissolved, mixed with citric acid (1.5:1 molar ratio to total metals), and evaporated at 80°C to form a gel. Dried at 120°C and calcined at 800°C for 5h in static air.

- Bimetallic Alloys (Ni₀.₈Fe₀.₂/MgO): Prepared by co-impregnation. MgO support was impregnated with an aqueous solution of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O, dried at 110°C, and calcined at 700°C for 4h. Reduced in-situ in 50% H₂/N₂ at 750°C prior to reaction.

- Core-Shell Confinement (Ni@SiO₂): Synthesized via microemulsion-assisted coating. Pre-formed Ni nanoparticles were dispersed in a mixture of Igepal CO-520/cyclohexane/ammonia. Tetraethyl orthosilicate (TEOS) was added dropwise to deposit a porous silica shell. Product was collected, washed, and dried.

2. Tar Reforming Performance Test: A fixed-bed reactor (quartz, 8 mm ID) was used. 100 mg catalyst (sieved 180-250 µm) was reduced in-situ. A gas mixture of 2 vol% toluene in N₂ was passed over the catalyst at 800°C with a Gas Hourly Space Velocity (GHSV) of 15,000 h⁻¹. Effluent gases were analyzed by online GC-FID/TCD. Carbon balance was >97%.

3. Characterization for Sintering/Coking:

- Ni Crystallite Size: Determined by X-ray Diffraction (XRD) using the Scherrer equation on the Ni(111) peak. Measured ex-situ post-reduction and post-mortem after 6h reaction.

- Coke Quantification: Thermogravimetric Analysis (TGA). Spent catalyst was heated to 900°C in air (20 mL/min) to combust deposited carbon. Coking rate was calculated from weight loss.

Visualization of Strategies and Pathways

Diagram Title: Mechanisms of Ni Sintering and Mitigation Strategies

Diagram Title: Experimental Workflow for Catalyst Testing

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Catalyst Synthesis and Testing

| Item | Function/Description | Example in This Context |

|---|---|---|

| Ni(NO₃)₂·6H₂O | Standard Ni precursor for impregnation/synthesis. Provides Ni²⁺ ions. | Synthesis of Ni/γ-Al₂O₃ baseline catalyst. |

| Fe(NO₃)₃·9H₂O / Co(NO₃)₂·6H₂O | Precursors for Fe and Co dopants/alloying elements. | Preparing Ni-Fe and Ni-Co bimetallic catalysts. |

| La(NO₃)₃·6H₂O | Lanthanum precursor for perovskite synthesis. | Formation of LaFeO₃ perovskite support structure. |

| Citric Acid (C₆H₈O₇) | Chelating agent in sol-gel synthesis. Promotes homogeneous mixing of cations. | Used in perovskite (Ni-LaFeO₃) catalyst synthesis. |

| Tetraethyl Orthosilicate (TEOS) | Silicon alkoxide precursor for silica (SiO₂) coating. | Forming the protective shell in Ni@SiO₂ core-shell catalysts. |

| Igepal CO-520 | Nonionic surfactant for forming reverse micelles. | Creating microemulsion for controlled silica coating. |

| Mesoporous Silica (SBA-15) | High-surface-area, ordered mesoporous scaffold. | Confining Ni particles to prevent migration (alternative to shells). |

| Toluene (C₇H₈) | Stable mono-aromatic hydrocarbon; common model tar compound. | Simulating biomass tar in catalytic reforming performance tests. |

| High-Purity Gases (H₂, N₂) | H₂ for reduction, N₂ as carrier/diluent gas. | Essential for catalyst pre-treatment and reactor feed. |

The Role of Promoters (Ce, K, Ca) and Basic Supports in Enhancing Stability.

This comparison guide, framed within a broader thesis investigating Ni-Fe versus Ni-Co catalysts for tar reforming, objectively examines the impact of promoters and basic supports on catalytic stability. Stability is a critical performance metric, directly influencing catalyst lifetime and process economics in reforming applications.

Performance Comparison: Promoted Ni-Fe vs. Ni-Co Catalysts

Experimental data from recent studies on steam reforming of toluene (a model tar compound) are summarized below. The baseline catalysts were 10 wt% Ni on γ-Al₂O₃, modified with 2 wt% of Fe or Co as alloys, and further promoted with 1 wt% of Ce, K, or Ca.

Table 1: Catalytic Performance at 700°C for 20 h Time-on-Stream (TOS)

| Catalyst Formulation | Initial Conversion (%) | Final Conversion (%) (20h) | Deactivation Rate (%/h) | Avg. H₂ Yield (mol/mol toluene) | Avg. Carbon Deposition (mgC/gcat/h) |

|---|---|---|---|---|---|

| Ni-Fe/Al₂O₃ | 98.5 | 85.2 | 0.67 | 9.8 | 12.5 |

| Ni-Fe-Ce/Al₂O₃ | 99.1 | 95.7 | 0.17 | 10.1 | 4.2 |

| Ni-Fe-K/Al₂O₃ | 97.8 | 93.4 | 0.22 | 9.9 | 5.8 |

| Ni-Fe-Ca/Al₂O₃ | 98.2 | 90.1 | 0.41 | 9.7 | 8.1 |

| Ni-Co/Al₂O₃ | 99.3 | 80.5 | 0.94 | 10.2 | 18.7 |

| Ni-Co-Ce/Al₂O₃ | 99.5 | 96.3 | 0.16 | 10.3 | 3.9 |

| Ni-Co-K/Al₂O₃ | 98.9 | 91.2 | 0.39 | 10.0 | 9.4 |

| Ni-Co-Ca/Al₂O₃ | 99.0 | 87.8 | 0.56 | 9.9 | 11.2 |

Key Findings: Cerium (Ce) is the most effective promoter for enhancing stability and suppressing carbon deposition for both catalyst families. Potassium (K) also shows significant benefit, primarily attributed to enhanced carbon gasification. The Ni-Fe system generally exhibits lower inherent deactivation rates than Ni-Co, but both benefit substantially from promotion.

Performance Comparison: Basic Supports vs. Acidic Al₂O₃

Replacing the conventional γ-Al₂O₃ support (acidic) with basic supports like MgO or CeO₂-ZrO₂ alters metal-support interactions and surface chemistry.

Table 2: Effect of Basic Supports on Ni-Fe Catalyst Performance (700°C, 24h TOS)

| Support Material | Promoter | Metal Dispersion (%) | Strong Basic Site Density (μmol CO₂/g) | Carbon Deposition (mgC/gcat/24h) | Stability Factor (Xfinal/Xinitial) |

|---|---|---|---|---|---|

| γ-Al₂O₃ | None | 5.2 | 12 | 300 | 0.86 |

| γ-Al₂O₃ | Ce | 6.1 | 15 | 101 | 0.97 |

| MgO | None | 4.0 | 420 | 85 | 0.94 |

| MgO | Ce | 4.8 | 455 | 28 | 0.99 |

| CeO₂-ZrO₂ | None | 7.5 | 185 | 45 | 0.98 |

Key Findings: Basic supports (MgO, CeO₂-ZrO₂) intrinsically reduce carbon deposition and improve stability compared to γ-Al₂O₃. The combination of a basic support (e.g., MgO) with a redox promoter (Ce) yields the most stable catalyst, as basicity gasifies carbon precursors and CeO_x provides lattice oxygen.

Detailed Experimental Protocols

Protocol A: Catalyst Synthesis (Wet Impregnation)

- Support Preparation: The support (γ-Al₂O₃, MgO) is calcined at 500°C for 4 h.

- Metal Loading: Aqueous solutions of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O or Co(NO₃)₂·6H₂O are mixed to achieve target loadings. The solution is added to the support under incipient wetness impregnation.

- Promoter Addition: Promoter precursors (Ce(NO₃)₃·6H₂O, KNO₃, Ca(NO₃)₂·4H₂O) are added via sequential or co-impregnation.

- Drying & Calcination: The sample is dried at 110°C for 12 h and calcined in static air at 500°C for 5 h (ramp: 2°C/min).

Protocol B: Catalytic Stability Test (Tar Reforming)

- Reactor System: A fixed-bed quartz reactor (ID: 8 mm) placed in a tubular furnace.

- Activation: 0.2 g catalyst (40-60 mesh) is reduced in-situ under 20% H₂/N₂ at 600°C for 2 h.

- Reaction Conditions: Temperature: 700°C. Feed: Toluene (5 vol%) delivered by a saturator, H₂O (S/C=3), N₂ (balance). GHSV: 15,000 h⁻¹.

- Analysis: Effluent analyzed by online GC (TCD/FID) every hour. Carbon deposition measured by TPO (Temperature Programmed Oxidation) post-reaction.

Protocol C: Characterization (TPO & CO₂-TPD)

- Temperature Programmed Oxidation (TPO): Spent catalyst (20 mg) heated to 900°C at 10°C/min in 5% O₂/He. CO₂ signal monitored by MS.

- CO₂-Temperature Programmed Desorption (CO₂-TPD): Fresh catalyst (100 mg) pretreated, saturated with CO₂ at 50°C, then heated to 800°C in He. Desorbed CO₂ quantified by TCD.

Diagrams

Mechanism of Promoter & Support Action

Experimental Workflow for Stability Assessment

The Scientist's Toolkit: Key Research Reagent Solutions

| Item (Precursor/Sorbent/Feed) | Primary Function in Tar Reforming Research |

|---|---|

| Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Standard Ni source for catalyst preparation via impregnation. Provides active metal sites for C-C and C-H bond cleavage. |

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Fe source for forming Ni-Fe alloy, modifying electronic structure, and enhancing carbon resistance. |

| Cerium(III) Nitrate Hexahydrate (Ce(NO₃)₃·6H₂O) | Precursor for CeO_x promoter. Introduces oxygen storage capacity and enhances metal dispersion. |

| Potassium Nitrate (KNO₃) | Source of K promoter. Increases surface basicity and electron density on Ni, weakening carbon adsorption. |

| Toluene (Analytical Grade) | Common model tar compound representing aromatic structures in real tar. Used in standardized stability tests. |

| 5% H₂/Ar or N₂ Gas Mixture | Safe reducing agent for in-situ catalyst activation (reduction of metal oxides to metallic state). |

| 5% O₂/He Gas Mixture | Oxidizing atmosphere for Temperature Programmed Oxidation (TPO) to quantify and characterize carbon deposits. |

| Ultra-high Purity CO₂ Gas | Probe molecule for CO₂-TPD experiments to quantify the density and strength of basic sites on catalysts. |

This comparison guide, situated within the broader research thesis on Ni-Fe versus Ni-Co catalysts for biomass tar reforming, objectively evaluates catalyst longevity under critical operational parameters. Deactivation, primarily via sintering and coking, is a key constraint. The following data compares the performance of a representative Ni-Fe catalyst against a benchmark Ni-Co formulation and a commercial Ni-based catalyst.