Ni-Fe/Al2O3 Bimetallic Catalysts: Advanced Synthesis, Optimization, and Application in Tar Reforming for Clean Syngas Production

This article provides a comprehensive guide for researchers and scientists on the synthesis, application, and optimization of Ni-Fe/Al2O3 bimetallic catalysts for catalytic tar reforming.

Ni-Fe/Al2O3 Bimetallic Catalysts: Advanced Synthesis, Optimization, and Application in Tar Reforming for Clean Syngas Production

Abstract

This article provides a comprehensive guide for researchers and scientists on the synthesis, application, and optimization of Ni-Fe/Al2O3 bimetallic catalysts for catalytic tar reforming. It explores the foundational synergy between Ni and Fe for enhanced activity and coke resistance, details established and novel synthesis methodologies (e.g., impregnation, co-precipitation), and addresses critical troubleshooting aspects like deactivation and selectivity control. The content further validates performance through comparative analysis with monometallic and other bimetallic systems, evaluating metrics such as tar conversion efficiency, H2/CO ratio, and long-term stability. The conclusion synthesizes key findings and outlines future research directions toward scalable, economically viable catalysts for biomedical-grade syngas applications and integrated biorefinery processes.

Unlocking the Ni-Fe Synergy: Principles and Design Rationale for Superior Tar Reforming Catalysts

Tar formation remains the principal technical challenge in biomass gasification, directly compromising syngas purity and downstream catalytic processes, including synthesis for fuels and chemicals. Within the context of developing advanced Ni-Fe/Al₂O₃ bimetallic catalysts for catalytic tar reforming, this application note details the quantitative impact of tar, standard analytical protocols, and experimental methodologies for catalyst evaluation.

Quantitative Impact of Tar on Syngas Quality & Downstream Applications

Table 1: Typical Tar Composition in Raw Producer Gas from Fluidized Bed Gasifiers

| Tar Compound Class | Examples | Typical Concentration Range (g/Nm³) | Key Challenge for Downstream |

|---|---|---|---|

| Heterocyclic Compounds | Pyridine, Quinoline | 1.0 - 5.0 | Poisoning of acid sites on catalysts. |

| Light Aromatics (1-ring) | Toluene, Xylene | 5.0 - 20.0 | Condensation and soot formation. |

| Light Polycyclic Aromatic Hydrocarbons (PAHs) | Naphthalene, Biphenyl | 2.0 - 15.0 | Primary cause of coke deposition. |

| Heavy PAHs (>3 rings) | Anthracene, Pyrene | 0.5 - 5.0 | Condensation at high temps, fouling. |

Table 2: Impact of Tar on Downstream Synthesis Catalysts (e.g., Fischer-Tropsch)

| Contaminant | Threshold for Catalyst Deactivation | Primary Deactivation Mechanism |

|---|---|---|

| Total Tar (as Carbon) | > 10 mg/Nm³ | Coke deposition, pore blockage. |

| Sulfur (from tar) | < 0.1 ppm | Irreversible poisoning of active metal sites. |

| Alkali Metals (aerosols) | < 10 ppb | React with support (Al₂O₃), induce sintering. |

Experimental Protocols for Tar Analysis & Catalyst Testing

Protocol: Tar Sampling and Analysis (Solid Phase Adsorption Method)

Principle: Tars are collected from the hot gas stream on a solid adsorbent (e.g., amino-phase silica), followed by solvent extraction and GC-MS analysis. Procedure:

- Sampling Train Setup: Isokinetically extract gas via a heated probe (>300°C) and a particle filter. Pass gas through two serial adsorption tubes packed with 150 mg of amino-phase silica.

- Sampling: Maintain adsorber at 0°C (ice bath). Sample for 20-30 minutes at a controlled flow rate of 0.5 L/min.

- Extraction: Spiked internal standard (e.g., deuterated naphthalene). Elute tars from the adsorbent with 2.0 mL of dichloromethane (DCM) into a calibrated vial.

- Analysis: Analyze via GC-MS (e.g., DB-5 column, 30 m x 0.25 mm, 0.25 µm film). Use external calibration curves for quantification of 20+ key tar species.

- Calculation: Report tar concentrations as mass per normalized gas volume (mg/Nm³).

Protocol: Catalytic Tar Reforming Activity Test for Ni-Fe/Al₂O₃ Catalysts

Objective: Evaluate tar conversion efficiency and hydrogen selectivity under simulated producer gas. Materials: Fixed-bed quartz reactor (ID 10 mm), mass flow controllers, syringe pump for tar, online micro-GC for product gas analysis. Feedstock Simulant: Model tar compound: Naphthalene (5 g/Nm³ in N₂). Simulated gas mix: 25% H₂O, 15% CO, 10% CO₂, 5% CH₄, 45% N₂. Procedure:

- Catalyst Preparation: Sieve catalyst to 180-250 µm. Load 0.5 g diluted with 2.0 g inert quartz sand into the reactor isothermal zone.

- Pre-treatment: Reduce catalyst in situ at 800°C for 2 hours under 20% H₂/N₂ (50 mL/min).

- Activity Test: Set reactor to 750°C. Introduce the full simulated wet gas mixture with naphthalene at a Gas Hourly Space Velocity (GHSV) of 15,000 h⁻¹.

- Data Acquisition: After 30 min stabilization, analyze effluent gas hourly for 10 hours via micro-GC (H₂, CO, CO₂, CH₄, C₂). Monitor naphthalene conversion via a second adsorbent trap downstream.

- Calculations:

- Naphthalene Conversion (%) = (1 - [Cout]/[Cin]) * 100

- H₂ Selectivity (%) = (Moles of H₂ produced) / (Theoretical max H₂ from complete reforming) * 100

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Tar Reforming Catalyst Research

| Reagent/Material | Function/Explanation |

|---|---|

| Ni(NO₃)₂·6H₂O & Fe(NO₃)₃·9H₂O | Common precursor salts for incipient wetness impregnation of Al₂O₃ support. Provide well-dispersed Ni-Fe alloy upon reduction. |

| γ-Al₂O₃ Support (High Purity, 150 m²/g) | Provides high surface area, thermal stability, and acid-base properties crucial for initial tar adsorption/cracking. |

| Naphthalene (≥99%) | Robust model tar compound representing light PAHs, used for standardized catalyst activity screening. |

| Amino-Phase Silica Cartridges | For standardized tar sampling (SPA method); selectively adsorbs organic compounds from gas streams. |

| Deuterated Internal Standards (e.g., Naphthalene-d8) | Essential for accurate quantification in GC-MS, correcting for recovery inefficiencies during sampling/extraction. |

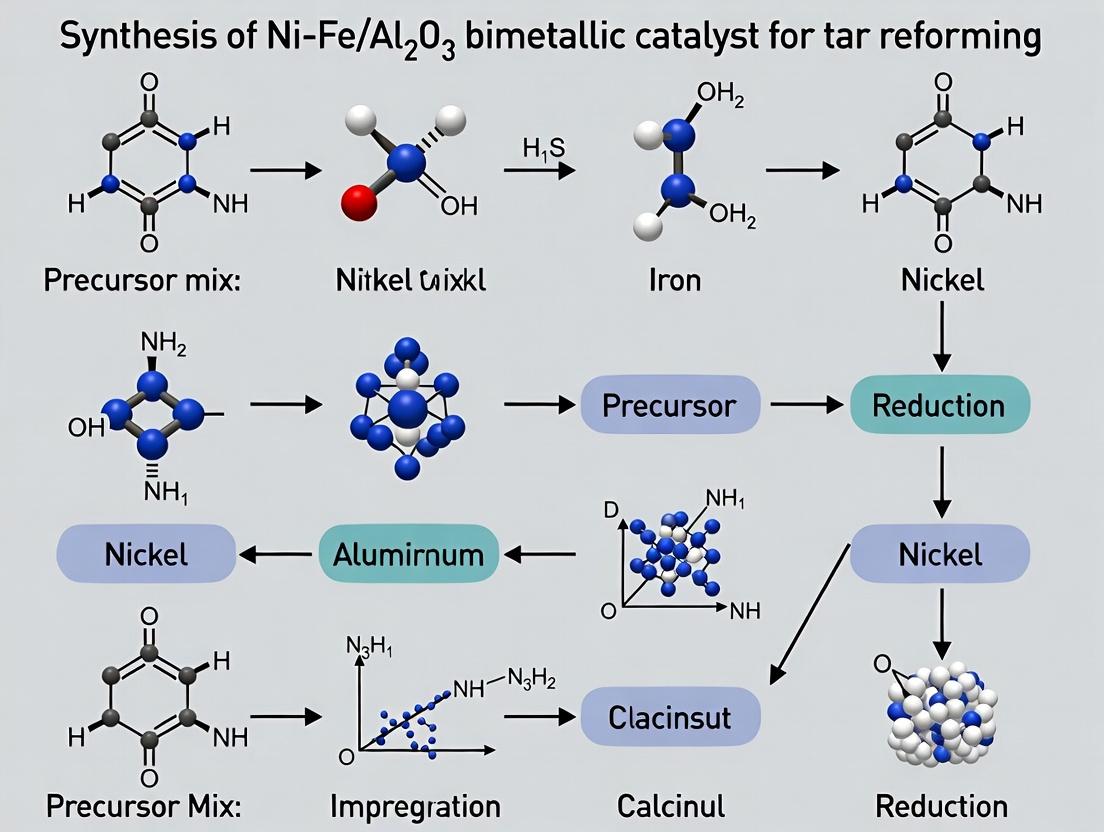

Diagrams

Diagram 1: Tar Reforming Catalyst R&D Workflow.

Diagram 2: Tar Reforming Reaction Pathway on Ni-Fe/Al₂O₃.

Why Bimetallic? The Fundamental Advantages of Ni-Fe Over Monometallic Systems.

Within the research on advanced Ni-Fe/Al₂O₃ bimetallic catalyst synthesis for tar reforming, a fundamental question persists: why pursue a bimetallic system? This application note delineates the core advantages of Ni-Fe bimetallic catalysts over their monometallic (Ni or Fe) counterparts, supported by recent data and detailed protocols. The synergistic interaction between Ni and Fe alters electronic, structural, and adsorptive properties, leading to superior activity, stability, and selectivity in the steam reforming of complex tar molecules.

Quantitative Advantages of Ni-Fe Bimetallic Systems

The table below summarizes key performance metrics comparing monometallic and bimetallic Ni-Fe catalysts in tar model compound (e.g., toluene, naphthalene) reforming.

Table 1: Performance Comparison of Monometallic vs. Ni-Fe Bimetallic Catalysts for Tar Reforming

| Catalyst | Tar Conversion (%) | H₂ Yield (%) | Carbon Deposition (mg C/g cat·h) | Stability (Time on Stream to 10% deactivation) | Activation Energy (kJ/mol) |

|---|---|---|---|---|---|

| Ni/Al₂O₃ | 85-92 | 65-75 | 12-18 | 15-25 h | 95-110 |

| Fe/Al₂O₃ | 40-60 | 30-50 | 5-8 (but high oxide formation) | >50 h (but low activity) | 120-140 |

| Ni-Fe/Al₂O₃ | 98-100 | 78-85 | 2-5 | >100 h | 75-85 |

Key Interpretation: The Ni-Fe bimetallic system exhibits a synergistic effect, combining the high intrinsic activity of Ni with the carbon-resistant and oxidation-stabilizing properties of Fe. This results in near-complete conversion, higher hydrogen yields, significantly reduced coking, and enhanced long-term stability.

Core Experimental Protocol: Synthesis & Testing of Ni-Fe/Al₂O₃ Catalysts

Protocol 2.1: Co-Impregnation Synthesis of Ni-Fe/Al₂O₃ Catalyst Objective: To prepare a 10wt% Ni - 5wt% Fe bimetallic catalyst on γ-Al₂O₃ support. Materials: See Scientist's Toolkit. Procedure:

- Support Pretreatment: Calcine γ-Al₂O₃ pellets (250-500 µm) at 500°C for 4 hours.

- Solution Preparation: Dissolve 2.48 g of Ni(NO₃)₂·6H₂O and 1.01 g of Fe(NO₃)₃·9H₂O in 20 mL of deionized water to achieve the target metal loading.

- Incipient Wetness Impregnation: Add the aqueous solution dropwise to 10 g of pretreated Al₂O₃ under constant stirring. Ensure the volume equals the total pore volume of the support.

- Aging: Allow the impregnated solid to rest at room temperature for 12 hours.

- Drying: Dry the sample in an oven at 110°C for 12 hours.

- Calcination: Calcine the dried precursor in a muffle furnace at 500°C for 4 hours under static air (ramp rate: 5°C/min).

- Reduction (Pre-reaction): Reduce the calcined catalyst in a quartz reactor under a 40% H₂/N₂ flow (50 mL/min) at 700°C for 2 hours prior to activity testing.

Protocol 2.2: Catalytic Activity & Stability Test for Tar Reforming Objective: To evaluate catalytic performance using toluene as a tar model compound. Setup: Fixed-bed quartz reactor (ID: 8 mm), connected to online GC (TCD/FID). Conditions:

- Temperature: 700°C

- Pressure: 1 atm

- Catalyst Mass: 0.5 g

- Feed: Steam/Toluene molar ratio = 2, carried in N₂ (total flow 100 mL/min).

- Procedure:*

- Load reduced catalyst into reactor bed.

- Establish feed flow under reaction conditions.

- Analyze effluent gas composition hourly by GC.

- Calculate conversion, H₂ yield, and carbon balance.

- Run continuous test for >24 hours to assess deactivation rate.

- Perform Temperature Programmed Oxidation (TPO) on spent catalyst to quantify carbon deposits.

Diagram Title: Ni-Fe Catalyst Testing & Synergy Analysis Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents for Ni-Fe/Al₂O₃ Catalyst Synthesis and Testing

| Reagent/Material | Specification/Function | Role in Research |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Precursor for active Ni phase. | Provides Ni²⁺ ions for dispersion on support; concentration determines final metal loading. |

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Precursor for Fe promoter. | Introduces Fe³⁺ to form bimetallic structures; modulates Ni electronic properties and inhibits sintering. |

| γ-Alumina (γ-Al₂O₃) | High-surface-area support (150-200 m²/g). | Provides a stable, porous structure for metal dispersion and facilitates reactant adsorption. |

| Ultra-High Purity Gases (H₂, N₂) | Carrier and reducing gases. | N₂ acts as inert carrier; H₂ is used for in-situ reduction of metal oxides to active metallic state. |

| Tar Model Compound (e.g., Toluene) | Analytical grade, >99.9% purity. | Serves as a well-defined proxy for aromatic tar molecules in catalytic activity tests. |

Mechanistic Insight: Synergistic Pathways

The superior performance originates from Ni-Fe synergy, illustrated below.

Diagram Title: Ni-Fe Synergy Mechanism in Tar Reforming

Context: This document details critical experimental protocols and characterization methods for investigating the Al2O3 support within a thesis focused on synthesizing and evaluating Ni-Fe/Al2O3 bimetallic catalysts for the steam reforming of biomass tar.

Table 1: Common Al2O3 Phases and Their Characteristics

| Al2O3 Phase | Typical Formation Temperature (°C) | Primary Acidic Site Type | Relative Surface Area (m²/g) | Stability in Steam |

|---|---|---|---|---|

| γ-Al2O3 | 400 - 750 | Lewis | High (150-300) | Moderate |

| δ-Al2O3 | 750 - 900 | Lewis | Medium (80-150) | Moderate to Low |

| θ-Al2O3 | 900 - 1000 | Lewis (weaker) | Low (50-100) | Low |

| α-Al2O3 | > 1000 | None (inert) | Very Low (< 15) | High (inert) |

Table 2: Typical Acidity Measurement Data for γ-Al2O3

| Characterization Technique | Probe Molecule | Measured Parameter | Typical Value for γ-Al2O3 | Information Obtained |

|---|---|---|---|---|

| NH3-TPD | Ammonia (NH3) | Total Acidity (μmol NH3/g) | 300 - 600 | Acid site density & strength distribution |

| Pyridine FTIR | Pyridine | Lewis Acid Site Concentration (μmol/g) | 200 - 400 | Specific identification of Lewis vs. Brønsted sites |

| IPA-TPD (Isopropanol) | Isopropanol | Dehydration Activity Peak Temp. (°C) | ~250 - 350 | Indicator of acid-catalyzed reaction strength |

Experimental Protocols

Protocol 2.1: Determination of Acidity via Ammonia Temperature-Programmed Desorption (NH3-TPD)

Objective: To quantify the total acid site density and strength distribution of the Al2O3 support and final catalyst. Materials: See "The Scientist's Toolkit" (Section 4). Procedure:

- Pretreatment: Load 100 mg of sample (pure Al2O3 or catalyst) into a quartz U-tube reactor. Heat to 500°C (10°C/min) under a 30 mL/min He flow for 1 hour to clean the surface.

- Ammonia Adsorption: Cool to 100°C. Switch to a 5% NH3/He gas mixture (30 mL/min) for 60 minutes to saturate acid sites.

- Physisorbed NH3 Removal: Flush with pure He at 100°C for 90 minutes to remove weakly bound NH3.

- Desorption: Heat the sample to 700°C at a ramp rate of 10°C/min under He flow (30 mL/min). Monitor desorbed NH3 using a downstream TCD detector.

- Data Analysis: Integrate the TPD signal. Calibrate the TCD peak area using known pulses of NH3. Report total acidity in μmol NH3 per gram of sample. Deconvolute peaks to identify weak (<250°C), medium (250-400°C), and strong (>400°C) acid sites.

Protocol 2.2: Assessment of Thermal Stability via In Situ XRD

Objective: To monitor phase transformations of the Al2O3 support under simulated reaction conditions. Materials: High-temperature XRD stage, Al2O3 sample. Procedure:

- Initial Scan: Place the γ-Al2O3 powder in the holder. Perform an XRD scan from 10° to 80° 2θ at room temperature.

- In Situ Heating: Mount the sample in the high-temperature stage. Under a flow of air or inert gas (20 mL/min), heat to a target temperature (e.g., 500°C, 700°C, 900°C). Hold for 30 minutes at each step.

- Data Collection: Perform an XRD scan at each isothermal hold.

- Post-Test Scan: Cool the sample to room temperature under flow and perform a final XRD scan.

- Analysis: Identify the crystalline phases present at each temperature (γ, δ, θ, α-Al2O3) using ICDD PDF databases. Report the onset temperature for phase transformation.

Protocol 2.3: Probing Metal-Support Interaction (MSI) via H2 Temperature-Programmed Reduction (H2-TPR)

Objective: To evaluate the reducibility and strength of interaction between Ni-Fe species and the Al2O3 support. Materials: 50 mg of calcined Ni-Fe/Al2O3 catalyst, 5% H2/Ar gas. Procedure:

- Pretreatment: Load catalyst into the quartz reactor. Heat to 300°C under Ar flow (30 mL/min) for 30 min to remove adsorbates.

- Cooling: Cool to 50°C under Ar.

- Reduction: Switch gas to 5% H2/Ar (30 mL/min). Stabilize the baseline.

- Temperature Ramp: Heat from 50°C to 900°C at a ramp rate of 10°C/min while monitoring H2 consumption with a TCD.

- Analysis: Identify reduction peaks. Low-temperature peaks (<500°C) indicate weakly interacting or free metal oxides. High-temperature peaks (>600-700°C) suggest strongly interacting species (e.g., formation of nickel aluminate, Fe3+ → Fe2+ in alumina matrix). Quantify H2 consumption to estimate reduction degree.

Visualizations

Diagram 1: Catalyst Development & Characterization Workflow (99 chars)

Diagram 2: Metal-Support Interaction (MSI) Effects on Catalyst (94 chars)

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Al2O3 and Catalyst Characterization

| Item | Function/Explanation |

|---|---|

| High-Purity γ-Al2O3 Powder (e.g., Sasol Puralox, Alfa Aesar) | Standardized support material with known baseline properties (surface area, porosity) for reproducible synthesis. |

| Ammonia Gas Mixture (5% NH3 in He, certified standard) | Probe molecule for quantifying total acidity via Temperature-Programmed Desorption (TPD). |

| Pyridine (anhydrous, 99.8%) | Infrared-active probe molecule for distinguishing Lewis and Brønsted acid sites via FTIR spectroscopy. |

| Hydrogen Gas Mixture (5% H2 in Ar, certified standard) | Reducing agent for H2-TPR experiments to study reducibility and metal-support interactions. |

| Nickel(II) Nitrate Hexahydrate (Ni(NO3)2·6H2O, >98.5%) | Common Ni precursor for wet impregnation. Decomposes to NiO upon calcination. |

| Iron(III) Nitrate Nonahydrate (Fe(NO3)3·9H2O, >98%) | Common Fe precursor. Used with Ni for bimetallic formulation. |

| Quartz Wool & U-Tube Reactors | Inert, high-temperature materials for packing samples in TPD/TPR/TPO setups. |

| High-Temperature XRD Coupons/Stages | Allow in situ phase analysis of supports and catalysts under controlled atmospheres and temperatures. |

Within the broader thesis on the development of efficient Ni-Fe/Al₂O₃ bimetallic catalysts for steam tar reforming, a central challenge is achieving high activity for cleaving resilient C-C bonds in aromatic tars while simultaneously preventing catalyst deactivation via carbon deposition (coking). This document provides detailed protocols and mechanistic insights into how the formation of a Ni-Fe alloy phase addresses this dual requirement. The synergy in bimetallic systems alters electronic and geometric properties, leading to enhanced C-O bond formation and weakened C-C bond adsorption, shifting the reaction pathway away from polymerization and toward gasification.

Table 1: Comparative Performance of Monometallic vs. Bimetallic Ni-Fe Catalysts in Toluene Steam Reforming (Model Tar Compound)

| Catalyst Formulation (5 wt% Total Metal) | Ni:Fe Ratio | Toluene Conversion (%) at 700°C | H₂ Yield (%) | Carbon Deposition (mg C/g cat·h) | Ni-Fe Alloy Crystallite Size (nm, from XRD) |

|---|---|---|---|---|---|

| Ni/Al₂O₃ | 100:0 | 82 | 68 | 152 | N/A |

| Fe/Al₂O₃ | 0:100 | 28 | 15 | 45 | N/A |

| Ni-Fe/Al₂O₃ | 90:10 | 94 | 78 | 98 | 12.4 |

| Ni-Fe/Al₂O₃ | 70:30 | 99 | 85 | 22 | 9.8 |

| Ni-Fe/Al₂O₃ | 50:50 | 95 | 80 | 18 | 8.1 |

Table 2: XPS Analysis of Surface Electronic States Pre- and Post-Reaction

| Catalyst (Ni₇₀Fe₃₀/Al₂O₃) | Condition | Ni 2p₃/₂ BE (eV) | Fe 2p₃/₂ BE (eV) | Surface O/(Ni+Fe) Atomic Ratio |

|---|---|---|---|---|

| Fresh, Reduced | H₂, 750°C, 2h | 852.1 (Ni⁰) | 706.8 (Fe⁰) | 1.8 |

| Spent (after 24h run) | No regeneration | 852.3 (Ni⁰) | 707.2 (Fe⁰) | 2.5 |

| Spent (Ni/Al₂O₃ reference) | No regeneration | 852.6 (Ni⁰) | N/A | 3.8 (High O from oxide passivation) |

Experimental Protocols

Protocol 3.1: Synthesis of Ni-Fe/Al₂O₃ Catalysts via Co-Impregnation Objective: To prepare a series of bimetallic catalysts with controlled Ni:Fe ratios.

- Support Preparation: Weigh 10.0 g of γ-Al₂O₃ support (calcined at 550°C for 4h). Load into a 250 mL round-bottom flask.

- Precursor Solution: Dissolve stoichiometric amounts of nickel nitrate hexahydrate (Ni(NO₃)₂·6H₂O) and iron nitrate nonahydrate (Fe(NO₃)₃·9H₂O) in 20 mL deionized water to achieve 5 wt% total metal loading and the desired atomic ratio (e.g., 70:30 Ni:Fe). Stir for 30 min.

- Impregnation: Add the solution dropwise to the Al₂O₃ under constant manual swirling. Continue for 1h.

- Drying: Place the slurry in a rotary evaporator at 60°C under reduced pressure until a damp solid forms. Transfer to an oven at 110°C for 12h.

- Calcination: Calcine the dried powder in a muffle furnace under static air. Heat from RT to 500°C at 5°C/min, hold for 4h, then cool naturally.

Protocol 3.2: In Situ Catalyst Reduction and Activity Testing for Tar Reforming Objective: To evaluate catalytic performance and stability for C-C cleavage in a model tar compound.

- Reactor Setup: Load 200 mg of calcined catalyst (sieve fraction 180-250 µm) into a fixed-bed quartz microreactor (ID 6 mm). Place thermocouple in direct contact with the catalyst bed.

- In Situ Reduction: Under a 50 mL/min flow of 20% H₂/Ar, heat the reactor from RT to 750°C at 10°C/min and hold for 2h.

- Activity Test: Cool the reactor to the target reaction temperature (e.g., 700°C). Switch feeds to the reactant mixture: Toluene (model tar) fed via a saturator at 20°C (partial pressure ~2.9 kPa) and H₂O fed via a syringe pump (H₂O/C molar ratio = 3), balanced with Ar for a total GHSV of 15,000 h⁻¹.

- Product Analysis: Analyze effluent gases online using a gas chromatograph (GC) equipped with a TCD (for H₂, CO, CO₂) and an FID (for hydrocarbons). Toluene conversion and product yields are calculated using an internal standard (N₂) method.

- Stability Test: Maintain reaction conditions for a minimum of 24h, monitoring conversion and yield at regular intervals.

Protocol 3.3: Post-Reaction Thermogravimetric Analysis (TGA) for Carbon Quantification Objective: To quantify the amount and type of carbon deposited on spent catalysts.

- Sample Collection: After activity testing (Protocol 3.2), cool the reactor to room temperature under Ar flow. Retrieve the spent catalyst.

- TGA Setup: Load 10-15 mg of spent catalyst into an alumina crucible of a TGA instrument.

- Analysis Program: (i) Purge with N₂ at 50 mL/min, hold at 100°C for 10 min to remove moisture. (ii) Heat to 900°C at 10°C/min under N₂ to track weight loss from unstable carbon/polymers. (iii) Switch gas to air or 20% O₂/N₂, hold isothermal at 900°C for 30 min. The weight loss in this oxidative step corresponds to the combustion of graphitic/encapsulating carbon.

- Calculation: The total weight loss during the oxidative step is used to calculate the carbon deposition rate (mg C/g cat·h).

Visualization Diagrams

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Ni-Fe/Al₂O₃ Catalyst Synthesis and Testing

| Item Name & Typical Specification | Function in Research |

|---|---|

| γ-Alumina (Al₂O₃) SupportHigh purity, BET SA >150 m²/g, pore size ~10 nm | Provides a high-surface-area, thermally stable, and inert platform for dispersing active metal phases. Influences metal-support interaction. |

| Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O)ACS reagent grade, ≥98.5% | The primary Ni precursor. Its decomposition during calcination forms NiO nanoparticles on the support. |

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O)ACS reagent grade, ≥98% | The primary Fe precursor. Co-impregnation with Ni enables intimate mixing for Ni-Fe alloy formation upon reduction. |

| High-Purity Gases: H₂ (5.0), Ar (5.0), 20% H₂/Ar Mixture99.999% purity, with in-line moisture/oxygen traps | H₂/Ar: For in situ catalyst reduction and activation. Ar: As inert carrier and purge gas. Essential for maintaining controlled atmospheres. |

| Toluene (C₇H₈), Anhydrous≥99.8%, inhibitor-free | A robust model compound for aromatic tars (e.g., from biomass gasification). Its stability makes it a stringent test for C-C cleavage activity. |

| Deionized (DI) Water, 18.2 MΩ·cm | Solvent for impregnation. Also used as the steam source (reactant) during reforming tests (H₂O/C). |

1. Introduction Within the broader thesis on the development of Ni-Fe/Al2O3 bimetallic catalysts for biomass tar reforming, rigorous quantification of performance is paramount. This document provides detailed application notes and protocols for the three principal KPIs: Tar Conversion, Product Selectivity, and Catalyst Lifespan. These KPIs are critical for evaluating catalyst activity, efficiency, and stability under industrially relevant conditions.

2. Defined KPIs and Quantitative Benchmarks

- Tar Conversion (Xtar): Measures the extent of tar destruction.

- Formula: Xtar (%) = [(Ctar,in - Ctar,out) / Ctar,in] × 100

- Where Ctar is the total concentration of tar (typically measured as gravimetric tar or by GC-MS).

- Selectivity (S_i): Measures the catalyst's ability to direct reactants toward a desired product (e.g., H2, CO) versus unwanted byproducts (e.g., coke, CH4).

- Formula: Si (%) = [ni, produced / (Σ nj, produced)] × 100 (for carbon-containing products) OR SH2 (%) = [nH2, produced / (nH2, theoretical for complete steam reforming)] × 100.

- Key Selectivity Metrics: H2/CO ratio in syngas, Carbon selectivity to CO2 vs. CO, Coke yield.

- Catalyst Lifespan (Stability): Evaluates the rate of deactivation over time under operating conditions.

- Primary Metric: Time-on-stream (TOS) until tar conversion drops below a defined threshold (e.g., 90% of initial conversion).

- Supporting Metrics: Decay rate constant (kd), total carbon deposited (mg coke / gcat), change in BET surface area post-reaction.

3. Standardized Experimental Protocol for KPI Evaluation

- Apparatus: Fixed-bed quartz reactor (ID: 10 mm), placed in a tubular furnace. Upstream vaporizer for tar/water feed. Downstream condensation train (ice/acetone) for liquid collection, with gas flow to online GC.

- Catalyst: Ni-Fe/Al2O3 (typical loadings: 5-15 wt% Ni, Fe/Ni atomic ratio 0.1-0.5), sieved to 250-355 μm. Weight: 0.2-0.5 g diluted with inert quartz sand.

- Feedstock: Model tar compound (e.g., 5-15 g/Nm³ toluene or naphthalene in N2 carrier) mixed with steam (S/C molar ratio 1-4).

- Procedure:

- In-situ Reduction: Heat catalyst to 700-800°C (10°C/min) under 20% H2/N2 flow (50 mL/min) for 2 hours.

- Reaction: Switch to reaction feed at target temperature (600-800°C). Gas Hourly Space Velocity (GHSV): 5,000 - 15,000 h⁻¹.

- Analysis:

- Gas: Online GC with TCD (for H2, CO, CO2, CH4) at 30-minute intervals.

- Tar: Capture condensate in dichloromethane; quantify gravimetrically or via GC-MS analysis.

- Coke: Post-run, temperature-programmed oxidation (TPO) to quantify deposited carbon via CO2 evolution.

- Stability Test: Maintain continuous operation for >20 hours, monitoring conversion and selectivity at regular intervals.

4. Data Presentation: Comparative Performance Table

Table 1: Benchmark KPI Data for Ni-Based Catalysts in Steam Reforming of Toluene (Model Tar).

| Catalyst Formulation | Temp. (°C) | X_tar (%) | S_H2 (%) | H2/CO Ratio | Coke Yield (mg/g_cat·h) | Stable TOS (h) @ X_tar >90% | Reference Context |

|---|---|---|---|---|---|---|---|

| 10% Ni/Al2O3 | 750 | 98.2 | 78.5 | 4.2 | 12.3 | ~12 | Baseline Monometallic |

| 10% Ni-2% Fe/Al2O3 | 750 | 99.5 | 85.1 | 4.8 | 5.8 | >24 | Thesis Bimetallic Target |

| 10% Ni-5% Fe/Al2O3 | 750 | 97.8 | 82.3 | 4.5 | 4.1 | >30 | High Fe Loading |

| Commercial Catalyst A | 750 | 95.5 | 75.0 | 3.8 | 15.0 | ~10 | Industrial Benchmark |

5. The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for Catalyst Testing.

| Item | Function/Explanation |

|---|---|

| Nickel Nitrate Hexahydrate (Ni(NO3)2·6H2O) | Precursor for active Ni metal phase via impregnation and calcination. |

| Iron Nitrate Nonahydrate (Fe(NO3)3·9H2O) | Precursor for Fe promoter, enabling formation of Ni-Fe alloy. |

| γ-Alumina Support (Al2O3) | High-surface-area support providing mechanical strength and dispersion. |

| Model Tar Compound (Toluene, Naphthalene) | Representative, reproducible proxy for complex biomass tars. |

| Dichloromethane (DCM) | Solvent for dissolving and quantifying condensable tars post-reaction. |

| Calibration Gas Mixture (H2, CO, CO2, CH4 in N2) | Essential for quantitative calibration of online GC-TCD/FID. |

6. Visualization of Workflow and Relationships

Diagram Title: KPI Evaluation Workflow for Tar Reforming Catalyst

Diagram Title: Key Parameters Impact on Tar Reforming KPIs

Step-by-Step Synthesis: Proven Methods for Preparing High-Performance Ni-Fe/Al2O3 Catalysts

This document provides a standardized protocol for the wet impregnation synthesis of supported bimetallic catalysts, specifically framed within a doctoral research thesis investigating Ni-Fe/Al₂O₃ catalysts for the steam reforming of tar derived from biomass gasification. The optimization of precursor selection, impregnation conditions, and thermal treatment is critical for achieving high metal dispersion, strong metal-support interaction, and synergistic Ni-Fe alloy formation, which directly influences catalytic activity and stability in tar destruction.

Research Reagent Solutions Toolkit

The following table details the essential materials and their functions for the synthesis of Ni-Fe/Al₂O₃ catalysts via wet impregnation.

Table 1: Essential Research Reagents and Materials for Ni-Fe/Al₂O₃ Synthesis

| Reagent/Material | Specification (Example) | Primary Function in Synthesis |

|---|---|---|

| γ-Alumina Support | High-purity, BET SA ~150-200 m²/g, particle size 150-250 μm | Provides high-surface-area matrix for active metal dispersion and influences metal-support interaction. |

| Nickel(II) Nitrate Hexahydrate | Ni(NO₃)₂·6H₂O, ≥98.5% metal basis | Precursor for active Ni⁰ sites. Nitrate decomposes cleanly during calcination. |

| Iron(III) Nitrate Nonahydrate | Fe(NO₃)₃·9H₂O, ≥98% metal basis | Precursor for Fe promoter. Facilitates formation of Ni-Fe alloy under reduction. |

| Deionized Water | Resistivity >18 MΩ·cm | Solvent for creating precursor impregnation solution. |

| Ethanol (Absolute) | ≥99.8% | Co-solvent sometimes used to improve pore wettability and precursor distribution. |

| Calcination Furnace | Programmable, max temp. ≥800°C, with air flow | For thermal decomposition of precursors to metal oxides and stabilization of catalyst structure. |

| Tube Furnace with Gas Flow System | Programmable, with H₂/Ar gas blending and safety features | For controlled reduction of metal oxides to active metallic (Ni-Fe) phase. |

Detailed Synthesis Protocol

Precursor Solution Preparation

Objective: To prepare a homogeneous aqueous solution containing the desired molar ratio of Ni and Fe.

- Calculate the required masses of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O to achieve a target total metal loading of 10-15 wt.% on Al₂O₃, with a Ni:Fe atomic ratio of 3:1.

- Dissolve the calculated mass of iron nitrate in approximately 80% of the required deionized water (using a volume equal to 1.5 times the pore volume of the support) under mild magnetic stirring (300 rpm) at room temperature.

- Add the calculated mass of nickel nitrate to the same solution. Stir for 30 minutes until a clear, homogeneous solution is obtained.

- Adjust the final volume with deionized water to exactly match 1.5 times the total pore volume of the alumina support to be impregnated.

Table 2: Example Precursor Calculation for 10g of γ-Al₂O₃

| Parameter | Value | Notes |

|---|---|---|

| Target Total Loading | 12 wt.% | Balance between activity (dispersion) and metal content. |

| Ni:Fe Atomic Ratio | 3:1 | Optimal for Ni-Fe alloy formation in cited thesis work. |

| Support Pore Volume | 0.8 mL/g | Measured via water absorption. |

| Solution Volume Needed | 12 mL | (1.5 x 0.8 mL/g x 10g). |

| Mass Ni(NO₃)₂·6H₂O | 2.47 g | Provides 9 wt.% Ni. |

| Mass Fe(NO₃)₃·9H₂O | 1.52 g | Provides 3 wt.% Fe. |

Incipient Wetness Impregnation

Objective: To uniformly load the precursor solution onto the porous alumina support.

- Weigh 10.00 g of γ-Al₂O₃ support in a glass beaker.

- Using a burette or micropipette, add the precursor solution dropwise to the support while continuously and gently hand-mixing with a glass rod to ensure even distribution.

- After all solution is added, continue mixing for 5 minutes. Seal the beaker with Parafilm and let it age at room temperature for 2 hours.

- Transfer the impregnated paste to a drying oven.

Drying and Calcination

Objective: To remove solvent and decompose metal nitrates to their corresponding oxides.

- Drying: Place the sample in an oven at 110°C for 12 hours (overnight).

- Calcination: Transfer the dried material to a quartz boat and load it into a preheated muffle furnace.

- Ramp Rate: 5°C/min.

- Target Temperature: 500°C.

- Hold Time: 4 hours.

- Atmosphere: Static air.

- Allow the furnace to cool naturally to <100°C before removing the calcined catalyst (now NiO-Fe₂O₃/Al₂O₃).

Table 3: Calcination Protocol Summary

| Step | Temperature | Rate/Time | Atmosphere | Purpose |

|---|---|---|---|---|

| Drying | 110°C | 12 hr (hold) | Air | Remove physisorbed water. |

| Ramp 1 | 110°C to 300°C | 5°C/min | Air | Gradual removal of water of crystallization. |

| Ramp 2 | 300°C to 500°C | 5°C/min | Air | Decomposition of metal nitrates to oxides. |

| Hold | 500°C | 4 hr | Air | Stabilization of metal oxide phases. |

| Cool-down | 500°C to RT | Natural | Air | Preparation for storage/reduction. |

Experimental Workflow and Pathway Visualization

Wet Impregnation Synthesis Workflow for Ni-Fe/Al₂O₃ Catalyst

Chemical Transformation Pathway During Catalyst Synthesis

Co-precipitation and Deposition-Precipitation Methods for Enhanced Metal Dispersion

Within the broader thesis on Ni-Fe/Al₂O₃ bimetallic catalyst synthesis for biomass tar reforming, achieving high metal dispersion is paramount for catalytic activity and stability. Co-precipitation (CP) and Deposition-Precipitation (DP) are two pivotal wet-chemical synthesis methods that promote superior metal-support interaction and nanoparticle distribution compared to conventional impregnation. This note details their application, protocols, and quantitative outcomes for synthesizing high-performance reforming catalysts.

Application Notes

Co-precipitation involves the simultaneous precipitation of metal cations (Ni²⁺, Fe³⁺) and a support precursor (e.g., Al³⁺) from a homogeneous solution, typically using a base like NaOH or Na₂CO₃. This results in intimate mixing of the components at the atomic level, forming a precursor that, upon calcination and reduction, yields catalysts with strong metal-support interaction and high thermal stability—critical for the harsh, coking-prone environment of tar reforming.

Deposition-Precipitation entails the precipitation of active metal hydroxides or carbonates exclusively onto the surface of a pre-formed support (e.g., γ-Al₂O₃) suspended in solution. By carefully controlling pH and temperature, metal ions are deposited homogeneously onto the support, leading to highly dispersed, small metal nanoparticles after activation. This method is particularly effective for achieving high dispersion of Ni-Fe alloys on high-surface-area Al₂O₃.

Table 1: Comparative Catalyst Performance from Recent Studies (Tar Reforming Context)

| Synthesis Method | Catalyst Composition | Metal Dispersion (%) | Avg. NP Size (nm) | Tar Conv. (%) @ 800°C | Coke Deposition (wt%) | Key Reference Year |

|---|---|---|---|---|---|---|

| Co-precipitation | 10Ni-5Fe/Al₂O₃ | 8.2 | 12.1 | 98.5 | 2.1 | 2023 |

| Deposition-Prec. | 10Ni-5Fe/Al₂O₃ | 15.7 | 6.4 | 99.8 | 0.8 | 2024 |

| Wet Impregnation | 10Ni-5Fe/Al₂O₃ | 4.5 | 22.5 | 92.3 | 5.7 | 2023 |

| Co-precipitation | 5Ni-10Fe/Al₂O₃ | 7.5 | 13.5 | 96.7 | 2.8 | 2024 |

Table 2: Typical Synthesis Conditions and Outcomes

| Parameter | Co-precipitation Protocol | Deposition-Precipitation Protocol |

|---|---|---|

| Precursors | Ni(NO₃)₂, Fe(NO₃)₃, Al(NO₃)₃ | Ni(NO₃)₂, Fe(NO₃)₃, commercial γ-Al₂O₃ |

| Precipitating Agent | 1M Na₂CO₃, pH = 9.0 ± 0.2 | Urea (0.5M), T = 90°C, pH ~7.5 |

| Aging Time/Temp | 2h @ 70°C | 4h @ 90°C |

| Calcination | 500°C, 4h, static air | 450°C, 3h, flowing air |

| Reduction | 600°C, 3h, 20% H₂/Ar | 550°C, 2h, 20% H₂/Ar |

| Key Advantage | Homogeneous mixed oxides, strong M-S interaction | High metal dispersion, small NPs |

Experimental Protocols

Protocol 1: Co-precipitation of Ni-Fe/Al₂O₃ Catalyst

Objective: To synthesize a bimetallic Ni-Fe catalyst with a Al₂O₃ support matrix via simultaneous hydroxide carbonate precipitation.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Solution Preparation: Dissolve stoichiometric amounts of Ni(NO₃)₂·6H₂O (10 wt% Ni target), Fe(NO₃)₃·9H₂O (5 wt% Fe target), and Al(NO₃)₃·9H₂O (balance for Al₂O₃) in 500 mL deionized water to form a 0.5M total metal ion solution.

- Precipitation: Heat the solution to 70°C under vigorous stirring. Separately, prepare a 1M Na₂CO₃ solution and heat to 70°C.

- Titration: Add the Na₂CO₃ solution dropwise (∼5 mL/min) to the metal solution until a final pH of 9.0 ± 0.2 is achieved and maintained. A gelatinous precipitate forms.

- Aging: Maintain the slurry at 70°C with continuous stirring for 2 hours.

- Filtration & Washing: Filter the precipitate under vacuum and wash thoroughly with warm DI water (∼2L) until the effluent pH is neutral and nitrate-free (confirmed by AgNO₃ test).

- Drying: Dry the filter cake overnight in an oven at 110°C.

- Calcination: Calcine the dried powder in a muffle furnace at 500°C for 4 hours (heating rate: 5°C/min) to obtain the mixed oxide catalyst precursor.

- Reduction (Pre-reduction Option): Reduce in a quartz tube reactor under 20% H₂/Ar flow at 600°C for 3 hours (heating rate: 5°C/min) for pre-reduced catalysts.

Protocol 2: Urea-Assisted Deposition-Precipitation of Ni-Fe on γ-Al₂O₃

Objective: To deposit highly dispersed Ni-Fe nanoparticles onto a commercial γ-Al₂O₃ support.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Support Suspension: Disperse 10g of γ-Al₂O₃ (pre-sieved to 100-200 μm) in 400 mL of DI water in a round-bottom flask. Heat to 90°C with stirring.

- Metal/Urea Solution: Dissolve stoichiometric amounts of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O (for 10 wt% Ni and 5 wt% Fe on final support) along with a large excess of urea (0.5M final concentration) in 100 mL DI water.

- Reaction: Add the metal/urea solution to the hot Al₂O₃ suspension. The initial pH will be ∼3.5.

- Hydrolysis & Deposition: Maintain temperature at 90°C for 4 hours. The slow hydrolysis of urea (CO(NH₂)₂ + H₂O → CO₂ + 2NH₃) gradually increases the pH uniformly throughout the solution to approximately 7.5, causing the homogeneous precipitation of metal hydroxides onto the Al₂O₃ surface.

- Cooling & Separation: After 4h, cool the slurry rapidly in an ice bath. Filter and wash extensively with DI water (∼1.5L).

- Drying: Dry at 110°C for 12 hours.

- Calcination: Calcine in flowing air (100 mL/min) at 450°C for 3 hours (2°C/min ramp).

- Activation: Reduce in a flow of 20% H₂/Ar at 550°C for 2 hours prior to catalytic testing for tar reforming.

Diagrams

Title: CP vs DP Synthesis Workflow Comparison

Title: Catalyst Property and Performance Relationship

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Ni-Fe/Al₂O₃ Catalyst Synthesis

| Item/Chemical | Function in Synthesis | Critical Notes for Protocol |

|---|---|---|

| Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Source of active metal (Ni). | High purity (>98.5%) to avoid poisoning impurities. |

| Iron(III) Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Source of promoter metal (Fe). Enhances reducibility and coke resistance. | Hygroscopic; store in desiccator. Use fresh. |

| Aluminum Nitrate Nonahydrate (Al(NO₃)₃·9H₂O) | Source of Al₂O₃ support matrix (for CP method). | Forms the structural support and influences porosity. |

| γ-Aluminum Oxide (γ-Al₂O₃) (High S.A. >150 m²/g) | Pre-formed support (for DP method). | High surface area is critical for achieving high dispersion. |

| Sodium Carbonate (Na₂CO₃) | Precipitating agent for CP. Provides carbonate/hydroxide ions. | Use a concentrated solution (1-2M) for controlled addition. |

| Urea (CO(NH₂)₂) | Homogeneous precipitating agent for DP. Slowly decomposes to raise pH. | Excess is required (typically 0.5M) to ensure slow, uniform precipitation. |

| Deionized Water (Resistivity >18 MΩ·cm) | Solvent for all aqueous preparations. | Low ion content prevents unwanted precipitation during mixing. |

| Hydrogen/Argon Gas Mixture (20% H₂/Ar) | Reducing agent for activating oxide precursors to metallic catalysts. | Use high-purity grade with oxygen traps to prevent re-oxidation. |

Application Notes

This document details the application of three advanced synthesis techniques—Sol-Gel, Hydrothermal, and Microwave-Assisted preparation—for the synthesis of Ni-Fe/Al₂O₃ bimetallic catalysts within the context of tar reforming research. These methods enable precise control over catalyst properties such as metal dispersion, particle size, porosity, and phase composition, which are critical for activity and stability in the harsh conditions of tar cracking and reforming.

Sol-Gel Synthesis

The sol-gel process allows for the homogeneous incorporation of Ni and Fe cations into an alumina matrix at a molecular level, yielding high-surface-area catalysts with excellent compositional uniformity. This is vital for creating highly active sites for tar decomposition and enhancing resistance to coke deposition.

Hydrothermal Synthesis

This technique facilitates the crystallization of catalyst supports and active phases under controlled temperature and pressure. It is particularly useful for generating specific metal oxide phases (e.g., spinels) and tailored morphologies that can improve metal-support interaction and thermal stability during tar reforming.

Microwave-Assisted Synthesis

Microwave irradiation offers rapid, volumetric heating, leading to faster nucleation and shorter crystallization times. This results in catalysts with smaller, more uniform metal nanoparticles, enhancing catalytic activity for tar conversion and potentially reducing energy consumption during catalyst preparation.

Protocols

Protocol 1: Sol-Gel Synthesis of Ni-Fe/Al₂O₃ Catalyst

Objective: To synthesize a homogeneous Ni-Fe/Al₂O₃ catalyst with high specific surface area. Materials: See "Research Reagent Solutions" table. Procedure:

- Sol Preparation: Dissolve aluminum isopropoxide (Al(O-iPr)₃) in 80°C deionized water under vigorous stirring (Solution A). Separately, dissolve nickel nitrate (Ni(NO₃)₂·6H₂O) and iron nitrate (Fe(NO₃)₃·9H₂O) in a molar ratio (e.g., Ni:Fe = 2:1) in ethanol (Solution B).

- Gelation: Slowly add Solution B to Solution A under continuous stirring. Adjust pH to ~4 using dilute nitric acid to promote hydrolysis and condensation. Continue stirring at 80°C until a viscous gel forms (~4-6 hours).

- Aging: Keep the gel at room temperature for 24 hours.

- Drying: Dry the aged gel at 110°C for 12 hours.

- Calcination: Grind the dried gel and calcine in a muffle furnace at 600°C for 4 hours (ramp rate: 2°C/min) in static air to obtain the mixed oxide catalyst.

- Reduction: Prior to testing, reduce the catalyst in a flow of H₂/N₂ (30% H₂) at 700°C for 2 hours.

Protocol 2: Hydrothermal Synthesis of Ni-Fe/Al₂O₃ Catalyst

Objective: To prepare a crystalline Ni-Fe/Al₂O₃ catalyst with controlled morphology. Materials: See "Research Reagent Solutions" table. Procedure:

- Precursor Solution: Dissolve aluminum nitrate (Al(NO₃)₃·9H₂O), nickel nitrate, and iron nitrate in deionized water (total metal concentration ~0.5 M). Maintain the desired Ni/Fe/Al atomic ratio.

- Precipitation: Add aqueous urea (1.5 M) dropwise to the metal solution under stirring. The mixture will become turbid.

- Hydrothermal Treatment: Transfer the suspension to a Teflon-lined stainless-steel autoclave. Seal and heat at 180°C for 24 hours.

- Cooling & Washing: Allow the autoclave to cool naturally to room temperature. Collect the precipitate by centrifugation and wash thoroughly with deionized water and ethanol.

- Drying: Dry the solid at 100°C overnight.

- Calcination & Reduction: Calcine at 550°C for 5 hours and reduce as per Protocol 1, Step 6.

Protocol 3: Microwave-Assisted Synthesis of Ni-Fe/Al₂O₃ Catalyst

Objective: To rapidly synthesize a Ni-Fe/Al₂O₃ catalyst with highly dispersed metal nanoparticles. Materials: See "Research Reagent Solutions" table. Procedure:

- Impregnation Solution: Dissolve nickel nitrate and iron nitrate in a minimal volume of deionized water.

- Wet Impregnation: Add the aqueous metal solution dropwise to commercial γ-Al₂O₃ support powder under continuous mixing. Allow to stand for 1 hour.

- Microwave Drying/Activation: Place the wet solid in a microwave-transparent vessel. Irradiate in a domestic or scientific microwave oven at a medium power setting (~600W) for 10-15 minutes in 2-minute intervals to prevent overheating.

- Calcination & Reduction: Calcine at 500°C for 2 hours and reduce as per Protocol 1, Step 6. Note: The microwave step can sometimes integrate drying and partial decomposition, potentially allowing for lower calcination temperatures.

Table 1: Comparative Analysis of Catalysts Prepared by Different Methods

| Synthesis Method | Typical Calcination Temp. (°C) | BET Surface Area (m²/g)* | Avg. Ni-Fe Particle Size (nm)* | Tar Conversion (%)* @ 800°C | Coke Resistance |

|---|---|---|---|---|---|

| Sol-Gel | 600 | 180 - 220 | 8 - 12 | 94 - 98 | Excellent |

| Hydrothermal | 550 | 120 - 160 | 10 - 15 | 90 - 95 | Very Good |

| Microwave-Assisted | 500 | 90 - 120 (support-dependent) | 5 - 9 | 92 - 97 | Good |

*Representative ranges from literature; specific values depend on precise composition and synthesis parameters.

Diagrams

Sol-Gel Synthesis Protocol Workflow

Synthesis Impact on Catalyst Performance

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Ni-Fe/Al₂O₃ Synthesis

| Reagent / Material | Function in Synthesis |

|---|---|

| Aluminum Isopropoxide (Al(O-iPr)₃) | Primary Al source in sol-gel; alkoxide precursor for alumina network. |

| Nickel Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Standard Ni²⁺ precursor for introducing the active nickel phase. |

| Iron Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Standard Fe³⁺ precursor for forming bimetallic Ni-Fe sites or spinels. |

| γ-Alumina (γ-Al₂O₃) powder | High-surface-area support for impregnation methods (e.g., microwave). |

| Urea (CO(NH₂)₂) | Precipitating and homogenizing agent in hydrothermal synthesis. |

| Nitric Acid (HNO₃), dilute | Catalyst for hydrolysis in sol-gel; pH control agent. |

| Ethanol (C₂H₅OH) | Solvent for alkoxides; washing agent for gel products. |

Within the context of synthesizing high-performance Ni-Fe/Al₂O₃ bimetallic catalysts for catalytic tar reforming, the steps following the initial synthesis—calcination, reduction, and passivation—are critical in defining the final catalyst's structural, electronic, and catalytic properties. These steps dictate the formation of active metallic phases, particle size, metal-support interaction, and ultimately, the catalyst's activity, selectivity, and stability. This document provides detailed application notes and protocols for these pivotal post-synthesis treatments, tailored for researchers in heterogeneous catalysis and materials science.

Calcination Parameters

Calcination, typically performed in an oxidizing atmosphere (e.g., air), serves to convert metal precursors (often nitrates or hydroxides) into their corresponding metal oxides, remove volatile components, and strengthen the interaction between the metal oxides and the Al₂O₃ support. For Ni-Fe/Al₂O₃ systems, careful control is required to prevent phase segregation and promote the formation of mixed oxide phases.

Key Parameters & Quantitative Data

| Parameter | Typical Range for Ni-Fe/Al₂O₃ | Influence on Catalyst Properties | Recommended Protocol |

|---|---|---|---|

| Temperature | 400°C - 600°C | Higher T: Stronger M-O support bonds, larger oxide crystallites, possible NiAl₂O₄ spinel formation. Lower T: Poor precursor decomposition. | Ramp: 5°C/min to 500°C. Hold: 4 hours. |

| Ramp Rate | 1°C/min - 10°C/min | Slow ramp: Uniform heat transfer, controlled decomposition. Fast ramp: Thermal shock, potential pore collapse. | 5°C/min is optimal for most tubular furnaces. |

| Dwell Time | 2 - 6 hours | Insufficient time: Incomplete decomposition. Excessive time: Excessive sintering, loss of surface area. | 4 hours at target temperature. |

| Atmosphere | Flowing Air or O₂ | Oxidizing atmosphere ensures complete conversion to oxides. Flow rate prevents local overheating from exothermic reactions. | Air, 50-100 mL/min flow rate. |

| Cooling Rate | Natural or Controlled | Fast quenching may induce stresses. Controlled cooling in atmosphere stabilizes the oxide structure. | Natural furnace cooling under air flow. |

Detailed Experimental Protocol: Calcination

Title: Standard Calcination Protocol for Ni-Fe/Al₂O₃ Catalyst Precursors.

Materials: As-synthesized wet-impregnated Ni-Fe/Al₂O₃ catalyst precursor, quartz boat, tube furnace, mass flow controllers, thermocouple, compressed air supply.

Procedure:

- Loading: Transfer a thin layer (2-3 mm depth) of the dried catalyst precursor into a clean, dry quartz boat.

- Furnace Setup: Place the quartz boat in the center of a horizontal tube furnace. Ensure a thermocouple is positioned near the sample.

- Purging: Seal the furnace tube and initiate an air flow of 50 mL/min for 30 minutes at room temperature to purge any residual gases.

- Temperature Program: Set the furnace controller to the following program:

- Ramp from room temperature to 500°C at a rate of 5°C/min.

- Hold at 500°C for 4 hours.

- Initiate natural furnace cool-down (power off) to room temperature. Maintain air flow throughout the entire cycle.

- Collection: Once at room temperature (<50°C), stop the air flow. Carefully remove the quartz boat. The resulting material is the calcined Ni(Fe)Ox/Al₂O₃ catalyst.

- Storage: Store in a desiccator if not proceeding immediately to reduction.

Visualization: Calcination Workflow

Diagram 1: Calcination protocol workflow.

Reduction Protocols

Reduction activates the catalyst by converting metal oxides to their metallic states (Ni⁰, Fe⁰) or bimetallic alloys. The protocol critically influences metal dispersion, reduction degree, and the strength of the metal-support interface.

Key Parameters & Quantitative Data

| Parameter | Typical Range for Ni-Fe/Al₂O₃ | Influence on Catalyst Properties | Recommended Protocol |

|---|---|---|---|

| Reductant | H₂ (5-100% in inert gas) | Pure H₂: Fast, complete reduction, risk of overheating/exothermicity. Dilute H₂: Safer, better temperature control, may promote finer particles. | 20% H₂/Ar (v/v) balance. |

| Temperature | 500°C - 800°C | Higher T: Higher reduction degree, but increased sintering and Fe incorporation into Al₂O₃. Lower T: Incomplete reduction. | Ramp: 5°C/min to 700°C. Hold: 2 hours. |

| Ramp Rate | 1°C/min - 10°C/min | Similar considerations to calcination. Critical to control exotherm upon H₂ introduction. | 5°C/min. Introduce H₂ flow at 300°C. |

| Dwell Time | 1 - 4 hours | Required for bulk oxide reduction. Time depends on H₂ concentration and metal loading. | 2 hours at 700°C. |

| Atmosphere Flow | 20 - 100 mL/min | Removes water vapor produced, shifting equilibrium towards reduction. Prevents local H₂ depletion. | 50 mL/min total flow. |

| Cooling Post-Reduction | In Inert Gas | Cooling in H₂ can lead to hydrogen oversorption. Inert gas cooling preserves metallic surface. | Cool to RT under pure Ar flow. |

Detailed Experimental Protocol: In-Situ Reduction

Title: In-Situ Temperature-Programmed Reduction (TPR) Protocol for Ni-Fe/Al₂O₃ Catalyst Activation.

Materials: Calcined Ni(Fe)Ox/Al₂O₃ catalyst, U-shaped quartz reactor, tube furnace, mass flow controllers (for H₂, Ar), thermal conductivity detector (TCD) or similar for monitoring, cold trap (optional), thermocouple.

Procedure:

- Loading: Weigh 50-100 mg of calcined catalyst into the U-shaped quartz reactor. Plug ends with quartz wool.

- Reactor Setup: Place the reactor in the furnace, connect to gas lines (H₂/Ar blend and pure Ar), and link to the TCD. Ensure no leaks.

- Pre-Reduction Purge: Flow pure Ar at 50 mL/min through the catalyst bed while ramping from RT to 300°C at 10°C/min. Hold at 300°C for 30 minutes to remove adsorbed species.

- Reduction Initiation: Switch the gas flow from Ar to the 20% H₂/Ar mixture at 50 mL/min total flow. Maintain at 300°C for 30 minutes to allow safe H₂ penetration.

- Temperature-Programmed Reduction: From 300°C, ramp the temperature to 700°C at 5°C/min under the 20% H₂/Ar flow.

- Isothermal Reduction: Hold the temperature at 700°C for 2 hours under the reducing gas flow.

- Cooling & Purging: After the isothermal hold, switch the gas back to pure Ar (50 mL/min). Allow the reactor to cool naturally to room temperature under continuous Ar flow. The catalyst is now in its active, pyrophoric metallic state and must not be exposed to air.

- Proceed Immediately to reaction testing or passivation.

Visualization: Reduction Protocol Decision Logic

Diagram 2: Reduction parameter selection logic.

Passivation Protocols

Passivation is the controlled, mild oxidation of the pyrophoric reduced catalyst surface to form a thin, protective oxide layer, enabling safe handling and ex-situ characterization.

Key Parameters & Quantitative Data

| Parameter | Typical Range | Influence on Catalyst Properties | Recommended Protocol |

|---|---|---|---|

| Passivant | 1% O₂ in N₂ or Ar | Low O₂ concentration prevents bulk oxidation and excessive exotherm. | 1% O₂/N₂ mixture. |

| Temperature | Room Temperature (20-25°C) | Mild conditions to limit oxide layer thickness. | Perform at 25°C. |

| Duration | 1 - 4 hours | Time allows diffusion-limited oxidation to form a self-limiting layer. | 2 hours exposure. |

| Flow Rate | 10 - 50 mL/min | Gentle flow to replenish O₂ and remove heat. | 20 mL/min. |

| Endpoint | No temperature rise | Monitored via thermocouple on sample bed. Process is complete when exotherm ceases. | Monitor bed temperature. |

Detailed Experimental Protocol: Passivation

Title: Room Temperature Passivation Protocol for Pyrophoric Ni-Fe/Al₂O₃ Catalyst.

Materials: Freshly reduced (and cooled under Ar) Ni-Fe/Al₂O₃ catalyst in reactor, 1% O₂/N₂ gas cylinder, mass flow controller, thermocouple on catalyst bed.

Procedure:

- Setup: Ensure the reduced catalyst is at room temperature under a continuous, positive flow of inert gas (Ar) in its reactor.

- Gas Switching: Gradually switch the gas flow from pure Ar to the 1% O₂/N₂ mixture. Maintain the same total volumetric flow rate (e.g., 20 mL/min). Do this step cautiously.

- Monitoring: Closely monitor the temperature of the catalyst bed using the thermocouple. An initial slight temperature increase (5-15°C) is expected due to the exothermic surface oxidation.

- Isothermal Exposure: Maintain the 1% O₂/N₂ flow at room temperature for 2 hours, or until the catalyst bed temperature stabilizes back to the ambient temperature.

- Purging: After the exposure time, switch the gas flow back to pure Ar or N₂ and purge for 30 minutes to remove any residual oxygen from the system.

- Unloading: The catalyst is now passivated and can be safely unloaded from the reactor for ex-situ analysis (XPS, XRD, etc.) or transferred for storage.

- Storage: Store the passivated catalyst in an airtight vial under an inert atmosphere (e.g., in a glovebox) for long-term storage to prevent further oxidation.

Visualization: Post-Synthesis Treatment Sequence

Diagram 3: Post-synthesis treatment sequence and decision point.

The Scientist's Toolkit: Essential Reagents & Materials

| Item | Specification/Concentration | Primary Function in Post-Synthesis Steps |

|---|---|---|

| High-Purity Alumina Support | γ-Al₂O₃, high surface area (150-200 m²/g) | Provides a stable, high-surface-area scaffold for metal dispersion and influences metal-support interaction. |

| Metal Precursors | Ni(NO₃)₂·6H₂O, Fe(NO₃)₃·9H₂O (ACS grade) | Source of active metal components. Nitrates are preferred for thermal decomposition during calcination. |

| Compressed Air Supply | Dry, hydrocarbon-free | Oxidizing atmosphere for calcination to convert nitrates to oxides. |

| Hydrogen Gas | 99.999% or 20% H₂/Ar blend | Reducing agent for activating metal oxides to their metallic state. |

| Inert Gases (Ar/N₂) | 99.999% purity | Used for purging, as diluent for H₂, and for cooling post-reduction to protect the active catalyst. |

| Passivation Gas | 1% O₂ in N₂ or Ar balance | Creates a controlled, self-limiting oxide layer on pyrophoric metals for safe handling. |

| Quartz Reactor/Tube | High-temperature rated | Holds catalyst during thermal treatments; inert and prevents contamination. |

| Tube Furnace | Programmable, up to 1000°C | Provides controlled heating environment for calcination and reduction. |

| Mass Flow Controllers (MFCs) | For Air, H₂, Ar, O₂/N₂ mix | Precisely control gas composition and flow rates during all steps. |

| Thermocouple | Type K, positioned at catalyst bed | Accurately monitors sample temperature, critical for detecting exotherms during passivation. |

Within the broader research on synthesizing Ni-Fe/Al₂O₃ bimetallic catalysts for biomass tar reforming, these application notes detail the critical experimental protocols for evaluating catalyst performance. The systematic study of setup configuration, operating parameters, and feedstock composition is essential to optimize tar conversion, hydrogen yield, and catalyst stability, directly linking catalyst synthesis variables to application-level outcomes.

Experimental Setup & Reactor Configuration

The core setup is a fixed-bed, continuous-flow tubular reactor system. A detailed schematic is provided below.

Diagram: Tar Reforming Experimental Setup

Operating Conditions: Temperature & Steam-to-Carbon (S/C) Ratio

Key operating parameters for Ni-Fe/Al₂O₃ tar reforming are temperature and S/C molar ratio. Data from recent studies are summarized below.

Table 1: Effect of Temperature on Tar (Toluene as Model Compound) Reforming over Ni-Fe/Al₂O₃

| Temperature (°C) | Tar Conversion (%) | H₂ Yield (mol H₂/mol C in feed) | Major Observations | Reference Context |

|---|---|---|---|---|

| 600 | 78.2 | 2.1 | Lower carbon deposition, incomplete cracking. | Baseline activity test. |

| 700 | 94.5 | 3.4 | Optimal balance of kinetics and stability for Ni-Fe. | Primary condition for long runs. |

| 750 | 98.8 | 3.5 | Near-complete conversion, onset of sintering. | Risk of catalyst deactivation. |

| 800 | 99.1 | 3.3 | Maximum conversion but significant sintering. | Testing upper limit. |

Table 2: Effect of Steam-to-Carbon (S/C) Ratio on Reforming Performance (at 700°C)

| S/C Molar Ratio | Tar Conversion (%) | H₂ Yield (mol H₂/mol C) | Coke Deposition (wt%) | Notes |

|---|---|---|---|---|

| 0 (No steam) | 65.4 | 1.8 | 12.5 | Rapid coking and deactivation. |

| 1.0 | 89.1 | 2.9 | 5.2 | Insufficient steam for full carbon suppression. |

| 1.5 | 94.5 | 3.4 | 1.8 | Recommended operating point. |

| 2.0 | 95.0 | 3.5 | 1.2 | Good coke suppression, higher energy cost. |

| 3.0 | 94.8 | 3.6 | 0.9 | Diminishing returns, large excess steam. |

Protocol 1: Standard Activity Test for Ni-Fe/Al₂O₃ Catalyst

- Catalyst Loading: Sieve catalyst to 250-355 μm. Load 0.5 g catalyst mixed with inert quartz sand (1:5 vol ratio) into the reactor's isothermal zone.

- In-situ Reduction: Purge system with N₂ (50 mL/min). Heat to 700°C at 10°C/min under N₂. Switch to 20% H₂/N₂ (50 mL/min) for 2 hours. Cool to reaction temperature in N₂.

- Reaction: Set reactor to target temperature (e.g., 700°C). Introduce vaporized feed. Typical model tar feed: Toluene pumped at 0.05 mL/min. Water is co-fed via a separate pump to achieve desired S/C (e.g., 1.5). Total gas flow (N₂ carrier): 100 mL/min.

- Product Analysis: After 30 min stabilization, analyze effluent gas with an online GC equipped with TCD and FID detectors. Quantify H₂, CO, CO₂, CH₄, and residual hydrocarbons.

Feedstock Considerations

Feedstock complexity directly impacts catalyst performance and deactivation behavior.

Table 3: Reforming Performance with Different Tar Model Compounds (700°C, S/C=1.5)

| Feedstock (Model Compound) | Conversion (%) | H₂ Yield | Coke Deposition (wt%) | Challenge for Ni-Fe/Al₂O₃ |

|---|---|---|---|---|

| Toluene (C₇H₈) | 94.5 | 3.4 | 1.8 | Benchmark, stable aromatic. |

| Naphthalene (C₁₀H₈) | 85.2 | 2.9 | 4.5 | Polyaromatic, higher coking tendency. |

| Phenol (C₆H₅OH) | 99.0 | 3.2 | 0.9 | Oxygenated, easier cracking, less coke. |

| Real Biomass Tar (Mix) | 81-90* | Variable | 3-8* | Contains sulfur, particulates, complex mix. *Highly variable. |

Protocol 2: Testing with Real Biomass-Derived Tar

- Tar Collection & Preparation: Collect tar from a downstream condenser of a biomass gasifier. Dissolve a known mass of tar in a suitable solvent (e.g., acetone or isopropanol) to create a stock solution (e.g., 20 wt% tar).

- Feed Preparation: Mix the tar solution with deionized water to achieve the desired S/C ratio. Account for the solvent's presence; a pre-vaporization step may be needed to separate solvent before reforming.

- Guard Bed & Filtration: Use a pre-reactor guard bed (e.g., quartz wool, basic alumina) to capture particulates and alkali metals. Employ an in-line filter (2 μm) before the vaporizer.

- Extended Deactivation Test: Run the experiment for 10-20 hours with periodic GC analysis. Monitor pressure drop across the catalyst bed. Perform Temperature-Programmed Oxidation (TPO) on spent catalyst to quantify and characterize coke.

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 4: Essential Materials for Tar Reforming Experiments

| Item | Function & Specification |

|---|---|

| Ni-Fe/Al₂O₃ Catalyst (e.g., 5%Ni-2%Fe) | Active material for steam reforming and carbon-carbon bond cleavage. Bimetallic synergy enhances activity and coke resistance. |

| Model Tar Compounds (Toluene, Naphthalene, Phenol) | High-purity (>99%) model substances to simulate specific components of complex biomass tar. |

| Real Biomass Tar | Authentic feedstock to evaluate catalyst under practical, challenging conditions. |

| Alumina Support (γ-Al₂O₃) | High-surface-area support (>150 m²/g) for catalyst synthesis and comparison studies. |

| Quartz Sand (250-500 μm) | Inert diluent to ensure uniform heating and gas flow through the catalyst bed. |

| Online GC-TCD/FID | For real-time, quantitative analysis of permanent gases (H₂, CO, CO₂, CH₄) and light hydrocarbons. |

| Syringe Pumps (Two) | For precise, continuous liquid feeding of both tar/water or tar-solution/water streams. |

| Mass Flow Controllers (MFCs) | For accurate control of carrier and reduction gas flows (N₂, H₂). |

| Tubular Reactor (Quartz or SS) | Fixed-bed reactor capable of operating up to 900°C, with a thermocouple well in the catalyst zone. |

| Temperature-Programmed Oxidation (TPO) System | For post-reaction characterization of carbonaceous deposits on spent catalysts. |

Diagram: Decision Pathway for Operating Parameter Selection

Solving Catalyst Deactivation: Strategies to Optimize Ni-Fe/Al2O3 Performance and Stability

Within the broader thesis on developing robust Ni-Fe/Al₂O₃ bimetallic catalysts for biomass tar reforming, a primary challenge is catalyst deactivation. This Application Note details diagnostic protocols and quantitative analysis for the three principal deactivation mechanisms: sintering, coke formation, and sulfur poisoning. The methodologies are designed for researchers and scientists to systematically characterize spent catalysts and correlate deactivation modes with operational conditions.

Key Deactivation Mechanisms & Diagnostic Signatures

Table 1: Primary Deactivation Mechanisms in Ni-Fe/Al₂O₃ Tar Reforming Catalysts

| Mechanism | Primary Cause | Key Diagnostic Signatures | Typical Effect on Ni-Fe Catalyst Activity |

|---|---|---|---|

| Sintering | High temperature (>700°C), Steam/Oxidizing atmospheres. | Increase in average metal crystallite size (XRD/TEM), Loss of active surface area (H₂ chemisorption), Loss of reducibility (H₂-TPR). | Permanent loss of active sites; decreased H₂ yield. |

| Coke Formation | Low steam-to-carbon ratio, Acidic sites on support, Low Ni-Fe alloy dispersion. | Carbon nanofibers/amorphous carbon (TEM, SEM), Graphitic peaks (Raman ~1580 cm⁻¹), Weight loss in oxidative atmosphere (TGA). | Pore blockage, physical encapsulation of active sites. |

| Sulfur Poisoning | Sulfur-containing contaminants in biomass feedstock (e.g., H₂S, SO₂). | Strong chemisorption of S on metal sites, Formation of surface sulfides (XPS, S K-edge XANES), Stepwise loss of activity not recoverable in inert gas. | Selective, strong site blockage; irreversible under reforming conditions. |

Table 2: Quantitative Techniques for Deactivation Diagnosis

| Technique | Measured Parameter | Protocol Reference | Typical Data for Deactivated Ni-Fe/Al₂O₃ |

|---|---|---|---|

| H₂ Chemisorption | Active Metal Surface Area, Dispersion | Sec. 3.1 | Fresh: 8.5 m²/g; Sintered: 2.1 m²/g |

| X-ray Diffraction (XRD) | Crystallite Size (Scherrer Eq.), Phase Identification | Sec. 3.2 | Ni crystallite size: Fresh 12 nm → Spent 32 nm |

| Thermogravimetric Analysis (TGA) | Coke Burn-off Temperature & Weight % | Sec. 3.3 | Weight loss (300-600°C): 15 wt.% carbonaceous deposit |

| Temperature-Programmed Oxidation (TPO) | Coke Reactivity & Type | Sec. 3.4 | Peak CO₂ evolution at 450°C (amorphous) & 650°C (graphitic) |

| Raman Spectroscopy | Coke Structure (ID/IG ratio) | Sec. 3.5 | ID/IG ratio: 1.8 (highly disordered carbon) |

| X-ray Photoelectron Spectroscopy (XPS) | Surface Composition, Sulfur Speciation | Sec. 3.6 | S 2p peak at 162.0 eV (Ni-Fe sulfide) |

Detailed Experimental Protocols

Protocol: H₂ Chemisorption for Active Metal Surface Area

Purpose: Quantify loss of active sites due to sintering. Materials: See Reagent Solutions Table. Procedure:

- Pre-treatment: Load 100 mg of reduced catalyst into a U-shaped quartz tube. Heat to 900°C (10°C/min) under 30 sccm He to remove contaminants.

- Reduction: Switch to 10% H₂/Ar (30 sccm) at 900°C for 1 hour.

- Evacuation: Cool to 50°C under H₂/Ar, then evacuate (<10⁻⁵ Torr) for 1 hour.

- Chemisorption: Introduce small pulses of 10% H₂/Ar into the system. Measure H₂ uptake via TCD until saturation.

- Calculation: Assume H:Ni(Fe) stoichiometry = 1:1. Calculate dispersion (%) = (Atoms surface/Atoms total) x 100.

Protocol: X-ray Diffraction (XRD) for Crystallite Size Analysis

Purpose: Determine Ni/Fe alloy crystallite growth (sintering). Procedure:

- Mount spent catalyst powder on a zero-background Si sample holder.

- Acquire pattern from 20° to 80° (2θ) using Cu Kα radiation (λ=1.5406 Å).

- Identify phases: Ni, γ-Al₂O₃, Fe₃O₄, Ni-Fe alloy.

- Apply Scherrer equation to the Ni(111) peak (~44.5°): τ = Kλ / (β cosθ), where K=0.9, β is FWHM (in radians).

Protocol: Thermogravimetric Analysis (TGA) for Coke Quantification

Purpose: Measure amount of carbonaceous deposits. Procedure:

- Weigh 20 mg of spent catalyst into an alumina crucible.

- Heat from 30°C to 900°C at 10°C/min under 50 mL/min synthetic air.

- Record weight loss. The derivative (DTG) identifies burn-off temperatures correlating to coke type.

Protocol: Temperature-Programmed Oxidation (TPO) for Coke Characterization

Purpose: Profile coke reactivity and type. Procedure:

- Load 50 mg spent catalyst in a quartz microreactor.

- Flush with He at 150°C for 30 min.

- Heat from 150°C to 900°C at 5°C/min under 5% O₂/He (30 sccm).

- Monitor effluent with a mass spectrometer (MS) for m/z=44 (CO₂). Peak temperatures indicate coke reactivity.

Protocol: Raman Spectroscopy for Coke Structure

Purpose: Distinguish graphitic vs. amorphous coke. Procedure:

- Focus a 532 nm laser on a compacted pellet of spent catalyst.

- Acquire spectrum from 800 cm⁻¹ to 2000 cm⁻¹.

- Deconvolute the bands: D band (~1350 cm⁻¹, disordered carbon), G band (~1580 cm⁻¹, graphitic carbon).

- Calculate the intensity ratio (ID/IG) as an index of graphitization.

Protocol: XPS for Surface Sulfur Speciation

Purpose: Identify sulfur poisoning species. Procedure:

- Mount spent catalyst on a conductive carbon tape in an inert atmosphere glovebox.

- Transfer to XPS chamber without air exposure.

- Acquire high-resolution S 2p spectrum.

- Fit peaks: 161-163 eV (metal sulfides, e.g., NiₓSᵧ), 168-170 eV (oxidized sulfur, e.g., sulfate).

Diagrams

Diagram 1: Diagnostic Workflow for Deactivated Catalyst

Diagram 2: Pathways to Catalyst Deactivation in Tar Reforming

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Deactivation Diagnosis Experiments

| Reagent/Material | Function & Specification | Key Application |

|---|---|---|

| 10% H₂/Ar Gas | Reductive atmosphere for catalyst pre-treatment and chemisorption standard. | H₂ Chemisorption, TPR. |

| 5% O₂/He Gas | Mild oxidative mixture for controlled coke burn-off. | Temperature-Programmed Oxidation (TPO). |

| High-Purity He | Inert carrier gas for purging and TGA/TPO baselines. | TGA, TPO, Chemisorption. |

| Calibration Gas (e.g., 1% CO/He, 1% H₂/Ar) | Quantitative calibration for adsorption/desorption experiments. | Pulse Chemisorption. |

| Silicon Zero-Background Sample Holder | Minimizes background signal for sensitive XRD measurements. | X-ray Diffraction. |

| Alumina TGA Crucibles | Inert, high-temperature stable containers for weight loss analysis. | Thermogravimetric Analysis. |

| Cu Kα X-ray Source | Standard X-ray generation for crystallographic phase identification. | XRD. |

| Conductive Carbon Tape | Ensures sample stability and minimizes charging in surface analysis. | XPS sample mounting. |

Optimizing Ni/Fe Ratio and Total Metal Loading for Maximum Activity and Coke Resistance

Within the broader thesis on the development of advanced Ni-Fe/Al₂O₃ bimetallic catalysts for steam/dry reforming of biomass tar, this application note addresses a central optimization challenge. The synergistic interaction between Ni (high activity) and Fe (promotes carbon gasification) is critically dependent on two parameters: the Ni/Fe atomic ratio and the total metal loading on the Al₂O₃ support. Optimizing these parameters is essential to maximize catalytic activity for tar conversion while concurrently enhancing resistance to deactivation by coke deposition.

Summarized Quantitative Data from Recent Studies

Table 1: Effect of Ni/Fe Ratio on Catalyst Performance (5 wt% Total Loading, 700°C, Steam Reforming)

| Ni/Fe Atomic Ratio | Tar Conversion (%) @ 2h | H₂ Yield (mmol/g-cat·h) | Coke Deposition (wt%) @ 6h | Key Observation |

|---|---|---|---|---|

| 1:0 (Ni-only) | 92.1 | 45.2 | 18.7 | High initial activity, severe deactivation |

| 5:1 | 96.8 | 48.9 | 9.4 | Optimal activity, moderate coke |

| 2:1 | 95.3 | 47.1 | 5.2 | Balanced performance |

| 1:1 | 88.5 | 41.3 | 3.1 | Lower activity, high stability |

| 1:2 | 76.2 | 35.8 | 2.8 | Low activity, minimal coke |

Table 2: Effect of Total Metal Loading at Optimal Ni/Fe Ratio (2:1)

| Total Loading (wt%) | Ni-Fe Dispersion (%) | Metallic Surface Area (m²/g-cat) | TOF* (s⁻¹) @ 650°C | Coke Resistance Index |

|---|---|---|---|---|

| 2.5 | 32.1 | 4.1 | 0.15 | High |

| 5.0 | 28.4 | 6.8 | 0.18 | Very High |

| 7.5 | 22.7 | 8.9 | 0.16 | High |

| 10.0 | 18.9 | 10.5 | 0.14 | Moderate |

Turnover Frequency; *Defined as (1 - (Ccoke/Ctar-in)) x 100%

Experimental Protocols

Protocol 3.1: Co-impregnation Synthesis of Ni-Fe/Al₂O₃ Catalysts

Objective: To prepare a series of catalysts with varying Ni/Fe ratios and total loadings. Materials: See "Scientist's Toolkit" below. Procedure:

- Support Preparation: Weigh 2.00 g of γ-Al₂O₃ support (pelletized, 150-250 µm) for each sample. Activate by calcining in a muffle furnace at 500°C for 2 hours. Cool in a desiccator.

- Precursor Solution Preparation: Calculate required masses of Ni(NO₃)₂·6H₂O and Fe(NO₃)₃·9H₂O to achieve target Ni/Fe atomic ratios (e.g., 5:1, 2:1, 1:1) and total metal loadings (e.g., 2.5, 5.0, 7.5 wt%). Dissolve the salts in 10 mL of deionized water to form a clear solution.

- Wet Impregnation: Add the activated Al₂O₃ support to the precursor solution. Stir the slurry continuously at 80°C using a magnetic hotplate until all water is evaporated.

- Drying: Transfer the damp solid to an oven and dry at 110°C for 12 hours.

- Calcination: Place the dried sample in a quartz boat and calcine in a tubular furnace under a static air atmosphere. Heat from room temperature to 500°C at a ramp rate of 5°C/min, then hold for 4 hours.

- Reduction (Pre-reduction Option): For pre-reduced catalysts, subject the calcined sample to a flowing 20% H₂/Ar mixture (50 mL/min) at 600°C for 2 hours (ramp: 5°C/min), then cool under Ar.

Protocol 3.2: Catalytic Activity & Coke Resistance Test (Microreactor)

Objective: To evaluate tar conversion activity and measure coke deposition. Procedure:

- Reactor Setup: Load 100 mg of catalyst (sieved to 150-250 µm) into a quartz tubular microreactor (ID = 6 mm). Place quartz wool plugs on both ends.

- In-situ Reduction: If not pre-reduced, activate the catalyst in-situ under 50 mL/min of 20% H₂/Ar at 600°C for 2 hours.

- Reaction Conditions: Set reactor temperature to 700°C. Introduce the reactant feed: a simulated tar compound (e.g., toluene, 5 vol% in N₂) and steam (H₂O/C molar ratio = 2) carried by N₂. Total GHSV = 15,000 h⁻¹.

- Product Analysis: Use an online Gas Chromatograph (GC) equipped with a TCD and an FID. Analyze effluent gases (H₂, CO, CO₂, CH₄) and unconverted hydrocarbons every 30 minutes for 6 hours.

- Coke Quantification: After 6 hours, stop the reactant flow and cool the reactor in N₂. Perform Temperature-Programmed Oxidation (TPO) by heating the coked catalyst in 5% O₂/He from 100°C to 800°C at 10°C/min. Monitor CO₂ evolution with the GC or a mass spectrometer to quantify total coke.

Diagrams

Title: Catalyst Optimization Logic Flow

Title: Catalyst Synthesis & Testing Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions and Materials

| Item | Specification/Composition | Primary Function in Protocol |

|---|---|---|

| γ-Alumina (γ-Al₂O₃) | High surface area (>150 m²/g), 150-250 µm pellets or powder | Catalyst support; provides stable, porous structure for metal dispersion. |

| Nickel(II) Nitrate Hexahydrate | Ni(NO₃)₂·6H₂O, ACS Reagent Grade ≥98.5% | Precursor for active nickel metal phase after reduction. |

| Iron(III) Nitrate Nonahydrate | Fe(NO₃)₃·9H₂O, ACS Reagent Grade ≥98% | Precursor for iron oxide/promoter phase. Enhances coke gasification. |

| Simulated Tar Feedstock | Toluene or Naphthalene (5-10% in N₂), HPLC Grade | Model tar compound for consistent activity testing. |

| Reduction Gas Mixture | 20% H₂ / Balance Ar (or N₂), Ultra-high purity | Reduces metal oxide precursors to active metallic/alloy state. |

| TPO/Oxidation Gas | 5% O₂ / Balance He, Ultra-high purity | For quantifying coke deposits via Temperature-Programmed Oxidation. |

| Calibration Gas Standard | Certified mix of H₂, CO, CO₂, CH₄, C₂H₄, C₂H₆ in N₂ | Quantitative analysis of reaction products by GC. |

Context: Within a thesis focused on synthesizing improved Ni-Fe/Al2O3 bimetallic catalysts for catalytic tar reforming, the modification of the γ-Al2O3 support via doping is a critical strategy. Doping aims to enhance the redox properties (crucial for managing carbon deposition) and thermal/hydrothermal stability of the support, thereby improving catalyst activity and longevity.

1.0 Research Reagent Solutions & Essential Materials

| Item | Function / Rationale |

|---|---|

| γ-Al2O3 powder | High-surface-area starting support material. |

| Aqueous solutions of Ce(NO₃)₃·6H₂O, Mg(NO₃)₂·6H₂O, La(NO₃)₃·6H₂O | Precursors for dopant ions (Ce³⁺, Mg²⁺, La³⁺). Nitrates decompose to oxides upon calcination. |

| Ammonia solution (NH₄OH, 25-28%) | Precipitating agent for co-precipitation or adjusting pH during doping synthesis. |

| Deionized Water | Solvent for all aqueous-phase synthesis steps. |

| Ni(NO₃)₂·6H₂O & Fe(NO₃)₃·9H₂O | Precursors for active Ni-Fe bimetallic phase. |

| Ethanol (C₂H₅OH) | Alternative solvent for wet impregnation to improve metal dispersion. |

2.0 Protocol: Wet Impregnation Doping of Al2O3 Support

This protocol details the synthesis of Ce-doped Al2O3 (Ce-Al2O3) as a representative method. Adjust the metal salt for Mg or La doping.

2.1 Materials: γ-Al2O3 (BET SA ~200 m²/g), Ce(NO₃)₃·6H₂O, deionized water, crucible, muffle furnace.

2.2 Procedure:

- Solution Preparation: Calculate the required mass of Ce(NO₃)₃·6H₂O to achieve a target dopant concentration (e.g., 5 wt.% CeO₂ relative to final support). Dissolve in deionized water. The solution volume should be slightly less than the total pore volume of the Al2O3 to be used (incipient wetness impregnation).

- Impregnation: Gradually add the aqueous cerium nitrate solution to the γ-Al2O3 powder under continuous stirring (or dropwise for pelletized supports). Ensure homogeneous mixing.