Optimizing 3D Printed Catalytic Reactors: A Comprehensive Guide for Pharmaceutical Research and Process Intensification

This article provides a detailed roadmap for researchers and pharmaceutical development professionals seeking to leverage 3D printing for catalytic reactor optimization.

Optimizing 3D Printed Catalytic Reactors: A Comprehensive Guide for Pharmaceutical Research and Process Intensification

Abstract

This article provides a detailed roadmap for researchers and pharmaceutical development professionals seeking to leverage 3D printing for catalytic reactor optimization. We explore the fundamental advantages of additive manufacturing for catalysis, including unprecedented geometric control for enhanced mass/heat transfer. The guide delves into practical methodologies for design, material selection, and printing, alongside troubleshooting common fabrication and performance issues. Finally, we examine validation frameworks and comparative analyses against conventional reactors, highlighting the transformative potential of 3D printing for process intensification in drug synthesis and green chemistry.

The Catalytic Revolution: Why 3D Printing is Transforming Reactor Design Fundamentals

This document provides application notes and protocols within a broader thesis on 3D-printed catalytic reactor optimization. The transition from subtractive manufacturing (SM) to additive manufacturing (AM) represents a paradigm shift, enabling the fabrication of reactors with unprecedented geometric complexity, integrated functionality, and tailored fluid dynamics, directly impacting catalytic performance metrics such as conversion, selectivity, and pressure drop.

Comparative Analysis: SM vs. AM for Catalytic Reactors

Table 1: Quantitative Comparison of Manufacturing Principles in Catalysis

| Parameter | Subtractive Manufacturing (e.g., CNC, Drilling) | Additive Manufacturing (e.g., SLM, DLP, FDM) |

|---|---|---|

| Geometric Freedom | Low (2.5D, simple channels) | Very High (3D, lattices, gyroids, helical paths) |

| Material Waste | High (>50% for complex parts) | Low (<10% with recycling) |

| Production Speed | Fast for simple designs | Layer-by-layer, slower but allows complexity |

| Surface Roughness (Ra) | 0.4 - 25 µm (machine dependent) | 5 - 50 µm (highly process-dependent) |

| Typical Feature Resolution | ~100 µm | 20 - 200 µm (varies by technology) |

| Multi-material Capacity | Very Difficult / Assembly Required | Possible with advanced printers |

| Catalyst Integration | Post-production: coating, packing | In-situ: direct printing of catalytic inks, graded compositions |

| Optimal Use Case | High-volume, simple fixed-bed reactors | Prototyping, complex monolithic reactors, mass/heat transfer optimization |

Table 2: Impact of Reactor Geometry on Catalytic Performance (Model System: CO Oxidation)

| Reactor Geometry (AM-fabricated) | Specific Surface Area (m²/m³) | Pressure Drop (kPa) | Conversion (%) @ 250°C | Key Advantage |

|---|---|---|---|---|

| Straight Channel (Baseline) | 500 | 1.0 | 65 | Reference |

| Triply Periodic Minimal Surface (Gyroid) | 2100 | 4.2 | 89 | Enhanced surface area & mixing |

| Fibonacci-inspired Helical Coil | 950 | 2.1 | 78 | Induced swirl flow, longer residence |

| Fractal-Based Branching Network | 1800 | 3.8 | 92 | Uniform radial distribution |

Experimental Protocols

Protocol 3.1: Direct Ink Writing (DIW) of a Catalytic Monolith

Aim: Fabricate a ceramic monolith with an integrated MnOₓ-Co₃O₄ catalyst for VOC oxidation. Materials: See "The Scientist's Toolkit" (Section 5). Workflow:

- Ink Formulation:

- Mix 40 wt% γ-Al₂O₃ powder (50 nm), 10 wt% colloidal silica binder (LUDOX), 2 wt% Mn(NO₃)₂·4H₂O, and 2 wt% Co(NO₃)₂·6H₂O.

- Add 46 wt% deionized water. Homogenize in a planetary centrifugal mixer (3 min at 2000 rpm).

- Characterize rheology: target viscosity 10-50 Pa·s at shear rate 10 s⁻¹.

- Printing Process:

- Load ink into a syringe barrel with a tapered nozzle (410 µm diameter).

- Set printer bed temperature to 60°C.

- Print gyroid structure (5x5x5 cm, pore density 30 CPI) using a layer height of 300 µm, print speed 15 mm/s, and extrusion pressure 450 kPa.

- Post-processing:

- Dry printed structure at 80°C for 24h in air.

- Calcine in a muffle furnace: ramp 2°C/min to 600°C, hold for 4h, cool naturally.

- Characterization:

- Perform SEM-EDS to confirm catalyst dispersion and strut morphology.

- Measure BET surface area (target: >80 m²/g).

- Test in a flow reactor (Protocol 3.2).

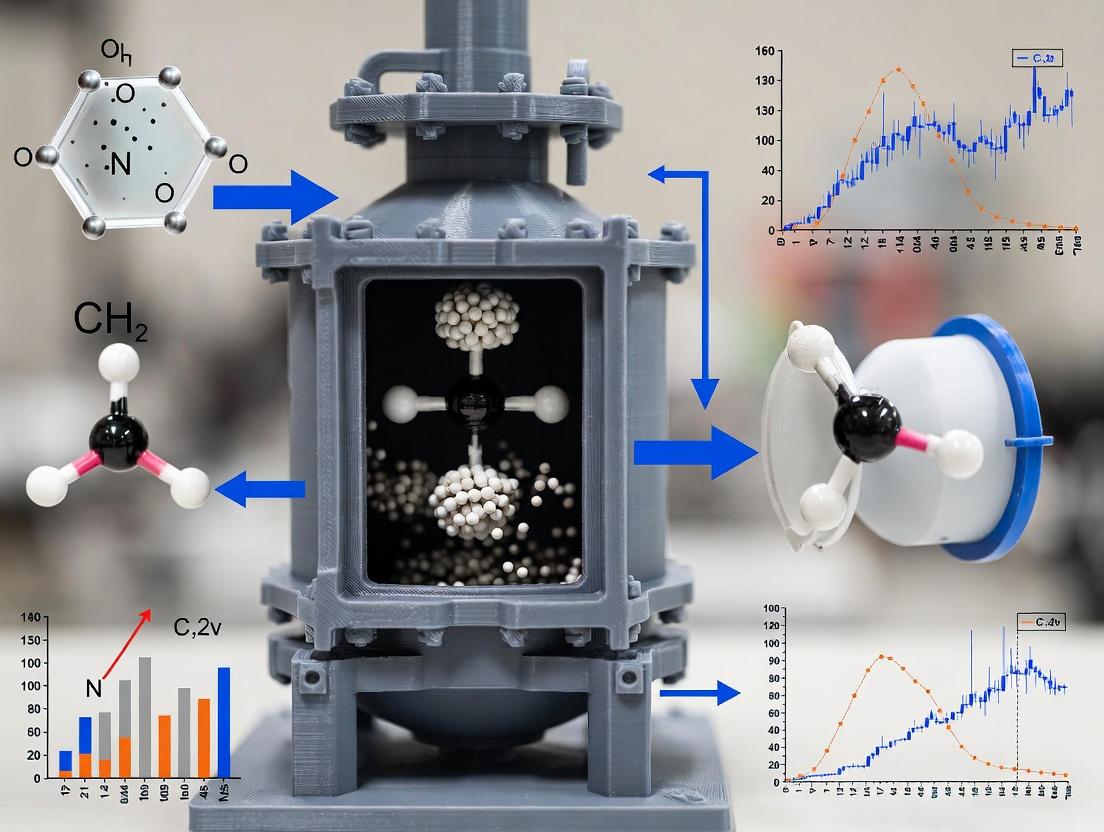

Diagram Title: DIW Catalytic Monolith Fabrication Workflow

Protocol 3.2: Performance Evaluation of a 3D-Printed Catalytic Reactor

Aim: Quantify conversion, selectivity, and pressure drop of an AM-fabricated reactor. Setup:

- Reactor Housing: Seal the printed monolith (from Protocol 3.1) in a stainless steel sleeve using high-temp ceramic gaskets.

- Flow System:

- Use mass flow controllers for feed gases (e.g., 1% CO in Air, total flow 500 mL/min).

- Pre-heat feed gas in a 1m coil before the reactor.

- Place the reactor in a tubular furnace with three independent heating zones.

- Analysis:

- Use an online GC or FTIR for inlet/outlet composition.

- Record differential pressure via a transducer across the reactor.

- Monitor temperature via three K-type thermocoules along the reactor length.

Procedure:

- Activate catalyst under flowing air at 300°C for 1h.

- Set reaction temperature (e.g., 150°C). Allow 30 min stabilization.

- Introduce reaction feed. Sample outlet gas every 10 min until steady state (3 consecutive stable readings).

- Record conversion (X) and pressure drop (ΔP).

- Repeat steps 2-4 across a temperature range (e.g., 100-350°C in 50°C increments).

- Calculate selectivity (S) for multi-product reactions: S (%) = (Moles of desired product / Moles of converted reactant) * 100.

Diagram Title: 3D Printed Reactor Performance Test Setup

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AM in Catalysis Research

| Item | Function & Rationale |

|---|---|

| Catalytic Precursor Salts (e.g., Ni(NO₃)₂, H₂PtCl₆, ZrOCl₂) | Metal ion source for in-situ catalyst integration into printable inks. |

| Ceramic Powders (γ-Al₂O₃, TiO₂, ZrO₂, SiO₂; <100 nm) | High-surface-area support material. Particle size controls ink rheology. |

| Colloidal Binders (LUDOX silica, boehmite sol) | Provides green strength after printing and sinters to form porous network. |

| Rheology Modifiers (Hydroxypropyl cellulose, polyvinyl alcohol) | Adjusts ink viscoelasticity for shape retention post-extrusion (DIW). |

| Photopolymer Resins (Reactive) with dispersed nanoparticles | For vat polymerization (DLP/SLA); UV-curable matrix holding catalyst particles. |

| Metal Alloy Powder (Stainless steel 316L, AlSi10Mg) | For Selective Laser Melting (SLM) of high-strength, thermally conductive reactor internals. |

| Platinum-Cured Silicone | For soft tooling or casting replicas of 3D printed master molds. |

| High-Temp Epoxy Sealant (e.g., Ceramabond 571) | For sealing ceramic printed structures into metal housings for pressure testing. |

Application Notes

Within 3D printed catalytic reactor optimization research, geometrical freedom is the pivotal advantage, moving beyond traditional manufacturing constraints (e.g., milling, extrusion) to create architectures that directly enhance transport phenomena. This enables precise control over reaction outcomes, critical for chemical synthesis and pharmaceutical intermediate production.

- Mass Transfer Enhancement: Complex lattices (gyroid, Schwarz-P) and fractal designs create turbulent flow at low Reynolds numbers, reducing boundary layer thickness and drastically improving reactant-catalyst contact. For gas-liquid reactions, 3D printed flow distributors ensure uniform bubble size and residence time, enhancing interfacial area.

- Heat Transfer Management: Integrated, conformal cooling channels allow isothermal operation in highly exothermic/endothermic reactions. Lattice structures act as static mixers and heat exchangers, preventing hot spots that degrade catalyst selectivity, especially in Fischer-Tropsch or hydrogenation reactions relevant to drug development.

Protocol 1: Evaluating Mass Transfer in 3D Printed Gyroid Reactors

Objective: Quantify the volumetric mass transfer coefficient (kLa) for a gas-liquid reaction within a 3D printed gyroid-structured reactor compared to a packed-bed control.

Materials & Equipment:

- Reactor: SS316L gyroid reactor (unit cell = 5mm, porosity = 0.7), printed via Laser Powder Bed Fusion (LPBF).

- Control: Conventional SS316L packed-bed reactor (filled with 3mm spherical inert beads).

- System: Liquid pump, mass flow controller, dissolved oxygen (DO) probe, data logger.

- Chemicals: Deoxygenated water (N2 sparged), air or oxygen gas, sodium sulfite (0.1 M) for chemical method validation.

Procedure:

- Setup: Mount reactors in parallel flow configuration. Connect liquid (water) and gas (air) feeds via a T-mixer upstream.

- Dynamic Gassing-Out Method:

- Sparge reactor with nitrogen until DO reaches zero.

- Switch gas feed to air at a fixed flow rate (e.g., 100 mL/min).

- Record DO concentration over time until saturation.

- Repeat for varying liquid flow rates (10, 20, 50 mL/min).

- Analysis: Plot ln(1 - C/C) vs. time (t). The slope of the linear region equals -k*La. Calculate enhancement factor vs. packed bed.

Protocol 2: Profiling Thermal Gradients in a Reactor with Conformal Cooling

Objective: Map axial and radial temperature profiles during an exothermic test reaction to validate conformal cooling channel efficacy.

Materials & Equipment:

- Reactor: AlSi10Mg reactor with embedded double-helix cooling channels, printed via LPBF.

- Catalyst: Pd/Al2O3 catalyst coating applied via washcoat impregnation.

- System: Syringe pumps, thermocouples (axial array: inlet, mid-bed, outlet), IR thermal camera, chilled water circulator.

- Test Reaction: Catalytic oxidation of ethanol (1% in air) as a model exothermic reaction.

Procedure:

- Instrumentation: Insert fine-gauge K-type thermocouples at specified ports. Coat reactor with high-emissivity paint for IR imaging.

- Baseline Run: Initiate reaction without active cooling. Record temperature profiles at steady-state.

- Active Cooling Run: Circulate coolant (e.g., 20°C water) at 1 L/min. Re-establish reaction flow and record steady-state temperatures.

- Data Acquisition: Log thermocouple data and capture IR images simultaneously. Calculate maximum temperature differential (ΔT_max) and spatial temperature uniformity.

Data Presentation

Table 1: Comparative Performance of 3D Printed vs. Conventional Reactor Geometries

| Geometry (Material) | Porosity [%] | Surface Area/Volume [m²/m³] | Pressure Drop [kPa] @ 50 mL/min | kLa [s⁻¹] @ Re=100 | ΔT_max in Exotherm [°C] |

|---|---|---|---|---|---|

| Gyroid (SS316L) | 70 | 650 | 12.5 | 0.15 | 8 (with cooling) |

| Packed Bed (Beads) | 40 | 1200 | 45.0 | 0.04 | 22 |

| Triply Periodic (Cu) | 80 | 450 | 8.2 | 0.09 | 5 (with cooling) |

Table 2: Reagent Solutions for Catalytic Test Reactions

| Reagent/Material | Function in Research Context | Example Supplier/Catalog |

|---|---|---|

| Pd/Al2O3 Washcoat Slurry | Provides catalytic activity for model oxidation/hydrogenation reactions; adherence to 3D printed surfaces is critical. | Sigma-Aldrich, 75992 |

| γ-Al2O3 Support Powder | High-surface-area substrate for custom catalyst formulation tailored to reactor geometry. | Alfa Aesar, 45734 |

| Pt Ink for Inkjet Printing | Enables precise, spatially resolved catalyst patterning on complex 3D printed substrates for activity profiling. | Sigma-Aldrich, 793747 |

| High-Temp Epoxy Sealant | For sealing fittings and sensor ports on printed reactors, ensuring leak-free operation up to 200°C. | Henkel, Loctite EA 9396 |

| Calibration Gas Mixtures | For accurate sensor calibration in mass transfer studies (e.g., O2 in N2, H2 in Ar). | Linde, SPEC Series |

Visualizations

Diagram 1: Mass Transfer Coefficient Protocol Workflow

Diagram 2: Heat Transfer Pathway in 3D Reactor

Within the context of optimizing 3D-printed catalytic reactors for applications such as continuous-flow pharmaceutical synthesis, the choice of support material is a critical determinant of reactor performance. The support dictates catalyst loading, dispersion, heat and mass transfer characteristics, and chemical stability under reaction conditions. This document details the properties, applications, and experimental protocols for evaluating polymers, metals, and ceramics as catalytic supports.

Application Note 1.1: Material Selection Guide for Flow Reactors

- Polymers (e.g., PDMS, PEEK, functionalized resins): Ideal for low-to-medium temperature (<250°C) reactions, especially in corrosive aqueous or organic environments where metal leaching is a concern. Their surface chemistry can be easily tailored via etching or grafting. Best for rapid prototyping of complex reactor geometries via vat photopolymerization or material extrusion.

- Metals (e.g., Stainless Steel, Aluminum, Ti-alloys): Chosen for extreme pressure (>100 bar) and high-temperature (>400°C) processes, such as hydrogenations or ammonia synthesis. They provide excellent thermal conductivity, facilitating efficient heat management in exothermic reactions. Supports are typically created via Direct Metal Laser Sintering (DMLS) or as sintered foams.

- Ceramics (e.g., Alumina, Zirconia, Silicon Carbide, Cordierite): Offer the best thermal and chemical inertness. Suitable for highly exothermic/endothermic reactions (oxidation, steam reforming) where thermal stability >1000°C and resistance to thermal shock is required. Can be 3D printed via Direct Ink Writing (DIW) of particle-loaded inks or stereolithography followed by sintering.

Table 1: Comparative Properties of Support Material Classes

| Property | Polymers | Metals | Ceramics |

|---|---|---|---|

| Typical 3D Print Method | SLA, FDM, DLP | DMLS, SLM | DIW, SLA, Binder Jetting |

| Max Use Temp. Range (°C) | 80 - 300 | 400 - 800+ | 1000 - 1500+ |

| Thermal Conductivity | Low (0.1-0.5 W/m·K) | High (15-50 W/m·K) | Low-Moderate (20-40 W/m·K) |

| Chemical Resistance | Variable (Solvent Swelling) | Poor to Acids | Excellent (Inert) |

| Surface Area (m²/g) | Low (<1) | Low (<1) | Moderate-High (5-200+) |

| Catalyst Integration | Surface Grafting | Washcoating, Anodization | Washcoating, Impregnation |

| Relative Cost | Low | High | Moderate |

Experimental Protocols

Protocol 2.1: Washcoating of 3D-Printed Ceramic Monoliths with γ-Alumina

Objective: To apply a high-surface-area ceramic washcoat onto a 3D-printed low-surface-area ceramic (e.g., cordierite) support.

- Support Pretreatment: Clean the 3D-printed monolith in an ultrasonic bath with isopropanol for 15 minutes. Dry at 110°C for 1 hour.

- Slurry Preparation: Prepare a colloidal suspension of γ-Al₂O₃ powder (particle size ~1 µm) in deionized water (25 wt% solids). Adjust pH to 4 using nitric acid to create a positive surface charge on the alumina. Add 2 wt% polyvinyl alcohol as a binder.

- Dip-Coating: Immerse the dried monolith in the slurry for 60 seconds. Withdraw at a constant rate of 2 cm/min.

- Blowing & Drying: Use compressed air to remove excess slurry from channels. Dry at room temperature for 12 hours, then at 110°C for 2 hours.

- Calcination: Heat in a muffle furnace with a ramp rate of 2°C/min to 550°C. Hold for 4 hours. Measure weight gain to determine washcoat loading. Target loading: 10-20 wt%.

Protocol 2.2: Surface Functionalization of 3D-Printed Polymer Supports via Plasma Grafting

Objective: To introduce amine groups onto a PDMS-based 3D-printed support for subsequent catalyst immobilization.

- Plasma Activation: Place the 3D-printed PDMS structure in a plasma cleaner. Evacuate chamber to <100 mTorr. Introduce oxygen gas at 200 mTorr. Apply RF plasma at 50 W for 60 seconds.

- Vapor-Phase Grafting: Immediately post-treatment, transfer the activated PDMS to a sealed chamber containing a vial of (3-Aminopropyl)triethoxysilane (APTES). Place the chamber under vacuum (5 Torr) and heat to 70°C for 2 hours, allowing APTES vapor to react with surface radicals.

- Post-Processing: Remove the functionalized support and cure in an oven at 120°C for 30 minutes. Rinse thoroughly with ethanol to remove unreacted silane.

- Characterization: Confirm amine grafting via ATR-FTIR (peaks ~3300 cm⁻¹ & ~1600 cm⁻¹) or by colorimetric assay using Acid Orange II dye.

Protocol 2.3: Catalyst Impregnation & Reduction on Metallic Foam Supports

Objective: To deposit active palladium nanoparticles on a 3D-printed Ni-alloy foam for hydrogenation reactions.

- Support Preparation: Oxidize the metallic foam in air at 500°C for 1 hour to form a passive oxide layer, improving wettability and adhesion.

- Wet Impregnation: Prepare an aqueous solution of Pd(NO₃)₂ to achieve a target Pd loading of 2 wt%. Submerge the foam in the solution under vacuum for 15 minutes to ensure infiltration. Remove and dry at 80°C for 12 hours.

- Calcination & Reduction: Calcine in static air at 350°C for 2 hours. Subsequently, reduce the catalyst in a flow of 5% H₂/Ar at 300°C for 3 hours (ramp rate 5°C/min).

- Passivation (Optional): For safe handling, expose the reduced catalyst to a 1% O₂/He flow for 1 hour at room temperature to form a thin protective oxide layer.

Diagrams

Support Material Selection Logic Flow

General Workflow for Catalytic Support Preparation

The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Research Reagents for Support Functionalization

| Reagent/Solution | Primary Function | Material Class |

|---|---|---|

| Nitric Acid (1M, pH 4 Slurry) | Peptizing agent for ceramic slurries; stabilizes colloidal suspension. | Ceramics |

| Polyvinyl Alcohol (2% in H₂O) | Binder; improves adhesion of washcoat particles to support surface. | Ceramics, Metals |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane coupling agent; grafts amine functional groups onto oxide surfaces. | Polymers, Ceramics |

| Pd(NO₃)₂ or H₂PtCl₆ Aqueous Solution | Precursor salts for impregnation of noble metal catalysts. | Metals, Ceramics |

| Oxygen Plasma | Creates reactive surface radicals and hydroxyl groups for subsequent grafting. | Polymers |

| 5% H₂/Ar Gas Mixture | Reducing atmosphere for activating metal oxide precursors to metallic catalysts. | Metals, Ceramics |

| Acid Orange II Dye Solution | Colorimetric agent for quantifying surface amine group density. | Polymers |

1. Introduction and Context Within the broader thesis on 3D printed catalytic reactor optimization, the shift from simple monolithic designs to mathematically defined, complex cellular architectures represents the current frontier. These structures—exemplified by triply periodic minimal surfaces (TPMS) like gyroids and other periodic open cellular structures (POCS)—offer unprecedented control over fluid dynamics, mass/heat transfer, and surface-to-volume ratios. This application note details recent breakthroughs, quantitative performance data, and standardized protocols for implementing these advanced architectures.

2. Recent Breakthroughs and Quantitative Data Summary Recent studies highlight the superiority of designed TPMS and POCS over conventional packed beds and straight-channel monoliths in key performance metrics.

Table 1: Comparative Performance of 3D Printed Reactor Architectures

| Architecture Type | Surface Area to Volume Ratio (m²/m³) | Pressure Drop (kPa) @ Comparable Flow | Mixing/Heat Transfer Coefficient (Relative Improvement) | Key Application Demonstrated | Reference (Year) |

|---|---|---|---|---|---|

| Gyroid (TPMS) | 800 - 2200 | 15 - 50 | 2.5 - 4.5x (vs. packed bed) | Photocatalysis, CO2 methanation | Capel et al. (2023) |

| Schwarz P (TPMS) | 750 - 2000 | 10 - 45 | 3.0 - 5.0x (vs. straight monolith) | Steam reforming, enzyme immobilization | Li et al. (2024) |

| Kelvin Cell (POCS) | 500 - 1500 | 5 - 30 | 1.8 - 3.0x (vs. packed bed) | Heterogeneous catalysis, cross-flow filtration | Rezvan et al. (2024) |

| Conventional Packed Bed | ~500 - 1000 | 100 - 500+ | 1.0 (Baseline) | Broad industrial use | N/A |

| Straight-Channel Monolith | 200 - 600 | 1 - 10 | 0.3 - 0.8x (vs. packed bed) | Automotive exhaust | N/A |

Table 2: Optimal Design Parameter Windows for TPMS Reactors

| Design Parameter | Recommended Range | Impact on Performance |

|---|---|---|

| Unit Cell Size (mm) | 2.0 - 10.0 | Smaller size increases SA:V but raises pressure drop. |

| Porosity (%) | 60 - 85 | 70-80% optimal for flow vs. surface area trade-off. |

| Wall Thickness (µm) | 200 - 600 | Dictates mechanical integrity and print fidelity. |

| Graded Density Strategy | Axial or radial variation | Manages pressure drop and reaction rate profiles. |

3. Experimental Protocol: Fabrication and Testing of a Gyroid Reactor for Photocatalysis Objective: To fabricate, activate, and evaluate the performance of a 3D printed gyroid reactor for photocatalytic degradation of organic pollutants.

Protocol 3.1: Digital Design and Printing

- Design: Using CAD or scripting (e.g., MATLAB, Python with

nTopology), generate a gyroid TPMS structure. Key parameters: Unit cell = 5 mm, porosity = 75%, reactor diameter = 25 mm, height = 50 mm. - File Preparation: Export as an STL file. Slice using printer-specific software (e.g., PreForm for SLA, Cura for FDM) with layer height ≤ 50 µm.

- Printing (SLA/DLP Recommended):

- Material: Load a vat with photocatalytic-ready resin (e.g., TiO2-doped ceramic resin or inert polymer for later coating).

- Print: Execute print. Post-process: Wash in appropriate solvent (e.g., isopropanol), then post-cure under UV light per resin specifications.

- Post-Processing (Polymer Templates): For inert polymer gyroids destined for ceramic conversion: subject to debinding and sintering in a furnace according to a material-specific thermal cycle.

Protocol 3.2: Catalyst Functionalization (Wet Impregnation for Polymer Gyroids)

- Solution Preparation: Prepare 1.0 M aqueous solution of titanium(IV) oxysulfate (TiOSO₄) as a TiO2 precursor.

- Impregnation: Immerse the clean, dry 3D printed gyroid structure in the precursor solution for 60 minutes under vacuum (25 inHg) to ensure infiltration.

- Drying: Remove and dry at 80°C for 12 hours.

- Calcination: Heat in a muffle furnace under air. Ramp at 2°C/min to 500°C, hold for 2 hours, then cool slowly to room temperature. This yields a TiO2-coated photocatalytic gyroid reactor.

Protocol 3.3: Performance Evaluation

- Setup: Integrate the reactor into a flow system. Use a peristaltic pump to circulate an aqueous solution of methylene blue (10 mg/L) at a fixed flow rate (e.g., 10 mL/min). Illuminate with a simulated solar light source (AM 1.5G) of known intensity.

- Testing: At regular time intervals, sample the effluent. Analyze methylene blue concentration via UV-Vis spectroscopy (absorbance at 664 nm).

- Data Analysis: Calculate degradation efficiency (𝐶₀−𝐶/𝐶₀ x 100%). Compare conversion rates and apparent quantum efficiency against a control reactor (e.g., packed bed of equivalent catalyst mass).

4. The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for 3D Printed Reactor Research

| Material / Reagent | Function / Rationale |

|---|---|

| TiO2-Doped Photocatalytic Resin (e.g., B9C Titanium Series) | Enables direct SLA printing of active photocatalytic structures without post-coating. |

| Alumina-Backed UV-Curable Resin | Provides a high-surface-area, chemically resistant ceramic skeleton after sintering for catalyst washcoating. |

| Titanium(IV) Oxysulfate (TiOSO₄) | Aqueous precursor for generating high-activity anatase TiO2 coatings via wet impregnation and calcination. |

| Ni/Al₂O₃ Catalyst Slurry (20 wt% Ni) | Standard slurry for washcoating onto sintered ceramic gyroids for methane reforming studies. |

| PDMS (Polydimethylsiloxane) | Used for creating negative molds of printed reactors for rapid replication in alternative materials. |

| Software: nTopology / MATLAB | Essential for algorithmic generation and parametric optimization of TPMS (gyroid, Schwarz P) lattice structures. |

5. Visualization of Design-to-Test Workflow

Title: Iterative Workflow for Optimizing 3D Printed Reactors

Title: Enhanced Transport Phenomena in Gyroid Reactors

Application Note 1: 3D Printed Static Mixer Reactor for API Intermediate Synthesis

Thesis Context: This protocol demonstrates the integration of a 3D printed catalytic static mixer (CSM) within a continuous flow system for a key photoredox coupling reaction, a core case study in catalytic reactor optimization research. The reactor's tortuous geometry enhances mixing and photon penetration, intensifying the process.

Protocol: Synthesis of 5-(2-Phenylpropan-2-yl)isobenzofuran-1(3H)-one

- Reaction: Visible-light-mediated α-alkylation of aldehydes via a photoredox catalyst.

- Setup: A stainless-steel PFA coil reactor (5 mL volume) is connected in series with the 3D printed CSM (Ti-6Al-4V, 2 mL internal volume, Gyroid lattice structure). The system is pressurized via a back-pressure regulator (BPR) set to 50 psi.

- Procedure:

- Prepare Feed A: Dissolve 4-formylbenzoic acid (1.0 equiv, 0.2 M) and organocatalyst (20 mol%) in anhydrous DMF.

- Prepare Feed B: Dissolve tert-butyl α-bromoisobutyrate (1.5 equiv) and [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ photoredox catalyst (1 mol%) in anhydrous DMF.

- Load Feed A and B into separate syringe pumps.

- Co-flow reagents through the PFA coil at a combined flow rate of 0.1 mL/min (residence time in coil: 50 min) at 25°C under blue LED irradiation.

- Direct the output from the coil into the 3D printed CSM reactor, maintained at 40°C, with a residence time of 20 min.

- Collect the product stream, depressurize, and analyze by UPLC-MS. Isolate via direct aqueous workup and precipitation.

Results Summary:

| Parameter | Batch (Literature) | Flow (PFA Coil Only) | Flow (PFA + 3D Printed CSM) |

|---|---|---|---|

| Overall Yield | 78% | 85% | 94% |

| Total Residence Time | 16 hours | 70 minutes | 70 minutes |

| Space-Time Yield (g L⁻¹ h⁻¹) | 2.1 | 18.5 | 41.2 |

| Photon Efficiency (Quantum Yield x10⁻²) | 1.8 | 3.5 | 6.1 |

Workflow for Photoredox API Synthesis in 3D Printed Reactor

Application Note 2: Multi-step Synthesis of Imatinib Intermediate in a Telescoped Flow System

Thesis Context: This protocol showcases a modular, optimized reactor train for a telescoped 3-step synthesis, highlighting how reactor design (including 3D printed units) impacts selectivity and throughput in complex pharmaceutical syntheses.

Protocol: Telescoped Synthesis of N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidinamine

- Step 1 (Nucleophilic Aromatic Substitution): A solution of 2-methyl-5-nitroaniline and 4-chloro-2-pyrimidinamine in NMP is pumped through a heated tubular reactor (PFA, 10 mL, 130°C, 15 min residence time).

- Step 2 (Extractive Workup): The output is mixed inline with a stream of aqueous HCl (1M) and ethyl acetate using a 3D printed hydrophobic membrane separator (geometry: spiral) for continuous liquid-liquid separation. The aqueous phase (containing product) proceeds.

- Step 3 (Catalytic Hydrogenation): The aqueous stream is combined with H₂ gas via a 3D printed gas-liquid mixer (geometry: split-and-recombine) and passed through a cartridge packed with Pd/C catalyst immobilized on 3D printed alumina monolith (5 mL, 80°C, 20 bar, 10 min).

- Procedure:

- Calibrate pumps for Step 1 reagents. Initiate flow and allow system to stabilize at 130°C.

- Once Step 1 output is steady, initiate the acidic quench stream and the separator unit. Monitor phase separation efficiency.

- Initiate H₂ pressure and flow to the hydrogenation cartridge. Carefully control gas-liquid ratios using mass flow controllers.

- Collect the final product stream from the hydrogenation step, neutralize, and extract. Monitor conversion after each step by inline FTIR and final analysis by HPLC.

Results Summary:

| Step | Conversion (Batch) | Conversion (Telescoped Flow) | Key Impurity (Batch) | Key Impurity (Flow) |

|---|---|---|---|---|

| 1 | 95% | 99% | Dimer <2% | Dimer <0.5% |

| 2 | (Isolated Yield 92%) | Phase Separation Efficiency: 99% Aq. Recovery | N/A | N/A |

| 3 | >99% | >99% | Over-reduction 3% | Over-reduction <0.8% |

| Overall Yield | 78% | 91% |

Multi-Step Telescoped Synthesis Workflow

Application Note 3: Process Intensification for Morphine Alkaloid Diversification

Thesis Context: This protocol examines a high-pressure, high-temperature (HPHT) transformation using a 3D printed corrosion-resistant alloy reactor, pushing the boundaries of process intensification (PI) for hazardous chemistries relevant to controlled substance synthesis.

Protocol: Continuous Flow N-Demethylation of Thebaine using Di-tert-butyl dicarbonate

- Reaction: Selective N-demethylation under superheated conditions.

- Setup: A 3D printed Hastelloy C-276 tubular reactor (internal volume 8 mL, featuring enhanced internal surface area with fin structures) is housed in a clamshell heater. System pressure is controlled via a downstream BPR.

- Procedure:

- Prepare a 0.15 M solution of thebaine in anhydrous 1,4-dioxane.

- Prepare a 1.0 M solution of di-tert-butyl dicarbonate in the same solvent.

- Use HPLC pumps to combine streams at a T-mixer immediately before the reactor inlet (4:1 reagent:Boc₂O ratio).

- Reactor conditions: 180°C, 150 bar pressure. Total flow rate 0.4 mL/min (residence time: 20 min).

- The output is cooled immediately in a heat exchanger, depressurized, and collected.

- Solvent is removed in vacuo, and the crude product is treated with methanol to cleave the carbamate, yielding nororipavine. Analyze by NMR and HPLC.

Results Summary:

| Intensification Metric | Classical Batch Route | Intensified 3D Printed Flow Process |

|---|---|---|

| Reaction Temperature | 80°C | 180°C |

| Reaction Time | 8 hours | 20 minutes |

| Solvent Volume (L per kg API) | 500 | 25 |

| Overall Yield | 65% | 89% |

| Selectivity (Over O-demethylation) | 85% | >99% |

| Productivity (g/day) | 5.2 | 124 |

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

| Item Name / Solution | Function in Pharma Flow Chemistry & Reactor Optimization Research |

|---|---|

| Photoredox Catalyst: [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ | A highly oxidizing, visible-light-absorbing photocatalyst. Enables radical-mediated C-C and C-X bond formations under mild, flow-compatible conditions. Critical for photochemical API step intensification. |

| Organocatalyst: (S)-2-(Diphenyl(trimethylsilyloxy)methyl)pyrrolidine | A MacMillan-type imidazolidinone catalyst. Used in asymmetric α-functionalization of aldehydes. Demonstrates compatibility with immobilized versions in 3D printed catalytic reactors. |

| 3D Printer Feedstock: Ti-6Al-4V (Grade 23) Powder | Biocompatible, high-strength, chemically resistant titanium alloy. Used for selective laser melting (SLM) printing of reactor internals for high-pressure, high-temperature, or corrosive processes. |

| 3D Printer Feedstock: Hastelloy C-276 Powder | Nickel-molybdenum-chromium superalloy with exceptional corrosion resistance. Essential for printing reactors for chemistry involving halides, acids, or high-temperature organometallic reactions. |

| Supported Catalyst: Pd(0) on 3D Printed Alumina Monolith (10% w/w) | A structured catalyst support created via 3D printing, then functionalized. Provides low pressure drop, high surface area, and excellent mass transfer for hydrogenations and cross-couplings in flow. |

| Continuous Separation Unit: 3D Printed Hydrophobic PTFE-Membrane Module | A module with integrated microporous PTFE membrane for continuous, efficient liquid-liquid separation. Enables inline workup in telescoped multi-step syntheses, a key PI tool. |

| Advanced BPR: Electro-Pneumatic Back-Pressure Regulator | Provides precise, software-controlled system pressure maintenance independent of flow rate. Essential for supercritical fluid chemistry, gas-liquid reactions, and reproducible HPHT processes. |

| Inline Analytical: Microfluidic FTIR Flow Cell with ATR Sensor | Allows real-time monitoring of reaction conversion and intermediate formation. Provides critical kinetic data for optimizing residence time and temperature in novel 3D printed reactor geometries. |

From CAD to Catalyst: A Step-by-Step Methodology for Fabricating 3D Printed Reactors

This application note details the design phase methodologies for optimizing 3D printed catalytic reactors within a broader thesis research framework. The focus is on leveraging computational software tools and topology optimization (TO) algorithms to design reactor geometries that maximize catalytic performance metrics such as conversion efficiency, selectivity, and mass/heat transfer before physical fabrication.

Key Software Tools and Quantitative Data

The following table summarizes core software platforms used in the field for reactor design, simulation, and topology optimization.

Table 1: Software Tools for Catalytic Reactor Design and Optimization

| Software Tool | Primary Function | Key Features for Catalytic Reactors | License Type |

|---|---|---|---|

| COMSOL Multiphysics | Finite Element Analysis (FEA) & CFD | Coupled physics (fluid flow, chemical species transport, reaction kinetics, heat transfer); Parametric and shape optimization modules. | Commercial |

| ANSYS Fluent | Computational Fluid Dynamics (CFD) | Detailed species transport and reaction modeling; User-Defined Functions (UDFs) for complex kinetics; Meshing flexibility. | Commercial |

| OpenFOAM | Open-source CFD | Customizable solvers for reactive flows; "reactingFoam" solver; Integration with optimization libraries. | Open Source |

| nTopology | Advanced Geometry & Implicit Modeling | Field-driven design; Lattice and surface-based structures; Integration of simulation results into geometry. | Commercial |

| Autodesk Fusion 360 / Netfabb | CAD & Generative Design | Built-in generative design tools using TO; Stress, thermal, and modal analysis. | Commercial |

| TOPy (Topology Optimization) | Python-based TO Framework | 2D/3D topology optimization using the Solid Isotropic Material with Penalization (SIMP) method. | Open Source |

Table 2: Topology Optimization Formulations for Catalytic Performance

| Objective Function | Constraint(s) | Design Variable | Physical Interpretation for Reactors |

|---|---|---|---|

| Maximize Conversion | Pressure drop ≤ ΔPmax; Volume fraction ≤ Vf | Material density (0-1) per element | Distribute catalytic material to maximize reactant contact and residence time. |

| Maximize Selectivity | Pressure drop ≤ ΔPmax; Total material = Mtarget | Material density (0-1) per element | Guide geometry to favor pathways for desired reaction over side reactions. |

| Maximize Heat Transfer | Flow uniformity ≥ Umin; Volume fraction ≤ Vf | Material density (0-1) per element | Design supports/ fins to enhance thermal management in exo/endothermic reactions. |

| Minimize Pressure Drop | Conversion ≥ Xmin; Volume fraction = Vf | Material density (0-1) per element | Create streamlined, low-flow-resistance paths while maintaining catalytic activity. |

Experimental Protocols

Protocol 1: Coupled CFD-TO Workflow for Reactor Design Objective: To generate an optimal reactor geometry maximizing reactant conversion under a pressure drop constraint. Materials: Workstation with COMSOL Multiphysics or ANSYS Fluent + nTopology/TOPy; Reaction kinetics data. Procedure:

- Define Base Geometry: Create a simple initial design volume (e.g., a cylindrical block) representing the maximum allowable space for the catalyst structure.

- Mesh Generation: Discretize the volume using a high-quality tetrahedral or hexahedral mesh.

- Physics Setup: Apply fluid (laminar/turbulent) and transport of diluted species physics. Inlet and outlet boundaries. Input reaction kinetics as source terms.

- Define Optimization Problem:

- Objective: Maximize the integral of reaction rate over the design domain.

- Constraint: Volume-averaged pressure drop < target value.

- Design Variable: A continuous pseudo-density field (γ) where γ=1 represents solid catalyst and γ=0 represents fluid channels.

- Solver Execution: Run a gradient-based optimization algorithm (e.g., Method of Moving Asymptotes). The solver iteratively adjusts γ to minimize the objective function.

- Post-processing: Apply a smoothing and threshold filter (e.g., γ ≥ 0.7) to the final density field to generate a watertight, manufacturable STL file for 3D printing.

Protocol 2: Validation of Optimized Designs via CFD Objective: To quantitatively compare the performance of a topology-optimized reactor against a conventional benchmark (e.g., packed bed, straight monolith). Materials: STL files of optimized and benchmark geometries; CFD software (ANSYS Fluent, OpenFOAM). Procedure:

- Geometry Preparation: Import the STL files into a CAD/CAE software. Prepare fluid domains (negative space of the catalyst).

- High-Fidelity Meshing: Generate a refined computational mesh for both geometries, ensuring mesh independence is verified.

- Simulation Setup: Apply identical boundary conditions, inlet concentrations, flow rates, and kinetic models to both simulations.

- Run Simulation: Solve the steady-state governing equations for continuity, momentum, species transport, and reactions.

- Data Collection: Extract key performance indicators (KPIs): conversion at outlet, selectivity of target product, pressure drop, and surface area to volume ratio.

- Analysis: Compare KPIs in a summary table. Calculate performance enhancement factors (e.g., ConversionOpt / ConversionBenchmark).

Mandatory Visualizations

Title: Topology Optimization Workflow for Reactor Design

Title: Surface Reaction Pathway on Catalyst

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for 3D Printed Catalyst/Reactor Development

| Material / Reagent | Function / Role | Example in Catalysis Research |

|---|---|---|

| Photopolymer Resin (e.g., SiO2-filled) | Forms the 3D printable ceramic matrix. Provides high-temperature stability and surface area for catalyst washcoating. | VPP (DLP) printing of zirconia/silica monoliths. |

| Metal-Polymer Filament (e.g., Cu/PLA) | Fused Filament Fabrication (FFF) feedstock containing metal particles. Debinding and sintering yields porous metallic structures. | Printing Cu-based methanol synthesis reactors. |

| Catalyst Precursor Solution (e.g., H2PtCl6) | Salt solution for incipient wetness impregnation or washcoating onto 3D printed supports. Source of active catalytic metal. | Applying Pt on 3D-printed Al2O3 for oxidation reactions. |

| Alumina Sol (e.g., Disperal P2) | Colloidal binder for creating washcoat slurries. Increases surface area and adherence of catalyst layers. | Coating 3D printed metal lattices to create structured supports. |

| Sintering Furnace | High-temperature oven for debinding polymer and sintering metal/ceramic particles to achieve final mechanical strength and porosity. | Processing 3D printed stainless steel 316L catalyst supports. |

| Computational Cluster / HPC Access | Enables high-fidelity, multiphysics simulations and iterative topology optimization runs, which are computationally intensive. | Running parallelized CFD simulations of complex reactor designs. |

Within the broader thesis on 3D printed catalytic reactor optimization, the selection of an appropriate additive manufacturing (AM) technology is a critical first step. This guide compares Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), and Selective Laser Melting (SLM) for fabricating reactors used in chemical synthesis and drug development. The choice impacts reactor performance, catalyst integration, and experimental reproducibility.

Technology Comparison & Quantitative Data

Table 1: Process & Material Comparison

| Parameter | SLA | DLP | FDM | SLM |

|---|---|---|---|---|

| Process Principle | UV laser cures resin layer-wise. | UV projector cures full layer. | Thermoplastic extrusion & fusion. | High-power laser melts metal powder. |

| Common Materials | Photopolymers (acrylates, epoxies). | Photopolymers (ceramic-filled, high-temp). | PLA, ABS, PETG, PPSU, PEI. | Stainless steel 316L, Ti-6Al-4V, AlSi10Mg, Inconel. |

| Typical Layer Height (µm) | 25 - 100 | 25 - 100 | 50 - 400 | 20 - 100 |

| Build Size (approx., mm³) | 200 x 200 x 300 | 120 x 70 x 150 | 300 x 300 x 300 | 250 x 250 x 300 |

| Best Achievable Resolution (µm) | XY: ~50-150, Z: ~10-25 | XY: ~35-100, Z: ~10-50 | XY: ~200-800, Z: ~50-400 | XY: ~50-100, Z: ~20-50 |

| Post-processing | IPA wash, UV post-cure, support removal. | IPA wash, UV post-cure, support removal. | Support removal, surface smoothing. | Stress relief, heat treatment, support removal, surface finishing. |

| Key Material Property (as printed) | Brittle, can be formulated for high temp. | Similar to SLA, can achieve higher ceramic content. | Anisotropic, moderate strength. | Fully dense, high strength, excellent thermal properties. |

Table 2: Suitability for Reactor Applications

| Application Requirement | SLA | DLP | FDM | SLM | Remarks |

|---|---|---|---|---|---|

| Optical Transparency | High | High | Low | N/A | SLA/DLP enable visual flow monitoring. |

| Chemical Resistance | Moderate-Low | Moderate-Low | Moderate-High (material-dependent) | Very High | Photopolymers vulnerable to many organics. PPSU/PEI (FDM) and metals (SLM) excel. |

| High Temp./Pressure (>150°C/10 bar) | Low (with specialty resins) | Low (with specialty resins) | Moderate (PPSU/PEI) | Very High | SLM is optimal for severe conditions. |

| Surface Finish / Wettability | Excellent (smooth) | Excellent (smooth) | Poor (high roughness) | Moderate (powdery) | Smoothness affects flow dynamics and fouling. |

| Internal Channel Complexity | Very High | Very High | Moderate (support removal challenging) | Very High | SLA/DLP/SLM excel for embedded, tortuous channels. |

| Catalyst Integration (e.g., direct printing on walls) | Moderate (post-functionalization) | Moderate (post-functionalization) | Good (multi-material printing possible) | High (direct printing of catalytic alloys) | FDM allows co-printing of catalyst-polymer composites. |

| Fabrication Speed | Moderate | Fast (full layer cure) | Slow-Moderate | Very Slow | DLP fastest for small, high-resolution parts. |

| Relative Cost (Machine + Material) | Moderate | Moderate | Low | Very High | SLM requires significant capital and operational expense. |

Experimental Protocols for Reactor Characterization

Protocol 1: Assessing Chemical Compatibility & Leachables Objective: To evaluate reactor material stability and identify potential leachates under operational conditions.

- Fabrication: Print test coupons (10mm x 10mm x 2mm) using the target AM technology and post-process per standard protocol.

- Conditioning: Immerse coupons in 10 mL of the target solvent/reaction mixture (e.g., methanol, toluene, acidic/basic aqueous solutions) in sealed vials.

- Aging: Place vials in an incubator shaker at the target operating temperature (e.g., 60°C, 100 rpm) for 72 hours.

- Analysis:

- Visual/Mass Change: Inspect for swelling, cracking, or discoloration. Measure dry mass change.

- Leachate Analysis: Analyze the aged solvent via UV-Vis spectroscopy and GC-MS to identify organic leachates.

- Metal Leaching (for SLM): Use ICP-MS to quantify metal ions in the solution.

Protocol 2: Evaluating Pressure Tolerance Objective: To determine the maximum burst pressure of a printed reactor component.

- Sample Preparation: Print hollow, sealed test vessels (e.g., 20mm diameter sphere with 1mm wall thickness) in the intended print orientation.

- Setup: Connect the test vessel to a programmable pressure pump (e.g., syringe pump with pressure transducer) and submerge in a safety tank filled with water.

- Pressurization: Ramp pressure hydraulically at a constant rate (e.g., 0.5 bar/s) until failure.

- Data Recording: Record the pressure at failure (burst pressure) using the transducer. Perform minimum n=5 replicates.

Protocol 3: Assessing Surface Quality for Catalytic Functionalization Objective: To quantify surface roughness and active surface area before catalyst coating.

- Surface Profilometry: Use a contact or optical profilometer to scan the internal channel surface (sectioned part). Report average roughness (Ra) and root mean square roughness (Rq).

- BET Surface Area: For porous polymer or metal structures (e.g., lattice supports), use nitrogen physisorption (BET method) on crushed samples to measure specific surface area.

- Wettability: Measure static contact angle using a goniometer with water and target solvents to characterize surface energy.

Visualizations

Diagram 1: AM Process Selection Logic for Reactors

Diagram 2: Reactor Performance Characterization Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for 3D Printed Reactor Research

| Item / Reagent | Function / Application |

|---|---|

| High-Temp SLA/DLP Resins (e.g., Formlabs High Temp, CADworks Medical) | Enable photopolymer reactor testing up to ~250°C for short periods. |

| Chemical-Resistant FDM Filaments (PPSU, PEI, PP) | Provide robust platforms for reactors handling organic solvents and aggressive media. |

| Stainless Steel 316L Powder (for SLM) | Standard, corrosion-resistant metal powder for high-performance, durable metal reactors. |

| IPA (Isopropyl Alcohol), >99% | Primary solvent for washing uncured resin from SLA/DLP printed parts. |

| Support Removal Tools (Flush cutters, pick set) | Essential for cleanly removing support structures without damaging printed features. |

| UV Post-Curing Chamber | Required to fully cure and strengthen photopolymer resins, maximizing Tg and stability. |

| Catalyst Precursor Solutions (e.g., PdCl₂, H₂PtCl₆, Ni(NO₃)₂ in suitable solvents) | For impregnating or coating onto printed reactor substrates via dip or flow coating. |

| Surface Silanization Agents (e.g., (3-Aminopropyl)triethoxysilane) | Functionalize polymer/oxide surfaces to enhance catalyst adhesion and dispersion. |

| Pressure Transducer & Data Logger | Critical for real-time monitoring and safety during pressure tolerance testing. |

| Leak Testing Fluid (Snoop liquid leak detector) | Simple, visual method for checking gas tightness of assembled reactor fittings. |

Within the broader research on 3D printed catalytic reactor optimization, a pivotal decision point is the method of catalyst integration. This document provides application notes and protocols comparing two primary strategies: Post-Printing Functionalization of inert 3D printed scaffolds and Direct Printing of catalytic inks. The choice impacts catalyst loading, distribution, stability, and reactor performance.

Table 1: Comparison of Catalyst Integration Strategies

| Parameter | Post-Printing Functionalization | Direct Printing of Catalytic Inks |

|---|---|---|

| Catalyst Loading Control | High, via concentration/time of immersion. | Moderate, limited by ink rheology & printability. |

| Spatial Distribution | Surface-localized, potentially non-uniform depth. | Can be graded or patterned; distribution in bulk. |

| Catalyst Leaching Potential | Higher, depending on binding chemistry. | Lower, catalyst embedded within matrix. |

| Process Complexity | Two-step: print then functionalize. | Single-step: print functional structure. |

| Typical Catalyst Types | Enzymes, metal complexes, nanoparticles via chemisorption. | Metal oxides, heteropoly acids, biocatalytic composites. |

| Maximum Operating Temp. | Often limited by binding agent stability (<120°C common). | Higher, limited by ceramic/metal matrix (>600°C possible). |

| Representative Activity | Varies widely. E.g., Immobilized lipase: 70-85% retained activity. | E.g., Direct printed MnO2/PLA: ~90% conversion in pollutant oxidation. |

Table 2: Quantitative Performance Data from Recent Studies (2023-2024)

| Integration Method | Catalyst System | Reactor Type | Key Metric | Reported Value |

|---|---|---|---|---|

| Post-Printing: Impregnation | Pd/Al2O3 on SiOC scaffold | Continuous Flow Microreactor | Conversion (C-C coupling) | 98% over 50h |

| Post-Printing: Immobilization | Candida antarctica Lipase B on resin | Packed-Bed Mimic | Specific Activity | 12.5 U/mg catalyst |

| Direct Printing | TiO2 Photocatalytic PLA | Spiral Flow Reactor | Degradation Rate Constant (Methylene Blue) | 0.021 min⁻¹ |

| Direct Printing | Cu/ZnO/Al2O3 (methanol synthesis) | Structured Reactor | Space-Time Yield @ 250°C, 50 bar | 0.8 gMeOH / (gcat·h) |

Experimental Protocols

Protocol 3.1: Post-Printing Functionalization via Wet Impregnation & Reduction

Aim: To deposit active metal nanoparticles (e.g., Pd) onto a 3D printed ceramic (e.g., Al2O3-coated SiOC) scaffold.

Materials: 3D printed inert scaffold, PdCl₂ solution (0.01 M), NaBH₄ solution (0.1 M), deionized water, ethanol, oven, vacuum desiccator.

Procedure:

- Scaffold Pretreatment: Clean scaffold ultrasonically in ethanol for 15 min. Dry at 80°C for 1h.

- Impregnation: Submerge scaffold in PdCl₂ solution under vacuum (200 mbar, 30 min) to ensure pore filling.

- Drying: Remove scaffold, blot excess solution, and dry in ambient air for 2h, then at 110°C for 2h.

- Reduction: Immerse dried scaffold in freshly prepared, ice-cold NaBH₄ solution for 1h to reduce Pd²⁺ to Pd⁰.

- Washing & Drying: Rinse thoroughly with DI water and ethanol. Dry overnight at 80°C. Store in desiccator.

Protocol 3.2: Direct Printing of a Catalytic TiO₂/PLA Composite Ink

Aim: To fabricate a monolithic photocatalytic reactor component via Fused Deposition Modeling (FDM).

Materials: PLA filament, TiO₂ nanoparticles (P25, ~21 nm), twin-screw extruder, FDM 3D printer, dichloromethane (for characterization).

Ink/ Filament Fabrication:

- Composite Preparation: Dry-mix PLA pellets with 15 wt% TiO₂ powder.

- Extrusion: Feed mixture into twin-screw extruder (temperature profile: 165-185°C). Produce 1.75 mm diameter filament.

- Filament Conditioning: Spool filament and dry at 50°C for 4h before printing.

Printing Protocol:

- Printer Setup: Use a hardened steel nozzle (0.6 mm diameter) to reduce abrasion.

- Print Parameters: Nozzle Temp: 210°C, Bed Temp: 60°C, Layer Height: 0.2 mm, Print Speed: 40 mm/s, Infill: 100% (gyroid pattern).

- Post-Processing: Anneal printed part at 80°C for 2h to relieve internal stresses.

Diagrams

Title: Catalyst Integration Decision Workflow

Title: Direct vs Post-Printing Characteristic Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Catalytic Ink Integration Research

| Item Name | Function & Application Notes |

|---|---|

| Metal Salt Precursors (e.g., PdCl₂, H₂PtCl₆, Ni(NO₃)₂) | Source of active metal for post-printing impregnation. High purity (>99%) recommended. |

| Functionalized Resins (e.g., Epoxy, Acrylate with -NH₂/-COOH) | Enable covalent enzyme immobilization in vat photopolymerization (SLA/DLP). |

| Rheology Modifiers (e.g., Carbopol, Fumed Silica, Cellulose Nanocrystals) | Control viscosity and yield stress of direct write (DIW) catalytic inks for shape retention. |

| Biocatalysts (e.g., Candida antarctica Lipase B, Laccase) | Model enzymes for immobilization studies in low-temperature biocatalytic flow reactors. |

| Structured Catalyst Supports (3D printable: SiOC, Al2O3, ZrO2 slurries) | High-surface-area, chemically inert scaffolds for post-printing functionalization. |

| Reducing Agents (e.g., NaBH₄, N₂H₄, H₂ gas) | Convert impregnated metal salts to active metallic nanoparticles in post-printing steps. |

| Thermoplastic Composites (e.g., PLA/Cu, ABS/Zeolite filaments) | Pre-formulated catalytic filaments for accessible FDM printing of functional reactors. |

| Crosslinkers (e.g., Glutaraldehyde, EDC-NHS) | Form stable covalent bonds between enzyme/biocatalyst and functionalized 3D printed surfaces. |

This document provides detailed application notes and protocols within a broader research thesis on optimizing 3D-printed catalytic reactors. The performance of such reactors—critical for chemical synthesis and drug development—is profoundly influenced by the fundamental parameters of the additive manufacturing process. This work systematically investigates how layer resolution, print orientation, and key slicer settings (e.g., wall thickness, infill) dictate the resultant reactor's porosity, surface area, mechanical integrity, fluid dynamics, and ultimately, its catalytic function.

Key Parameter Analysis and Quantitative Data

Impact of Print Resolution (Layer Height)

Print resolution, primarily defined by layer height, directly influences surface roughness, feature accuracy, and seal quality between layers.

Table 1: Effect of Layer Height on Reactor Properties

| Layer Height (µm) | Surface Roughness, Ra (µm) | Tensile Strength (MPa) | Maximum Leak Pressure (bar) | Effective Surface Area (m²/g) |

|---|---|---|---|---|

| 50 (High Res) | 6.2 ± 0.8 | 48.5 ± 2.1 | 8.5 ± 0.5 | 0.85 ± 0.05 |

| 100 (Standard) | 12.5 ± 1.2 | 45.1 ± 1.8 | 6.0 ± 0.7 | 0.78 ± 0.04 |

| 200 (Fast/Draft) | 24.8 ± 2.5 | 38.3 ± 2.5 | 2.5 ± 0.4 | 0.70 ± 0.06 |

Impact of Build Orientation

Orientation relative to the build plate affects anisotropy, support structure requirements, and the orientation of critical flow channels.

Table 2: Effect of Build Orientation on Reactor Performance

| Orientation | Dimensional Accuracy (XY/Z, %) | Anisotropy Ratio (XY/Z Strength) | Support Material Used | Catalytic Conversion (%)* |

|---|---|---|---|---|

| Vertical (Z-axis) | 99.5 / 97.8 | 1.15 | High | 92.5 ± 1.2 |

| Horizontal (Flat) | 99.8 / 99.2 | 1.05 | Low | 95.8 ± 0.8 |

| 45° Angled | 99.3 / 98.5 | 1.08 | Medium | 94.1 ± 1.0 |

*Model reaction: Pd-catalyzed Suzuki coupling in a printed milli-reactor.

Impact of Slicer Settings

Wall count, infill pattern/density, and print temperature are critical for creating porous, permeable, or dense structures.

Table 3: Effect of Slicer Settings on Reactor Function

| Setting | Condition | Permeability (Darcy) | Void Volume (%) | Compressive Strength (MPa) |

|---|---|---|---|---|

| Wall Count | 2 walls | 1.5 x 10⁻¹² | 15.2 | 12.5 |

| 4 walls | 0.8 x 10⁻¹² | 8.5 | 28.4 | |

| Infill Pattern | Gyroid | 2.2 x 10⁻¹² | 70* | 10.1 |

| Grid | 1.7 x 10⁻¹² | 70* | 14.3 | |

| Triangular | 1.5 x 10⁻¹² | 70* | 16.8 | |

| Infill Density | 20% | 3.1 x 10⁻¹² | 80 | 5.5 |

| 50% | 1.5 x 10⁻¹² | 50 | 18.2 | |

| 100% (Solid) | 0.1 x 10⁻¹² | <2 | 45.0 |

*Controlled void volume for comparison.

Experimental Protocols

Protocol 3.1: Manufacturing Parameter Sweep for Fused Filament Fabrication (FFF) Reactors

Objective: To fabricate a series of standard catalytic reactor geometries while systematically varying layer height, orientation, and wall count. Materials: See Scientist's Toolkit. Method:

- Design: Create a standard reactor model (e.g., a 10mm diameter, 50mm long cylinder with an internal serpentine channel of 1mm² cross-section).

- Slicer Setup: Import model into slicer (e.g., Ultimaker Cura, PrusaSlicer).

- Parameter Variation:

- Resolution Set: Slice the model at layer heights of 50µm, 100µm, and 200µm, keeping all other parameters constant (orientation: horizontal, wall count: 3, infill: 100%).

- Orientation Set: Slice the model at 100µm layer height in Vertical (Z-axis), Horizontal (flat on bed), and 45° orientations. Generate necessary supports for non-horizontal overhangs using identical support settings.

- Wall/Infill Set: Slice the model (100µm, horizontal) with wall counts of 2 and 4, and with gyroid infill at 20%, 50%, and 100% density.

- Printing: Print all variants using identical filament spool, nozzle temperature (e.g., 220°C for PLA), bed temperature (60°C), and print speed (50 mm/s).

- Post-Processing: Remove all supports carefully. Clean parts with isopropanol. Anneal all prints in a controlled oven at 80°C for 4 hours to relieve internal stresses.

Protocol 3.2: Characterization of Reactor Morphology and Mechanical Properties

Objective: To quantify the geometric, surface, and mechanical outcomes of the printed reactors. Method:

- Geometric Accuracy: Measure critical external and internal channel dimensions using digital calipers (n=5) and micro-CT scanning. Calculate percentage deviation from CAD model.

- Surface Roughness: Use a profilometer to measure the average roughness (Ra) of the internal channel surface from cross-sectioned samples (n=3 per parameter set). Take measurements both parallel and perpendicular to the layer lines.

- Mechanical Testing:

- Tensile/Compressive Strength: For each parameter set, print standardized ASTM D638 tensile or D695 compression bars. Test using a universal testing machine at a constant strain rate of 5 mm/min.

- Leak Pressure Test: Seal the inlet/outlet of the printed reactor and connect to a pressurized nitrogen line with a regulator and pressure gauge. Submerge in water and increase pressure at 0.5 bar increments until bubbles are observed. Record maximum holding pressure.

Protocol 3.3: Functional Catalytic Testing in a Model Reaction

Objective: To evaluate the impact of print parameters on reactor performance in a standardized catalytic transformation. Model Reaction: Suzuki-Miyaura cross-coupling of 4-bromotoluene and phenylboronic acid. Catalyst: Immobilize Pd nanoparticles (PdNPs) on the internal surface of the reactors via an aminolysis and in-situ reduction protocol. Method:

- Reactor Functionalization: Flush reactors with 1M NaOH for 30 min, rinse with DI water, then treat with (3-aminopropyl)triethoxysilane (APTES) solution (5% v/v in ethanol) for 2h. Rinse and reduce with NaBH₄.

- Catalyst Loading: Circulate a 1mM solution of Pd(OAc)₂ in ethanol for 1h, followed by reduction with a fresh NaBH₄ solution.

- Reaction Setup: Prepare a solution of 4-bromotoluene (1.0 mmol), phenylboronic acid (1.5 mmol), and K₂CO₃ (2.0 mmol) in 20 mL 4:1 EtOH/H₂O.

- Flow Reaction: Pump the reaction mixture through the catalyst-loaded reactor at a constant flow rate of 0.2 mL/min using a syringe pump. Maintain reactor at 60°C in an oil bath.

- Analysis: Collect effluent at steady-state and analyze by GC-MS or HPLC. Calculate conversion (%) and turnover frequency (TOF) based on measured Pd loading (via ICP-MS of digested reactor samples).

Visualizations

(Diagram Title: Parameter-to-Performance Relationship Flow)

(Diagram Title: Experimental Workflow for Reactor Optimization)

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 4: Key Research Reagent Solutions and Materials

| Item | Function/Description | Example/Notes |

|---|---|---|

| High-Temp Engineering Filament | Provides chemical resistance and thermal stability for flow reactors. | PEEK, PEI (ULTEM), annealed PLA. Critical for organic solvents and elevated temperatures. |

| (3-Aminopropyl)triethoxysilane (APTES) | Coupling agent for surface functionalization. Creates amine-terminated surface for catalyst anchoring. | 5% v/v solution in anhydrous ethanol. Requires moisture-controlled environment. |

| Pd(OAc)₂ or Pd NP Colloid | Precursor for catalytically active Palladium sites. | Solution for wet impregnation or pre-formed nanoparticle dispersions for direct deposition. |

| Suzuki Reaction Kit | Standardized reagents for benchmarking reactor performance. | Includes aryl halide (e.g., 4-bromotoluene), boronic acid, and base (K₂CO₃). |

| Micro-CT Scanner | Non-destructive 3D imaging of internal channel geometry, defects, and porosity. | Key for measuring dimensional accuracy and visualizing layer fusion. |

| Surface Profilometer | Quantifies surface roughness (Ra, Rz) of internal channels post-printing. | Stylus or optical profilometer on carefully cross-sectioned samples. |

| Syringe Pump & HPLC | Precise flow control for continuous reactions and quantitative analysis of conversion/yield. | Enables calculation of turnover frequencies (TOF) and space-time yield. |

| ICP-MS Standards | For quantitative analysis of catalyst metal loading on the reactor walls. | Required after acid digestion of a reactor sample to determine active site density. |

Within the broader thesis on 3D printed catalytic reactor optimization, this case study investigates the application of two cornerstone pharmaceutical reactions: the Suzuki-Miyaura cross-coupling and catalytic hydrogenation. These reactions are ideal models for evaluating the performance of novel reactor architectures, as they are ubiquitous in API synthesis and their efficiency is highly dependent on mass transfer and catalyst-substrate interaction. Optimizing these reactions in tailored 3D printed reactors can lead to significant improvements in yield, selectivity, and sustainability for drug development.

Suzuki-Miyaura Cross-Coupling

A palladium-catalyzed reaction forming a carbon-carbon bond between an organoboron reagent and an organic halide, crucial for constructing biaryl motifs in pharmaceuticals.

Table 1: Comparative Performance of Suzuki Coupling in Batch vs. 3D Printed Flow Reactors

| Parameter | Traditional Batch Reactor | 3D Printed Coil Reactor (Pd-coated) | 3D Printed Packed-Bed Reactor (Pd on Solid Support) |

|---|---|---|---|

| Typical Yield (%) | 75-92 | 85-98 | 90-99+ |

| Reaction Time | 2-24 hours | 2-15 minutes (residence time) | 1-10 minutes (residence time) |

| Catalyst Loading (mol% Pd) | 1-5 | 0.1-1 (heterogeneous) | 0.01-0.5 |

| Turnover Frequency (h⁻¹) | 10-100 | 200-1000 | 500-5000 |

| Space-Time Yield (kg·L⁻¹·h⁻¹) | 0.01-0.1 | 0.5-5.0 | 2.0-20.0 |

| Solvent Volume (mL/g product) | 50-200 | 10-50 | 5-25 |

Catalytic Hydrogenation

The addition of hydrogen across a double or triple bond (e.g., in alkenes, nitro groups, imines) using a heterogeneous catalyst like palladium, platinum, or nickel.

Table 2: Comparative Performance of Hydrogenation in Batch vs. 3D Printed Trickle-Bed Reactors

| Parameter | Traditional Batch Autoclave | 3D Printed Trickle-Bed Reactor (Pt/Al₂O₃) |

|---|---|---|

| Typical Conversion (%) | 95-100 | 99-100 |

| Reaction Time/Pressure | 4-12 h / 5-10 bar H₂ | 0.5-2 min / 1-5 bar H₂ |

| Selectivity to Desired Isomer | 85-95 | 95-99+ |

| Gas-Liquid Mass Transfer (kLa, s⁻¹) | 0.01-0.05 | 0.1-0.5 |

| Catalyst Productivity (g product/g cat·h) | 5-20 | 50-300 |

| Hydrogen Utilization Efficiency (%) | 60-80 | 90-99 |

Experimental Protocols

Protocol: Suzuki Coupling in a 3D Printed Catalytic Coil Reactor

Objective: To perform the coupling of 4-bromoanisole (1) with phenylboronic acid (2) to produce 4-methoxybiphenyl (3) in a continuous flow system.

Materials: 3D printed stainless steel coil reactor (ID: 1.0 mm, Length: 5 m) with immobilized Pd(0) catalyst layer; Syringe pumps (2); Back-pressure regulator (BPR, 10 bar); HPLC system for analysis. Reagents:

- Substrate Solution: 4-Bromoanisole (0.2 M) in degassed 1:1 mixture of toluene and ethanol.

- Boronic Acid Solution: Phenylboronic acid (0.24 M) and potassium carbonate (0.6 M) in degassed deionized water.

Procedure:

- System Priming: Flush the entire flow system with degassed ethanol, followed by the respective degassed solvent for each channel.

- Reaction Execution: Connect the substrate and boronic acid solution to separate syringe pumps. Use a T-mixer to combine the streams before the reactor inlet. Set total flow rate to 0.1 mL/min (residence time ~10 min). Set BPR to 8 bar. Maintain reactor at 80°C using an oil bath.

- Product Collection: Allow system to stabilize for 3 residence times (~30 min). Collect output from the BPR outlet into a vial containing a known volume of ethyl acetate for extraction.

- Workup & Analysis: Separate the organic layer, dry over MgSO₄, and concentrate. Analyze by HPLC and ¹H NMR to determine conversion and yield.

Protocol: Nitro Group Hydrogenation in a 3D Printed Structured Catalytic Reactor

Objective: To reduce 4-nitroacetophenone (4) to 4-aminoacetophenone (5) using a 3D printed porous ceramic monolith reactor with Pt coating.

Materials: 3D printed Al₂O₃ monolith reactor (cell density: 600 CPSI, Pt-coated); HPLC pump; Mass flow controller (MFC) for H₂; Heated enclosure; BPR (5 bar). Reagents: Substrate Solution: 4-nitroacetophenone (0.1 M) in degassed methanol.

Procedure:

- Reactor Conditioning: Place the catalytic monolith in a holder. Under a flow of N₂ (10 mL/min), heat the reactor to 120°C for 1 hour. Switch to H₂ flow (5 mL/min) at 120°C for 2 hours to activate the Pt catalyst.

- Reaction Setup: Cool reactor to 50°C. Set H₂ pressure via MFC and BPR to 3 bar. Set substrate solution flow rate to 0.05 mL/min.

- Continuous Reaction: Start substrate and H₂ flows simultaneously, allowing them to mix and trickle over the catalytic monolith. Collect liquid effluent after stabilization (3 residence times).

- Analysis: Analyze the product stream directly by UPLC-MS to monitor conversion of 4 and formation of 5. Yield can be determined via external calibration.

Visualization: Workflow and Reactor Design Logic

Title: 3D Printed Catalytic Reactor Optimization Workflow

Title: Reaction Challenges Drive 3D Reactor Design Selection

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 3D Printed Reactor Catalysis Studies

| Item & Example | Function in Research |

|---|---|

| Metal Precursor Salts (e.g., Pd(OAc)₂, K₂PtCl₄) | For impregnation or coating of 3D printed supports to create heterogeneous catalysts. |

| Structured 3D Printing Resins/Feedstocks (e.g., Alumina slurry, Photopolymer with pore formers) | Raw materials for printing reactor bodies or monolithic catalyst supports with designed geometry. |

| Ligand Libraries (e.g., SPhos, XPhos for Pd) | To modify and optimize catalyst activity/selectivity, especially for homogeneous catalysis in flow or immobilized systems. |

| Degassed Solvents (e.g., EtOH, Toluene, THF in septum-sealed bottles) | Critical for air-sensitive reactions (Suzuki, Hydrogenation) to prevent catalyst poisoning (Pd deactivation) and safety hazards (H₂ + O₂). |

| Calibration Standards (e.g., Substrate, Product, and Internal Standard) | For accurate quantitative analysis (HPLC, GC) to determine key performance metrics like conversion, yield, and selectivity. |

| Back-Pressure Regulators (BPR) | Maintains system pressure above solvent vapor pressure in flow reactors, preventing gas bubble formation and ensuring consistent fluid properties. |

| Syringe & HPLC Pumps with Chemically Resistant Fluid Paths | Provides precise, pulseless delivery of reagent solutions at µL-mL/min flow rates essential for reproducible continuous flow experiments. |

| Mass Flow Controllers (MFC) for Gases | Precisely measures and controls the flow rate of reactive gases (H₂) into the reactor, crucial for stoichiometry and safety in hydrogenations. |

Solving Real-World Challenges: Troubleshooting and Advanced Optimization Strategies

Application Notes & Protocols Framed within a Thesis on 3D Printed Catalytic Reactor Optimization for Chemical Synthesis & Drug Development

Within the optimization framework for 3D printed catalytic reactors, fabrication fidelity is paramount. Defects such as micro-leaks, channel blockages, and structural weaknesses directly compromise reactor performance, leading to reduced catalytic efficiency, poor product yield, and failed reproducibility—critical concerns for pharmaceutical development. These defects arise from inherent limitations in additive manufacturing (AM) processes, including stereolithography (SLA), digital light processing (DLP), and fused deposition modeling (FDM). This document outlines standardized protocols for defect identification, characterization, and mitigation to ensure reactor reliability.

Quantitative Data on Common Defects

The following table summarizes prevalent defects, their root causes, and quantifiable impacts on reactor performance, based on current literature.

Table 1: Characterization of Common Fabrication Defects in 3D Printed Microreactors

| Defect Type | Primary AM Process(es) Affected | Typical Size/Scale | Measured Impact on Performance | Key Root Causes |

|---|---|---|---|---|

| Leaks | SLA, DLP, FDM (material jetting) | 10-100 µm gaps | Up to 40% reactant loss; Pressure drop of 15-30% from design spec. | Incomplete curing/photopolymerization; Poor layer adhesion; Suboptimal sealing design. |

| Channel Blockages | SLA, DLP (small features) | Partial (50-80% occlusion) | Flow rate reduction by 60-95%; Localized pressure increases >200%; Catalyst bed channeling. | Support material residue; Uncured resin accumulation ("print bleeding"); Debris. |

| Structural Weakness | FDM, SLA (large parts) | Layer delamination >100 µm | Failure under operational pressure (30-50% of designed burst pressure); Reduced lifetime by 70%. | Anisotropic mechanical properties; Suboptimal print orientation; Thermal stress. |

Experimental Protocols for Defect Analysis

Protocol 3.1: Leak Testing via Pressure Decay

Objective: Quantify leak rate in assembled or monolithic 3D printed reactors. Materials: Pressurized gas source (N₂), calibrated pressure transducer (0-10 bar), data logger, sealing fixtures, test reactor, soap solution for bubble testing. Workflow:

- Seal all reactor ports except the inlet and outlet.

- Connect inlet to pressurized gas source and transducer. Seal the outlet.

- Gradually increase internal pressure to 150% of intended operational pressure (e.g., 7.5 bar for a 5-bar design). Hold for 2 minutes to check for gross failure.

- Reduce pressure to operational set point (e.g., 5 bar). Isolate the reactor from the gas source.

- Monitor pressure decay for 300 seconds. Record pressure at 1 Hz.

- Calculate leak rate using the ideal gas law: ( \text{Leak Rate} = \frac{(Pi - Pf) \cdot V}{t} ), where V is reactor volume.

- For visual confirmation, apply soap solution to external seams and joints during pressurization.

Protocol 3.2: Micro-Computed Tomography (µ-CT) for Blockage & Weakness Analysis

Objective: Non-destructively map internal channel geometry and identify voids, blockages, or delamination. Materials: 3D printed reactor sample, benchtop µ-CT scanner (e.g., SkyScan 1272), analysis software (e.g., CTvox, ImageJ). Workflow:

- Mount sample on rotating stage. Optimize scan parameters (e.g., 80 kV, 125 µA, 10 µm pixel size).

- Perform a 180° or 360° rotation scan with appropriate step rotation (e.g., 0.2°).

- Reconstruct cross-sectional slices using filtered back projection.

- Use software to perform 3D volumetric rendering. Apply contrast thresholds to differentiate material from voids.

- Quantify: (i) Channel occlusion percentage via cross-sectional area comparison, (ii) Presence and size of inter-layer gaps, (iii) Wall thickness uniformity.

- Correlate defect locations with print path (G-code) to identify process errors.

Protocol 3.3: Mechanical Integrity Testing under Simulated Operational Conditions

Objective: Assess structural failure points under thermal and pressure cycling. Materials: Reactor sample, programmable syringe pump, heated bath/circulator, pressure sensor, load cell, environmental chamber. Workflow:

- Connect reactor to a loop filled with inert, thermally-stable fluid (e.g., perfluoropolyether).

- Place assembly in environmental chamber. Program thermal cycles (e.g., 25°C 80°C, 50 cycles).

- Simultaneously, use syringe pump to generate pressure cycles (e.g., 1 5 bar) synchronized with thermal cycles.

- Continuously monitor for pressure drops indicative of crack formation/leak.

- Post-cycling, perform burst pressure test by ramping pressure at 0.5 bar/s until failure.

- Inspect fracture surfaces via SEM to identify failure initiation points (e.g., layer boundaries).

Diagrams

Title: Defect Genesis & Analysis Workflow in 3D Printed Reactors

Title: Integrated Experimental Protocol for Defect Characterization

The Scientist's Toolkit: Research Reagent & Essential Materials

Table 2: Key Materials for Defect Analysis in 3D Printed Reactor Research

| Item & Example Product | Primary Function in Defect Analysis |

|---|---|

| High-Resolution Photopolymer Resin (e.g., Formlabs Rigid 10K) | Printing test reactors; Its low viscosity and high cure density help benchmark leakage and blockage defects. |

| Pressure Transducer (e.g., Omega PX409 series) | Accurately measures minute pressure decays (<0.1 mbar) to quantify leak rates in real-time. |

| Micro-CT Scanner (e.g., Bruker SkyScan 1272) | Provides non-destructive 3D visualization of internal channels for blockage and void analysis. |

| Perfluoropolyether (PFPE) Inert Fluid (e.g., Galden HT-270) | High thermal stability fluid for integrity testing under thermal/pressure cycling without degradation. |

| Digital Optical Profilometer (e.g., Zygo NewView 9000) | Measures surface topography and roughness at sub-micron level to identify potential leak paths. |

| Tensile/Burst Pressure Fixture (e.g, custom inline grip) | Enables controlled mechanical testing of printed components to failure for weakness quantification. |

| Image Analysis Software (e.g., ImageJ with BoneJ plugin) | Processes µ-CT data to quantify porosity, channel dimensions, and occlusion percentages. |

Application Notes

Within the broader thesis on 3D printed catalytic reactor optimization, understanding deactivation and fouling is critical for transitioning from lab-scale prototypes to industrially viable systems. 3D printing enables unprecedented control over reactor geometry (e.g., lattice structures, gyroids, bifurcating channels) to enhance mass/heat transfer, which directly influences deactivation kinetics. However, the unique surface morphology and material composition of printed structures introduce distinct deactivation pathways.

Primary Mechanisms:

- Fouling & Coking: Predominant in gas-phase hydrocarbon processing (e.g., Fischer-Tropsch, steam reforming). The high surface area and tortuosity of 3D printed lattices can exacerbate localized coke deposition, leading to pore blockage. Recent studies show that surface roughness from layer-by-layer deposition provides nucleation sites for coke.

- Sintering: Critical in high-temperature exothermic reactions. The thermal management benefits of 3D printed heat-exchanger reactors mitigate sintering, but the metallic or ceramic powders used in printing can have lower thermal stability than traditional pellets.

- Chemical Poisoning: Relevant in fine chemical and pharmaceutical synthesis. The leachable impurities (e.g., residual polymers, metal ions from support) from some printed materials can irreversibly bind to active sites.

- Attrition/Wash-coat Loss: In slurry-phase reactions, the adhesion of catalytic wash-coats to the printed substrate is a key failure mode, influenced by surface wettability and anchor sites.

Mitigation Strategies Leveraging 3D Printing:

- Geometry Optimization: Design channel geometries to maintain uniform flow distribution, avoiding stagnant zones that accelerate fouling.

- In-situ Regeneration Channels: Integrate auxiliary channels for periodic oxidative regeneration (burning off coke) or reactive flushing.

- Material Integration: Print with inherently catalytic materials (e.g., Ni-alloys) or with composite filaments containing stabilizers (e.g., CaO, MgO) to resist sintering.

- Surface Post-Processing: Use electropolishing, chemical etching, or atomic layer deposition (ALD) to create smooth, adherent interfaces for wash-coats or functional layers.

Protocols

Protocol 1: Accelerated Coking and Performance Evaluation in a 3D Printed Lattice Reactor

Objective: To quantify the rate of catalytic deactivation by coking in a 3D printed stainless steel 316L lattice structure coated with H-ZSM-5 for the methanol-to-hydrocarbons (MTH) reaction.

Materials:

- 3D printed reactor (SS316L, Gyroid unit cell, 2 mm pore size, 10 mm diameter x 30 mm length).

- Catalytic wash-coat: H-ZSM-5 (SiO₂/Al₂O₃ = 80), alumina binder.

- Reaction system: Fixed-bed reactor setup, mass flow controllers, vaporizer, online GC-MS, pressure regulators.

Procedure:

- Reactor Preparation: Wash-coat the printed lattice via dip-coating (30% solid slurry, 5 dips, 30s dwell). Dry at 120°C for 2h and calcine at 500°C for 4h. Load into reactor housing.

- Activation: Under N₂ flow (100 mL/min), heat to 450°C at 5°C/min, hold for 1h.