Precious vs. Non-Precious Metal Electrocatalysts: A Comparative Life Cycle Assessment (LCA) for Sustainable Biomedical Research

This article provides a comprehensive comparative Life Cycle Assessment (LCA) of precious metal (e.g., Pt, Ir, Ru) versus non-precious metal (e.g., Fe, Co, Ni, carbon-based) electrocatalysts, critical for applications like...

Precious vs. Non-Precious Metal Electrocatalysts: A Comparative Life Cycle Assessment (LCA) for Sustainable Biomedical Research

Abstract

This article provides a comprehensive comparative Life Cycle Assessment (LCA) of precious metal (e.g., Pt, Ir, Ru) versus non-precious metal (e.g., Fe, Co, Ni, carbon-based) electrocatalysts, critical for applications like biosensors and implantable devices. We explore the foundational environmental burdens of raw material extraction and processing, detail the methodologies for conducting a cradle-to-gate LCA in a research context, address common challenges in data collection and system boundary definition, and present a validated comparative analysis of key impact categories (e.g., global warming potential, resource scarcity, toxicity). Tailored for researchers and development professionals, this analysis aims to guide sustainable material selection and greener electrocatalyst design for biomedical innovation.

Understanding the Environmental Footprint: Mining the Data on Catalyst Raw Materials

This document provides application notes and protocols for research in electrocatalysis, framed within a Life Cycle Assessment (LCA) thesis comparing precious metal (PM) and earth-abundant (EA) catalysts. The focus is on two critical reactions: the Oxygen Reduction Reaction (ORR) for fuel cells and the Hydrogen Evolution Reaction (HER) for water electrolysis. Selection between PM (Pt, Ir, Au) and EA (Fe, Co, Ni, C) catalysts involves trade-offs between activity, stability, cost, and environmental impact, which are the core metrics of an LCA study.

Table 1: Benchmark Performance Metrics for Key Electrocatalytic Reactions

| Catalyst Class | Exemplary Material | Target Reaction | Key Metric (Performance) | Typical Stability (Cycles or Hours) | Approx. Price (USD/g, 2024) |

|---|---|---|---|---|---|

| Precious Metal | Pt/C (20% wt.) | ORR (Acidic) | Half-wave Potential (E1/2): ~0.85 V vs. RHE | 10k-30k cycles (10% activity loss) | 30 - 35 |

| Precious Metal | IrO₂ | OER (Acidic) | Overpotential @10 mA/cm² (η10): ~280 mV | <100 h (severe dissolution) | 150 - 170 |

| Precious Metal | Au nanoparticles | ORR (Alkaline) | Onset Potential: ~0.95 V vs. RHE | >5k cycles | 60 - 70 |

| Earth-Abundant | Fe-N-C | ORR (Acidic) | E1/2: ~0.80 V vs. RHE | <5k cycles (peroxide attack) | < 0.10* |

| Earth-Abundant | NiFe (oxy)hydroxide | OER (Alkaline) | η10: ~210 mV | >500 h | < 0.05* |

| Earth-Abundant | CoP nanoparticles | HER (Alkaline) | η10: ~90 mV | >100 h | < 0.20* |

| Earth-Abundant | N-doped Carbon Nanotubes | ORR (Alkaline) | E1/2: ~0.83 V vs. RHE | >10k cycles | < 0.50 |

Note: Material cost only; synthesis and processing add significant cost. OER = Oxygen Evolution Reaction. Price data sourced from recent metal commodity and chemical supplier platforms.

Table 2: LCA-Relevant Inventory Data for Catalyst Production (Per Gram of Active Catalyst)

| Process / Impact Category | Pt/C Catalyst (from ore) | Fe-N-C Catalyst (lab-scale) | Key Differentiating Factor |

|---|---|---|---|

| Estimated Energy Use (MJ/g) | 250 - 500 | 50 - 150 | PM mining, concentration, and refining are extremely energy-intensive. |

| Water Consumption (L/g) | 200 - 400 | 100 - 300 | PM ore processing requires large volumes of water for flotation and leaching. |

| Global Warming Potential (kg CO₂-eq/g) | 30 - 50 | 5 - 15 | Directly correlated with fossil-fuel-based energy consumption. |

| Waste Generation (Mining Tailings, kg/kg metal) | 200,000 - 400,000 | < 10 | EA metals are often co-products with lower ore-to-metal ratios than PMs. |

Experimental Protocols

Protocol 3.1: Standard Three-Electrode Setup for ORR/HER Activity Assessment

Objective: To electrochemically characterize the activity of PM vs. EA catalyst samples for ORR or HER using a rotating disk electrode (RDE). Materials: Potentiostat/Galvanostat, RDE setup, standard 3-electrode cell (Pt counter, Hg/HgO or Ag/AgCl reference, working electrode), N₂ and O₂ (for ORR) or Ar (for HER) gas cylinders, 0.1 M KOH or 0.1 M HClO₄ electrolyte. Working Electrode Preparation:

- Weigh 5 mg of catalyst powder.

- Disperse in 1 mL solution of 750 µL isopropanol, 240 µL DI water, and 10 µL 5% Nafion by sonication for 30 min.

- Pipette 10-20 µL of the ink onto a polished glassy carbon RDE tip (5 mm diameter, ~0.196 cm²).

- Dry under ambient air to form a thin, uniform film. Catalyst loading typically 0.2-0.6 mg/cm².

ORR Activity Measurement (in O₂-saturated 0.1 M KOH):

- Activate the electrode via cyclic voltammetry (CV) from 0.05 to 1.2 V vs. RHE at 100 mV/s for 20 cycles.

- Record CVs in N₂-saturated electrolyte (background).

- Saturate electrolyte with O₂ for 20 min.

- Record linear sweep voltammograms (LSV) from 1.2 to 0.05 V vs. RHE at 10 mV/s with electrode rotation at 1600 rpm.

- Calculate kinetic current density (Jk) using the Koutecky-Levich equation.

HER Activity Measurement (in Ar-saturated 0.1 M HClO₄):

- Activate via CV.

- Record LSV from 0.05 to -0.3 V vs. RHE at 5 mV/s.

- Report the overpotential (η) required to achieve a current density of -10 mA/cm².

Protocol 3.2: Accelerated Degradation Test (ADT) for Stability Assessment

Objective: To evaluate catalyst durability under rapid potential cycling, simulating operational stress. Materials: As in Protocol 3.1. Procedure:

- After initial activity measurement (E1/2 or η10), keep the working electrode in the same cell.

- For ORR catalysts: Apply potential cycles between the upper and lower potential limits relevant to the application (e.g., 0.6 - 1.0 V vs. RHE for PEMFC cathodes) at a high scan rate (e.g., 500 mV/s) in an inert atmosphere.

- For OER catalysts: Cycle in the water oxidation region (e.g., 1.2 - 1.6 V vs. RHE).

- Interrupt cycling every 1000-5000 cycles to repeat the LSA measurement (Protocol 3.1).

- Continue until a predefined loss of activity (e.g., 20-50% drop in kinetic current or increase in overpotential) is observed. Plot performance metric vs. cycle number.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Electrocatalyst Research

| Item | Function & Rationale |

|---|---|

| Nafion Perfluorinated Resin | Proton-conducting binder for catalyst inks; ensures electrical contact and proton access to active sites. |

| Vulcan XC-72R Carbon | Standard high-surface-area conductive support for dispersing both PM and EA nanoparticles. |

| Rotating Ring-Disk Electrode (RRDE) | Used to quantify reaction selectivity (e.g., H₂O₂ yield during ORR), critical for evaluating EA Fe-N-C catalysts. |

| Ionomer (e.g., Sustainion) | Anion-conducting binder essential for testing in alkaline media, replacing Nafion. |

| High-Purity N₂, O₂, Ar (5.0 or better) | For electrolyte deaeration and saturation; trace O₂ can contaminate HER measurements. |

| Commercial Pt/C (20-40% wt.) | Benchmark material for ORR/HER; essential as a baseline for comparing novel EA catalysts. |

| Commercial IrO₂ | Benchmark material for acidic OER. |

| Metal Precursors (e.g., FeCl₃, Co(NO₃)₂, NiCl₂) | Common, soluble salts for synthesizing EA catalysts via pyrolysis or precipitation. |

| Nitrogen-rich precursors (e.g., 1,10-Phenanthroline, Dicyandiamide) | Provide N-doping for carbon supports, crucial for creating M-Nx sites in EA catalysts. |

Diagrams & Workflows

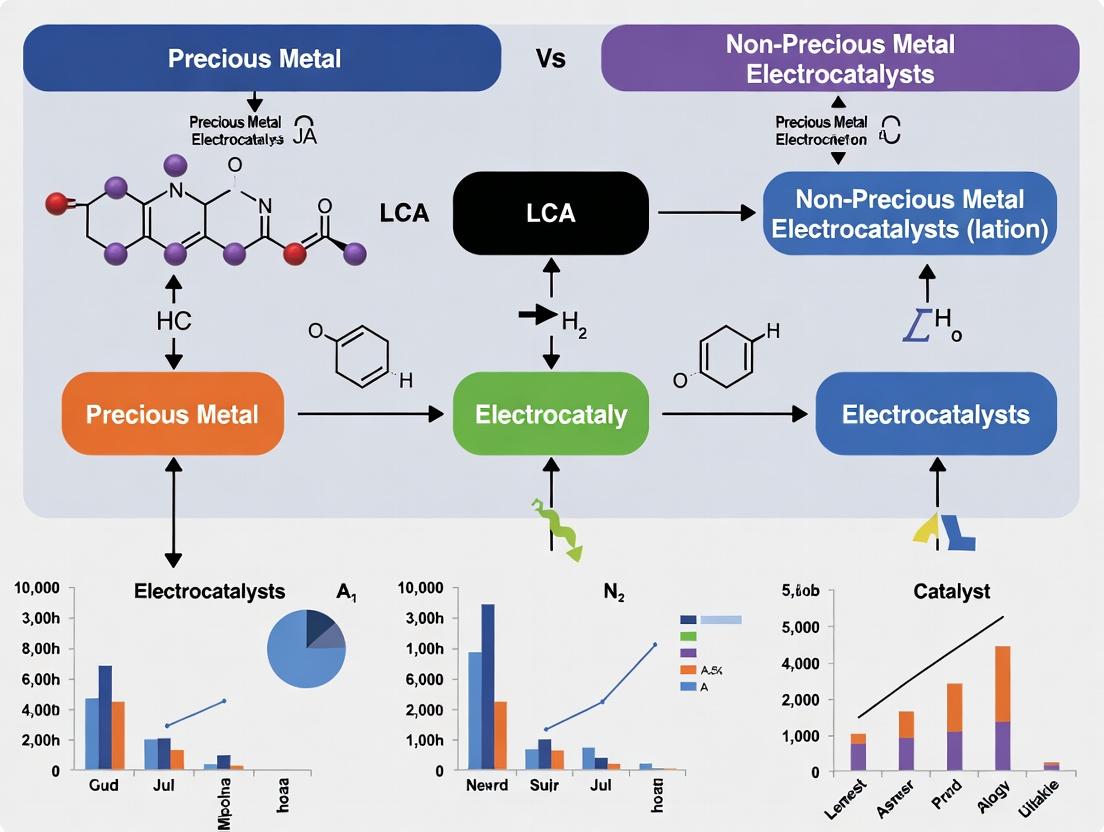

Diagram 1: Catalyst Selection & LCA Framework

Diagram 2: Experimental Workflow for Catalyst Benchmarking

Application Notes

These notes provide a comparative Life Cycle Assessment (LCA) framework for evaluating the environmental footprint of precious metal electrocatalysts (e.g., Pt, Pd, Ir) versus non-precious metal alternatives (e.g., Fe-N-C, NiCo oxides) in research applications such as fuel cells and electrosynthesis.

1. Quantified Environmental Burden of Primary Metal Production Data sourced from recent industry reports and LCA databases (2020-2024) highlight the disproportionate impacts of primary precious metal production.

Table 1: Environmental Impact Indicators for Primary Metal Production (Per kg of Metal)

| Impact Category | Unit | Platinum (Pt) | Palladium (Pd) | Iridium (Ir) | Iron (Fe) | Nickel (Ni) |

|---|---|---|---|---|---|---|

| Ore Grade (Avg.) | g/tonne | 3.1 | 3.5 | 0.3 | 350,000 | 12,000 |

| Rock Mined | tonnes | 322,580 | 285,710 | ~3,333,333 | 2.86 | 83.33 |

| Energy Use | GJ | 120,000 - 180,000 | 95,000 - 150,000 | >200,000 (est.) | 20 - 25 | 150 - 200 |

| GHG Emissions | t CO2-eq | 8,000 - 12,000 | 6,500 - 10,000 | 15,000 (est.) | 1.8 - 2.2 | 10 - 13 |

| Water Consumption | kL | 200,000 - 300,000 | 150,000 - 250,000 | 400,000 (est.) | 20 - 40 | 300 - 500 |

| SO2 Emissions | kg | 12,000 | 10,000 | N/A | 15 - 20 | 50 - 70 |

Table 2: Toxic Waste and Tailings Generation

| Metal | Solid Waste (Tailings) Generated (tonnes/kg metal) | Notable Contaminants in Tailings/Acid Mine Drainage |

|---|---|---|

| Pt, Pd | 250,000 - 400,000 | Sulfuric acid, cyanide residues, arsenic, mercury |

| Ir | >1,000,000 (est.) | Sulfides, heavy metals (Pb, Cd) |

| Au (Ref.) | 300,000 - 500,000 | Cyanide, arsenic, mercury |

| Fe, Ni | 2 - 10 | Sulfates, trace metals (managed in modern operations) |

2. Protocol for Integrating Mining LCA Data into Electrocatalyst Research Assessment

Protocol 1: Calculating Embedded Environmental Cost per Research Gram of Catalyst Objective: To translate primary production impacts into a functional unit relevant to lab-scale research (per gram of catalyst coated on electrode). Materials: LCI data (Table 1), catalyst synthesis protocol, metal loading data (e.g., 20 wt% Pt/C), analytical balance. Procedure:

- Determine the precise precious metal loading (mg metal cm⁻²) on your electrode (e.g., via ICP-MS analysis).

- For the metal component, calculate the embedded impact using the formula:

Embedded Impact (per cm²) = [Metal Loading (g/cm²)] * [Impact Factor per kg metal (from Table 1)] / 1000. - For a full catalyst comparison, repeat Step 2 for all critical metals (e.g., Co, Ni in non-precious catalysts) and sum the impacts.

- Normalize the total embedded impact by the electrochemical performance metric (e.g., mA cm⁻² at 0.9 V for ORR) to yield a cost/performance ratio (e.g., kg CO2-eq per A).

Protocol 2: Laboratory-Scale Simulation of Metal Leaching from Tailings (Acid Rock Drainage) Objective: To experimentally assess the potential aquatic toxicity of mining waste associated with catalyst metals. Materials: Simulated tailings (ore samples or synthetic mineral mixes containing FeS₂, CuFeS₂), pH meter, 0.1M H₂SO₄, orbital shaker, ICP-OES. Procedure:

- Prepare 1 g of finely ground (<100 µm) mineral sample containing target metal sulfides.

- Add to 100 mL of acidified rainwater (pH 4.0, adjusted with H₂SO₄) in a sealed flask.

- Agitate continuously at 120 rpm and 25°C for 168 hours (1 week).

- Sample 10 mL of supernatant at 0h, 24h, 72h, and 168h. Filter (0.45 µm).

- Analyze filtrate via ICP-OES for concentrations of leached metals (e.g., Pt, Pd, Ni, Co, Cu, As, Cd).

- Compare leachate profiles against regulatory limits for freshwater discharge.

Protocol 3: Life-Cycle Inventory (LCI) Data Integration for Catalyst Selection Objective: To create a decision matrix for selecting electrocatalysts based on combined performance and environmental criteria. Materials: Performance data (activity, stability), LCI data (Table 1), multi-criteria decision analysis (MCDA) software or spreadsheet. Procedure:

- Define selection criteria (e.g., Overpotential @ 10 mA cm⁻², Tafel slope, 1000-cycle stability loss, Embedded GHG/kg metal, Water Use/kg metal).

- Normalize all criteria scores to a 0-1 scale (where 1 is best).

- Assign researcher-determined weightings to each criterion (e.g., Performance 40%, Stability 30%, GHG 20%, Water 10%).

- Calculate a weighted total score for each candidate catalyst (precious and non-precious).

- Use score to guide sustainable material selection for target application (e.g., PEMFC cathode, HER anode).

Visualizations

Title: LCA Workflow for Electrocatalyst Research

Title: Precious Metal Production & Environmental Burden

The Scientist's Toolkit: Research Reagent Solutions for Sustainable Electrocatalysis

Table 3: Essential Materials for Comparative LCA-Informed Research

| Item / Reagent | Function in Research | Sustainable Consideration |

|---|---|---|

| Precious Metal Salts (e.g., H₂PtCl₆, Pd(NO₃)₂) | Standard precursors for synthesizing benchmark precious metal catalysts (Pt/C, Pd nanoparticles). | High embedded LCA cost. Use sparingly. Optimize loading (µg cm⁻²). Recycle synthesis waste. |

| Non-Precious Metal Salts (e.g., FeCl₃, Ni(NO₃)₂, Co(Ac)₂) | Precursors for developing alternative catalysts (Fe-N-C, NiFe LDH, spinel oxides). | Significantly lower embedded LCA impact (see Table 1). Prioritize in screening. |

| N-doped Carbon Supports (e.g., CNTs, Ketjenblack) | Conductive, high-surface-area supports to enhance dispersion and activity of metal sites. | Source from suppliers with green chemistry practices. Consider biomass-derived carbon. |

| Nafion Binder | Proton-conducting ionomer for preparing catalyst inks and coating electrodes (e.g., for PEMFC tests). | PFAS-containing. Handle and dispose as hazardous waste. Research alternative binders (e.g., sulfonated polyaryl ethers). |

| Electrochemical Cell (3-electrode) | Standard setup for evaluating catalyst activity (ORR, HER, OER) in aqueous or organic electrolytes. | Prioritize durable cells (e.g., glass) over single-use parts. Implement electrolyte recycling protocols. |

| Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) | Instrument for quantifying metal loading on electrodes and measuring metal leaching in experiments. | Critical for accurately measuring minimal precious metal use and assessing environmental leaching (Protocol 2). |

| LCA Software / Databases (e.g., OpenLCA, Ecoinvent, GREET) | Tools to access and process the life cycle inventory data (like Table 1) for quantitative sustainability assessment. | Essential for performing Protocol 1 & 3, moving beyond anecdotal green claims to data-driven decisions. |

Introduction Within the broader thesis on Life Cycle Assessment (LCA) of precious metal versus non-precious metal electrocatalysts, a critical evaluation of abundant metal alternatives is essential. This document provides application notes and experimental protocols for quantifying and comparing the environmental and supply chain impacts of candidate abundant metals (e.g., Fe, Co, Ni, Cu, Mn) used in electrocatalyst synthesis, with a focus on extraction phases and material sourcing.

1. Application Notes: Comparative Impact Assessment

1.1. Key Impact Metrics for Metal Extraction The environmental footprint of metal extraction is quantified through several key indicators, which must be inventoried for inclusion in LCA models (e.g., using databases like Ecoinvent or the U.S. Life Cycle Inventory).

Table 1: Global Average Impact Indicators for Primary Metal Production (per kg of refined metal)

| Metal | Energy Use (MJ) | Greenhouse Gas Emissions (kg CO₂-eq) | Water Consumption (L) | Acidification Potential (kg SO₂-eq) | Major Global Producers (2023-2024) |

|---|---|---|---|---|---|

| Nickel (Ni) | 150 - 250 | 12 - 18 | 300 - 500 | 15 - 25 | Indonesia, Philippines, Russia |

| Cobalt (Co) | 2800 - 5000 | 800 - 1700 | 8000 - 16000 | 40 - 70 | DR Congo, Indonesia, Canada |

| Iron (Fe) | 18 - 25 | 1.8 - 2.5 | 40 - 60 | 0.8 - 1.2 | China, Australia, Brazil |

| Copper (Cu) | 40 - 80 | 3 - 6 | 150 - 300 | 8 - 15 | Chile, Peru, DR Congo |

| Manganese (Mn) | 25 - 40 | 2.5 - 4.0 | 100 - 200 | 2 - 4 | South Africa, Gabon, Australia |

Note: Data represents industry averages; site-specific values can vary significantly based on ore grade, extraction technology, and energy grid mix.

1.2. Supply Chain Risk Assessment Matrix Geopolitical and socio-economic factors introduce volatility. A qualitative risk matrix complements quantitative LCA data.

Table 2: Supply Chain Risk Matrix for Abundant Metals

| Risk Factor | Fe | Ni | Co | Cu | Mn |

|---|---|---|---|---|---|

| Geopolitical Concentration (Supply) | Low | High | Critical | High | High |

| Conflict-Affected Sourcing | Low | Medium | Critical | Medium | Low |

| Price Volatility (5-yr trend) | Low | High | Very High | High | Medium |

| By-Product Dependence | N/A | Low | High (~60% as by-product of Cu/Ni) | Low | Low |

2. Experimental Protocols

2.1. Protocol: Integrating Extraction Inventory Data into Catalyst LCA Objective: To incorporate region-specific extraction data into the cradle-to-gate LCA of an electrocatalyst. Materials:

- GaBi LCA software or openLCA.

- Ecoinvent 3.8+ database or similar.

- Specific metal production data from industry reports (e.g., ICMM, USGS). Methodology:

- Goal & Scope: Define functional unit (e.g., 1 kg of synthesized catalyst powder).

- Inventory (LCI): a. Bill of Materials: Precisely quantify mass of each metal in the catalyst. b. Data Selection: In the LCA software, replace global average data with specific market mix datasets. If assessing a Co-based catalyst from the DR Congo, seek and apply inventory data for "cobalt, primary, from DR Congo, at refinery." c. Allocation: For co-produced metals (e.g., Co from Ni/Co sulfide ore), apply allocation by mass or economic value as per ISO 14044.

- Impact Assessment (LCIA): Calculate impacts using methods like ReCiPe 2016 or EF 3.0, focusing on global warming, acidification, water use, and resource depletion.

- Interpretation: Compare the contribution of the metal extraction phase to the total catalyst production impact.

2.2. Protocol: Laboratory-Scale Assessment of Catalyst Metal Leaching Objective: To experimentally determine potential aquatic toxicity impacts by measuring metal leaching from a catalyst under operational conditions. Materials:

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS) system.

- Electrochemical cell with controlled potential/current setup.

- pH meter and conductivity meter.

- Nitric acid (trace metal grade) for sample preservation.

- Standard solutions for ICP-MS calibration for target metals. Methodology:

- Electrolyte Preparation: Prepare 1.0 M electrolyte (e.g., KOH for HER, OER; H₂SO₄ for ORR) using ultra-pure water (18.2 MΩ·cm).

- Leaching Test: Immerse a known mass (e.g., 50 mg) of catalyst deposited on a substrate (e.g., carbon paper) in 100 mL of electrolyte. Apply the intended operating potential (vs. RHE) for 24 hours. Run a control (no potential applied) simultaneously.

- Sample Collection: At intervals (1h, 6h, 24h), withdraw 5 mL of electrolyte, acidify immediately with 50 µL concentrated HNO₃, and store at 4°C.

- ICP-MS Analysis: Dilute samples appropriately. Use standard addition method to calibrate the ICP-MS and quantify the concentration of leached metals (Fe, Co, Ni, etc.) in parts per billion (ppb).

- Data Analysis: Calculate total mass leached per gram of catalyst. This data feeds into the "toxicity potential" impact category in the LCA model.

3. The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Abundant Metal Electrocatalyst Research

| Item | Function / Relevance to LCA & Supply Chain |

|---|---|

| High-Purity Metal Salts (e.g., Ni(NO₃)₂·6H₂O, CoCl₂·6H₂O) | Precursors for catalyst synthesis. Source purity (>99.95%) minimizes impurity-driven performance variability and ensures accurate mass balance for LCI. |

| Carbon Substrates (Vulcan XC-72, Graphene Oxide) | High-surface-area supports. Their own LCA (from fossil or biomass feedstocks) must be included in the full catalyst assessment. |

| Nafion Binder | Common ionomer for electrode preparation. Its perfluorinated composition contributes to the catalyst's overall environmental footprint and end-of-life considerations. |

| ICP-MS Standard Solutions | Critical for quantifying metal content in synthesized catalysts and measuring leaching rates, providing essential data for inventory and toxicity assessment. |

| Solid-Phase Extraction Kits for Metal Recovery | Used in experimental end-of-life protocols to recover metals from spent electrolyte, simulating and quantifying potential recycling efficiency. |

4. Visualizations

4.1. Diagram: LCA Workflow for Electrocatalyst Assessment

4.2. Diagram: Supply Chain & Impact Decision Pathway

Application Notes

The comparative Life Cycle Assessment (LCA) of precious metal (e.g., Pt) versus non-precious metal (NPM) electrocatalysts for applications like fuel cells and electrolyzers necessitates a detailed understanding of candidate NPM materials. Carbon-based materials such as graphene and carbon nanotubes (CNTs) are pivotal as high-surface-area supports, co-catalysts, or even primary active sites when doped with heteroatoms like nitrogen. Their intrinsic properties—high electrical conductivity, tunable surface chemistry, and corrosion resistance—make them essential for durable, cost-effective electrochemical devices. However, their environmental footprint is intrinsically tied to their production pathways. The energy intensity, precursor materials, and chemical usage in synthesis directly influence the LCA outcome, making the evaluation of production methods a critical research parameter.

Graphene Production Pathways: Top-down methods like Hummers' modified redox exfoliation of graphite produce graphene oxide (GO), subsequently reduced to rGO. This route is scalable but involves aggressive chemicals (e.g., KMnO₄, H₂SO₄) and generates waste. Bottom-up methods like Chemical Vapor Deposition (CVD) on metal substrates yield high-quality, monolayer graphene but are energy-intensive and low-yield for bulk powder production.

CNT Production Pathways: Catalytic CVD is the dominant commercial method, using hydrocarbon gases (e.g., CH₄, C₂H₂) over metal nanoparticle catalysts (Fe, Co, Ni). Arc discharge and laser ablation produce high-quality CNTs but with significant energy input and low scalability. The choice of catalyst, carbon source, and reactor conditions dictates CNT type (SWCNT vs. MWCNT), purity, and yield, all impacting the material's functional performance and LCA inventory.

LCA Implications: For a fair comparison with Pt-based catalysts, the functional unit must be defined per unit of electrochemical performance (e.g., mA/cm² at 0.9 V for ORR) over the catalyst lifetime. The cradle-to-gate inventory for graphene and CNTs must account for:

- Precursor sourcing: Natural graphite mining (for graphene) vs. hydrocarbon feedstock (for CNTs).

- Energy consumption: High-temperature processes (CVD, arc discharge) versus chemical processing.

- Chemical utilization and waste: Acid/oxidizer usage in Hummers' method, metal catalyst recovery/recycling in CNT synthesis.

- Post-processing: Purification, doping (e.g., with N, S, B), and integration into electrode inks.

Protocols

Protocol 1: Synthesis of Nitrogen-Doped Reduced Graphene Oxide (N-rGO) via Thermal Annealing

Application: Production of a model non-precious metal electrocatalyst support for Oxygen Reduction Reaction (ORR) studies.

Materials:

- Graphene Oxide (GO) dispersion (2 mg/mL in water)

- Melamine (as nitrogen precursor)

- Tube furnace with quartz tube and boat

- Argon and Ammonia gas cylinders

- Centrifuge and freeze drier

Procedure:

- Mix 50 mL of GO dispersion with 500 mg of finely ground melamine. Sonicate for 1 hour.

- Freeze-dry the mixture for 48 hours to obtain a solid GO/melamine composite.

- Load the composite into a quartz boat and place it in the center of a tube furnace.

- Purge the system with Argon (200 sccm) for 30 minutes to remove oxygen.

- Heat the furnace to 800°C at a ramp rate of 5°C/min under a continuous Ar flow (100 sccm).

- Once at 800°C, switch the gas to a mixture of Ar (90 sccm) and NH₃ (10 sccm). Maintain for 2 hours.

- Cool naturally to room temperature under Ar flow.

- Collect the resulting N-rGO powder. Characterize via Raman spectroscopy, XPS, and BET surface area analysis.

Protocol 2: Synthesis of Multi-Walled Carbon Nanotubes (MWCNTs) via Catalytic CVD

Application: Production of conductive carbon support for dispersing non-precious metal nanoparticles (e.g., Fe-N-C sites).

Materials:

- Ferrocene (catalyst precursor)

- Xylene (carbon source)

- Two-zone horizontal tube furnace

- Quartz boat and tube

- Argon and Hydrogen gas cylinders

Procedure:

- Place 500 mg of ferrocene in a quartz boat positioned in the first (low-temperature) zone of the furnace.

- Place an empty, clean quartz boat in the second (high-temperature) zone.

- Seal the system and purge with Argon (300 sccm) for 30 minutes.

- Heat the first zone to 180°C (to sublime ferrocene) and the second zone to 750°C.

- Once temperatures are stable, introduce xylene vapor into the Ar carrier gas using a syringe pump at a rate of 0.1 mL/min. Introduce H₂ at 50 sccm.

- Run the reaction for 60 minutes. The MWCNTs grow on the walls of the quartz tube in the high-temperature zone.

- Turn off the furnace and syringe pump. Continue Ar flow until the system cools to <100°C.

- Collect the black MWCNT mat. Purify by stirring in 6M HCl for 12 hours to remove iron particles, followed by washing with DI water until neutral pH and drying at 80°C.

Data Tables

Table 1: Key Characteristics and Typical LCA Inventory Parameters for Carbon Material Production Pathways

| Material & Pathway | Typical Yield | Key Inputs (per kg output*) | Energy Demand (est. kWh/kg*) | Key Output/Performance Metric for LCA |

|---|---|---|---|---|

| Graphene via Hummers' rGO | 60-80% (from graphite) | Graphite (1.5 kg), KMnO₄ (3 kg), H₂SO₄ (20 L), NaNO₃ (0.5 kg) | 200 - 500 | Conductivity: 1000 - 10,000 S/m; C/O ratio: ~10 |

| Graphene via CVD | >95% (on substrate) | Cu foil, CH₄ (10 L), H₂ (50 L) | 3000 - 5000 | Domain size: ~10s μm; Purity: >99% |

| SWCNT via Arc Discharge | 30-70% | Graphite rods (3 kg), Metal catalysts (Ni, Y) | 10,000 - 50,000 | Purity: 60-90%; Defect density: Low |

| MWCNT via CVD | >90% | Hydrocarbon (C₂H₂: 2 kg), Catalyst (Fe: 0.1 kg) | 100 - 300 | Aspect Ratio: 100 - 1000; Purity: >95% (after acid treatment) |

Note: Values are indicative for laboratory/small pilot scale and vary significantly with process optimization.

Table 2: Electrochemical Performance Comparison in 0.1M KOH (ORR)*

| Catalyst Material | Half-Wave Potential (E₁/₂ vs. RHE) | Kinetic Current Density (jk @ 0.9V) | Electron Transfer Number (n) | Durability (Cycles to 10% E₁/₂ loss) |

|---|---|---|---|---|

| Pt/C (20 wt%) | 0.85 V | 5.0 mA/cm² | ~4.0 | 5,000 - 10,000 |

| N-doped rGO | 0.75 V | 1.2 mA/cm² | 3.5 - 3.8 | 2,000 - 5,000 |

| Fe-N-C / CNT | 0.82 V | 3.8 mA/cm² | ~4.0 | 10,000 - 20,000 |

Note: Performance data are typical ranges from recent literature and are highly dependent on synthesis specifics.

Diagrams

Title: Graphene Synthesis Pathways for Electrocatalysts

Title: LCA Workflow for CNT-Based Catalyst Production

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Carbon-Based Electrocatalyst Development

| Item | Function/Benefit | Typical Specification/Notes |

|---|---|---|

| Graphene Oxide Dispersion | Standardized starting material for consistent rGO and doped rGO synthesis. Eliminates variability in initial graphite oxidation. | 2-4 mg/mL in H₂O, single-layer content >90%, lateral size customizable (e.g., 1-5 µm). |

| Nafion Perfluorinated Resin Solution | Binder/Ionomer for preparing catalyst inks. Provides proton conductivity and adhesion to electrodes in PEM fuel cell testing. | 5 wt% in lower aliphatic alcohols/water. Critical for membrane electrode assembly (MEA) fabrication. |

| Nitrogen Precursors (for Doping) | Introduce active N-sites (pyridinic, graphitic) into carbon frameworks for ORR/OER activity. | Urea, Melamine, Cyanamide, Ammonia gas. Choice affects N-configuration and doping level. |

| Metal Salt Precursors | Source for non-precious metal active sites (e.g., Fe, Co) or CVD catalysts (e.g., Fe for CNT growth). | Ferric chloride (FeCl₃), Cobalt nitrate (Co(NO₃)₂), Nickel acetate (Ni(Ac)₂). High purity (>99.99%) recommended. |

| CVD Carbon Sources | Feedstock for controlled CNT or graphene growth in CVD reactors. | Acetylene (C₂H₂), Ethylene (C₂H₄), Methane (CH₄). Purity >99.5% required for reproducible growth. |

| Rotating Disk Electrode (RDE) System | Standardized platform for intrinsic electrocatalytic activity measurement (ORR, OER, HER). | Glassy carbon working electrode, rotation control (0-2500 rpm), coupled with potentiostat. |

Application Notes for Electrocatalyst LCA Research

Life Cycle Assessment (LCA) is a critical tool for evaluating the environmental footprint of electrocatalyst technologies, pivotal in energy conversion and pharmaceutical electrosynthesis. Within a thesis comparing precious metal (e.g., Pt, Ir) and non-precious metal (e.g., Fe-N-C, NiCo) electrocatalysts, the core impact categories of Global Warming, Acidification, and Resource Depletion provide a focused lens. These categories are influenced by divergent material sourcing, synthesis energy, and end-of-life scenarios. Precise protocols and data normalization are essential for robust, comparative conclusions relevant to researchers and process developers.

Table 1: Comparative Mid-Point Impact Indicators for Electrocatalyst Production (Per kg of Catalyst). Data are illustrative, based on recent literature and inventory databases.

| Impact Category | Unit | Precious Metal Catalyst (e.g., Pt/C) | Non-Precious Metal Catalyst (e.g., Fe-N-C) | Key Contributing Life Cycle Stage |

|---|---|---|---|---|

| Global Warming | kg CO₂-eq | 1.2E+05 to 2.5E+05 | 5.0E+03 to 2.0E+04 | Ore mining & refining (PM), Precursor synthesis (NPM) |

| Acidification | kg SO₂-eq | 5.0E+02 to 1.2E+03 | 2.0E+01 to 1.0E+02 | Smelting & purification, Acid use in synthesis |

| Resource Depletion (Abiotic) | kg Sb-eq | 3.0E+03 to 8.0E+03 | 1.0E+02 to 5.0E+02 | Platinum Group Metal extraction, Metal ore mining |

Table 2: Key Inventory Flows Driving Impact Categories.

| Inventory Flow | Relation to Global Warming | Relation to Acidification | Relation to Resource Depletion |

|---|---|---|---|

| Hard coal, in ground | Fossil CO₂ from energy use | SOx emissions from combustion | Resource extraction |

| Platinum, in ground | Low direct impact | Low direct impact | Primary driver for PM catalysts |

| Sulfuric acid | Energy for production | Primary driver (H+ release) | --- |

| Ammonia, liquid | Energy for production | Potential atmospheric nitrate | --- |

| Electricity, grid | Primary driver for synthesis | SOx/NOx from fossil generation | Fossil fuel depletion |

Experimental Protocols

Protocol 1: Life Cycle Inventory (LCI) Compilation for Catalyst Synthesis

Objective: To compile a cradle-to-gate inventory of material and energy flows for 1 kg of functional electrocatalyst. Materials: Process data from lab/pilot-scale synthesis, Ecoinvent/USLCI database access, SimaPro/GaBi LCA software. Procedure:

- System Boundary Definition: Define as cradle-to-gate: raw material extraction → precursor production → catalyst synthesis (e.g., impregnation, pyrolysis, leaching).

- Data Collection: For each input (metals, supports, chemicals, solvents, gases) and unit process (furnace, reactor, dryer), collect mass/volume and energy consumption (kWh) data.

- Primary Data Acquisition:

- Monitor electricity consumption of tube furnaces (pyrolysis) and microwave reactors using calibrated power meters.

- Record exact masses of metal precursors (e.g., H₂PtCl₆, FeCl₃), carbon supports, and nitrogen sources (e.g., phenanthroline, urea).

- Measure solvent (e.g., ethanol, water) volumes for wet impregnation and account for recovery/recycling rates.

- Secondary Data Sourcing: For upstream processes (e.g., mining of Pt, production of HNO₃), use cut-off system models in recognized databases (Ecoinvent v3.9, USLCI).

- Allocation: If synthesis yields multiple valuable products (e.g., different catalyst grades), allocate flows based on mass, economic value, or elemental content.

- Inventory Tabulation: Aggregate all flows into a table listing inputs from nature/technosphere and emissions to air/water/soil per kg catalyst.

Protocol 2: Impact Assessment Calculation and Normalization

Objective: To calculate characterized impacts for the three core categories and normalize them for comparison. Materials: LCI results, IPCC 2021 GWP100 factors, ReCiPe 2016 (H) or TRACI 2.1 methodology, normalization world (2010) reference set. Procedure:

- Characterization: Multiply each inventory flow (e.g., kg CH₄, kg SO₂) by its corresponding category-specific characterization factor.

- Global Warming: Use IPCC AR6 100-year factors (CO₂=1, CH₄=27.9, N₂O=273).

- Acidification: Use accumulated exceedance factors (SO₂=1, NOx=0.5, NH₃=1.64).

- Resource Depletion: Use abiotic depletion potential (ADP) for elements (e.g., Pt, Fe) and fossil resources.

- Calculation: Sum the weighted contributions within each category to obtain total kg CO₂-eq, kg SO₂-eq, and kg Sb-eq.

- Normalization (Optional but Recommended): Divide the characterized result for each category by the corresponding annual global impact per capita (e.g., ReCiPe 2016 normalization factors: GWP=7390 kg CO₂-eq/yr/cap, Acidification=62.7 kg SO₂-eq/yr/cap). This yields dimensionless "person-equivalent" impacts, highlighting the relative magnitude of each category.

Protocol 3: Sensitivity Analysis on Catalyst Lifetime & Loading

Objective: To test how functional unit definition (e.g., per mole of active site or per hour of operation) alters comparative conclusions. Materials: Electrochemical durability data (accelerated stress tests, long-term chronoamperometry), catalyst loading data (mg/cm²). Procedure:

- Define Alternative Functional Units: e.g., "1 mole of product formed in an electrochemical CO₂ reduction reaction" or "1 kWh of hydrogen produced in a PEM electrolyzer."

- Incorporate Performance Data: Obtain catalyst-specific activity (mass-normalized current density at set overpotential) and lifetime (hours to 20% activity decay) from experimental results.

- Recalculate Impacts: Extend the system boundary to include the operating phase (electricity input for electrolysis). Calculate total impacts per original functional unit (kg catalyst), then divide by total moles of product or kWh produced over the catalyst's lifetime.

- Scenario Modeling: Model scenarios using: a) lab-scale performance data, and b) projected industrial-scale performance and lifetime. Compare the relative difference between PM and NPM catalysts across these scenarios.

Visualizations

LCA Workflow for Electrocatalyst Comparison

Key Impact Drivers in Catalyst Synthesis

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Essential Materials for Electrocatalyst LCA Research

| Item | Function in LCA Context | Example Supplier/DB |

|---|---|---|

| Life Cycle Inventory (LCI) Database | Provides background data for upstream materials (e.g., Pt mining, H₂SO₄ production) and energy processes. | Ecoinvent, US Life Cycle Inventory (USLCI), GREET |

| LCA Software | Manages inventory data, performs impact calculations, and facilitates scenario modeling. | SimaPro, openLCA, GaBi |

| ICP-MS Standards | For precise quantification of trace metal content in catalysts, crucial for accurate inventory of scarce metals. | Inorganic Ventures, Sigma-Aldrich |

| High-Purity Metal Precursors | Precise knowledge of precursor stoichiometry and sourcing allows for accurate upstream burden tracking. | Alfa Aesar (e.g., Chloroplatinic acid), Strem Chemicals |

| Calibrated Power Meter | For direct measurement of energy consumption during synthesis steps (e.g., pyrolysis, drying). | Fluke, Keysight |

| Impact Assessment Method Package | Contains the characterization factors required to convert LCI flows into impact category results. | ReCiPe 2016, EF 3.0, TRACI 2.1 |

| Reference Electrode & Potentiostat | To generate crucial performance data (activity, stability) for alternative functional unit analysis. | Gamry Instruments, Metrohm Autolab |

Establishing the "Functional Unit" for Fair Comparison in Biomedical Applications

Within the broader thesis on the Life Cycle Assessment (LCA) of precious metal (e.g., Pt, Au) versus non-precious metal (e.g., Fe, Co, Ni-based) electrocatalysts for biomedical applications, defining a rigorous Functional Unit (FU) is paramount. The FU quantifies the performance basis for all environmental and economic comparisons. For biomedical electrocatalysts, this extends beyond simple mass or catalytic activity to encompass in vivo or in vitro efficacy, stability, and safety over a defined therapeutic or diagnostic outcome.

Defining the Biomedical Functional Unit

The FU must be application-specific. Below are candidate FUs for key biomedical applications of electrocatalysts.

Table 1: Proposed Functional Units for Biomedical Electrocatalyst Applications

| Application | Proposed Functional Unit | Rationale and Measured Parameters |

|---|---|---|

| Implantable Biofuel Cell | Provision of 1 µW of electrical power for 30 days in vivo. | FU integrates power output, duration, and stability in physiological conditions. Key metrics: Power density (µW/cm²), operational lifetime, biofouling resistance. |

| Electrochemical Biosensor | Accurate detection of 1 mmol/L of target analyte (e.g., glucose, dopamine) with ≥ 95% accuracy over 100 measurement cycles. | FU focuses on analytical performance and reusability/stability. Key metrics: Sensitivity (µA/mM/cm²), Limit of Detection (LoD), selectivity, cycle stability. |

| Electro-therapeutic Device (e.g., catalytic reduction of reactive oxygen species) | Scavenging of 90% of a 1 mM ROS (e.g., H₂O₂) solution within a 5-minute treatment cycle. | FU quantifies therapeutic catalytic efficiency. Key metrics: Turnover frequency (TOF), catalyst leaching, biocompatibility (cell viability %). |

| Drug Activation/Catalysis | Release of 95% of the prescribed drug dose from a prodrug via catalytic reaction. | FU links catalyst performance to pharmacological outcome. Key metrics: Conversion efficiency (%), byproduct toxicity, reaction time. |

Application Notes and Protocols for FU Determination

Application Note 1: FU for an Implantable Glucose Biofuel Cell

Objective: To experimentally determine if a non-precious metal (NPM) cathode catalyst meets the FU of "Provision of 1 µW of electrical power for 30 days in simulated body fluid (SBF) at 37°C."

Protocol 1: Long-Term Stability and Power Output Test

- Cell Assembly: Construct a membrane-less glucose biofuel cell. Anode: Glucose oxidase on carbon felt. Cathode: The test electrocatalyst (e.g., Fe-N-C or Pt/C) coated on a carbon cloth gas diffusion electrode.

- Electrolyte: Use continuously circulating, deaerated SBF (pH 7.4) with 5 mM glucose at 37°C. Purge the cathode chamber with air at a constant flow.

- Polarization Curves: Perform chronoamperometry at a fixed cell voltage corresponding to the maximum power point. Record current every hour.

- Data Calculation: Calculate power (P = I x V). The experiment concludes when power drops below 1 µW. The FU is met if this threshold is sustained for ≥ 30 days.

- Post-Test Analysis: Use Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to measure metal ion leaching into the SBF.

Visualization: Biofuel Cell FU Assessment Workflow

Title: Workflow for Biofuel Cell Functional Unit Validation

Application Note 2: FU for a Biosensor Detecting Hydrogen Peroxide

Objective: To compare precious (Pt) vs. non-precious (Mn₃O₄) catalysts against the FU: "Detection of 1 mM H₂O₂ with ±5% accuracy over 100 amperometric cycles in phosphate buffer saline (PBS)."

Protocol 2: Biosensor Cyclic Stability and Accuracy Test

- Electrode Modification: Drop-cast catalyst ink (containing catalyst, Nafion, carbon black) onto glassy carbon electrodes. Dry.

- Calibration Curve: In stirred PBS (pH 7.4, 0.1 M), apply a constant detection potential (e.g., -0.2V vs. Ag/AgCl for H₂O₂ reduction). Record amperometric current while making successive standard additions of H₂O₂ stock (0.1, 0.5, 1, 2 mM). Plot current vs. concentration.

- Accuracy & Cycle Test: From the calibration, determine the response for 1 mM H₂O₂. This is the reference current (I_ref). Repeat the amperometric measurement for 1 mM H₂O₂ 100 times on the same electrode, with a 30-second wash in PBS between cycles.

- FU Assessment: For each cycle, calculate accuracy: (Imeasured / Iref) * 100%. The FU is met if ≥95 cycles fall within 95-105% accuracy.

Visualization: Biosensor Performance Validation Pathway

Title: Biosensor Functional Unit Assessment Logic

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Functional Unit Experiments

| Item | Function in FU Assessment | Example Product/Catalog |

|---|---|---|

| Simulated Body Fluid (SBF) | Mimics ionic composition of blood plasma for in vitro stability and biocompatibility testing. | Kokubo SBF Recipe (Standard ISO 23317) or commercial biofluid simulants. |

| Rotating Ring-Disk Electrode (RRDE) | Quantifies electrocatalytic activity (disk current) and reaction selectivity (ring current) for oxygen reduction. | Pine Research or Metrohm Autolab RRDE setups. |

| Electrochemical Quartz Crystal Microbalance (EQCM) | Measures mass changes on the electrode surface in situ during operation (e.g., biofouling, catalyst degradation). | Stanford Research Systems QCM200. |

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) | Detects trace levels of metal ions leached from catalysts into solution, critical for safety and stability assessment. | Agilent 7900 or PerkinElmer NexION systems. |

| Biocompatibility Assay Kit (e.g., MTT/XTT) | Assesses cell viability after exposure to catalyst or its leachates, linking FU to biological safety. | Thermo Fisher Scientific CellTiter 96. |

| Gas Diffusion Electrode (GDE) | Provides a three-phase interface for testing fuel cell or biosensor catalysts under physiologically relevant, air-breathing conditions. | Freudenberg H23C2 or Sigracet 29 BC. |

Establishing these application-specific FUs moves the comparison beyond "catalytic activity per mg catalyst" to a basis of actual delivered function. In the LCA thesis, the environmental impacts (energy use, GHG emissions, resource depletion) of producing 1 gram of Pt can now be fairly compared to the impacts of producing the quantity of a non-precious metal catalyst required to deliver the same functional unit (e.g., 30 days of power or 100 accurate sensor readings). This ensures the sustainability assessment is grounded in equivalent performance, guiding the development of truly sustainable biomedical devices.

Conducting a Cradle-to-Gate LCA for Electrocatalyst Research: A Step-by-Step Guide

In a Life Cycle Assessment (LCA) comparing precious metal (PM, e.g., Pt, Ir) and non-precious metal (NPM, e.g., Fe, Co, N-doped carbon) electrocatalysts, defining the "cradle-to-gate" system boundary for catalyst synthesis is critical. This boundary, "From Ore to Lab-Synthesized Catalyst Powder," encapsulates all material and energy inputs, emissions, and waste outputs from raw material extraction through to the production of a characterized catalyst powder ready for electrode integration. For PM catalysts, the high environmental burden of mining and refining dominates. For NPM catalysts, the synthesis and purification of molecular precursors (e.g., metal-organic frameworks, porphyrins) and the energy-intensive pyrolysis steps are often the hotspots. Precise definition enables fair comparison of "catalyst production" phases, isolating synthesis efficiency from downstream performance variables.

Application Notes: Delineating the System Boundary

Key Inclusion Criteria:

- Raw Material Acquisition: Mining of ore (e.g., platinum group metal (PGM) ore, iron ore) or harvesting of precursor materials (e.g., natural gas for carbon, nitrogen).

- Primary Processing: Beneficiation, smelting, and refining to produce pure metals or standard chemical compounds (e.g., H₂PtCl₆, FeCl₃, urea).

- Catalyst Synthesis: All chemical reactions, pyrolysis, hydrothermal treatment, washing, and drying steps.

- Post-Synthesis Processing: Milling, sieving, and any activation steps (e.g., acid leaching).

- Lab-Scale Characterization: Essential characterization for quality control (e.g., XRD, SEM, bulk elemental analysis).

- Associated Inputs/Outputs: All energy, solvents, gases, water, and generated waste streams within the above stages.

Key Exclusion Criteria:

- Catalyst Performance Testing: Fabrication of membrane electrode assemblies (MEAs), fuel cell/electrolyzer testing.

- Downstream Manufacturing: Incorporation of catalyst into commercial devices.

- Use Phase & End-of-Life: Device operation, catalyst degradation, recycling (though recycling loops can be modeled as a separate, cutoff system).

- Capital Equipment: The embodied energy of lab equipment (reactors, furnaces) is typically excluded due to complexity and minor contribution at lab scale.

Table 1: Comparative Inventory for Synthesizing 1g of Catalyst Powder (Theoretical Basis)

| Parameter | Precious Metal Catalyst (e.g., Pt/C) | Non-Precious Metal Catalyst (e.g., Fe-N-C) | Notes / Data Source |

|---|---|---|---|

| System Boundary Start | PGM Ore in Ground | Iron Ore / Natural Gas / Urea | |

| Typical Precursor | Chloroplatinic acid (H₂PtCl₆) | Iron(III) chloride, Phenanthroline, Zinc-based ZIF-8 | |

| Mass of Ore Required | ~200-300 g PGM ore | ~2-5 g Iron ore | Estimated from avg. ore grades (Pt: ~3-5 g/tonne; Fe: ~62% Fe). |

| Primary Processing Energy | 150-250 MJ/g Pt | 10-20 MJ/g Fe | Smelting/refining for metals. |

| Key Synthesis Step | Impregnation & H₂ reduction | Pyrolysis (inert/NH₃ atm) | |

| Synthesis Energy | Low (80°C reduction) | Very High (900-1100°C for 1-2 hrs) | Tube furnace energy demand is major LCA hotspot for NPMC. |

| Solvent Use (e.g., Water) | Moderate (impregnation, washing) | Low-Moderate (precursor mixing, washing) | |

| Characterization Included | ICP-OES (Pt loading), XRD, BET | XRD, SEM-EDS, XPS, BET | ICP-MS for metal leaching. |

| Estimated GWP (CO₂-eq) | 50-100 kg/g Pt (mining dominated) | 5-20 kg/g catalyst (pyrolysis dominated) | Broad ranges; highly dependent on local energy mix and process yields. |

Experimental Protocols

Protocol 1: Synthesis of Pt/C Catalyst (Impregnation-Reduction Method)

- Objective: To prepare 0.5g of 20 wt% Pt on Vulcan XC-72R carbon.

- Materials: Chloroplatinic acid hexahydrate (H₂PtCl₆·6H₂O), Vulcan XC-72R carbon, Sodium borohydride (NaBH₄), 0.5M H₂SO₄ solution, Deionized (DI) water, Ethanol.

- Procedure:

- Impregnation: Suspend 0.40g of Vulcan carbon in 100mL DI water via sonication for 30 min. Slowly add an aqueous solution containing 0.26g of H₂PtCl₆·6H₂O (equivalent to 0.10g Pt) under vigorous stirring. Stir for 4 hours at room temperature.

- Reduction: Prepare a 0.1M NaBH₄ solution in 0.5M NaOH (ice-cold). Add this reducing solution dropwise to the Pt/C slurry under N₂ atmosphere. Stir for 2 hours.

- Filtration & Washing: Filter the slurry through a 0.2 μm PTFE membrane. Wash thoroughly with copious DI water (≥500 mL) and then with ethanol.

- Drying: Transfer the wet cake to a vacuum oven and dry at 80°C overnight.

- Characterization: Determine actual Pt loading via Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES). Perform XRD to confirm Pt crystallinity and BET for surface area.

Protocol 2: Synthesis of Fe-N-C Catalyst (MOF-Derived Pyrolysis Method)

- Objective: To prepare 0.3g of Fe-N-doped carbon catalyst.

- Materials: Zinc nitrate hexahydrate (Zn(NO₃)₂·6H₂O), 2-Methylimidazole, Iron(III) chloride hexahydrate (FeCl₃·6H₂O), Methanol, Ammonia gas (NH₃), Argon gas (Ar).

- Procedure:

- MOF Synthesis: Dissolve 1.19g Zn(NO₃)₂·6H₂O in 40mL methanol (Solution A). Dissolve 2.63g 2-methylimidazole in 40mL methanol (Solution B). Mix B into A rapidly. Stir for 1 hour. Centrifuge, wash with methanol 3x, dry at 60°C to obtain ZIF-8 powder.

- Iron Impregnation: Prepare 10mL methanolic solution with 30mg FeCl₃·6H₂O. Incipient wetness impregnate 0.5g ZIF-8 powder. Dry at 60°C.

- Pyrolysis: Place powder in a quartz boat inside a tube furnace. Purge with Ar for 30 min. Pyrolyze at 950°C for 1 hour under Ar (100 sccm), with a 30 min hold at 180°C for drying. Optionally, introduce a 20% NH₃/Ar mix for the final 15 min for additional N-doping.

- Acid Leaching: Cool under Ar. Stir the pyrolyzed powder in 0.5M H₂SO₄ at 80°C for 8 hours to remove unstable species and metallic Fe nanoparticles.

- Washing & Drying: Filter, wash with DI water to neutral pH, and dry at 80°C overnight.

- Characterization: Perform XRD (amorphous carbon), Raman (ID/IG), XPS (N, Fe species), SEM-EDS (morphology, elemental mapping).

Diagrams

Diagram Title: System Boundary for Catalyst LCA

Diagram Title: Pt/C Catalyst Synthesis Protocol

Diagram Title: Fe-N-C Catalyst Synthesis Protocol

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Electrocatalyst Synthesis & LCA Inventory

| Item | Function in Synthesis | Relevance to LCA System Boundary |

|---|---|---|

| Chloroplatinic Acid (H₂PtCl₆) | Standard Pt precursor for impregnation methods. | Represents the end point of energy-intensive PGM mining and refining. Its production data is crucial for PM-LCA. |

| Vulcan XC-72R Carbon | Conductive high-surface-area catalyst support. | Production from petroleum coke has associated carbon/energy footprint. Often a common factor in PM and NPM studies. |

| Metal-Organic Frameworks (e.g., ZIF-8) | Sacrificial templates/precursors for N-doped carbon structures. | Synthesis of MOFs requires ligands and metal salts; their production footprint must be included in the NPM catalyst boundary. |

| Ammonia (NH₃) Gas | Nitrogen doping agent during pyrolysis. | High environmental impact from industrial Haber-Bosch process. A key input for many NPM catalysts. |

| Sodium Borohydride (NaBH₄) | Reducing agent for metal precursors. | Its chemical production footprint is included within the synthesis step. |

| Inert Gases (Ar, N₂) | Atmosphere control during pyrolysis and reduction. | Energy cost of gas separation/purification (cryogenic distillation) is a non-trivial energy input, especially for high-temp pyrolysis. |

| Tube Furnace | High-temperature reactor for pyrolysis. | While capital equipment is often excluded, the electricity consumed during pyrolysis is a major LCA hotspot and must be meticulously measured. |

Application Notes for Electrocatalyst LCA Research

Within the context of a Life Cycle Assessment (LCA) comparing precious metal (e.g., Pt, Ir) and non-precious metal (e.g., Fe-N-C, Ni-based) electrocatalysts, a robust Life Cycle Inventory (LCI) is foundational. The primary data challenge lies in the disparity between well-established, high-quality data for conventional precious metals and the evolving, often proprietary or lab-scale data for emerging non-precious metal alternatives.

Key LCI Data Categories and Sourcing Challenges:

- Catalyst Synthesis: Energy and reagent inputs for methods like hydrothermal synthesis, chemical vapor deposition, or impregnation for non-precious metal catalysts (NPMCs) are often derived from lab-scale experiments. In contrast, precious metal catalyst (PMC) production data is more industrialized but energy-intensive.

- Material Sourcing: Precious metal mining (e.g., Pt from South Africa) has well-documented but significant environmental inventories (land use, acidification, energy use). NPMC precursors (e.g., iron salts, carbon supports, nitrogen sources) have their own supply chains with varying data quality.

- Process Operations: Cell performance data (current density, overpotential, lifetime) directly impacts the electricity input/credit during the use phase. NPMCs may have lower performance but avoid critical material supply risks.

- End-of-Life: Recycling rates for precious metals are relatively high (>50% for automotive catalysts), whereas recycling pathways for NPMCs are underdeveloped, often modeled as landfilling or incineration.

Protocols for LCI Data Compilation

Protocol 1: Primary Data Collection for Lab-Scale Catalyst Synthesis

Objective: To generate primary LCI data for a novel Fe-N-C electrocatalyst synthesis procedure.

Materials & Equipment: Three-neck flask, Schlenk line, tube furnace, lyophilizer, mass flow controllers, balances, solvents (ethanol, HCl), precursors (Iron(III) chloride, 1,10-phenanthroline, Carbon Black).

Procedure:

- Impregnation: In a N₂-glovebox, dissolve 100 mg FeCl₃ and 212 mg 1,10-phenanthroline in 50 mL ethanol. Add 500 mg Vulcan carbon black. Sonicate for 1 hour.

- Drying: Transfer slurry to a rotary evaporator (70°C, 30 min) followed by lyophilization for 12 hours. Record total energy consumption of both units.

- Pyrolysis: Place dried powder in a quartz boat. Insert into a tube furnace. Purge with Ar (100 sccm) for 30 min. Pyrolyze at 800°C for 2 hours under Ar (50 sccm) and NH₃ (20 sccm). Record exact furnace power draw via a watt-meter.

- Work-up: Cool under Ar. Weigh product. Acid-leach in 0.5 M H₂SO₄ at 80°C for 8 hours. Filter, wash, and dry. Record mass losses and chemical consumption.

- Data Recording: Record masses of all inputs (precursors, solvents, gases) and outputs (product, waste). Log precise energy use (kWh) for sonication, evaporation, lyophilization, and pyrolysis.

Protocol 2: Secondary Data Sourcing and Validation

Objective: To source and evaluate reliable secondary LCI data for comparative processes.

Procedure:

- Database Selection: Prioritize peer-reviewed databases: Ecoinvent v3.9+, GREET 2022, and the U.S. Life Cycle Inventory Database.

- Data Retrieval:

- For precious metals, query "platinum group metal production, primary" or "chloroplatinic acid production." Use market allocation for multi-metal ores.

- For chemicals & energy, query regional-specific processes (e.g., "electricity, medium voltage, US-grid" vs. "EU-grid").

- Data Quality Assessment: Score each dataset via the Pedigree Matrix (reliability, completeness, temporal, geographical, and technological representativeness). Note gaps.

- Proxy & Modeling: For novel NPMC precursors without existing datasets, use a proxy from the same chemical class (e.g., use "iron chloride" for FeCl₃) and adjust stoichiometry. Document all assumptions.

Table 1: Representative LCI Data Points for Electrocatalyst Production (Per kg of Catalyst)

| Data Item | Precious Metal Catalyst (Pt/C) | Non-Precious Metal Catalyst (Fe-N-C) | Data Source & Notes |

|---|---|---|---|

| Pt/Fe Metal Input | 200 g (from primary ore) | 20 g (from FeCl₃) | Ecoinvent 3.9 "Pt, primary"; FeCl₃ proxy from market data. |

| Energy for Synthesis | 800-1200 kWh | 300-500 kWh (lab-scale) | PMC: Industrial calcination. NPMC: Lab furnace data (Primary). |

| Solvent Use | Low (water) | High (Ethanol, ~50 L) | Primary lab data for NPMC; Industrial data for PMC. |

| Global Warming Potential (A1-A3) | 15,000 - 25,000 kg CO₂-eq | 5,000 - 10,000 kg CO₂-eq (estimate) | Highly sensitive to energy mix and metal inventory. |

| Catalyst Lifetime | 5,000 - 10,000 hours | 1,000 - 4,000 hours | Literature review; major use-phase impact driver. |

Table 2: Research Reagent Solutions Toolkit

| Item | Function in Electrocatalyst LCA Research |

|---|---|

| ICP-MS Standard Solutions | Quantify trace metal leaching from catalysts into electrolyte, critical for toxicity impact assessment. |

| High-Purity Gases (N₂, Ar, NH₃) | For controlled synthesis (pyrolysis) and electrochemical cell operation. Purity affects catalyst performance data. |

| Nafion Binder Solution | Standard electrode preparation. Inventory of this perfluorinated polymer is essential for full LCI. |

| Rotating Disk Electrode (RDE) Setup | Standardized protocol (e.g., from Pine Research) to measure intrinsic activity (mass activity, Tafel slope) for functional unit definition. |

| Accelerated Stress Test (AST) Protocols | Standardized potential cycling to estimate catalyst durability (lifetime), a critical use-phase parameter. |

Visualizations

LCI Data Sourcing and Compilation Workflow

From Inventory Flows to Impact Assessment

Within a Life Cycle Assessment (LCA) thesis comparing precious metal (e.g., Pt, Ir, Pd) and non-precious metal (e.g., Fe, Ni, Co-based) electrocatalysts for applications like fuel cells and electrolyzers, the allocation of environmental burdens from upstream mining and refining is a critical, unresolved methodological challenge. These metals are rarely the sole product of a mining operation; they are co-produced or occur as by-products within complex multi-product streams. The chosen allocation method (mass, economic value, energetic content, or system expansion) directly and significantly influences the calculated environmental footprint (e.g., GHG emissions, water use) of the catalyst, potentially altering the comparative conclusions of the thesis. These Application Notes provide protocols for navigating this complexity.

Foundational Allocation Methods: Protocols & Data

The following table summarizes the core allocation methods, their protocols for application, and key considerations within the electrocatalyst LCA context.

Table 1: Core Allocation Methods for Multi-Product Mining Streams

| Method | Protocol for Application | Rationale | Key Advantage | Key Disadvantage for Catalyst LCA |

|---|---|---|---|---|

| Mass-Based | 1. Identify total output mass of all co-products from the process. 2. Calculate the mass fraction of the target metal (e.g., Pt) relative to total output. 3. Allocate the same fraction of the total process's environmental burden (e.g., CO2e, energy) to the target metal. | Burden is distributed according to physical quantity. | Simple, objective, reproducible. | Highly misleading for precious metals. A gram of platinum carries the same burden as a gram of waste rock, ignoring the economic and functional driver for the operation. |

| Economic Value-Based | 1. Obtain average market prices for all saleable co-products (e.g., Pt, Cu, Ni) over a relevant period (e.g., 5-year average). 2. Calculate the revenue fraction attributable to the target metal. 3. Allocate the environmental burden in proportion to this revenue fraction. | Burden is tied to the economic driver of the process. | Reflects the primary motivation for extraction; often recommended in LCA standards (e.g., ISO 14044). | Subject to price volatility. A price surge can drastically lower the allocated burden for a precious metal, affecting LCA comparability over time. |

| System Expansion (Substitution) | 1. Define the studied system yielding the target metal. 2. Expand system boundaries to include the avoided production of co-products. 3. The system is credited with the burdens of producing the co-products by alternative means. 4. Net burden = Burden of mining/refining complex - Avoided burdens of alternative co-product production. | Avoids allocation by modeling the multi-output process as a multi-function system. | Conceptually robust, avoids arbitrary partitioning. | Data-intensive. Requires full LCA data for the alternative production routes of all co-products. Complex to implement and communicate. |

| Physical / Energetic | 1. Determine a relevant underlying physical property (e.g., enthalpy of formation, exergy content, elemental scarcity). 2. Allocate burdens in proportion to this property across all outputs. | Seeks a causal, scientific basis for distribution. | Attempts to move beyond purely economic or mass metrics. | No consensus on the "correct" property. Methods are often complex and not widely adopted in databases. |

Experimental Protocol: Implementing Economic Allocation for a Platinum-Group Metal (PGM) Stream

This protocol details the steps to calculate the allocated global warming potential (GWP) for 1 kg of refined Platinum from a typical South African Bushveld Complex mine, which co-produces Platinum, Palladium, Rhodium, Gold, Copper, and Nickel.

Protocol Title: Economic Allocation for Platinum in a Multi-Product PGM-Cu-Ni Refining Stream.

Objective: To determine the share of total refining GWP burden allocated to 1 kg of Platinum based on the relative economic value of co-products.

Materials & Data Requirements:

- Total annual GWP (kg CO2e) for the integrated mining and refining process (from industry LCA or database e.g., Ecoinvent, GaBi).

- Annual production mass data for all saleable metal outputs (kg/year).

- Long-term average market prices for each metal (USD/kg).

Procedure:

- System Definition: Define the process system boundary as "Integrated mining, concentration, smelting, and refining of PGM-Cu-Ni ore."

- Data Collection: a. Obtain process output data (see example in Table 2). b. Source 10-year average metal prices from authoritative sources (e.g., London Metal Exchange, Johnson Matthey PGM market reports).

- Revenue Calculation:

a. For each co-product

i, calculate annual revenue:Revenue_i = Mass_i * Price_i. b. Sum revenues of all co-products to determineTotal Annual Revenue. - Allocation Factor Calculation:

a. For Platinum, calculate its revenue fraction (allocation factor):

AF_Pt = Revenue_Pt / Total Annual Revenue. - Burden Allocation:

a. Multiply the

Total Annual Process GWPbyAF_Ptto get theAnnual GWP allocated to Platinum production. b. DivideAnnual GWP allocated to Platinum productionbyAnnual Mass of Pt producedto get theAllocated GWP per kg of Pt.

Table 2: Exemplary Economic Allocation Calculation for a PGM Refinery Output

| Co-product | Annual Mass (kg) [Example] | 10-Yr Avg Price (USD/kg) [Example] | Annual Revenue (USD) | Revenue Fraction (Allocation Factor) |

|---|---|---|---|---|

| Platinum (Pt) | 10,000 | 30,000 | 300,000,000 | 0.576 |

| Palladium (Pd) | 5,000 | 40,000 | 200,000,000 | 0.384 |

| Rhodium (Rh) | 500 | 200,000 | 100,000,000 | 0.192 |

| Gold (Au) | 100 | 60,000 | 6,000,000 | 0.012 |

| Copper (Cu) | 5,000,000 | 8 | 40,000,000 | 0.077 |

| Nickel (Ni) | 2,000,000 | 15 | 30,000,000 | 0.058 |

| Total | 7,015,600 | - | $521,000,000 | 1.000 |

- Result: Using the example data, 57.6% of the total refinery GWP burden would be allocated to Platinum. If the Total Annual Process GWP were 500,000,000 kg CO2e, then the Allocated GWP per kg of Pt = (500,000,000 kg CO2e * 0.576) / 10,000 kg Pt = 28,800 kg CO2e/kg Pt.

The Scientist's Toolkit: Research Reagent Solutions & Materials

Table 3: Essential Materials for Electrocatalyst LCA & Allocation Research

| Item / Solution | Function / Relevance in Allocation Research |

|---|---|

| LCA Software (e.g., OpenLCA, SimaPro, GaBi) | Core platform for building product system models, applying allocation rules, and calculating impact assessment results. |

| Life Cycle Inventory Database (e.g., Ecoinvent, GREET, Industry Data) | Source of foreground (specific process) and background (energy, chemicals) data. Critical for finding multi-output process data to which allocation must be applied. |

| Metal Market Price Database (e.g., LME, USGS, S&P Global) | Provides historical and current price data essential for performing economic allocation calculations. Long-term averages are recommended to smooth volatility. |

| ISO 14044:2006 Standard | The international standard providing the hierarchy for dealing with multi-functionality: 1) process subdivision, 2) system expansion, 3) allocation based on physical relationships, 4) allocation based on other relationships (e.g., economic). |

| Sensitivity Analysis Scripts (e.g., Python/R) | Custom scripts to automate the recalculation of LCA results under different allocation methods (mass, economic, etc.) to test the robustness of comparative conclusions. |

| Industry Sustainability Reports | Source of primary, site-specific data for mining and refining operations, which can provide actual co-product mass ratios and sometimes life cycle inventory data. |

Visualization: Decision Pathway for Allocation in Electrocatalyst LCA

Diagram Title: Decision Pathway for Allocation Method Selection in LCA

Visualization: Comparative LCA Workflow for Precious vs. Non-Precious Metal Catalysts

Diagram Title: LCA Workflow with Allocation for Catalyst Comparison

Application Notes

Life Cycle Assessment (LCA) is a critical methodology for evaluating the environmental impacts of precious metal (e.g., Pt, Ir) and non-precious metal (e.g., Fe-N-C, Ni-based) electrocatalysts used in applications like fuel cells and electrolyzers. The choice of software and database directly influences the accuracy, reproducibility, and scope of such assessments. This section details the application of three cornerstone tools.

Ecoinvent Database

Ecoinvent is a comprehensive, process-based life cycle inventory database. It provides background data for materials, energy, transport, and waste management.

- Primary Application in Electrocatalyst Research: Used to model upstream processes such as metal mining and refining (e.g., platinum group metals), chemical synthesis for catalyst precursors, and energy supply chains. The system models (Allocation at the Point of Substitution) are essential for handling multi-output processes in mining.

- Current Version & Notes: Ecoinvent v3.9.1 (2023) features updated data on global metal sectors and energy grids. Researchers must carefully select geographic correlations (e.g., global vs. regional mining data) and technological representations to match their catalyst supply chain assumptions.

GREET Model

The Greenhouse gases, Regulated Emissions, and Energy use in Technologies (GREET) model, developed by Argonne National Laboratory, is a foremost tool for cradle-to-grave lifecycle analysis of vehicle fuels and advanced transportation technologies.

- Primary Application in Electrocatalyst Research: Particularly valuable for analyzing electrocatalysts within the context of their end-use application (e.g., proton exchange membrane fuel cell vehicles or hydrogen production via electrolysis). GREET's well-to-wheels framework integrates fuel cycles and vehicle operations.

- Current Version & Notes: GREET 2023 (rev1) includes expanded modules for carbon-intensive materials, low-carbon hydrogen, and updated electricity generation profiles. Its integrated material and fuel cycle modeling is unique.

OpenLCA Software

OpenLCA is an open-source LCA software that can utilize multiple databases, including Ecoinvent and the US Life Cycle Inventory (USLCI) database.

- Primary Application in Electrocatalyst Research: Serves as the primary calculation and modeling platform to integrate foreground data (lab-scale synthesis, catalyst performance) with background databases. Its open-source nature allows for high customization and transparency, crucial for novel catalyst pathways not present in commercial databases.

- Current Version & Notes: OpenLCA 2.1.0 offers improved performance and native support for the Environmental Footprint method. The integration with the Nexus repository simplifies access to numerous LCA datasets.

Table 1: Comparative Summary of LCA Tools for Electrocatalyst Research

| Feature | Ecoinvent Database | GREET Model | OpenLCA Software |

|---|---|---|---|

| Primary Type | Life Cycle Inventory (LCI) Database | Integrated LCA Model & Database | LCA Calculation Software |

| Core Strength | Comprehensive, granular background data on material/energy flows. | Holistic analysis of fuels & vehicles; integrated system boundaries. | Open-source, flexible, supports multiple databases and impact methods. |

| Key Use in Catalyst LCA | Modeling upstream impacts of metal production, chemical inputs, and energy. | Assessing catalysts within the full fuel/vehicle cycle (well-to-wheels). | Performing the full LCA by linking foreground inventory to background data. |

| Latest Version | v3.9.1 (2023) | GREET 2023 (rev1) | 2.1.0 (2024) |

| Access Model | Commercial license (free for academic use in some regions). | Free. | Free and open-source. |

| Impact Methods | N/A (provides inventory data) | Focus on GHG, energy, criteria pollutants. | Extensive library (ReCiPe, EF, TRACI, etc.) |

Experimental Protocols

Protocol for Integrating Lab-Scale Synthesis Data into OpenLCA (Foreground Modeling)

This protocol outlines the steps to model the laboratory-scale synthesis of a novel non-precious metal Fe-N-C electrocatalyst within OpenLCA, creating a transparent and modifiable foreground system.

I. Goal and Scope Definition

- Define the functional unit (e.g., "1 kg of synthesized catalyst with a specified oxygen reduction reaction activity").

- Set system boundaries from cradle-to-gate, including raw material extraction, chemical production, synthesis, and post-processing.

II. Primary Data Collection (Inventory for 1 kg Catalyst Batch)

- Mass Balance: Precisely weigh all input masses (e.g., Iron(III) nitrate nonahydrate, 1,10-Phenanthroline, Carbon black, NH₃ gas).

- Energy Monitoring: Record electricity consumption (kWh) of all equipment (tube furnace for pyrolysis, ultrasonicators, stirrers, drying ovens) using plug-load meters. Record duration of each step.

- Solvent & Waste Tracking: Measure volumes of solvents used (e.g., ethanol, water for washing) and masses of waste generated. Assume evaporation losses for volatile solvents unless recovered.

III. OpenLCA Modeling Procedure

- Create a New Project: Open OpenLCA, create a new project titled "Fe-N-CCatalystSynthesis_v1."

- Build the Product System:

- Create a new Process for the final catalyst.

- For each input (chemicals, energy), add an Input Flow.

- Link commercial chemicals (e.g., Phenanthroline) to corresponding market datasets from Ecoinvent (e.g., "phenanthroline, at plant/GLO").

- For electricity, select the appropriate grid mix (e.g., "electricity, medium voltage, at grid/US").

- Create Intermediate Processes for major synthesis steps (e.g., "Precursor Mixing," "Pyrolysis," "Acid Leaching"). Allocate energy and material flows to these sub-processes.

- Define the reference flow as 1 kg of the catalyst output flow from the main process.

- Calculate and Interpret: Run the calculation using an impact method (e.g., EF 3.1). Analyze contribution analysis to identify hotspots (e.g., pyrolysis energy, precursor chemicals).

Protocol for Conducting a Comparative LCA in GREET

This protocol details a well-to-wheels comparison of a fuel cell vehicle using a Pt-based catalyst versus a non-precious metal catalyst.

I. Vehicle and Fuel System Definition

- Baseline Setup: Launch GREET 2023. In the "Fuel-Cycle" (GREET1) tab, select "Hydrogen" as the fuel and "Fuel Cell Vehicle" as the vehicle technology.

- Define Hydrogen Pathways: For each catalyst scenario, model the hydrogen production pathway (e.g., PEM electrolysis). The catalyst choice affects the electrolyzer's efficiency and lifetime.

- Scenario A (Pt): Set electrolyzer stack efficiency based on literature using Pt-based anodes/ cathodes. Assume a stack lifetime of 80,000 hours.

- Scenario B (Non-Precious): Adjust stack efficiency (potentially lower) and lifetime (potentially shorter) based on experimental data for the alternative catalyst.

- Embed Material Impacts: Navigate to the "Material-Cycle" module in GREET. Input the mass of catalyst per kW of stack power for each scenario. GREET will pull in the material production energy and emissions, linking it to the fuel-cycle model.

II. Parameter Specification and Run

- For each scenario, specify key parameters in the graphical user interface:

- Electricity grid mix for electrolysis (e.g., U.S. National Average).

- Catalyst loading (g/kW), recovery rate at end-of-life.

- Vehicle efficiency (miles per kg H₂), which can be held constant or varied if catalyst performance affects fuel cell efficiency.

- Execute Runs: Run the GREET model for both scenarios.

- Extract Results: Export the well-to-wheels GHG emissions (g CO₂-eq/mile), total energy use (MJ/mile), and criteria pollutant results for comparison.

Table 2: Key Research Reagent Solutions & Materials for Electrocatalyst LCA

| Item / Reagent | Function in LCA Modeling | Source / Database Entry Example |

|---|---|---|

| Platinum, primary, at refinery | Models the high-impact upstream mining and refining of precious metal catalysts. | Ecoinvent: market for platinum, at refinery/GLO |

| Iron(III) nitrate nonahydrate | Models precursor for non-precious metal catalyst synthesis. | Ecoinvent: iron nitrate production, at plant/GLO |

| Ammonia, liquid, at plant | Models nitrogen source for doping carbon catalysts during pyrolysis. | Ecoinvent: ammonia, liquid, at plant/RER |

| Electricity, medium voltage | Models energy consumption for synthesis (furnaces) and catalyst operation (electrolyzers). | Ecoinvent: electricity, medium voltage, at grid/CN (Choose relevant region) |

| Carbon Black | Models the primary catalyst support material. | GREET Material-Cycle: Carbon Black |

| Nafion membrane | Models the ionomer used in catalyst layer fabrication. | USLCI (via OpenLCA): Perfluorosulfonic acid polymer resin production |

| Hydrogen, PEM electrolysis | Models the fuel production pathway enabled by the catalyst. | GREET Fuel-Cycle: Hydrogen, Central, PEM Electrolysis |

Visualizations

Diagram 1: LCA Framework for Electrocatalyst Comparison

Diagram 2: OpenLCA Modeling Workflow for Catalyst LCA

This application note provides a structured framework for conducting a comparative Life Cycle Assessment (LCA) of three distinct synthesis routes—Hydrothermal, Pyrolysis, and Sputtering—for the production of electrocatalysts. This work is framed within a broader thesis evaluating the environmental and resource sustainability of transitioning from precious metal (e.g., Pt, Ir) to non-precious metal (e.g., Fe-N-C, transition metal oxides) electrocatalysts for applications like fuel cells and water electrolyzers. A rigorous LCA of the synthesis phase is critical, as the environmental footprint of novel catalyst manufacturing can offset operational benefits.

Goal and Scope Definition

- Goal: To quantify and compare the environmental impacts associated with the synthesis of 1 gram of active electrocatalyst material via three routes.

- Scope: Cradle-to-Gate (from raw material extraction to synthesized catalyst powder/film).

- System Boundaries: Include energy consumption for synthesis, material inputs (precursors, solvents, gases), equipment manufacturing (amortized), waste streams, and auxiliary processes (e.g., drying, milling, annealing). Catalyst performance (activity, stability) is excluded but is a critical parameter for the broader thesis, linking environmental cost to functional output.

- Functional Unit: 1 gram of synthesized electrocatalyst with defined electrochemical surface area (ECSA) ≥ 50 m²/g.

Life Cycle Inventory (LCI) Data & Comparative Tables

Data is compiled from recent literature (post-2020) and process modeling.

Table 1: Key Inventory Data per Functional Unit (1g catalyst)

| Inventory Item | Hydrothermal Synthesis (Fe₃O₄ NPs) | Pyrolysis Synthesis (Fe-N-C) | Sputtering Synthesis (PtCo Film) |

|---|---|---|---|

| Energy Input | 1.2 kWh (Autoclave heating, 180°C, 12h) | 3.8 kWh (Tube furnace, 900°C, 2h under Ar) | 4.5 kWh (Vacuum & RF power, 30 min) |

| Key Material Inputs | 2.5g FeCl₃·6H₂O, 100g H₂O, 5g Urea, 50g EtOH (wash) | 1.5g Phenolic resin, 0.3g Fe(Ac)₂, 2g Melamine, 10L Argon | 0.05g Pt target, 0.02g Co target, 5L Argon (process gas) |

| Water Consumption | 120 g (primarily for cooling) | 50 g (cooling) | 500 g (chiller system for target cooling) |

| Waste Outputs | 105g Alkaline wastewater (NH₃, Cl⁻), 50g EtOH waste | 0.5g VOC off-gas, spent quartz tube (infrequent) | Negligible solid waste (target erosion) |

| Synthesis Time | 12-24 h | 3-5 h (excl. precursor prep) | 0.5-1 h (excl. substrate prep) |

| Catalyst Yield | ~85% | ~65% (includes etching) | >95% (on substrate) |

Table 2: Potential Impact Indicators (Mid-Point, CML-IA Baseline)

| Impact Category | Unit | Hydrothermal | Pyrolysis | Sputtering | Dominant Driver for High Impact |

|---|---|---|---|---|---|

| Global Warming Potential (GWP) | kg CO₂ eq. | 0.45 | 1.52 | 2.15 | Sputtering: High vacuum energy. Pyrolysis: High thermal energy. |

| Energy Demand (CED) | MJ | 4.3 | 13.7 | 16.2 | Sputtering: RF power & vacuum pumps. |

| Acidification Potential | kg SO₂ eq. | 0.0012 | 0.0041 | 0.0058 | Linked to grid electricity generation. |