Seeing the Invisible

How Neutrons Illuminate Catalysis in Action

Article Navigation

Imagine trying to repair a car engine while it's running—blindfolded. This is the challenge scientists face when studying catalysts, the molecular "engines" driving 90% of industrial chemistry. For decades, researchers struggled to observe these processes in real-time, until neutron scattering spectroscopy transformed the field.

Why Catalysts Need Neutron Vision

Catalysts accelerate chemical reactions without being consumed, enabling everything from fertilizer production to pollution control. Yet their atomic-scale workings remain shrouded in mystery. Traditional techniques like X-rays struggle to detect light elements (hydrogen, oxygen) central to reactions, while electron microscopy often requires artificial vacuum conditions 1 2 .

Enter the neutron:

"Neutrons provide a unique perspective—they make heavy metal catalysts virtually disappear, letting us focus on the hydrocarbon actors in the chemical drama"

The In Situ Revolution

Static observations miss catalyst behavior during actual reactions. In situ neutron facilities create "movie mode" for chemistry:

Reaction conditions

Maintain industrial temperatures (up to 950°C) and pressures 2

Simultaneous measurement

Combine neutron data with gas chromatography (GC) or mass spectrometry (MS) 1

Key neutron techniques:

Anatomy of a Breakthrough: The SNS Catalysis Facility

The Spallation Neutron Source (SNS) at Oak Ridge National Laboratory houses a pioneering in situ catalysis suite. Designed by Cheng et al., this facility became the first to combine neutron spectroscopy with industrial reaction conditions 1 5 .

The Spallation Neutron Source at Oak Ridge National Laboratory

The Experiment: Watching Hydrocarbons Dance

In a landmark study, researchers investigated the Fischer-Tropsch process—where syngas (CO+H₂) transforms into fuels. Iron-based catalysts produce mysterious hydrocarbon layers that control selectivity, but their composition evaded detection for decades.

Step-by-step methodology:

- Reactor loading: Packed 10g of hematite catalyst (Fe₂O₃) into a quartz tube reactor 1 2

- Gas control: Syngas flowed via mass flow controllers (0.5 L/min) at 300°C and 20 bar 1

- Neutron probing: INS spectra collected on MAPS beamline during reaction 3

- Product analysis: Online GC/MS monitored exhaust gases every 5 minutes 1

Results that rewrote textbooks:

- INS peaks at 900 cm⁻¹ revealed polyethylene-like chains coating the catalyst 3

- QENS showed chains slowed reactant diffusion by 60%, explaining selective olefin production

- Swapping H₂ for D₂ confirmed surface species were reaction intermediates, not byproducts 3

| Peak (cm⁻¹) | Molecular Assignment | Significance |

|---|---|---|

| 720 | Fe-C stretch | Catalyst-hydrocarbon bond formation |

| 900 | -(CH₂)- rock | Long-chain hydrocarbon overlayer |

| 1060 | C-O bend | CO dissociation intermediate |

| 2900 | C-H stretch | Confirmed organic nature of layer |

"This hydrocarbon 'skin' acts like a bouncer—it lets small olefins leave quickly but keeps larger molecules trapped for further processing"

The Scientist's Toolkit

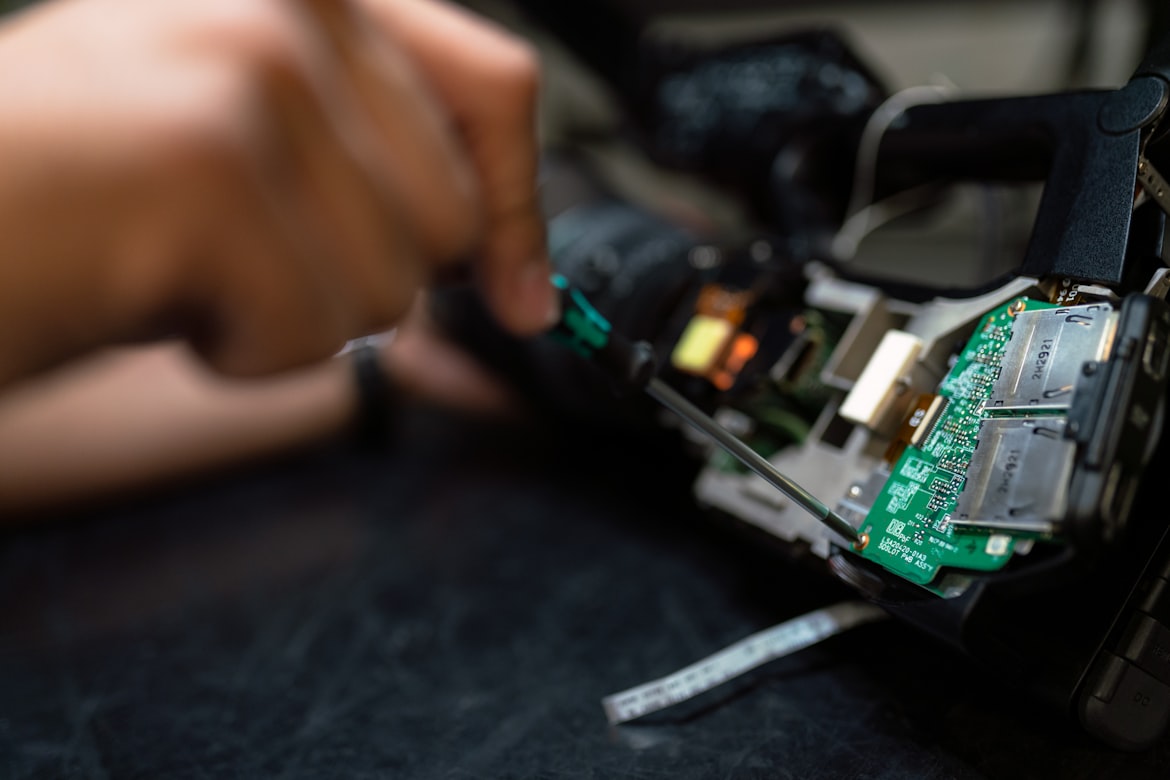

Designing such facilities requires ingenious solutions to extreme challenges:

| Component | Function | Innovation |

|---|---|---|

| Quartz reactors | Holds catalyst during neutron exposure | Brittle yet transparent; avoids metal-induced side reactions 2 |

| Mass flow controllers | Precise reactant gas blending | Computer-controlled mixing with 0.1% accuracy 1 |

| ANSYS modeling | Stress simulation | Prevents quartz fracture at 950°C thermal gradients 2 |

| AlMg₃ sample cells | High-pressure containment | Withstands 100 bar but avoids hydrogen embrittlement 2 |

| Cryogenic choppers | Energy filtering | Time-of-flight separation of neutron energies 1 |

Thermal management is critical:

Future Frontiers

Recent advances are pushing neutron catalysis into new realms:

Operando imaging

ISIS facility now tracks hydrogen fronts moving through Pd/C catalysts at 5-second resolution 4

Machine learning

AI deciphers complex QENS diffusion data 100x faster 3

Extreme conditions

China's CSNS achieves 800°C measurements for biomass conversion catalysts 2

"We've reduced catalyst optimization time from years to months by integrating neutron data—this is how we'll design carbon-neutral catalysts"

The Catalyst's New Eyes

Neutron scattering facilities have transformed catalysis from alchemy to atomic engineering. By peering inside working reactors, scientists now tweak catalyst architectures to boost efficiency, selectivity, and sustainability. As facilities like SNS and CSNS push temperature and resolution limits, they illuminate the path to replacing fossil fuels with green alternatives—one neutron at a time.

The next time you fill your car, remember: invisible neutrons helped craft that fuel.