Sol-Gel Catalyst Synthesis: A Guide to Advanced Materials for Biomedical and Environmental Applications

This article provides a comprehensive exploration of the sol-gel process for synthesizing advanced catalytic materials, tailored for researchers and drug development professionals.

Sol-Gel Catalyst Synthesis: A Guide to Advanced Materials for Biomedical and Environmental Applications

Abstract

This article provides a comprehensive exploration of the sol-gel process for synthesizing advanced catalytic materials, tailored for researchers and drug development professionals. It covers the foundational chemistry of sol-gel reactions, detailed methodologies for creating catalysts for drug delivery and environmental uses, strategies for optimizing critical parameters like heat treatment and composition, and modern validation techniques including AI-assisted analysis. The content synthesizes recent research to serve as a practical guide for developing high-performance, tailored catalysts.

The Chemistry and Principles of Sol-Gel Synthesis for Advanced Catalysts

The sol-gel process is a versatile wet-chemical technique widely employed for the fabrication of solid materials, ranging from metal oxides and ceramics to organic-inorganic hybrids [1]. This method involves the transformation of a colloidal solution (sol) into a solid, three-dimensional network (gel) that encapsulates a liquid phase [2] [3]. Its significance in modern materials science, particularly in catalyst synthesis, stems from its ability to produce materials with fine microstructural control, high purity, and homogeneous composition at relatively low temperatures [1] [4]. The process is considered a green synthesis route, as it often utilizes mild conditions, with water or alcohols as solvents, and operates frequently at room temperature [2]. For catalytic applications, the sol-gel method enables the design of high-surface-area materials with stable surfaces and the precise incorporation of catalytic active sites, such as vanadium oxide, into a support matrix like silica [4].

Core Chemical Principles

The sol-gel process is fundamentally governed by two sequential types of chemical reactions: hydrolysis and condensation. These reactions transform molecular precursors into an extended oxide network.

Hydrolysis

Hydrolysis is the initial step where metal alkoxide precursors (e.g., tetraethyl orthosilicate, or TEOS, for silica) react with water. This reaction replaces alkoxide groups (OR) with hydroxyl groups (OH) [1] [5].

General Reaction: Si(OR)4 + H2O → HO-Si(OR)3 + R-OH [1]

Condensation

Following hydrolysis, condensation reactions occur, leading to the formation of metal-oxygen-metal (M-O-M) bridges. This step is responsible for building the polymeric network and liberates small molecules like water or alcohol as byproducts [1] [5].

Polymerization Example: (OR)3Si-OH + HO-Si(OR)3 → (OR)3Si-O-Si(OR)3 + H2O [1]

The progression of these reactions is critically influenced by several parameters, which are summarized in the table below.

Table 1: Key Parameters Influencing the Sol-Gel Process and Final Material Properties

| Parameter | Influence on Process & Material | Typical Experimental Levers |

|---|---|---|

| pH (Acid/Base Catalyst) | Determines reaction rates and network structure. Acid catalysis favors linear, polymeric gels; base catalysis favors particulate, colloidal gels [1]. | Use of HNO₃, HCl (acidic) or NH₄OH (basic) [4] [3]. |

| Precursor to Water Ratio ([H₂O]/[M]) | Affects the extent of hydrolysis. Low ratios lead to incomplete hydrolysis and weakly branched networks; high ratios drive hydrolysis toward completion [1]. | Varying the molar amount of water added to the alkoxide precursor. |

| Reaction Temperature | Influences reaction kinetics and network density. Higher temperatures accelerate reactions and can lead to higher condensation degrees and a more cross-linked network [6]. | Conducting reactions at room temperature vs. elevated temperatures (e.g., 65 °C) [6]. |

| Solvent Type | Affects the polarity of the medium, nanocrystal growth, and self-assembly, ultimately influencing the morphology and porosity of the final nanostructures [3]. | Use of water, ethanol, dimethylformamide (DMF), or toluene [3]. |

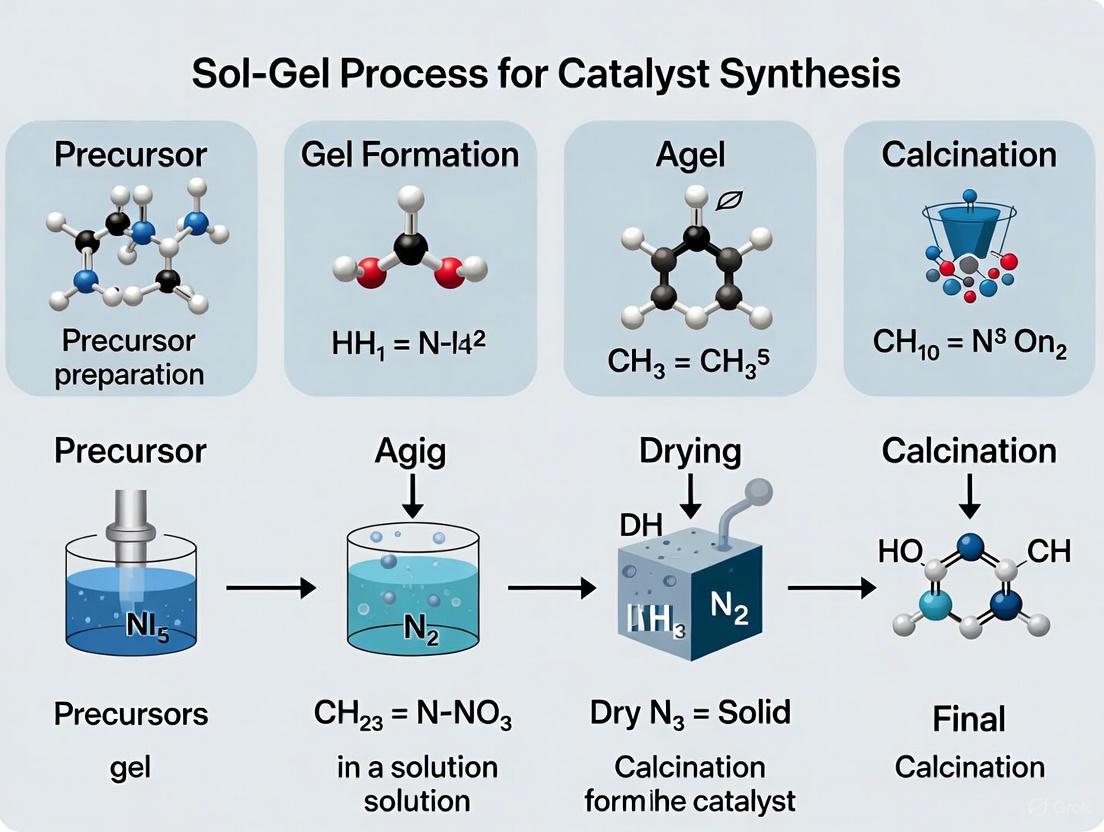

The Core Stages of the Sol-Gel Process

The transformation from a solution of precursors to a final solid material can be broken down into several distinct stages. The following workflow diagram illustrates the primary pathway and key decision points in a standard sol-gel synthesis.

Diagram 1: The Sol-Gel Process Workflow

Sol Formation

The process begins with the formation of a sol—a stable colloidal suspension of solid particles (ranging from 1 to 100 nm) in a liquid medium [5] [6]. This is achieved through the controlled hydrolysis of molecular precursors (e.g., metal alkoxides like TMOS or TEOS). The hydrolysis reaction is often catalyzed by an acid or a base, which determines the size and nature of the resulting particles [1].

Gelation

The sol gradually evolves into a gel through polycondensation reactions. During gelation, the particles or polymers in the sol link together to form a three-dimensional, continuous solid network that spans the entire volume of the liquid medium, trapping it within its pores [1] [3]. This point is marked by a sharp increase in viscosity, leading to a solid-like, often gelatinous material [5].

Aging

After gelation, the wet gel is typically aged for a period that can range from hours to weeks. Aging strengthens the gel network through processes like Ostwald ripening and neoformation, where condensation reactions continue, thickening the network strands and increasing the gel's mechanical strength [1] [5]. This step is crucial to prevent cracking during the subsequent drying stage.

Drying

The drying stage involves the removal of the liquid pore fluid from the gel network. The method chosen for drying profoundly impacts the final material's properties, leading to different classes of products:

- Xerogels: Formed when the gel is dried under ambient conditions or at moderately low temperatures (25–100 °C). This process is accompanied by significant capillary pressure, leading to substantial shrinkage and densification of the network [1].

- Aerogels: Produced when the liquid is removed under supercritical conditions, which avoids the formation of a liquid-vapor meniscus. This method minimizes shrinkage and collapse of the pore structure, resulting in a highly porous and extremely low-density material [1].

Thermal Treatment (Firing)

A final thermal treatment is often applied to xerogels or other densified gels. This firing process serves several purposes: it removes residual organic species and hydroxyl groups, enhances polycondensation, and promotes sintering and grain growth [1]. This step is essential for achieving the desired mechanical properties, structural stability, and crystallinity in the final ceramic or glass product. A key advantage of the sol-gel route is that densification is often achieved at much lower temperatures than those required by traditional ceramic processing [1].

The Scientist's Toolkit: Essential Reagents & Materials

The following table details key reagents and materials commonly used in sol-gel synthesis for catalyst research.

Table 2: Essential Research Reagents for Sol-Gel Synthesis

| Reagent/Material | Typical Examples | Function in the Sol-Gel Process |

|---|---|---|

| Metal Alkoxide Precursors | Tetraethyl orthosilicate (TEOS), Tetramethyl orthosilicate (TMOS), Titanium isopropoxide, 3-methacryloxypropyltrimethoxysilane (MPTS) [1] [6] | Primary network formers. They undergo hydrolysis and condensation to build the inorganic or hybrid matrix. MPTS is an example of an organically-modified silicate for hybrid materials. |

| Solvents | Ethanol, Water, Dimethylformamide (DMF), Toluene [2] [3] | To dissolve precursors and facilitate homogenization. Solvent polarity can be used to control nanocrystal growth and final morphology [3]. |

| Catalysts | Nitric acid (HNO₃), Hydrochloric acid (HCl), Ammonia (NH₄OH) [4] [6] | To accelerate hydrolysis and condensation reactions. The choice of acid or base dictates the structure of the resulting gel network [1]. |

| Dopant/Active Phase Precursors | Vanadium acetylacetonate, Metal chlorides (e.g., MnCl₂, CuCl₂), Metal acetates, Rare-earth salts [1] [4] [3] | To introduce specific functional properties (e.g., catalytic activity) into the gel matrix. They can be added to the initial sol for homogeneous dispersion. |

| Chelating Agents | Citric Acid [1] | Used in processes like the Pechini method to chelate metal cations, preventing premature precipitation and ensuring atomic-level homogeneity in multi-component systems [1]. |

Experimental Protocol: Base-Catalyzed Synthesis of Mesoporous Metal Oxide Nanostructures

This protocol is adapted from a study demonstrating the synthesis of shape-controlled manganese oxide (Mn₃O₄) and copper oxide (CuO) nanostructures, relevant for catalysis applications [3].

Objective

To synthesize mesoporous metal oxide nanostructures via a base-catalyzed sol-gel approach combined with solvent-driven self-assembly.

Materials

- Metal Precursor: Manganese(II) chloride (MnCl₂) or Copper(II) chloride (CuCl₂).

- Base Solution: Sodium hydroxide (NaOH) solution.

- Solvents: Deionized water, ethanol, dimethylformamide (DMF), toluene.

- Equipment: Magnetic stirrer, beakers, centrifuge, drying oven.

Step-by-Step Procedure

- Sol Preparation: Dissolve the metal precursor (e.g., MnCl₂) in a 50 mL mixture of solvent (e.g., water, 70% ethanol, DMF, or a water/toluene mixture) under constant stirring. The concentration of the metal ion should be in the range of 0.1 M.

- Base Addition and Hydrolysis: Add a NaOH solution to the metal precursor solution dropwise. The study utilized molar ratios of metal precursor to base of 1:5, 1:10, and 1:15 [3]. The addition will initiate hydrolysis and the formation of a colloidal sol.

- Gelation and Aging: Continue stirring the mixture at low temperature (<80 °C) for several hours. The sol will gradually evolve into a gel. Allow the gel to age in the mother liquor for 24 hours to strengthen the network.

- Washing and Drying: Recover the gel by centrifugation. Wash the precipitate repeatedly with deionized water and ethanol to remove excess ions and byproducts. Dry the resulting product in an oven at 60-80 °C for 12 hours to obtain a xerogel.

- Characterization: The final nanostructures can be characterized by X-ray diffraction (XRD) for crystallinity, nitrogen adsorption-desorption for surface area and porosity, and scanning electron microscopy (SEM) for morphology.

Expected Outcomes

Using this method, the authors reported the formation of:

- Mn₃O₄ with hexagonal, irregular particle, or ribbon-like morphologies, with a high BET surface area of up to 91.68 m²/g [3].

- CuO nanostructures in the form of highly nanoporous thin sheets [3].

Advanced Applications in Catalyst Synthesis

The sol-gel process offers unique advantages for the design and synthesis of heterogeneous catalysts.

- High Dispersion of Active Sites: The process allows for the incorporation of catalytic active phases, such as vanadium oxide, directly into the sol, resulting in a highly dispersed and homogeneous distribution within the final oxide support (e.g., SiO₂) [4]. This can lead to stronger metal-support interactions compared to traditional impregnation methods.

- Organic-Inorganic Hybrid Catalysts: The sol-gel method can be used to create metal-organic frameworks (MOFs) and metal phosphonate hybrids, which have shown promise in catalysis for reactions such as aerobic oxidation and hydrogenation [2].

- Control over Porosity and Morphology: By manipulating sol-gel parameters and employing templating agents, catalysts with tailored pore sizes and high surface areas can be synthesized, enhancing mass transfer and accessibility to active sites [1] [3].

Troubleshooting and Best Practices

- Cracking During Drying: To mitigate cracking, ensure adequate aging time to strengthen the gel network. Slow, controlled drying rates and the use of drying control chemical additives (DCCAs) can also be effective.

- Precipitation Instead of Gelation: This often results from overly rapid hydrolysis and condensation. Slow down the reaction by using less vigorous catalyst concentrations, adding water slowly, or cooling the reaction mixture.

- Reproducibility: Maintain strict control over all parameters, including precursor concentration, [H₂O]/[Precursor] ratio, pH, temperature, and solvent type, as small variations can significantly alter the final product.

The sol-gel process is a versatile synthetic methodology for producing advanced inorganic and organic-inorganic hybrid materials, widely employed in catalyst synthesis, drug development, and materials science. This bottom-up approach involves the transition of a system from a colloidal solution (sol) into a porous, three-dimensional network (gel) through controlled chemical reactions. The fundamental chemistry driving this process centers on two pivotal reaction classes: hydrolysis and condensation. These sequential and parallel reactions transform molecular precursors—typically metal alkoxides—into extended oxide networks under mild, low-temperature conditions, enabling fine control over the composition, structure, and texture of the final material [4] [1] [7]. For researchers designing catalytic materials, mastering these mechanisms is essential for tailoring critical parameters such as surface area, porosity, active site distribution, and structural stability.

Fundamental Reaction Mechanisms

Hydrolysis Reactions

Hydrolysis is the initial and critical step in the sol-gel process, wherein a water molecule attacks the metal alkoxide precursor. This nucleophilic substitution reaction results in the replacement of an alkoxy group (-OR) with a hydroxyl group (-OH).

The general form of the hydrolysis reaction is:

≡Si-OR + H₂O → ≡Si-OH + R-OH [1] [8]

This reaction is catalyzed by acids or bases and is the first step in activating the precursor for subsequent condensation. The mechanism proceeds through a nucleophilic addition of a water molecule to the metal center (e.g., Si, Ti, Zr), which is followed by a proton transfer, making the alcohol (ROH) a suitable leaving group [7]. The kinetics and extent of hydrolysis are profoundly influenced by the strength of the M-OR bond, the steric hindrance of the alkyl group R, the water-to-precursor ratio (R value), the pH of the solution, and the nature of the catalyst used [8].

Condensation Reactions

Following hydrolysis, condensation reactions link the hydrolyzed monomers to form a growing M-O-M network. These polycondensation reactions are the primary builders of the inorganic framework and can proceed via two distinct pathways, both of which liberate a small molecule:

- Water-Forming Condensation:

≡Si-OH + HO-Si≡ → ≡Si-O-Si≡ + H₂O[1] [8] - Alcohol-Forming Condensation:

≡Si-OH + RO-Si≡ → ≡Si-O-Si≡ + R-OH[9] [1] [8]

Condensation can occur between various species in the solution, including molecules and particles, leading to the formation of dimers, trimers, and eventually, a macroscopic gel network. The relative rates of the two condensation pathways depend on the reaction conditions, particularly the catalyst type [10].

Quantitative Kinetic Analysis

The rates of hydrolysis and condensation reactions determine the structure and properties of the final gel. Kinetic studies using techniques like ¹H and ²⁹Si NMR spectroscopy provide quantitative insight into these processes.

Table 1: Experimentally Determined Rate Constants for Acid-Catalyzed TMOS Hydrolysis and Condensation [10]

| Reaction Type | Rate Constant (1/(mol·min)) | Relative Rate |

|---|---|---|

| Hydrolysis | > 0.2 | Much Faster |

| Water-Forming Condensation | 0.006 | ~3-6x Slower than Hydrolysis |

| Alcohol-Forming Condensation | 0.001 | ~3x Slower than Water-Forming |

The data in Table 1 confirms that under acid-catalyzed conditions, hydrolysis is significantly faster than condensation, allowing for a high degree of precursor hydrolysis before significant network formation begins. This typically results in more extended and less branched polymer networks, which can lead to the formation of microporous gels with high specific surface area [10] [1].

Table 2: Factors Influencing Hydrolysis and Condensation Kinetics [1] [7] [8]

| Factor | Effect on Hydrolysis | Effect on Condensation |

|---|---|---|

| Catalyst (pH) | Acid catalysis: Faster. Base catalysis: Faster. | Acid catalysis: Favors linear chains. Base catalysis: Favors branched clusters/particles. |

| Water/Si Ratio (R) | Higher ratio drives reaction to completion. | Lower ratio limits cross-linking, leading to less branched polymers. |

| Precursor Type | Si(OCH₃)₄ > Si(OC₂H₅)₄ (due to sterics). Transition metal alkoxides are much more reactive. |

Reactivity correlates with hydrolysis rate; affects network density and homogeneity. |

| Solvent | Polar solvents can accelerate the reaction. | Influences the reaction medium's polarity and the solubility of growing oligomers. |

| Temperature | Increases reaction rate. | Increases reaction rate and can affect the gel time. |

Experimental Protocols

Protocol 1: Acid-Catalyzed Synthesis of Silica Gel via TMOS Hydrolysis and Condensation

This protocol describes the synthesis of a silica xerogel through the acid-catalyzed sol-gel route, ideal for producing materials with high surface area and microporosity [11] [1] [7].

Research Reagent Solutions: Table 3: Essential Reagents for Acid-Catalyzed Silica Synthesis

| Reagent | Function | Typical Purity |

|---|---|---|

| Tetramethoxysilane (TMOS) | Primary silica network precursor | >98% |

| Anhydrous Methanol | Solvent | >99.8% |

| Deionized Water | Hydrolyzing agent | N/A |

| Hydrochloric Acid (HCl, 0.1M) | Acid catalyst for hydrolysis & condensation | ACS Reagent Grade |

Step-by-Step Procedure:

- Solution Preparation: In a sealed vessel to prevent solvent evaporation, mix 2.85 mL of TMOS with 6 mL of anhydrous methanol under vigorous stirring.

- Hydrolysis Initiation: Slowly add a solution containing 2.43 mL of deionized water and 0.07 mol of 0.1M HCl catalyst to the TMOS/methanol solution drop-by-drop.

- Sol Formation: Continue stirring the mixture at room temperature for 1-2 hours. The solution will remain clear (the "sol") as hydrolysis progresses.

- Gelation and Aging: Transfer the sol to a static container and seal it. Gelation typically occurs within 4-8 hours, forming a rigid, wet gel. Age the gel for 24 hours at room temperature to strengthen the network via continued condensation.

- Drying: Dry the aged gel in an oven at 60-80°C for 16-24 hours to remove the liquid phase, resulting in a porous silica xerogel.

- Thermal Treatment (Optional): For enhanced mechanical stability and removal of residual organics, calcine the xerogel in a furnace at 500-600°C for 2-5 hours.

Troubleshooting Notes:

- Slow Gelation: Increase the catalyst concentration or the aging temperature slightly.

- Cracking During Drying: This is often due to rapid solvent evaporation. Slower drying rates or the use of a drying control chemical additive (DCCA) can mitigate this.

- Precipitation: If a precipitate forms instead of a gel, it may indicate that the condensation rate is too high relative to hydrolysis. Ensure the catalyst is well-mixed during the addition step.

Protocol 2: Base-Catalyzed Synthesis of Monodisperse Silica Nanoparticles (Stöber Process)

The Stöber process is a classic example of a base-catalyzed sol-gel synthesis that yields uniform, spherical silica particles [1].

Research Reagent Solutions: Table 4: Essential Reagents for the Stöber Process

| Reagent | Function | Typical Purity |

|---|---|---|

| Tetraethoxysilane (TEOS) | Silica precursor | >98% |

| Absolute Ethanol | Solvent | >99.9% |

| Ammonium Hydroxide (NH₄OH, 28-30%) | Base catalyst | ACS Reagent Grade |

| Deionized Water | Hydrolyzing agent | N/A |

Step-by-Step Procedure:

- Base Solution Preparation: In a clean flask, mix 50 mL of absolute ethanol, 5 mL of deionized water, and 3 mL of ammonium hydroxide.

- Precursor Addition: Under continuous stirring, rapidly add 2.5 mL of TEOS to the base solution.

- Reaction and Aging: Allow the reaction to proceed under stirring for 2-4 hours at room temperature. The solution will turn opalescent due to the formation of monodisperse silica nanoparticles.

- Product Isolation: Recover the nanoparticles by centrifugation (e.g., 10,000 rpm for 15 minutes), wash several times with ethanol to remove unreacted precursors and ammonia, and finally dry the powder at 80°C.

Protocol 3: One-Pot Sol-Gel Synthesis of a Supported Metal Catalyst (Ru/SiO₂)

This protocol illustrates the integration of a catalytic metal (Ruthenium) into a silica matrix during the sol-gel process, ensuring high dispersion of the active phase [11].

Research Reagent Solutions: Table 5: Essential Reagents for Ru/SiO₂ Catalyst Synthesis

| Reagent | Function | Typical Purity |

|---|---|---|

| Tetraethoxysilane (TEOS) | SiO₂ support precursor | >98% |

| Ruthenium(III) Chloride Hydrate (RuCl₃·xH₂O) | Metal catalyst precursor | Reagent Grade |

| Absolute Ethanol | Solvent | >99.8% |

| Deionized Water | Hydrolyzing agent | N/A |

| Hydrochloric Acid (HCl, conc.) or Ammonium Hydroxide (NH₄OH, conc.) | Reaction catalyst | ACS Reagent Grade |

Step-by-Step Procedure:

- Precursor Dissolution: Dissolve 0.06 g of RuCl₃·3H₂O in 6 mL of absolute ethanol.

- Silica Precursor Addition: Add 4.1 mL of TEOS dropwise to the ruthenium solution under vigorous stirring.

- Catalyzed Hydrolysis: Prepare a solution of 1.30 mL of deionized water with either concentrated HCl (0.07 mol) or concentrated NH₄OH (0.06 mol). Add this solution to the metal/TEOS mixture to initiate the catalyzed hydrolysis.

- Reflux and Gelation: Reflux the resulting sol until gelation occurs. The time is highly catalyst-dependent: ~4 hours for acid-catalysis and ~8 hours for base-catalysis.

- Drying and Calcination: Dry the gel in vacuo at 80°C for 16 hours. Finally, calcine the material under a nitrogen stream at 300°C for 5 hours to form the final Ru/SiO₂ catalyst.

Visualization of Sol-Gel Pathways and Workflows

Sol-Gel Process Workflow

Hydrolysis and Condensation Reaction Network

The sol-gel process represents a cornerstone of modern materials science, enabling the synthesis of advanced catalytic frameworks with tailored properties for applications ranging from heterogeneous catalysis to drug development. This transformative technology facilitates the transition of molecular precursors into integrated solid networks through controlled hydrolysis and condensation reactions, operating at low temperatures that preserve structural integrity and functionality. The strategic selection of precursors—primarily metal alkoxides and metal salts—dictates the architecture, porosity, and surface chemistry of the resulting metal oxides, thereby governing their catalytic performance. Within the broader context of sol-gel research for catalyst synthesis, understanding the chemical behavior and application protocols of these precursors is paramount for designing materials with precision. This document provides a comprehensive overview of the essential precursors used in sol-gel chemistry, detailing their reaction mechanisms, comparative advantages, and practical synthesis protocols to equip researchers with the foundational knowledge for innovative catalyst development.

Fundamental Chemistry of Sol-Gel Precursors

Metal Alkoxides: Structure and Reactivity

Metal alkoxides (M(OR)ₓ) are metal cations coordinated by alkoxide anions (RO⁻). Their chemical nature is fundamentally different from silicon alkoxides, as theoretical calculations reveal localization of occupied bonding molecular orbitals essentially solely on the oxygen atoms of the alkoxide ligands [12]. This indicates that these species are primarily held together by electrostatic, ionic bonding, which is associated with quick and reversible ligand exchange reactions [12]. The structure of oligonuclear alkoxide complexes is governed by the dense packing of cations and anions and the minimization of surface energy, often resulting in spheroidal or ellipsoidal topologies [13]. These complexes can be considered molecular models for metal oxide surfaces, providing insights into surface complexation and redox properties [13].

The high reactivity of metal alkoxides stems from the strong basicity of the alkoxide ligands and the electrophilic character of the metal center. The kinetics of hydrolysis and condensation are significantly faster than those of silicon alkoxides due to the lower electronegativity of metal atoms and their ability to readily expand their coordination sphere [12] [14]. This high reactivity often necessitates chemical modification of precursors to control reaction rates and achieve desired material properties.

Metal Salts: Aqueous Chemistry and Condensation

In the aqueous sol-gel route, metal salts (e.g., chlorides, nitrates) dissolved in water serve as inexpensive and accessible precursors. When dissolved, metal cations become solvated, forming aquo complexes [M(H₂O)ₙ]ᶻ⁺ [15]. The subsequent hydrolysis and condensation processes are heavily influenced by the solution pH, which controls the formation of hydroxo and oxo ligands.

The forced hydrolysis of metal salts in aqueous solutions proceeds through the formation of hydroxo complexes, which then condense via two primary pathways [14] [15]:

- Olation: Bridging by hydroxide groups (OH⁻), typically favored for low-valent metal cations and leading to polycations and hydroxide precipitation.

- Oxolation: Bridging by oxide groups (O²⁻), common for high-valent cations and resulting in the formation of polyanions and oxide networks.

A key challenge in the aqueous route is avoiding uncontrolled precipitation. Techniques such as the epoxide-mediated method are employed to raise the pH homogeneously and gradually, promoting controlled gelation instead of precipitate formation [14]. This method uses propylene oxide, which undergoes irreversible ring-opening reactions to consume protons and uniformly increase pH throughout the solution [14].

Comparative Analysis of Key Precursor Classes

Table 1: Comparative Characteristics of Metal Alkoxides and Metal Salts as Sol-Gel Precursors

| Feature | Metal Alkoxides | Metal Salts |

|---|---|---|

| Chemical Nature | M(OR)ₓ, ionic bonding [12] | [M(H₂O)ₙ]ᶻ⁺X⁻, ionic in water [15] |

| Primary Solvent | Organic (alcohols, THF) [7] | Aqueous [15] |

| Reactivity | Very high, fast hydrolysis [14] | Moderate, controlled by pH [15] |

| Cost | Relatively high [15] | Low, cost-effective [15] |

| Handling | Air- and moisture-sensitive, require inert atmosphere [7] | Less sensitive, easier to handle [15] |

| Process Control | Requires modification (chelation) for control [7] [12] | Controlled via pH, concentration, and complexing agents [15] |

| Key Advantage | High purity, molecular-level mixing, direct M-O-M bonds [7] [16] | Low cost, scalability, industrial suitability [15] |

| Key Challenge | Differing hydrolysis rates in multi-component systems [7] | Risk of uncontrolled precipitation, anion incorporation [14] [15] |

| Typical Products | High-purity oxides, thin films, mixed oxides [7] [16] | Bulk oxides, supported catalysts, monoliths [17] [14] |

Selecting Precursors for Multi-Component Systems

Synthesizing complex mixed oxides and supported catalysts requires careful precursor selection to achieve homogeneity. The Pechini process, a variant of the sol-gel method, is particularly effective for multi-cation systems [1]. It involves using a chelating agent, most often citric acid, to surround aqueous cations and sterically entrap them, preventing phase segregation that results from differing hydrolysis rates [1]. A polymer network, typically formed by polyesterification with ethylene glycol, is then created to immobilize the chelated cations in a gel or resin [1]. Subsequent combustion removes the organic material, yielding a homogeneous mixed oxide.

For alkoxide-based systems, the use of heterometallic alkoxides or careful matching of hydrolysis rates through chelating ligands (e.g., acetylacetonate) is crucial for achieving atomic-level dispersion [7] [12].

Experimental Protocols

Protocol 1: Base-Catalyzed Synthesis of SiO₂ Nanoparticles from TEOS

This protocol describes the synthesis of monodisperse silica nanoparticles via the hydrolysis and condensation of tetraethyl orthosilicate (TEOS) under basic conditions, adapting the well-known Stöber process [1] [12].

Research Reagent Solutions: Table 2: Essential Reagents for SiO₂ Nanoparticle Synthesis

| Reagent | Function | Specifications |

|---|---|---|

| Tetraethyl Orthosilicate (TEOS) | Primary silica precursor | ≥99% purity, store under anhydrous conditions |

| Anhydrous Ethanol | Solvent medium | Low water content (<0.1%) to control hydrolysis |

| Ammonium Hydroxide (NH₄OH) | Base catalyst | 28-30% NH₃ in water, analytical grade |

| Deionized Water | Hydrolyzing agent | 18.2 MΩ·cm resistivity |

Procedure:

- Preparation of Reaction Mixture: In a 250 mL polypropylene bottle, add 100 mL of anhydrous ethanol, 20 mL of deionized water, and 5 mL of ammonium hydroxide. Seal the bottle and mix thoroughly on a magnetic stirrer.

- Precursor Addition: Rapidly add 5 mL of TEOS to the stirring mixture. Note the time of addition (t=0).

- Gelation and Aging: Continue stirring for 2 hours at room temperature. The solution will turn opalescent, indicating the formation of a silica sol. After stirring, allow the mixture to age without disturbance for 24 hours.

- Recovery and Calculation: Recover the nanoparticles by centrifugation (10,000 rpm for 15 minutes). Wash the pellet three times with anhydrous ethanol to remove residual ammonia and water. Dry the white powder at 80°C for 12 hours. For complete condensation and removal of organic residues, calcine the powder at 550°C for 4 hours in a muffle furnace (ramp rate: 2°C/min).

Notes: The size of the resulting nanoparticles can be tuned by varying the concentration of TEOS, water, and catalyst [12]. The base-catalyzed conditions favor faster gelation and the formation of highly cross-linked, spherical particles compared to acid catalysis [18] [12].

Protocol 2: Acid-Catalyzed Sol-Gel Synthesis of a NiO-Fe₂O₃-SiO₂/Al₂O₃ Catalyst

This protocol outlines the synthesis of a bimetallic catalyst supported on alumina, demonstrating the use of heat treatment control to achieve high dispersion and surface area [17].

Research Reagent Solutions: Table 3: Essential Reagents for NiO-Fe₂O₃-SiO₂/Al₂O₃ Catalyst Synthesis

| Reagent | Function | Specifications |

|---|---|---|

| Aluminum Oxide (Al₂O₃) Powder | Catalyst support | High-purity γ-phase, high surface area |

| Nickel Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Nickel oxide precursor | ≥98% purity |

| Iron Nitrate Nonahydrate (Fe(NO₃)₃·9H₂O) | Iron oxide precursor | ≥98% purity |

| Tetraethoxysilane (TEOS) | Binder and matrix former | ≥99% purity |

| Nitric Acid (HNO₃) | Acid catalyst | 2M solution in ethanol |

| Anhydrous Ethanol | Solvent |

Procedure:

- Support Impregnation: Dissolve 2.90 g of Ni(NO₃)₂·6H₂O and 4.04 g of Fe(NO₃)₃·9H₂O (Ni/Fe molar ratio = 1/1) in 50 mL of ethanol. Add 10 g of Al₂O₃ powder to the solution and sonicate for 30 minutes to ensure uniform wetting. Stir the suspension for 4 hours.

- Sol Preparation: In a separate beaker, hydrolyze 5 mL of TEOS in 50 mL of ethanol containing 1 mL of 2M HNO₃. Stir this mixture for 1 hour to allow for partial hydrolysis and the formation of a silica sol.

- Combination and Gelation: Slowly add the hydrolyzed TEOS sol to the metal salt-impregnated alumina suspension under vigorous stirring. Continue stirring until a thick gel forms (typically 1-2 hours).

- Drying: Age the gel for 12 hours, then dry it in an oven at 100°C for 24 hours.

- Controlled Calcination: Place the dried material in a furnace and heat to 400°C at a controlled ramp rate of 5°C/min. Hold at this temperature for 40 minutes. Critical Step: Exceeding a ramp rate of 5°C/min can lead to microcracks, elemental segregation, and deterioration of the catalyst's structural integrity [17].

Characterization: The optimized catalyst prepared with this protocol is expected to have a particle size of approximately 44 nm and a specific surface area of 134.79 m²/g [17].

Synthesis Workflow and Precursor Reaction Pathways

The following diagram illustrates the general decision-making workflow and chemical pathways involved in selecting and processing metal alkoxide and metal salt precursors for sol-gel synthesis.

The strategic selection and application of metal alkoxides and metal salts form the molecular cornerstone of sol-gel catalyst synthesis. While alkoxides offer unparalleled control and purity for advanced material design, salts provide a robust and economical pathway for industrial-scale catalyst production. The protocols and analyses presented herein underscore the criticality of understanding precursor chemistry—including hydrolysis kinetics, condensation mechanisms, and strategies for homogeneity control—in the rational design of catalytic frameworks. As the field progresses, the integration of these fundamental principles with emerging approaches, such as green solvent systems [19] and machine-learning-assisted optimization [16] [17], will further empower researchers to push the boundaries of catalytic material science, enabling more efficient and sustainable chemical processes.

The sol-gel process represents a fundamental shift in ceramic and catalyst synthesis methodology, enabling unprecedented control over material properties at the nanoscale. This bottom-up approach facilitates the fabrication of ceramic materials through preparation of a sol, gelation of the sol, and removal of the solvent [20]. Unlike traditional impregnation methods that often suffer from loss of material dispersion, reduced specific surface area, and uneven particle distribution [17], sol-gel processing offers a versatile pathway to materials with tailored architectures. For researchers and drug development professionals, this methodology provides critical advantages in developing catalytic systems with enhanced performance characteristics, particularly through its ability to achieve nanoscale homogeneity and exceptional purity in multicomponent systems.

The fundamental chemistry of sol-gel processing revolves around hydrolysis and condensation reactions of molecular precursors, typically metal alkoxides (M(OR)ₙ) [20] [4]. This process converts precursors into a colloidal solution (sol), which then evolves toward forming an integrated network (gel) of discrete particles or polymer chains [2]. The transition from sol to gel state represents the foundation for creating materials with controlled porosity, high surface area, and uniform component distribution - attributes particularly valuable in catalyst design and pharmaceutical development.

Key Advantages: Quantitative Comparisons with Traditional Methods

Nanoscale Homogeneity Through Molecular-Level Control

The sol-gel process provides exceptional control over material composition at the molecular level, enabling homogeneous multi-component systems that are difficult to achieve through traditional methods [4]. This homogeneity stems from the ability to mix precursors in solution, ensuring uniform distribution of components before network formation. In catalyst synthesis, this translates to highly dispersed active sites and consistent performance characteristics.

Table 1: Comparative Analysis of Sol-Gel vs. Traditional Impregnation Methods

| Parameter | Sol-Gel Method | Traditional Impregnation | Experimental Evidence |

|---|---|---|---|

| Component Distribution | Molecular-level mixing [21] | Surface deposition only [17] | Elemental mapping shows uniform distribution vs. clustering [17] |

| Particle Size Control | Narrow distribution (e.g., 44 nm achieved) [17] | Broad distribution, often >100 nm | SEM analysis demonstrates uniform particles [17] |

| Specific Surface Area | High (e.g., 134.79 m²/g for NiO-Fe₂O₃-SiO₂/Al₂O₃) [17] | Moderate to low (significant reduction after calcination) [17] | BET analysis confirms enhanced surface area [17] |

| Processing Temperature | Low (room temperature to 100°C) [21] | High (typically >400°C) [17] | Successful synthesis at 400°C with maintained dispersion [17] |

| Doping Precision | Excellent (systematic Mn-doping in Ca₃Co₂O₆) [22] | Limited control | XRD reveals lattice parameter shifts consistent with dopant incorporation [22] |

| Phase Purity | High (avoids spinel formation at lower temperatures) [17] | Contamination common (e.g., NiAl₂O₄ formation) [17] | XRD confirms desired phases without intermediates [17] [22] |

The statistical analysis of NiO-Fe₂O₃-SiO₂/Al₂O₃ catalysts demonstrates that optimal sol-gel processing produces materials with particle sizes of 44 nm and specific surface area of 134.79 m²/g, substantially outperforming traditional methods where high-temperature treatment causes "coarsening of active components" [17]. This nanoscale homogeneity directly enhances catalytic performance by providing uniform active sites and improved accessibility to reactants.

Enhanced Purity and Structural Control

Sol-gel processing enables exceptional material purity due to the use of high-purity precursors and the absence of contamination from crucibles or processing equipment [21]. The low processing temperatures (room temperature to ~100°C) prevent thermal degradation and undesirable phase transformations that commonly plague traditional high-temperature methods [21].

Table 2: Purity and Structural Advantages in Experimental Systems

| Material System | Sol-Gel Advantage | Traditional Method Limitation | Characterization Evidence |

|---|---|---|---|

| NiO-Fe₂O₃-SiO₂/Al₂O₃ | Prevents NiAl₂O₄ spinel formation at 400°C [17] | Spinel formation reduces reducibility of nickel phase [17] | XRD confirms absence of spinel phases [17] |

| Mn-doped Ca₃Co₂O₆ | Precise dopant incorporation [22] | Inhomogeneous doping common | XRD shows lattice parameter shifts [22] |

| Silica-based Ionogels | Continuous 3D network with controlled porosity [23] | Limited control over pore architecture | SEM/TEM reveal micropores and mesopores (≤20 nm) [23] |

| VOx-SiO₂ Catalysts | Stronger V-SiO₂ interactions [4] | Weaker interaction leads to crystalline V₂O₅ formation [4] | Enhanced catalytic activity in oxidative dehydrogenation [4] |

| Organic-Inorganic Hybrids | Molecular-level integration [2] | Physical mixing only | Proton conduction demonstrated [2] |

The ability to control structure and composition at a molecular level represents perhaps the most significant advantage of sol-gel processing [20]. This capability enables researchers to "impose kinetic constraints on a system and thereby stabilize metastable phases" while "fine-tuning the activation behavior of a sample" to trace the genesis of active species [20]. For pharmaceutical researchers, this level of control is invaluable for developing tailored catalyst systems with predictable performance characteristics.

Experimental Protocols: Methodologies for Reproducible Synthesis

Standard Sol-Gel Protocol for Mixed Oxide Catalysts

This protocol details the synthesis of NiO-Fe₂O₃-SiO₂/Al₂O₃ catalysts as representative of mixed oxide systems, with adaptations for other compositions noted [17].

Materials and Reagents:

- Tetraethyl orthosilicate (TEOS, ≥98% purity)

- Nickel and iron precursors (nitrates or alkoxides)

- Al₂O₃ support (high purity, specific surface area >150 m²/g)

- Ethanol (anhydrous, ≥99.8%)

- Hydrochloric acid (37%) or ammonia solution (25%) as catalysts

- Deionized water (18 MΩ·cm)

Synthetic Procedure:

Sol Formation: Combine 0.0448 mol (10 mL) of TEOS with 0.1200 mol (7 mL) of ethanol in a sealed glass vessel. Heat to 60°C with continuous stirring for 30 minutes using a magnetic stirrer [17].

Precursor Addition: Rapidly add 1g of ionic liquid templating agent (if using) and metal precursors at desired molar ratios (e.g., Ni/Fe = 1/1 for optimal homogeneity) [17].

Catalyzed Hydrolysis: Add 0.0303 mol of HCl (2.5 mL, 37% concentration) diluted with 3 mL deionized water. Continue stirring for 10 minutes to ensure complete hydrolysis [17].

Gelation and Aging: Transfer solution to controlled environment and allow gelation to proceed (typically 24-72 hours). Age the resulting gel for 48 hours at 40°C to strengthen the network through continued condensation and localized reprecipitation [20].

Controlled Drying: Implement slow drying protocol at ambient temperature for xerogel formation or supercritical drying for aerogel synthesis. Critical point drying with CO₂ preserves nanostructure for high-surface-area materials [20].

Thermal Treatment: Calcine materials at precisely controlled heating rates (1-5°C/min) to target temperature (400°C for optimal dispersion [17] or 1000°C for specific crystalline phases [22]). Maintain at target temperature for 10 hours to ensure complete crystallization [22].

Critical Parameters for Reproducibility:

- Maintain strict control of hydrolysis water ratio (R = [H₂O]/[M])

- Precisely control catalyst concentration and type (acid vs. base)

- Implement controlled heating rates during thermal treatment (≤5°C/min)

- Standardize aging conditions (time, temperature, atmosphere)

Advanced Protocol: Acid vs. Base Catalysis for Tailored Morphologies

The choice of catalyst (acid or base) significantly impacts the structural properties of the final material, enabling tailored morphologies for specific applications [23].

Acid-Catalyzed Protocol (Continuous Network Formation):

- Use HCl, HNO₃, or formic acid as catalyst at pH 2-4

- Produces linear polymer chains with microporous structures

- Results in continuous 3D networks ideal for crystal growth applications [23]

- Yields materials with micropores and mesopores (≤20 nm diameter) [23]

Base-Catalyzed Protocol (Particulate Morphology):

- Use NH₄OH or amines as catalyst at pH 8-11

- Produces compact, dense structures through clustered particle growth

- Results in weakly connected nanoparticles with large voids [23]

- Creates materials with textural properties less suited for confined crystal growth [23]

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents for Sol-Gel Catalyst Synthesis

| Reagent Category | Specific Examples | Function in Synthesis | Purity Requirements |

|---|---|---|---|

| Metal Alkoxides | Tetraethyl orthosilicate (TEOS), Titanium isopropoxide, Aluminum isopropoxide | Molecular precursors for oxide network formation [21] | ≥98% (moisture-free storage critical) |

| Solvents | Ethanol, Methanol, Isopropanol | Dissolution medium, reaction environment [2] [21] | Anhydrous (water content <0.01%) |

| Catalysts | HCl, HNO₃, NH₄OH, Formic acid | Control hydrolysis/condensation rates [23] [21] | ACS grade, precise concentration verification |

| Structure Directors | Alkyl-imidazolium ILs, Pluronic surfactants | Template pore structure, control morphology [23] | Purified to remove synthesis byproducts |

| Dopant Precursors | Metal acetylacetonates, nitrates, chlorides | Introduce specific functionality [4] [22] | ≥99% purity for reproducible doping |

| Water Sources | Deionized water, Buffer solutions | Hydrolysis agent, reaction medium [20] | 18 MΩ·cm resistance for controlled reactivity |

Structural and Performance Advantages: Mechanism of Enhancement

The fundamental advantage of sol-gel processing lies in its ability to create materials with controlled nanostructures that directly enhance performance in catalytic applications. The relationship between synthesis conditions, resulting morphology, and catalytic performance can be visualized as follows:

The mechanism of performance enhancement operates through several interconnected pathways:

Enhanced Active Site Accessibility: The controlled porosity and high surface area (e.g., 134.79 m²/g demonstrated in NiO-Fe₂O₃ systems [17]) enables optimal access to active sites, significantly improving catalytic efficiency compared to traditionally synthesized materials where pore blockage and inhomogeneous distribution limit accessibility.

Synergistic Effects in Multicomponent Systems: The molecular-level mixing achievable through sol-gel processing creates synergistic interactions between components. In bimetallic Ni-Fe systems, the "synergistic effect of metal interaction" allows regulation of "electronic and redox properties," significantly increasing system stability compared to monometallic catalysts [17].

Thermal Stability and Sinter Resistance: The integrated network structure of sol-gel derived materials provides enhanced resistance to thermal degradation and sintering. The ability to form strong bonds between active components and support matrices (e.g., through silica binding agents [17]) prevents aggregation and maintains dispersion under operational conditions.

The sol-gel process demonstrates unequivocal advantages over traditional synthetic methods for catalyst preparation, particularly through its ability to achieve nanoscale homogeneity and exceptional purity. The quantitative improvements in surface area, particle size control, and compositional uniformity directly translate to enhanced catalytic performance across diverse applications. For researchers in catalysis and pharmaceutical development, these advantages provide critical tools for designing next-generation materials with tailored properties.

Future developments in sol-gel processing will likely focus on advancing continuous flow methodologies to address traditional scalability challenges [21], developing novel organic-inorganic hybrid architectures [2], and refining computational approaches to predict and optimize synthesis parameters. The integration of artificial intelligence and machine learning for experimental optimization, as demonstrated in the statistical analysis of NiO-Fe₂O₃ catalysts [17], represents a particularly promising direction for achieving unprecedented control over material properties at the nanoscale.

As the demands for specialized catalytic materials continue to grow across pharmaceutical, energy, and environmental applications, the sol-gel approach will remain an indispensable methodology for researchers seeking to overcome the limitations of traditional synthesis routes and develop materials with precisely controlled architectures and enhanced performance characteristics.

The sol-gel process has emerged as a transformative synthesis platform in materials science, enabling the precise engineering of materials across a spectrum of functionality from passive bioinert substrates to interactive bioactive and stimuli-responsive systems. This technological evolution mirrors the increasing sophistication required in advanced biomedical and catalytic applications, where material systems must not only provide structural support but also actively participate in biological and chemical processes. The inherent versatility of sol-gel chemistry facilitates bottom-up design of materials with tailored porosity, surface functionality, and compositional control at the molecular level, making it particularly suitable for developing next-generation intelligent materials.

Within catalyst synthesis research, the sol-gel method offers distinct advantages over traditional approaches, including superior control over catalyst morphology, composition, and particle size distribution. The ability to achieve molecular-level mixing of precursors results in highly homogeneous multifunctional materials with enhanced catalytic properties and stability. This application note details the protocols and mechanistic insights for synthesizing and characterizing three generations of sol-gel derived materials, providing researchers with practical methodologies for advancing their catalytic and biomedical research.

Application Note: Bioactive Sol-Gel Systems for Drug Delivery

Protocol: Synthesis of Drug-Loaded Bioactive Glass Scaffolds

Principle: This protocol describes the synthesis of CaO-SiO₂-P₂O₅-Na₂O bioglass and bioceramics via the sol-gel method for use as drug delivery matrices. The process leverages low-temperature synthesis to preserve the bioactivity and drug-loading capacity of the materials, making them suitable for controlled release applications and antimicrobial therapy [24].

Reagents and Materials:

- Calcium carbonate (CaCO₃) as CaO precursor

- Silicon dioxide (SiO₂) powder as primary glass former

- Phosphorus pentaoxide (P₂O₅) powder as secondary glass former

- Sodium hydroxide (NaOH) as network modifier (Na₂O source)

- Nitric acid (HNO₃) as catalyst

- Deionized water as solvent

- Therapeutic agents: ciprofloxacin, amoxicillin, or levofloxacin

Equipment:

- Analytical balance

- Magnetic stirrer with heating capability

- pH meter

- Drying oven

- Muffle furnace

- Characterization tools: XRD, FTIR, TGA, SEM

Procedure:

- Solution Preparation: Prepare stoichiometric mixtures of precursors to achieve the desired 45S5 bioglass composition (45% SiO₂, 24.5% Na₂O, 24.5% CaO, 6% P₂O₅ by weight).

- Hydrolysis: Gradually add the precursor mixture to deionized water under constant stirring at room temperature. Maintain a liquid/solid ratio of 20:1.

- Catalysis: Add nitric acid to adjust pH to approximately 2.5-3.0 to catalyze hydrolysis and condensation reactions.

- Gelation: Allow the solution to stand undisturbed at 40°C for 48 hours until a rigid gel forms.

- Ageing: Age the gel at 60°C for 72 hours to strengthen the network structure.

- Drying: Dry the aged gel gradually, increasing temperature from 60°C to 130°C over 24 hours.

- Stabilization: Thermally treat the dried gel at 700°C for 2 hours to remove residual organics and stabilize the structure.

- Drug Loading: Immerse the synthesized bioglass scaffolds in antibiotic solutions (0.75% w/v drug concentration) for 24 hours under vacuum to facilitate drug incorporation.

- Characterization: Perform structural, chemical, and thermal characterization using XRD, FTIR, and TGA to confirm material properties [24].

Performance Data and Analysis

Table 1: Drug loading and release profiles of sol-gel derived bioglass systems

| Therapeutic Agent | Drug Loading Capacity (%) | Cumulative Release (%) | Release Duration (Hours) | Antimicrobial Efficacy (Inhibition Zone, mm) |

|---|---|---|---|---|

| Ciprofloxacin | 0.65 | 30 | 72 | 33.5 ± 1.32 (against S. abony) |

| Levofloxacin | 0.75 | 70 | 72 | 29.8 ± 1.15 (against S. aureus) |

| Amoxicillin | 0.10 | 10 | 72 | 25.3 ± 0.95 (against E. coli) |

Table 2: Structural properties of sol-gel synthesized bioactive materials

| Material Type | Crystallographic Structure | Specific Surface Area (m²/g) | Thermal Stability (°C) | Key Functional Groups |

|---|---|---|---|---|

| Bioglass | Amorphous | 134-150 | Up to 700 | Si–O–Si, P–O |

| Bioceramics | Semi-crystalline | 100-120 | Up to 650 | Si–O–Si, P–O, Ca–O |

The drug release profiles demonstrate the sustained release capability of sol-gel derived bioglass, with variations attributable to drug-polymer interactions and scaffold porosity. The superior antimicrobial efficacy of ciprofloxacin-loaded bioglass against Gram-negative pathogens highlights its potential for targeted infection control [24].

Diagram 1: Synthesis workflow for drug-loaded bioactive glass scaffolds via sol-gel process

Application Note: Stimuli-Responsive Nanostructured Catalysts

Protocol: Sol-Gel Synthesis of NiO-Fe₂O₃-SiO₂/Al₂O₃ Catalysts

Principle: This protocol outlines the synthesis of bimetallic nickel-iron catalysts supported on silica-alumina matrices using sol-gel technology. The method enables precise control over metal distribution and particle size, critical for catalytic activity in hydrocarbon oxidation reactions. The optimized process reduces heat treatment temperature while maintaining high material dispersion, eliminating the need for expensive modifiers [17].

Reagents and Materials:

- Nickel and iron precursors (e.g., nitrates or chlorides)

- Tetraethoxysilane (TEOS) as silica source

- Aluminum oxide (Al₂O₃) as support material

- Solvents (ethanol, isopropanol)

- Acid or base catalysts for hydrolysis control

Equipment:

- Precision heating mantle with temperature control

- Reflux condenser

- Vacuum filtration system

- Tube furnace for controlled calcination

- Characterization equipment: SEM, XRD, BET surface area analyzer

Procedure:

- Precursor Preparation: Dissolve nickel and iron salts in molar ratios ranging from 20:1 to 1:20 (Ni:Fe) in suitable solvent.

- Support Integration: Disperse Al₂O₃ support in the solution under continuous stirring.

- Sol Formation: Add tetraethoxysilane (TEOS) dropwise to the mixture while maintaining temperature at 60°C to initiate hydrolysis.

- Gelation: Adjust pH to promote polycondensation reactions, continuing stirring until gel point is reached.

- Ageing: Age the gel for 24 hours at room temperature to strengthen the network.

- Controlled Drying: Implement gradual drying at 80°C for 12 hours to prevent cracking.

- Optimized Heat Treatment: Calcine the material at 400°C for 40 minutes using a controlled heating rate of 5°C/min to preserve structural integrity.

- Characterization: Analyze morphological characteristics using SEM and elemental distribution through EDS mapping [17].

Performance Optimization and Analysis

Table 3: Effect of synthesis parameters on catalyst properties

| Synthesis Parameter | Optimal Value | Impact on Catalyst Properties | Performance Outcome |

|---|---|---|---|

| Ni/Fe Ratio | 1:1 | Homogeneous particle distribution | Balanced active sites |

| Heating Rate | 5°C/min | Prevents microcrack formation | Enhanced structural integrity |

| Calcination Temperature | 400°C | Maintains high surface area | Improved catalytic activity |

| TEOS Content | 10-15 mol% | Optimal binding with support | Strong metal-support interaction |

The structural analysis reveals that the optimized catalyst exhibits a particle size of 44 nm with a specific surface area of 134.79 m²/g. The critical synthesis parameters identified are the Ni/Fe ratio and the heating rate during thermal treatment. Catalytic testing in decane oxidation demonstrates significant activity, with the synergistic effect between nickel and iron enhancing both stability and performance [17].

Advanced Protocol: Automated Synthesis of Nanoporous Silica

High-Throughput Sol-Gel Synthesis Platform

Principle: This advanced protocol describes an automated workflow for sol-gel synthesis of mesoporous silica nanoparticles using the open-source Science-Jubilee automation platform integrated with small-angle X-ray scattering (SAXS) for real-time characterization. This approach enables high-throughput exploration of synthesis parameter space and reproducible production of silica nanomaterials with controlled pore architectures for catalytic and drug delivery applications [25].

Reagents and Materials:

- Tetraethyl orthosilicate (TEOS) as silica precursor

- Cetyltrimethylammonium bromide (CTAB) as surfactant template

- Pluronic F127 as dispersing agent

- Ammonium hydroxide (catalyst)

- Anhydrous ethanol

- Ultra-pure water (18 MΩ·cm resistivity)

Equipment:

- Science-Jubilee automation platform with Digital Pipette tools

- SAXS instrument (lab-scale or synchrotron)

- NIST-AFL sample loading module

- Temperature-controlled mixing stations

Procedure:

- System Setup: Configure Science-Jubilee platform with five Digital Pipette tools dedicated to specific reagents (water, TEOS, ammonia, surfactants, ethanol).

- Reagent Dispensing: Automatically dispense precise volumes of CTAB and Pluronic F127 surfactant solutions using dedicated pipettes.

- Precursor Addition: Add TEOS and ammonium hydroxide solution using glass syringes to prevent solvent compatibility issues.

- Mixing Protocol: Implement automated mixing sequence using 10 cm³ disposable syringe for consistent reagent combination.

- Gelation Control: Maintain reaction at ambient temperature for 20 minutes to form mesoporous structures.

- In-Line Characterization: Transfer samples to SAXS instrument via NIST-AFL sample loader for structural analysis.

- Morphology Assessment: Analyze SAXS data for particle size, polydispersity, internal porosity, and pore-phase order.

- Iterative Optimization: Use characterization data to refine synthesis parameters for target morphologies [25].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: Key reagents for sol-gel synthesis of functional materials

| Reagent | Function | Application Examples | Considerations |

|---|---|---|---|

| Tetraethyl orthosilicate (TEOS) | Primary silica precursor | Mesoporous silica nanoparticles, catalyst supports | Hydrolysis rate controlled by pH and catalysts |

| Tetraethyl orthotitanate (TTIP) | Titanium source for mixed oxides | TiO₂-SiO₂ photocatalysts | Sensitivity to moisture requires anhydrous conditions |

| Cetyltrimethylammonium bromide (CTAB) | Surfactant template | Mesoporous silica with controlled pore size | Concentration determines pore diameter and ordering |

| Pluronic F127 | Block copolymer dispersant | Colloidally stable nanoparticles | Enhances monodispersity and prevents aggregation |

| Calcium carbonate (CaCO₃) | Bioactivity enhancer precursor | Bioactive glasses for drug delivery | Transforms to CaO during calcination |

| Nickel/iron salts | Catalytic active sites | NiO-Fe₂O₃-SiO₂/Al₂O₃ catalysts | Ratio determines synergistic effects and activity |

Mechanistic Insights: Structure-Property Relationships

The functional performance of sol-gel derived materials is governed by fundamental structure-property relationships that originate from the synthesis conditions. Understanding these relationships enables precise engineering of material characteristics for specific applications.

Diagram 2: Structure-property relationships in sol-gel derived functional materials

The sol-gel process enables precise control over material properties through manipulation of synthesis parameters. Precursor chemistry and concentration directly influence the porosity and pore architecture, which subsequently determines drug release profiles and catalytic activity. Catalyst type and concentration during synthesis control the surface chemistry, affecting both bioactivity and catalytic performance. Processing temperature governs crystallinity and phase composition, which directly impacts structural stability. Surfactant templates direct particle morphology, which influences biological integration and functionality [24] [17] [25].

The integration of advanced characterization techniques with automated synthesis platforms has accelerated the understanding of these structure-property relationships, enabling data-driven optimization of material performance. Small-angle X-ray scattering provides real-time insights into structural development during synthesis, while machine learning approaches facilitate the identification of optimal synthesis parameters for target material properties [25].

The evolution of sol-gel derived materials from simple bioinert substrates to sophisticated bioactive and stimuli-responsive systems represents a significant advancement in materials design for catalytic and biomedical applications. The protocols detailed in this application note provide researchers with robust methodologies for synthesizing functional materials with tailored properties. The integration of automation and advanced characterization techniques continues to accelerate the development of next-generation sol-gel materials, with emerging trends pointing toward intelligent systems with adaptive functionality and enhanced therapeutic and catalytic capabilities.

Future developments in the field will likely focus on multi-functional materials that combine catalytic activity with biological functionality, such as the TiO₂-SiO₂ composites that exhibit both photocatalytic performance and bioactivity [26]. Additionally, the incorporation of machine learning and AI-driven design approaches will further enhance our ability to navigate the complex synthesis parameter space and optimize material properties for specific applications [25]. As these technologies mature, sol-gel derived materials are poised to play an increasingly important role in advanced catalytic systems, personalized medicine, and sustainable technologies.

Synthesis Protocols and Biomedical Applications of Sol-Gel Catalysts

The sol-gel process is a versatile wet-chemical technique for fabricating solid materials from small molecules, widely used for synthesizing advanced catalytic systems with precise control over composition and structure [1]. This method involves the transition of a colloidal solution (sol) into a network-containing gel phase, followed by aging and drying to produce materials with tailored porosity, high surface area, and homogeneous component distribution [1] [27]. For catalytic applications, particularly in the synthesis of systems like NiO-Fe2O3-SiO2/Al2O3 catalysts, the sol-gel route offers significant advantages over traditional methods like impregnation, including lower processing temperatures, enhanced dispersion of active components, and avoidance of expensive modifiers [17] [28]. The ability to control the hydrolysis and polycondensation of precursors such as metal alkoxides enables the production of catalysts with optimized textural and structural properties for applications in hydrocarbon processing, oxidation reactions, and biomass conversion [17] [28].

Foundational Principles and Key Concepts

Chemical Mechanisms

The sol-gel process is governed by two principal chemical reactions: hydrolysis and condensation. Hydrolysis involves the replacement of alkoxide groups (OR) with hydroxyl groups (OH) through reaction with water [1]. For a metal alkoxide precursor M(OR)n, this can be represented as: M(OR)n + xH2O → M(OH)x(OR)n-x + xROH [27]

Condensation follows, wherein hydrolyzed species link together via the formation of M-O-M bonds, liberating water or alcohol as byproducts [1] [27]: ≡M-OH + HO-M≡ → ≡M-O-M≡ + H2O (Water Liberation) ≡M-OR + HO-M≡ → ≡M-O-M≡ + ROH (Alcohol Liberation)

These polymerization reactions build a three-dimensional network, progressively increasing viscosity until gelation occurs [27].

Catalyst Influence on Gel Structure

The choice of catalyst (acid or base) profoundly influences the kinetics of hydrolysis/condensation and the final gel morphology [23] [18]. The table below summarizes the key differences:

Table: Effects of Acid vs. Base Catalysis on Sol-Gel Process

| Parameter | Acid-Catalyzed Process | Base-Catalyzed Process |

|---|---|---|

| Hydrolysis Rate | Faster [18] | Slower [18] |

| Condensation Rate | Slower [18] | Faster [18] |

| Primary Reaction | Hydrolysis favored [18] | Condensation favored [18] |

| Gel Time | Longer [18] | Shorter [18] |

| Resulting Gel Structure | Linear, polymer-like chains leading to higher micropore volume [29] [23] | Particulate, colloidal network with larger pores and voids [29] [23] |

| Typical Surface Area | Higher [29] | Lower [29] |

Experimental Protocols: A Detailed Guide

The Scientist's Toolkit: Essential Reagents and Equipment

The following table details key reagents and their functions in a typical sol-gel synthesis for catalysts, as exemplified by the preparation of NiO-Fe2O3-SiO2/Al2O3 systems [17] [28] [30].

Table: Essential Research Reagent Solutions for Sol-Gel Catalyst Synthesis

| Reagent/Material | Typical Example(s) | Function in Synthesis |

|---|---|---|

| Metal Alkoxide Precursor | Tetraethyl orthosilicate (TEOS), Titanium isopropoxide [1] [31] | Source of metal oxide framework (e.g., SiO₂); undergoes hydrolysis and condensation. |

| Active Component Precursors | Nickel and Iron salts (e.g., nitrates) [17] [28] | Introduce catalytically active phases (e.g., NiO, Fe₂O₃) into the gel matrix. |

| Solvent | Ethanol, Methanol [23] [30] | Dissolves precursors to form a homogeneous solution; controls viscosity and reaction rate. |

| Catalyst | HCl (acid), NH₄OH (base) [29] [23] [18] | Modifies pH to control hydrolysis/condensation rates and the final gel porosity. |

| Support Material | Al₂O₃ powder [17] [28] | Provides a high-surface-area support for the active gel phases. |

Required Laboratory Equipment:

- Reaction Vessel: Multi-neck round-bottom flask equipped with a reflux condenser and drying tube [23].

- Temperature Control: Thermostatic oil bath or heating mantle with a magnetic stirrer for precise temperature maintenance [23].

- Drying Oven: Programmable oven for controlled xerogel formation [29].

- Furnace: High-temperature furnace for calcination/thermal treatment of the dried gel [17] [31].

- Characterization Tools: BET surface area analyzer, XRD, SEM/EDS [17] [28].

Protocol 1: Standard Acid-Catalyzed Sol Preparation and Gelation

This protocol is adapted for synthesizing a silica-based catalyst support with high microporosity [29] [23].

Step 1: Solution Preparation

- In a clean multi-neck flask, add 100 mL of anhydrous ethanol.

- Under vigorous stirring, introduce 0.045 mol (10 mL) of Tetraethyl Orthosilicate (TEOS).

- Heat the mixture to 60°C in a thermostatic oil bath while stirring for 30 minutes to ensure homogeneity [23].

Step 2: Catalyzed Hydrolysis

- Prepare an acidic solution by diluting 0.030 mol of concentrated HCl (e.g., 2.5 mL of 37% HCl) in 3 mL of deionized water [23].

- Critical: Add the acidified water dropwise (approximately 1 drop per second) to the TEOS/ethanol solution under continuous stirring.

- After complete addition, continue stirring at 60°C for 60 minutes. The sol will remain clear.

Step 3: Gelation and Aging

- Stop stirring and heating. Seal the flask and transfer it to an oven at 40°C.

- Allow the sol to undergo undisturbed gelation. This process may take from several hours to days, depending on precursor concentrations and pH.

- Once gelation is complete (a rigid, shape-retaining mass is formed), age the gel in its mother liquor at 40°C for 24-48 hours to strengthen the network [29].

Protocol 2: Base-Catalyzed Synthesis for Mesoporous Materials

This method yields materials with larger mesopores, suitable for reactions involving large molecules [29] [23].

Step 1: Solution Preparation

- Mix 0.045 mol of TEOS with 100 mL of ethanol in the reaction flask.

- Heat to 60°C with stirring for 30 minutes.

Step 2: Catalyzed Hydrolysis and Gelation

- Instead of acid, add an ammonia solution as the catalyst. The concentration can be varied: for example, using 0.5 M NH₃(aq) yields mesopores around 4.0 nm, while 2.0 M NH₃(aq) shifts the pore size to about 5.4 nm [29].

- Add the base catalyst in one portion under rapid stirring.

- Gelation in base-catalyzed systems is typically rapid. The sol will turn translucent or opaque as it approaches the gel point.

- Age the resulting gel in the basic solution for 24 hours to promote Ostwald ripening, which increases the average pore size and strengthens the network [29].

Protocol 3: Incorporation of Active Components (NiO/Fe2O3)

This procedure outlines the integration of catalytic active phases into the silica gel matrix [17] [28].

Step 1: Precursor Mixing

- During Step 1 of Protocol 1 or 2, after the TEOS is dissolved in ethanol, add stoichiometric amounts of nickel and iron precursor salts (e.g., nitrates).

- The Ni/Fe ratio is critical. A 1:1 molar ratio is recommended for the formation of a homogeneous mixed oxide phase with strong adhesion to the Al₂O₃ support. Deviations (e.g., 20/1 or 1/20) lead to phase separation and weak adhesion [17] [28].

Step 2: Support Introduction

- After the hydrolysis step, introduce the Al₂O₃ support powder into the sol.

- Maintain stirring for an additional 30-60 minutes to ensure uniform coating of the support particles by the hydrolyzing sol before gelation occurs.

Drying and Thermal Treatment Protocols

Xerogel Formation (Atmospheric Drying) [29] [30]

- Carefully transfer the aged gel to a drying vessel.

- Dry in an oven at 60-80°C for 24-48 hours. Crucially, control the heating rate to a maximum of 5°C/min. Faster rates (e.g., 10°C/min) induce capillary stresses that cause severe cracking and macropore formation, rendering the material unsuitable for catalysis [17] [28].

- After solvent evaporation, a xerogel is obtained.

Aerogel Formation (Supercritical Drying) [29] [30]

- Transfer the wet gel to a high-pressure autoclave.

- Fill the autoclave with ethanol (or another solvent) and slowly raise the temperature and pressure above the solvent's critical point (for ethanol: Tc = 243°C, Pc = 63 bar).

- Maintain supercritical conditions while flushing with an inert gas (e.g., argon) to remove the solvent without creating a liquid-vapor interface, thus avoiding capillary forces.

- Slowly release the pressure and cool to ambient conditions to obtain an aerogel with extremely high porosity and low density.

Calcination and Thermal Treatment [17] [31]

- Subject the dried xerogel or aerogel to a final heat treatment (calcination) to remove residual organics, enhance crystallinity, and develop the final active phases.

- For the NiO-Fe2O3-SiO2/Al2O3 catalyst, an optimized calcination at 400°C for 40 minutes with a controlled heating rate of up to 5°C/min produces a catalyst with a particle size of 44 nm and a specific surface area of 134.79 m²/g [17] [28].

- Warning: High-temperature treatments (>800°C) can cause sintering, phase transformations (e.g., formation of less reducible NiAl2O4 spinel), and significant loss of surface area [17] [28].

Data Presentation and Analysis

Quantitative Analysis of Synthesis Parameters

The following table consolidates key quantitative data from research on how synthesis parameters affect the final material's properties [17] [29].

Table: Effect of Synthesis Parameters on Final Gel Properties

| Synthesis Parameter | Condition/Variable | Resulting Material Property | Quantitative Outcome |

|---|---|---|---|

| Aging Solution | Ethanol | Surface Area / Micropore Volume | Higher [29] |

| Aging Solution | 0.5 M NH₃(aq) | Mesopore Size (BJH Max) | 4.0 nm [29] |

| Aging Solution | 2.0 M NH₃(aq) | Mesopore Size (BJH Max) | 5.4 nm [29] |

| Drying Method | Atmospheric (Xerogel) | Primary Porosity | Micro/Mesoporous [29] |

| Drying Method | Supercritical (Aerogel) | Primary Porosity / Macropore Volume | Macroporous / >92% [29] |

| Heating Rate during Treatment | 5 °C/min | Morphology / Elemental Distribution | Coherent structure, uniform distribution [17] [28] |

| Heating Rate during Treatment | 10 °C/min | Morphology | Macrocracks, fragmentation [17] [28] |

| Ni/Fe Ratio | 1/1 | Structure / Elemental Distribution | Homogeneous particles, strong adhesion [17] [28] |

| Ni/Fe Ratio | 20/1 or 1/20 | Structure | Fragmented aggregates, weak adhesion [17] [28] |

Workflow and Process Visualization

The diagram above illustrates the complete sol-gel pathway, highlighting critical decision points (catalyst type, drying method) that determine the final material's structural properties.

Troubleshooting and Optimization

Problem: Gel Cracks during Drying.

- Cause: Excessive capillary pressure from rapid solvent evaporation [17] [30].

- Solution: Implement a slower drying rate (<5°C/min) and use a controlled humidity environment. For monolithic structures, consider chemical additives like formamide as drying control chemical additives (DCCAs) [30].

Problem: Low Surface Area or Non-Uniform Active Phase.

- Cause: Incorrect Ni/Fe ratio or excessively high calcination temperature leading to sintering and spinel formation [17] [28].

- Solution: Maintain a 1:1 Ni/Fe ratio for homogeneity and optimize the final heat treatment to a lower temperature (e.g., 400°C) [17] [28].

Problem: Long or Uncontrollable Gelation Times.

- Cause: Improper catalyst type or concentration [18].

- Solution: For faster gelation, use a base catalyst. Pre-hydrolyze the precursor under acidic conditions before adding active components for a two-step acid-base process that offers better control over the microstructure [29].

Dip-Coating and Other Deposition Techniques for Creating Thin-Film Catalysts

The synthesis of advanced catalysts via the sol-gel process provides unparalleled control over structural and compositional homogeneity at the molecular level. This wet-chemical technique involves the transition of a solution system from a liquid "sol" into a solid "gel" phase through a series of hydrolysis and condensation reactions [7]. The resulting materials can be engineered with tailored porosity, high specific surface area, and controlled active site distribution, making them particularly valuable for catalytic applications. However, the ultimate performance of these catalytic materials is profoundly influenced by the deposition method used to create thin films on appropriate substrates.

Deposition techniques serve as the critical bridge between sol-gel chemistry and functional catalyst design, determining key characteristics such as film uniformity, thickness control, adhesion properties, and microstructural organization. The selection of an appropriate deposition method depends on multiple factors including the nature of the substrate, desired film properties, scalability requirements, and economic considerations. This application note provides a comprehensive overview of major deposition techniques used in fabricating thin-film catalysts, with detailed protocols and comparative analysis to guide researchers in selecting and optimizing these methods for specific catalytic applications.

Various deposition methods are available for creating thin films from sol-gel precursors, each offering distinct advantages and limitations. The table below summarizes the key characteristics of these techniques:

Table 1: Comparison of Thin-Film Deposition Techniques for Sol-Gel Catalysts

| Technique | Typical Film Thickness | Uniformity | Scalability | Wastage | Complexity | Best Applications |

|---|---|---|---|---|---|---|

| Dip Coating | 0.05-5 μm [32] | High on simple geometries [32] | Moderate | High [32] | Low | Complex shapes, R&D, uniform coatings [32] |

| Spin Coating | Nanometers to microns [32] | High on flat substrates [32] | Low (batch) | Very High [32] | Low | Flat substrates, R&D, microelectronics [32] [33] |

| Spray Coating | Variable | Low to Moderate | High | Low | Moderate | Large areas, curved surfaces, industrial scale [32] |

| Doctor Blade Coating | >10 μm [32] | Moderate | High | Low [32] | Low | Thick films, prototyping, industrial scale [32] |

| Slot Die Coating | 0.5-100 μm | High | Very High [32] | Very Low [32] | High | Patterned coatings, roll-to-roll manufacturing [32] |

Detailed Deposition Protocols

Dip-Coating Protocol

Dip coating stands as one of the most versatile and widely implemented techniques for depositing sol-gel derived catalyst films, particularly valued for its simplicity and applicability to complex geometries.

Materials and Equipment

- Sol-gel precursor solution: Typically metal alkoxides (e.g., tetraethoxysilane, titanium isopropoxide) in appropriate solvent [7]

- Substrate: Properly cleaned and functionalized support material

- Dip coater apparatus: Precision withdrawal rate control (Stable Microsystems Texture Analyser or equivalent) [33]

- Environmental control chamber: For temperature and humidity regulation

- Drying oven: For solvent evaporation and preliminary processing

- Muffle furnace: For calcination treatments

Step-by-Step Procedure

Substrate Preparation: Clean substrates thoroughly using appropriate solvents (e.g., THF, isopropanol/water mixture) and dry with filtered nitrogen gas to ensure complete removal of contaminants [33].

Precursor Solution Preparation: Formulate sol-gel solution with controlled viscosity and concentration. For example, prepare a solution containing tetraethoxysilane (TEOS) as the SiO₂ precursor, ethanol as solvent, with hydrochloric acid or ammonia as catalyst for hydrolysis [11] [7].

Immersion: Slowly immerse the substrate into the sol-gel solution at a constant rate, ensuring complete wetting of the surface. Maintain immersion for 30-60 seconds to establish equilibrium at the solid-liquid interface [27].

Withdrawal: Withdraw the substrate at a controlled speed typically between 0.1-10 mm/s [33]. The withdrawal speed is a critical parameter determining final film thickness according to the Landau-Levich relationship: h ∝ u₀²/³, where h is thickness and u₀ is withdrawal speed [33].