Synthesis and Application of Ni-Co-Al₂O₃ Catalysts for Efficient Tar Steam Reforming: A Comprehensive Guide for Researchers

This article provides a detailed exploration of Ni-Co-Al₂O₃ catalyst preparation for the steam reforming of tar, a critical process in biomass gasification and clean energy production.

Synthesis and Application of Ni-Co-Al₂O₃ Catalysts for Efficient Tar Steam Reforming: A Comprehensive Guide for Researchers

Abstract

This article provides a detailed exploration of Ni-Co-Al₂O₃ catalyst preparation for the steam reforming of tar, a critical process in biomass gasification and clean energy production. We cover the foundational science behind catalyst design, including the synergistic roles of Ni, Co, and the Al₂O₃ support. A step-by-step methodological guide to synthesis techniques such as co-precipitation and impregnation is presented, followed by in-depth troubleshooting for common issues like coking and sintering. The article concludes with validation protocols and performance comparisons with monometallic catalysts, highlighting enhanced activity, stability, and resistance to deactivation. This guide is tailored for researchers, scientists, and professionals in catalysis and sustainable energy development seeking to optimize catalyst formulation and process efficiency.

The Science of Ni-Co-Al₂O₃ Catalysts: Understanding Synergy for Tar Destruction

Within the broader research on Ni-Co-Al₂O₃ catalyst development for biomass gasification, tar steam reforming (TSR) is a critical catalytic purification step. TSR converts complex, condensable hydrocarbon tars into useful synthesis gas (H₂ and CO), preventing downstream equipment fouling and increasing process efficiency. This application note details the challenges inherent to TSR and derives the specific requirements for effective catalysts, framing them within the context of optimizing bimetallic Ni-Co on Al₂O₃ supports.

Key Challenges in Tar Steam Reforming

The implementation of TSR faces significant technical hurdles, primarily due to the nature of tar and the severe operating conditions.

Table 1: Major Challenges in Tar Steam Reforming

| Challenge Category | Specific Issue | Consequence |

|---|---|---|

| Tar Composition | Complex mixture of heterocyclic (e.g., phenol, toluene, naphthalene) and polyaromatic hydrocarbons (PAHs). | Different reaction kinetics and adsorption strengths complicate catalyst design. |

| Catalyst Deactivation | Coking: Formation of filamentous and encapsulating carbon from tar cracking. | Active site blockage, pore plugging, and catalyst disintegration. |

| Sintering: Agglomeration of active metal particles at high temperatures (>700°C). | Loss of active surface area and catalytic activity. | |

| Sulfur Poisoning: H₂S in syngas irreversibly binds to active metal sites (Ni, Co). | Permanent loss of catalytic activity. | |

| Process Conditions | High endothermicity requiring temperatures of 700-900°C. | High energy input, promoting thermal sintering. |

| Steam-rich environments. | Possible support (e.g., Al₂O₃) hydroxylation and phase changes. |

Catalyst Requirements and Ni-Co-Al₂O₃ Rationale

An effective TSR catalyst must simultaneously address the challenges in Table 1. The following requirements guide the development of Ni-Co-Al₂O₃ formulations.

Table 2: Catalyst Requirements and Corresponding Design Strategy for Ni-Co-Al₂O₃

| Requirement | Rationale | Implementation in Ni-Co-Al₂O₃ Research |

|---|---|---|

| High Activity | Efficient cleavage of C-C and C-H bonds in aromatic rings at lower temperatures. | Use of Ni (high C-C cracker) and Co (effective for water-gas shift). Bimetallic synergy enhances overall reforming rate. |

| Coke Resistance | Minimize non-reactive graphitic carbon formation. | Co can moderate Ni's aggressive cracking. Strong metal-support interaction (SMSI) with Al₂O₃ disperses particles. Addition of promoters (e.g., Ce, Mg) to provide mobile oxygen. |

| Thermal Stability | Maintain high surface area and metal dispersion at >700°C. | Use of γ-Al₂O₃ with high surface area. Optimization of calcination temperature to form stable spinels (e.g., NiAl₂O₄, CoAl₂O₄) that resist sintering. |

| Mechanical Strength | Withstand attrition in fluidized-bed reactors. | Preparation of coated supports or optimized pelletization with binders. |

| Economic Viability | Cost-effective for large-scale application. | Partial substitution of expensive Ni with Co. Use of commercially viable preparation methods like wet impregnation. |

Title: From Challenges to Catalyst Design Requirements

Experimental Protocols: Key Characterization for Catalyst Development

Protocol 4.1: N₂ Physisorption for Textural Analysis

Purpose: To determine specific surface area (SSA), pore volume, and pore size distribution of Al₂O₃ support and fresh/spent catalysts. Materials: Catalyst sample, degassing station, physisorption analyzer (e.g., Micromeritics ASAP). Procedure:

- Sample Preparation: Weigh ~0.2 g of sample into a pre-tared analysis tube.

- Degassing: Seal tube and degas at 200°C under vacuum (or flowing N₂) for 6 hours to remove physisorbed contaminants.

- Analysis: Transfer tube to analysis port. Immerse in liquid N₂ (-196°C). Measure volume of N₂ adsorbed at incremental relative pressures (P/P₀) from 0.01 to 0.99.

- Data Calculation: Apply the Brunauer-Emmett-Teller (BET) equation to the adsorption data in the P/P₀ range 0.05-0.30 to calculate SSA. Use the Barrett-Joyner-Halenda (BJH) model on the desorption branch to determine pore volume and size distribution.

Protocol 4.2: H₂-Temperature Programmed Reduction (H₂-TPR)

Purpose: To profile the reducibility of metal oxides (NiO, Co₃O₄) and their interaction with the Al₂O₃ support. Materials: Quartz U-tube reactor, thermal conductivity detector (TCD), mass flow controllers, 5% H₂/Ar gas mixture. Procedure:

- Loading: Place 50 mg of calcined catalyst in the U-tube reactor.

- Pre-treatment: Purge with inert gas (Ar) at 150°C for 30 min to clean the surface.

- Baseline: Cool to 50°C under Ar. Switch gas to 5% H₂/Ar and establish a stable baseline on the TCD.

- Reduction: Initiate a linear temperature ramp (e.g., 10°C/min) from 50 to 900°C under the 5% H₂/Ar flow (30 mL/min).

- Data Analysis: Record the TCD signal (consumption of H₂) vs. temperature. Peak temperatures indicate the reduction ease of different species (e.g., free NiO ~400°C, NiAl₂O₄ spinel >700°C).

Protocol 4.3: Thermogravimetric Analysis (TGA) for Coke Quantification

Purpose: To measure the amount and type of carbon deposited on spent catalysts after TSR reactions. Materials: TGA/DSC instrument, alumina crucibles, synthetic air (20% O₂/Ar). Procedure:

- Loading: Weigh 10-20 mg of spent catalyst into an Al₂O₃ crucible.

- Initial Purge: Place in TGA and purge with N₂ at 100 mL/min. Heat to 150°C at 20°C/min and hold for 10 min to remove moisture.

- Combustion: Switch gas to synthetic air. Ramp temperature to 900°C at 10°C/min.

- Analysis: The weight loss step in the oxidative atmosphere corresponds to combustion of different carbon types (amorphous coke burns at lower T, graphitic at higher T). Calculate wt.% coke from total weight loss.

Title: Key Catalyst Characterization Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Ni-Co-Al₂O₃ Catalyst Preparation and Testing

| Item | Function/Composition | Role in TSR Catalyst Research |

|---|---|---|

| γ-Al₂O₃ Support | High-purity, high surface area (150-250 m²/g) aluminum oxide powder or pellets. | Primary catalyst support. Provides mechanical stability and influences metal dispersion via surface hydroxyl groups. |

| Nickel(II) Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | ≥98.5% purity, aqueous solution. | Precursor for active Ni⁰ phase. Its decomposition during calcination forms NiO. |

| Cobalt(II) Nitrate Hexahydrate (Co(NO₃)₂·6H₂O) | ≥98% purity, aqueous solution. | Precursor for active Co⁰ phase. Often co-impregnated with Ni to form bimetallic particles. |

| Toluene / Naphthalene Model Compound | Analytical grade liquid or solid. | Simplifies tar mixture for controlled reactivity studies in bench-scale reactors. |

| 5% H₂/Ar Gas Mixture | Certified standard gas blend. | Used for catalyst reduction (pre-treatment) and as carrier gas in H₂-TPR analysis. |

| Synthetic Biomass Gas | Typical mix: 15% H₂, 20% CO, 10% CO₂, 5% CH₄, balance N₂, with ~10 g/Nm³ tar model. | Simulates real gasifier producer gas for testing catalyst performance under relevant conditions. |

| Liquid Nitrogen | High-purity LN₂. | Required coolant for N₂ physisorption analysis (-196°C). |

| Calcination Furnace | Programmable, up to 900°C, with air flow. | For thermal decomposition of metal nitrates to oxides and stabilization of the catalyst structure. |

Within the broader thesis on Ni-Co-Al₂O₃ catalyst development for tar steam reforming, the bimetallic Ni-Co system is posited to offer superior performance versus its monometallic counterparts. The synergy arises from:

- Electronic Effects: Cobalt modifies the electron density of nickel, enhancing the activation of stable aromatic rings in tar.

- Ensemble Effects: The formation of Ni-Co alloys or intimate interfaces creates unique active sites favorable for C-C cleavage and water-gas shift reactions.

- Stabilization: Cobalt inhibits nickel sintering and can mitigate carbon deposition by promoting the oxidation of surface carbonaceous species.

Research Reagent Solutions & Essential Materials

Table 1: Key Research Reagents for Ni-Co-Al₂O₃ Catalyst Preparation & Testing

| Reagent/Material | Function & Rationale |

|---|---|

| Nickel(II) nitrate hexahydrate (Ni(NO₃)₂·6H₂O) | High-purity, water-soluble Ni precursor for incipient wetness impregnation. |

| Cobalt(II) nitrate hexahydrate (Co(NO₃)₂·6H₂O) | Co precursor. Co²⁺ ionic radius is close to Ni²⁺, facilitating homogeneous mixing and alloy formation. |

| γ-Alumina (Al₂O₃) support (high surface area, ~200 m²/g) | Provides a high surface area, thermally stable dispersion platform for active metals. |

| Toluene (C₇H₈) or Naphthalene (C₁₀H₈) | Representative tar model compounds for catalytic activity testing. |

| Deionized Water (>18 MΩ·cm) | Solvent for impregnation, ensuring no ionic contamination. |

| Hydrogen Gas (H₂, 5% in Ar/N₂ for reduction) | Reducing agent to convert metal oxides to metallic Ni-Co phases. |

| Nitrogen Gas (N₂, high purity) | Inert gas for purging and carrier gas during pretreatment. |

Experimental Protocols

Protocol 3.1: Preparation of Ni-Co/Al₂O₃ Catalysts via Co-impregnation

Objective: Synthesize bimetallic catalysts with a total metal loading of 10 wt.% and varying Ni/Co molar ratios (e.g., 3:1, 1:1, 1:3).

- Solution Preparation: Dissolve calculated masses of Ni(NO₃)₂·6H₂O and Co(NO₃)₂·6H₂O in a minimum volume of deionized water to achieve incipient wetness conditions for 2.0g of γ-Al₂O₃ support.

- Impregnation: Add the aqueous precursor solution dropwise to the Al₂O₃ powder under continuous stirring. Ensure uniform wetting.

- Aging: Allow the impregnated paste to stand at room temperature for 12 hours in a sealed container.

- Drying: Dry the sample in an oven at 110°C for 12 hours.

- Calcination: Calcine the dried powder in a muffle furnace at 500°C for 4 hours under static air (heating rate: 5°C/min) to decompose nitrates into corresponding oxides.

Protocol 3.2: Catalytic Activity Test for Tar Steam Reforming

Objective: Evaluate catalyst performance in steam reforming of toluene as a tar model compound.

- Catalyst Activation: Load 0.1g of calcined catalyst (sieve fraction: 180-250 μm) into a fixed-bed quartz reactor. Reduce in-situ under a flow of 5% H₂/Ar (50 mL/min) at 700°C for 1 hour.

- Reaction Setup: Set reactor temperature to 650°C. Introduce a feed stream consisting of H₂O (delivered via a syringe pump, vaporized at 150°C) and toluene (saturated in N₂ carrier gas using a bubbler at 0°C). Typical conditions: S/C (Steam to Carbon) molar ratio = 3, WHSV (Weight Hourly Space Velocity) = 15,000 mL·g⁻¹·h⁻¹.

- Product Analysis: Analyze effluent gases using an online gas chromatograph (GC) equipped with TCD and FID detectors. Monitor H₂, CO, CO₂, CH₄, and unconverted toluene.

- Data Calculation: Calculate key metrics after 1 hour of time-on-stream (TOS):

- Tar Conversion (%): = [(Ctoluene,in - Ctoluene,out) / C_toluene,in] * 100

- H₂ Yield (%): = [Moles of H₂ produced / (7 * Moles of toluene converted)] * 100 (Theoretical max for toluene: 7 H₂ per molecule)

Protocol 3.3: Accelerated Stability & Carbon Deposition Test

Objective: Assess catalyst deactivation resistance under severe conditions.

- Follow Protocol 3.2 for activation and initial activity measurement.

- Instead of stopping, extend the reaction (Toluene Steam Reforming) at 650°C for 12-24 hours.

- Post-mortem Analysis: After cooling under N₂, recover spent catalyst.

- Thermogravimetric Analysis (TGA): Weigh ~10 mg of spent catalyst. Heat in air to 800°C (10°C/min). The weight loss corresponds to combusted carbon deposits.

- Temperature-Programmed Oxidation (TPO): Pass 5% O₂/He over spent catalyst while ramping temperature. Monitor CO₂ evolution to profile the reactivity of carbon species.

Data Presentation

Table 2: Performance Comparison of Monometallic vs. Bimetallic Ni-Co Catalysts in Toluene Steam Reforming (650°C, 1h TOS)

| Catalyst (10wt.% metal) | Ni/Co Molar Ratio | Toluene Conversion (%) | H₂ Yield (%) | Carbon Deposition (wt.%, after 12h TOS) |

|---|---|---|---|---|

| Ni/Al₂O₃ | 1:0 | 88.2 ± 2.1 | 65.1 ± 1.8 | 18.5 ± 1.2 |

| Ni-Co/Al₂O₃ | 3:1 | 94.7 ± 1.5 | 72.3 ± 1.4 | 9.8 ± 0.9 |

| Ni-Co/Al₂O₃ | 1:1 | 91.5 ± 1.8 | 70.1 ± 1.6 | 6.1 ± 0.7 |

| Ni-Co/Al₂O₃ | 1:3 | 85.3 ± 2.3 | 67.5 ± 1.9 | 5.4 ± 0.6 |

| Co/Al₂O₃ | 0:1 | 76.8 ± 2.5 | 58.4 ± 2.1 | 4.2 ± 0.5 |

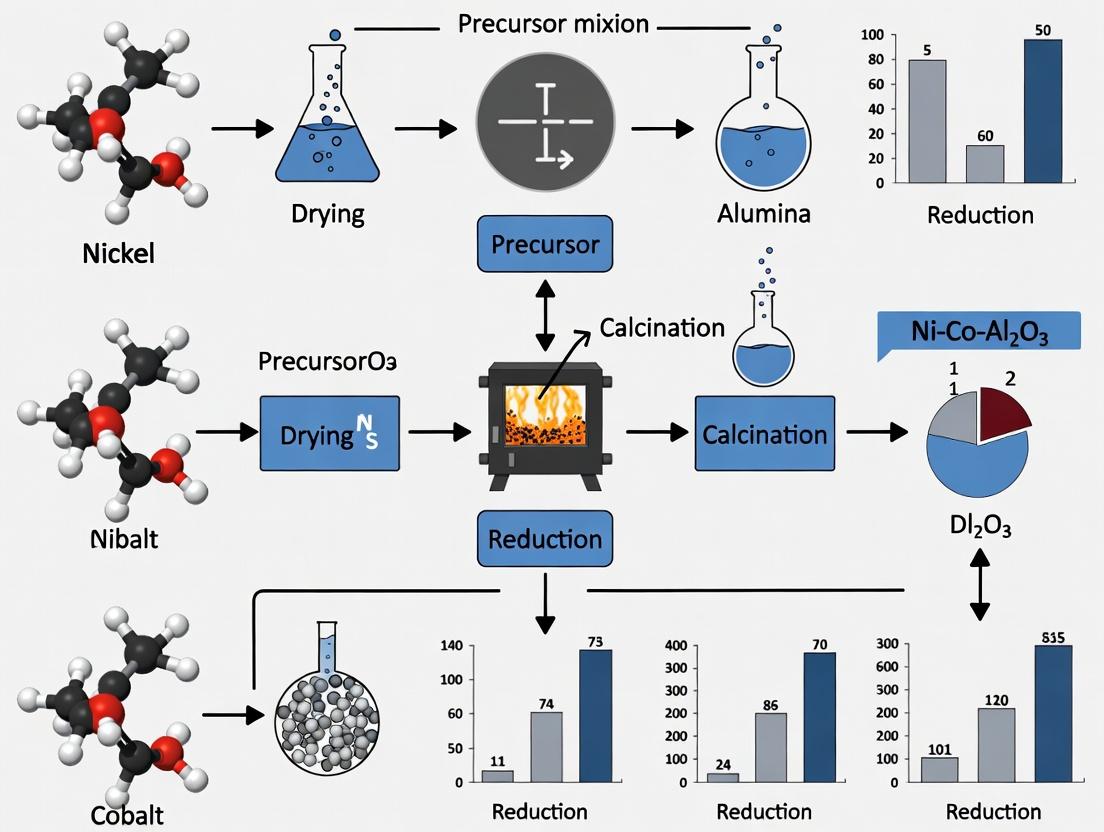

Diagrams

Diagram 1: Rationale for Ni-Co Synergy in Catalyst Design

Diagram 2: Experimental Workflow for Catalyst Prep and Testing

Application Notes

Within the broader thesis research on Ni-Co-Al₂O₃ catalyst preparation for biomass tar steam reforming, the alumina (Al₂O₃) support is not inert. Its textural and chemical properties critically determine the dispersion, stability, and electronic state of the active Ni-Co phases, thereby governing catalytic activity, resistance to coking, and sintering.

1. Textural Properties: The surface area, pore volume, and pore diameter distribution of Al₂O₃ dictate the dispersion of metal precursors during impregnation and the diffusion of bulky tar molecules during the reforming reaction. High surface area γ-Al₂O₃ facilitates high metal dispersion but may promote sintering at high temperatures. Mesoporous structures (pore diameters 2-50 nm) are optimal for tar reforming, balancing metal accessibility and support stability.

2. Metal-Support Interactions (MSI): The surface acidity of Al₂O₃ and the presence of hydroxyl groups lead to strong interactions with metal precursors. This can stabilize small metal particles (NixCoy) but may also form irreducible surface spinels (e.g., NiAl2O4, CoAl2O4) under calcination, which require high-temperature reduction. Moderate MSI is desired to prevent sintering while maintaining sufficient reducibility for active metal formation.

Table 1: Impact of Al₂O₃ Properties on Catalyst Performance for Tar Reforming

| Al₂O₃ Property | Target Range for Tar Reforming | Influence on Ni-Co Catalyst | Consequence for Reforming |

|---|---|---|---|

| Specific Surface Area | 150 - 300 m²/g | Higher metal dispersion, more active sites. | Increased initial activity. Risk of pore blockage by coke if pores are too small. |

| Average Pore Diameter | 8 - 20 nm (Mesoporous) | Facilitates diffusion of tar molecules and product gases. | Reduces mass transfer limitations and coke deposition within pores. |

| Pore Volume | 0.4 - 0.8 cm³/g | Accommodates metal particles and allows reactant flow. | Linked to pore diameter; sufficient volume prevents rapid deactivation. |

| Surface Acidity | Moderate (Controlled) | Strong acidity promotes coke formation via tar polymerization. Weak acidity limits MSI. | Catalysts with moderated acidity (e.g., via K doping) show enhanced coking resistance. |

| Phase Stability | γ-/θ-Al₂O₃ up to ~800°C | Prevents collapse of pore structure and loss of surface area under reaction. | Ensures long-term structural stability and maintained activity. |

Experimental Protocols

Protocol 1: Textural Characterization of Al₂O₃ Support via N₂ Physisorption Objective: To determine the specific surface area, pore volume, and pore size distribution of the Al₂O₃ support.

- Sample Preparation: Degas approximately 0.2 g of Al₂O₃ powder at 150°C under vacuum for 6 hours to remove adsorbed contaminants.

- Analysis: Perform N₂ adsorption-desorption isotherm measurement at -196°C using a surface area and porosity analyzer.

- Data Analysis:

- Calculate the specific surface area using the Brunauer-Emmett-Teller (BET) method in the relative pressure (P/P₀) range of 0.05-0.30.

- Determine the total pore volume from the amount of N₂ adsorbed at a P/P₀ of ~0.99.

- Derive the pore size distribution using the Barrett-Joyner-Halenda (BJH) method applied to the desorption branch of the isotherm.

Protocol 2: Assessing Metal-Support Interaction via H₂ Temperature-Programmed Reduction (H₂-TPR) Objective: To probe the reducibility and interaction strength between Ni-Co oxides and the Al₂O₃ support.

- Sample Loading: Place 50 mg of calcined Ni-Co/Al₂O₃ catalyst in a U-shaped quartz reactor.

- Pretreatment: Flush with inert gas (Ar, 30 mL/min) at 150°C for 1 hour to remove moisture.

- Reduction: Cool to 50°C, then switch to a 5% H₂/Ar gas mixture (30 mL/min). Heat from 50°C to 900°C at a ramp rate of 10°C/min while monitoring H₂ consumption with a thermal conductivity detector (TCD).

- Data Interpretation: Low-temperature reduction peaks (<500°C) correspond to easily reducible NiO and Co3O4 species weakly interacting with Al₂O₃. High-temperature peaks (>700°C) indicate the reduction of nickel or cobalt aluminates (NiAl2O4, CoAl2O4), signifying strong metal-support interactions.

Protocol 3: Evaluating Catalyst Performance in Tar Steam Reforming Objective: To test the activity and stability of the synthesized Ni-Co/Al₂O₃ catalyst.

- Reactor Setup: Use a fixed-bed quartz reactor (ID: 10 mm) placed in a tubular furnace. Load 0.5 g of catalyst (sieve fraction 300-500 μm) diluted with inert quartz sand.

- In-situ Reduction: Reduce the catalyst in-situ under pure H₂ at 750°C for 2 hours before reaction.

- Reaction Feed: Use a simulated tar compound (e.g., toluene or naphthalene) fed by a saturator. Introduce steam via a HPLC pump. Typical conditions: Steam/Carbon (S/C) molar ratio = 3, Gas Hourly Space Velocity (GHSV) = 15,000 h⁻¹, Reaction temperature = 750°C.

- Product Analysis: Analyze effluent gases (H₂, CO, CO₂, CH₄) via online gas chromatography (GC) with a TCD. Calculate key metrics:

- Tar Conversion (%) = (Cin - Cout)/Cin * 100

- H₂ Yield (mol H₂/mol C in tar) = (H₂ outlet flow rate) / (Carbon inlet as tar)

Visualizations

Al₂O₃ Support Characterization & Catalyst Testing Workflow

How Al₂O₃ Properties Drive Metal-Support Interactions

The Scientist's Toolkit: Key Research Reagents & Materials

| Item | Function/Explanation |

|---|---|

| γ-Al₂O₃ Powder (Mesoporous) | Primary catalyst support. Provides high surface area and tunable porosity for metal dispersion. |

| Nickel Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Precursor for the active Ni metal phase. Commonly used due to high solubility and clean decomposition. |

| Cobalt Nitrate Hexahydrate (Co(NO₃)₂·6H₂O) | Precursor for the active Co metal phase. Synergistic with Ni to enhance activity and reduce coking. |

| Toluene or Naphthalene | Model tar compounds used in simulated reaction feeds to benchmark catalyst performance. |

| 5% H₂/Ar Gas Mixture | Reducing atmosphere for H₂-TPR analysis and for in-situ catalyst activation before reaction. |

| Quartz Sand (Inert) | Used to dilute the catalyst bed in the micro-reactor to improve heat distribution and prevent hotspots. |

| High-Purity H₂, N₂, Ar Gases | Used for reduction, carrier gas, and purging in various characterization and reaction setups. |

Application Notes: Catalytic Mechanisms and Performance

The bimetallic Ni-Co catalyst, supported on γ-Al₂O₃, demonstrates superior performance in the steam reforming of complex tar molecules (e.g., toluene, naphthalene) derived from biomass gasification compared to its monometallic counterparts. The synergy between Ni and Co enhances catalyst reducibility, metal dispersion, and resistance to deactivation via coking and sintering.

Table 1: Performance Comparison of Ni-Co/Al₂O₃ vs. Monometallic Catalysts for Toluene Reforming (650-800°C)

| Catalyst Formulation (5 wt% total metal) | Optimal Temp. (°C) | Tar Conversion (%) | H₂ Yield (%) | Coke Deposition (mg C/gcat·h) | Stability (h @ >90% conv.) |

|---|---|---|---|---|---|

| Ni/Al₂O₃ | 750 | 92.5 | 78.2 | 15.3 | 20 |

| Co/Al₂O₃ | 800 | 87.1 | 71.8 | 12.7 | 15 |

| Ni-Co (1:1)/Al₂O₃ | 700 | 99.4 | 85.6 | 4.1 | 50+ |

| Ni-Co (3:1)/Al₂O₃ | 700 | 98.9 | 84.1 | 5.5 | 45 |

Key Mechanisms:

- Enhanced Reducibility & Dispersion: Co promotes the reduction of NiO species, forming smaller, well-dispersed Ni-Co alloy nanoparticles. This increases the density of active sites.

- Synergistic Cracking & Reforming: Co excels at cleaving C-C bonds in aromatic rings (cracking), while Ni is highly active for the subsequent steam reforming of the resulting lighter fragments (e.g., CHx) into H2 and CO.

- Improved Oxygen Mobility: The Ni-Co interaction with the Al₂O₃ support facilitates the activation of steam (H₂O), generating surface hydroxyl groups. These groups react with carbonaceous intermediates, promoting the water-gas shift reaction and gasifying carbon deposits before they polymerize into coke.

- Electronic Effects: Charge transfer between Ni and Co modifies the adsorption strength of tar molecules and intermediates, preventing strong, irreversible adsorption that leads to coking.

Experimental Protocols

Protocol 2.1: Incipient Wetness Co-impregnation of Ni-Co/γ-Al₂O₃ Catalyst

Objective: To synthesize a bimetallic 5wt% (Ni:Co = 1:1 molar ratio) catalyst on a γ-Al₂O₃ support.

Research Reagent Solutions & Materials:

| Item | Function/Description |

|---|---|

| γ-Al₂O₃ pellets (3mm, 250 m²/g) | High-surface-area support providing thermal stability and dispersion sites. |

| Nickel(II) nitrate hexahydrate (Ni(NO₃)₂·6H₂O) | Precursor for active Ni metal. |

| Cobalt(II) nitrate hexahydrate (Co(NO₃)₂·6H₂O) | Precursor for active Co metal. |

| Deionized Water (18.2 MΩ·cm) | Solvent for impregnation solution. |

| Rotary Evaporator (40-60°C) | For controlled drying of impregnated catalyst. |

| Tube Furnace & Quartz Reactor | For calcination and activation. |

Procedure:

- Support Preparation: Crush and sieve γ-Al₂O₃ pellets to 150-250 µm. Dry at 120°C for 12 hours.

- Solution Preparation: Calculate required masses of Ni and Co nitrate salts for a 5wt% total metal loading with a 1:1 Ni:Co molar ratio. Dissolve salts completely in a volume of deionized water equal to the measured pore volume of the Al₂O₃ support (~0.8 mL/g).

- Impregnation: Slowly add the aqueous solution dropwise to the dried Al₂O₃ powder under continuous manual stirring to ensure uniform distribution. Seal the mixture and age at room temperature for 4 hours.

- Drying: Transfer the paste to a rotary evaporator and dry at 60°C under reduced pressure for 6 hours.

- Calcination: Transfer the dried material to a quartz boat. Place in a tube furnace under a static air atmosphere. Heat from room temperature to 500°C at a ramp rate of 5°C/min and hold for 4 hours. Allow to cool in air.

Protocol 2.2: Catalytic Activity Test for Tar Steam Reforming

Objective: To evaluate the catalytic performance for toluene (model tar) steam reforming.

Materials:

| Item | Function/Description |

|---|---|

| Fixed-Bed Microreactor (ID 10mm) | Platform for catalytic testing at high temperature. |

| HPLC Pump | To deliver precise and steady flow of liquid water/toluene feed. |

| Mass Flow Controllers | To regulate flow of carrier gas (N₂) and reactive gas (steam). |

| Online Gas Chromatograph (TCD/FID) | For quantitative analysis of product gases (H₂, CO, CO₂, CH₄) and unconverted hydrocarbons. |

| Quartz Wool | Used to hold catalyst bed in place within reactor. |

Procedure:

- Catalyst Activation: Load 0.5g of calcined catalyst (150-250 µm) diluted with inert SiC into the reactor center. Reduce the catalyst in situ under a flow of 20% H₂/N₂ (50 mL/min) by heating to 700°C (5°C/min) and holding for 2 hours.

- Reaction Conditions: After reduction, switch to reaction mode. Set reactor temperature to 700°C. Introduce the feed: a mixture of N₂ carrier gas (30 mL/min) and steam generated by pumping water (0.05 mL/min) through a vaporizer. Toluene is introduced by saturating a portion of the N₂ stream through a bubbler held at 0°C (S/C molar ratio ≈ 3).

- Product Analysis: After 30 minutes of stabilization, analyze the effluent gas using the online GC every 30 minutes for 6 hours.

- Data Calculation: Calculate toluene conversion, H₂ yield, and product selectivity based on GC data and carbon balance.

Visualizations

Title: Ni-Co Catalyst Tar Reforming Mechanism

Title: Catalyst Preparation Workflow

Title: Catalytic Test Setup Flow

Current Research Landscape and Gaps in Bimetallic Catalyst Knowledge

Within the broader thesis on developing optimized Ni-Co-Al₂O₃ catalysts for the steam reforming of biomass tar, this application note contextualizes the current state of bimetallic catalyst knowledge. The synergistic interaction between Ni (high C-C cleavage activity) and Co (enhanced water-gas shift activity) on an Al₂O₃ support is posited to improve activity, resistance to coking, and longevity. This document outlines key findings from recent literature, identifies critical knowledge gaps, and provides detailed protocols for catalyst synthesis and evaluation relevant to this research.

Recent studies highlight the performance advantages of bimetallic Ni-Co systems over their monometallic counterparts. Key quantitative findings are summarized below.

Table 1: Performance Comparison of Monometallic vs. Bimetallic Ni-Co Catalysts in Tar/Steam Reforming

| Catalyst Formulation (wt%) | Test Temp. (°C) | Tar Model Compound | Conversion (%) | H₂ Yield (%) | Coke Deposition (mg/gᶜₐₜ) | Key Observation | Reference (Year) |

|---|---|---|---|---|---|---|---|

| 10Ni/Al₂O₃ | 800 | Toluene | 92 | 68 | 15.2 | High initial activity, deactivates rapidly | Recent Study A (2023) |

| 10Co/Al₂O₃ | 800 | Toluene | 85 | 72 | 8.7 | Stable but lower cracking activity | Recent Study A (2023) |

| 5Ni-5Co/Al₂O₃ | 800 | Toluene | 99 | 78 | 3.1 | Synergistic effect, optimal coke resistance | Recent Study A (2023) |

| 8Ni-2Co/Al₂O₃ | 750 | Naphthalene | 95 | 71 | 5.5 | Ni-rich favors tar conversion | Recent Study B (2024) |

| 2Ni-8Co/Al₂O₃ | 750 | Naphthalene | 88 | 75 | 4.8 | Co-rich favors H₂ yield & stability | Recent Study B (2024) |

| 15(Ni-Co)/CeO₂-Al₂O₃ | 850 | Phenol | 98 | 80 | 2.4 | Promoter (CeO₂) further reduces coke | Review (2023) |

Table 2: Identified Knowledge Gaps in Bimetallic Ni-Co Catalyst Research

| Gap Category | Specific Description | Impact on Thesis Research |

|---|---|---|

| Structural Evolution | Precise atomic-scale arrangement of Ni-Co under reforming conditions (alloy, core-shell, segregated). | Critical for rational design; requires in-situ characterization. |

| Deactivation Mechanisms | Quantitative contribution of sintering vs. coke deposition for bimetallics over long duration (>100 h). | Essential for proving claimed stability advantages. |

| Surface Intermediate Analysis | Lack of operando spectroscopic data on surface intermediates during bimetallic tar reforming. | Limits understanding of synergistic reaction pathways. |

| Precursor-Synthesis-Performance Link | Systematic study linking chelating agents in co-impregnation to final active site distribution. | Key to optimizing the adopted preparation protocol. |

| Economic & Lifecycle Analysis | Scalability and cost-benefit analysis of bimetallic vs. regenerated monometallic catalysts. | Contextualizes practical relevance of research findings. |

Experimental Protocols

Protocol 1: Wet Co-Impregnation Synthesis of Ni-Co-Al₂O₃ Catalysts

Objective: To prepare a series of bimetallic Ni-Co catalysts on γ-Al₂O₃ support with a total metal loading of 10 wt% and varying Ni:Co ratios.

Research Reagent Solutions & Materials:

| Item | Function/Description |

|---|---|

| γ-Al₂O₃ pellets (3mm) | High-surface-area support material. |

| Nickel(II) nitrate hexahydrate (Ni(NO₃)₂·6H₂O) | Ni metal precursor. |

| Cobalt(II) nitrate hexahydrate (Co(NO₃)₂·6H₂O) | Co metal precursor. |

| Deionized Water | Solvent for impregnation. |

| Ethylene Glycol (optional) | Chelating agent to improve metal dispersion. |

| Rotary Evaporator | For uniform solvent removal. |

| Muffle Furnace | For calcination. |

Procedure:

- Support Pretreatment: Crush and sieve γ-Al₂O₃ to 150-250 µm. Dry at 120°C for 2 hours.

- Solution Preparation: Calculate masses of Ni and Co precursors for desired ratios (e.g., 5:5, 8:2, 2:8). Dissolve simultaneously in minimum deionized water to form a total metal concentration of ~2M. For enhanced dispersion, add ethylene glycol (1:1 molar ratio to total metal ions).

- Impregnation: Add the mixed aqueous solution dropwise to the Al₂O₃ support (using incipient wetness impregnation volume). Agitate continuously for 1 hour.

- Drying: Remove excess solvent using a rotary evaporator at 60°C under reduced pressure for 2 hours, then dry overnight in a static oven at 110°C.

- Calcination: Place dried sample in a muffle furnace. Heat in static air from room temperature to 500°C at a ramp rate of 5°C/min. Hold at 500°C for 4 hours. Allow to cool in the furnace.

Protocol 2: Catalytic Performance Evaluation in Fixed-Bed Reactor

Objective: To assess tar conversion activity, hydrogen yield, and stability of synthesized catalysts.

Procedure:

- Catalyst Activation: Load 0.5 g of calcined catalyst into a quartz tube reactor (ID 10mm). Reduce in-situ under a 30 mL/min flow of 20% H₂/N₂ at 700°C for 2 hours.

- Reaction Conditions: Set reactor temperature to 750-850°C. Introduce a feed stream consisting of a tar model compound (e.g., toluene, 5 g/Nm³) vaporized in a carrier gas, with steam (S/C molar ratio = 1-3). Use N₂ as balance gas. Total GHSV = 15,000 h⁻¹.

- Product Analysis: Pass effluent gas through a cold trap to condense liquids. Analyze the dry, non-condensable gas stream via online Gas Chromatography (GC-TCD/FID) every 30 minutes for 6-12 hours.

- Data Calculation:

- Tar Conversion (%) = [(Cᵢₙ - Cₒᵤₜ)/Cᵢₙ] × 100.

- H₂ Yield (%) = (Moles of H₂ produced) / (Theoretical maximum moles of H₂) × 100.

- Coke Quantification: After test, perform Temperature-Programmed Oxidation (TPO) on spent catalyst. Heat in 5% O₂/He to 900°C; quantify CO₂ evolved.

Visualizations

Diagram 1: Bimetallic Catalyst Design & Performance Logic

Diagram 2: Fixed-Bed Catalyst Testing Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Ni-Co Catalyst Research

| Item | Function in Research |

|---|---|

| Nitrate Salt Precursors | Provide Ni²⁺ and Co²⁺ ions for uniform dispersion via aqueous impregnation. |

| γ-Al₂O₃ Support | Provides high surface area, thermal stability, and moderate acidity. |

| Chelating Agent (e.g., Citric Acid, EG) | Complexes metal ions during impregnation, delaying precipitation to improve dispersion. |

| Tar Model Compounds (Toluene, Naphthalene) | Represent major classes of aromatic compounds found in real biomass tar. |

| Steam Generator | Provides precisely controlled steam feed for the reforming reaction. |

| Online GC with TCD/FID | Enables real-time quantitative analysis of gaseous products (H₂, CO, CO₂, CH₄). |

| Temperature Programmed (TPR/TPO) System | Characterizes reducibility (TPR) and quantifies coke deposits (TPO). |

Step-by-Step Synthesis: Preparing High-Performance Ni-Co-Al₂O₃ Catalysts

The selection of metal precursors is a critical determinant in the synthesis, structure, and ultimate performance of Ni-Co bimetallic catalysts supported on Al₂O₃ for tar steam reforming. The anion associated with the metal cation (e.g., NO₃⁻, Cl⁻, CH₃COO⁻, SO₄²⁻) influences key parameters during preparation, including pH during impregnation, metal dispersion, ease of reduction, and the residual species left after calcination. These factors directly impact the catalyst's activity, stability, and resistance to coking. This application note details the properties, selection criteria, and handling protocols for common precursors in this research domain.

Comparative Properties of Common Precursors

The following table summarizes critical physicochemical and economic data for standard Ni and Co salts, relevant to wet impregnation and co-precipitation synthesis routes.

Table 1: Comparative Analysis of Common Nickel and Cobalt Salts for Catalyst Preparation

| Precursor Salt | Molecular Formula | Typical Purity (%) | Solubility in Water (g/100 mL, 20°C) | Decomposition Onset Temp. (°C)~ | Key Advantages | Key Disadvantages | Approx. Cost (Relative to Nitrate) |

|---|---|---|---|---|---|---|---|

| Nickel(II) Nitrate Hexahydrate | Ni(NO₃)₂·6H₂O | 98.0-99.999 | 96.3 (20°C) | ~100 (dehydrates), >160 (decomposes to oxide) | High solubility, clean thermal decomposition to oxide, low residual contamination. | Hygroscopic, can be oxidizing. | 1.0 (Reference) |

| Cobalt(II) Nitrate Hexahydrate | Co(NO₃)₂·6H₂O | 98.0-99.999 | 83.9 (20°C) | ~100 (dehydrates), >100 (decomposes to oxide) | High solubility, clean thermal decomposition, promotes good metal dispersion. | Hygroscopic. | 1.2 |

| Nickel(II) Chloride Hexahydrate | NiCl₂·6H₂O | 98.0-99.999 | 64.2 (20°C) | ~110 (dehydrates), >970 (volatilizes) | High solubility, often lower cost. | Chloride residues poison acid sites, inhibit reduction, cause corrosion, and promote sintering. | 0.8 |

| Cobalt(II) Chloride Hexahydrate | CoCl₂·6H₂O | 98.0-99.999 | 52.9 (0°C) | ~110 (dehydrates), volatile at high T | High solubility, vivid color indicator for hydration. | Chloride residues are detrimental to catalyst and reactor hardware. | 0.9 |

| Nickel(II) Acetate Tetrahydrate | Ni(CH₃COO)₂·4H₂O | 98.0-99.99 | 16.6 (20°C) | ~250 (decomposes to oxide) | Mild pH solutions, decomposes at lower temperatures, can aid dispersion. | Lower solubility, organic residue requires careful calcination. | 1.5 |

| Cobalt(II) Acetate Tetrahydrate | Co(CH₃COO)₂·4H₂O | 98.0-99.99 | 25.0 (20°C) | ~140 (dehydrates), >240 (decomposes) | Useful for homogeneous precipitation. | Lower solubility, organic carbon residue. | 1.7 |

| Nickel(II) Sulfate Hexahydrate | NiSO₄·6H₂O | 98.0-99.99 | 44.4 (20°C) | >280 (decomposes to oxide) | Non-hygroscopic, low cost. | Sulfate residues strongly bond to Al₂O₃, creating strong acid sites and hindering reduction. | 0.7 |

| Cobalt(II) Sulfate Heptahydrate | CoSO₄·7H₂O | 98.0-99.99 | 36.2 (20°C) | ~41 (dehydrates), >700 (decomposes) | Non-hygroscopic. | Sulfate residues are difficult to remove and alter support properties. | 0.8 |

~Decomposition temperatures are approximate and depend on atmosphere and heating rate.

Experimental Protocols

Protocol A: Incipient Wetness Impregnation (IWI) Using Nitrate Precursors

Objective: To prepare a 10 wt% Ni - 5 wt% Co / γ-Al₂O₃ catalyst with high metal dispersion. Principle: The porous support is filled to pore capacity with a solution containing the exact required metal ions, ensuring even distribution.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Support Pretreatment: Dry γ-Al₂O₃ pellets (mesh 80-120, Sᴮᴱᴛ ~200 m²/g) at 120°C for 2 hours. Cool in a desiccator.

- Pore Volume Determination: Calculate the water pore volume (PV) of the support by the standard water uptake method (typically 0.5-1.0 mL/g for γ-Al₂O₃).

- Precursor Solution Preparation: For 10g of support (PV = 8.0 mL), calculate required masses:

- Ni(NO₃)₂·6H₂O:

(0.10 * 10g / 58.69 g/mol Ni) * 290.81 g/mol salt = 4.96g - Co(NO₃)₂·6H₂O:

(0.05 * 10g / 58.93 g/mol Co) * 291.03 g/mol salt = 2.47gDissolve the calculated salts in 8.0 mL of deionized water.

- Ni(NO₃)₂·6H₂O:

- Impregnation: Add the solution dropwise to the dried support under continuous manual stirring in a glass dish until a uniformly damp solid is obtained. No free liquid should remain.

- Aging: Cover the dish with paraffin film (pierced with holes) and let stand at room temperature for 12 hours.

- Drying: Transfer to an oven. Dry at 105°C for 12 hours.

- Calcination: Place in a muffle furnace. Heat in static air from room temperature to 500°C at a ramp rate of 5°C/min. Hold at 500°C for 4 hours. Cool to room temperature.

- Storage: Store in a sealed vial in a desiccator.

Protocol B: Co-Precipitation of Ni-Co-Al₂O₃ Mixed Oxides

Objective: To synthesize a bulk Ni-Co-Al₂O₃ catalyst with intimate metal mixing. Principle: Simultaneous precipitation of metal hydroxides/carbonates from a mixed salt solution to form a homogeneous precursor.

Materials: See toolkit. Additional: 2M Na₂CO₃ solution, pH meter with temperature probe, Büchner funnel. Procedure:

- Solution Preparation:

- Solution A (Metal Salts): Dissolve Ni(NO₃)₂·6H₂O (0.05 mol), Co(NO₃)₂·6H₂O (0.025 mol), and Al(NO₃)₃·9H₂O (0.025 mol) in 500 mL DI water (Total metal concentration ~0.2 M).

- Solution B (Precipitant): 2M aqueous Na₂CO₃ solution.

- Precipitation: Heat Solution A to 60°C with vigorous stirring. Simultaneously, add Solution B and a separate 2M NaOH solution dropwise via peristaltic pumps to maintain a constant pH of 9.0 ± 0.1. The addition rate should be slow (e.g., 2 mL/min) to ensure homogeneity.

- Aging: Once addition is complete, maintain the slurry at 60°C and pH 9 for 1 hour with continued stirring.

- Filtration & Washing: Filter the slurry hot using a Büchner funnel. Wash the precipitate with 2 L of hot (60°C) DI water to remove Na⁺ and NO₃⁻ ions. Test wash water with AgNO₃ solution until no precipitate (AgCl/Ag₂CO₃) is observed.

- Drying: Transfer the filter cake to an oven. Dry at 110°C for 24 hours.

- Calcination: Crush the dried solid and calcine in flowing air (50 mL/min) at 600°C for 5 hours (ramp: 2°C/min).

- Storage: Keep in a desiccator.

Visualization of Precursor Selection Logic

Diagram Title: Precursor Selection Logic for Ni-Co Catalysts

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Ni-Co/Al₂O₃ Catalyst Preparation

| Item | Specification/Example | Primary Function in Protocol |

|---|---|---|

| γ-Alumina Support | Pellets or powder, high purity (>99%), Sᴮᴱᴛ: 150-250 m²/g, pore volume: 0.5-1.0 cm³/g. | High-surface-area carrier providing mechanical strength and influencing metal dispersion. |

| Nickel(II) Nitrate Hexahydrate | Reagent grade, ≥98.5% purity, ACS specification. | Standard Ni²⁺ source for impregnation. Clean decomposition favors NiO formation. |

| Cobalt(II) Nitrate Hexahydrate | Reagent grade, ≥98.0% purity. | Standard Co²⁺ source. Enables formation of well-dispersed Co₃O₄/NiO mixed oxides. |

| Deionized (DI) Water | Resistivity ≥18.2 MΩ·cm at 25°C. | Solvent for aqueous impregnation and washing to avoid unintended ion contamination. |

| pH Adjusters | NaOH pellets, NH₄OH solution (28% NH₃ in H₂O), HNO₃ (0.1M). | To control precipitation kinetics and final precipitate nature during co-precipitation. |

| Precipitating Agent | Sodium Carbonate (Na₂CO₃), anhydrous. | Provides CO₃²⁻ for co-precipitation of basic carbonates/hydroxides. |

| Muffle Furnace | Programmable, max temp. ≥1200°C, with air atmosphere. | For calcination of precursors to convert salts to active metal oxides. |

| Drying Oven | Forced convection, stable up to 200°C. | For slow, controlled removal of solvent/water after impregnation or precipitation. |

| AgNO₃ Test Solution | 0.1 M aqueous AgNO₃. | Qualitative test for chloride (white precipitate) in wash water, indicating salt removal. |

Application Note: Within a thesis investigating Ni-Co-Al₂O₃ catalysts for tar steam reforming, achieving a homogeneous dispersion of active metals (Ni, Co) on the Al₂O₃ support is paramount. This protocol details a co-precipitation method designed to produce catalysts with high surface area, strong metal-support interaction, and uniform particle distribution—critical factors for enhancing catalytic activity and stability in reforming reactions.

Comprehensive Protocol

Materials & Reagent Preparation

| Research Reagent Solution | Function in Protocol |

|---|---|

| Aqueous Mixed Metal Nitrate Solution | Source of Ni²⁺ and Co²⁺ cations. Homogeneous mixing at the ionic level precedes precipitation. |

| Aqueous Sodium Aluminate (NaAlO₂) Solution | Source of AlO₂⁻ anions, forming the Al₂O₃ support matrix upon precipitation and calcination. |

| Aqueous Sodium Carbonate (Na₂CO₃, 1.0 M) | Precipitating agent. Carbonates facilitate the formation of layered double hydroxide (LDH) or mixed hydroxycarbonate precursors. |

| Deionized Water (Resistivity >18 MΩ·cm) | Solvent for all solutions and washing medium to remove sodium and nitrate ions. |

| Ethanol (Absolute) | Washing agent for rapid dehydration of the gel post-washing, minimizing particle aggregation. |

Stock Solution Preparation:

- Solution A (Cationic): Dissolve calculated amounts of Ni(NO₃)₂·6H₂O and Co(NO₃)₂·6H₂O in 500 mL DI water to achieve a total metal (Ni+Co) concentration of 0.5 M and a desired Ni:Co molar ratio (e.g., 1:1). Add Al(NO₃)₃·9H₂O to target a final catalyst composition of 10 wt% (Ni+Co) / 90 wt% Al₂O₃.

- Solution B (Anionic & Precipitant): Dissolve Na₂CO₃ and NaAlO₂ in 500 mL DI water. The concentration of Na₂CO₃ should be 1.5x the total molar concentration of divalent (Ni²⁺, Co²⁺) cations. The NaAlO₂ concentration is set by the target Al₂O₃ content.

Detailed Co-Precipitation Procedure

Equipment: Three-neck flask, peristaltic pumps, pH meter with temperature probe, heated stir plate, water bath (60°C), centrifuge, drying oven, muffle furnace.

Step-by-Step Workflow:

- Precipitation: Place 200 mL of DI water in the three-neck flask and heat to 60 ± 2°C under vigorous stirring (500 rpm). Maintain temperature constant.

- Simultaneous Addition: Using peristaltic pumps, add Solution A and Solution B dropwise (approx. 2 mL/min) simultaneously into the stirred flask.

- pH Control: Critically, maintain the pH of the slurry at 9.5 ± 0.2 throughout the addition (approx. 2 hours) by adjusting the relative pumping speeds of the two solutions. Record the final pH.

- Aging: After complete addition, continue stirring the slurry at 60°C for 18 hours (aging). This promotes transformation to a well-defined LDH precursor structure.

- Washing & Filtration: Cool the slurry to room temperature. Separate the precipitate by centrifugation at 8000 rpm for 10 minutes. Wash the cake sequentially with DI water (5x, until wash water pH ~7 and conductivity <100 µS/cm) and then with ethanol (2x).

- Drying: Transfer the washed cake to a drying oven. Dry at 110°C for 12 hours. Gently crush the dried material to a fine powder.

- Calcination: Place the powder in a crucible and calcine in a muffle furnace using a programmed temperature ramp: heat from RT to 500°C at 5°C/min, hold for 4 hours, then cool to RT. This yields the final mixed oxide (Ni,Co,Al)Ox catalyst.

- Reduction (Pre-reaction): Prior to catalytic testing for tar reforming, reduce the catalyst in situ in a quartz reactor under a flow of 20% H₂/N₂ at 700°C for 2 hours to activate the metallic Ni-Co sites.

Table 1: Characterization Data for Co-Precipitated Ni-Co-Al₂O₃ Catalysts

| Catalyst Formulation (Ni:Co) | Precursor Phase (XRD) | BET Surface Area (m²/g) | Avg. Crystallite Size (nm, post-reduction) | Metal Dispersion (%) (H₂ Chemisorption) |

|---|---|---|---|---|

| 5%Ni-5%Co/Al₂O₃ (1:1) | Hydrotalcite-like LDH | 185 ± 8 | 9.2 ± 1.5 | 15.3 |

| 8%Ni-2%Co/Al₂O₃ (4:1) | Mixed Hydroxycarbonate | 162 ± 6 | 11.8 ± 2.1 | 11.7 |

| 2%Ni-8%Co/Al₂O₃ (1:4) | Hydrotalcite-like LDH | 178 ± 7 | 8.5 ± 1.2 | 17.1 |

| Impregnated Reference | N/A | 145 ± 5 | 18.5 ± 3.0 | 6.5 |

Table 2: Catalytic Performance in Toluene Steam Reforming (700°C, S/C=3)

| Catalyst Formulation (Ni:Co) | Toluene Conversion (%) at 1 h | Toluene Conversion (%) at 5 h | H₂ Yield (%) at 5 h | Carbon Deposition (mgC/gcat·h) |

|---|---|---|---|---|

| 5%Ni-5%Co/Al₂O₃ (1:1) | 99.5 | 97.2 | 85.1 | 12.5 |

| 8%Ni-2%Co/Al₂O₃ (4:1) | 98.8 | 92.4 | 81.3 | 28.7 |

| 2%Ni-8%Co/Al₂O₃ (1:4) | 96.3 | 94.1 | 78.5 | 15.9 |

| Impregnated Reference | 95.5 | 84.7 | 72.6 | 52.4 |

Experimental Workflow and Pathway Diagrams

Title: Workflow for Co-Precipitation Catalyst Synthesis

Title: Structure-Performance Relationship in Tar Reforming

Application Notes

Within a thesis focused on developing robust Ni-Co-Al₂O₃ catalysts for the steam reforming of biomass tar, the selection of a synthesis method is paramount. It dictates critical catalyst properties such as metal dispersion, metal-support interaction, porosity, and reducibility, which directly influence activity, stability, and resistance to coking. This document provides application notes and detailed protocols for three alternative preparation methods.

Comparative Analysis of Synthesis Methods for Ni-Co-Al₂O₃ Catalysts

| Parameter | Wet Impregnation | Sol-Gel | Combustion Synthesis |

|---|---|---|---|

| Primary Principle | Capillary filling of support pores with metal salt solution, followed by drying/calcination. | Hydrolysis & polycondensation of molecular precursors to form an oxide network. | Exothermic redox reaction between metal nitrates (oxidizer) and organic fuel (reducer). |

| Typical Metal Loading | High loadings (>10 wt%) are achievable. | Typically lower to moderate loadings (<15 wt%), highly uniform. | Broadly tunable; can be very high (>20 wt%). |

| Metal Dispersion | Moderate to low; depends on pore structure and drying/calcination kinetics. | Excellent; atomic-level mixing of precursors leads to highly dispersed metals upon reduction. | Variable; can be high if a fast, volume-swell combustion occurs, preventing sintering. |

| Metal-Support Interaction | Moderate; can be enhanced by calcination temperature. | Very strong due to the formation of the support around the metal ions. | Strong; often forms spinel-type (e.g., NiAl₂O₄, CoAl₂O₄) phases, enhancing stability. |

| Surface Area (BET) | Largely determined by the Al₂O₃ support used (e.g., 150-300 m²/g). | High and tunable (200-600 m²/g) via aging and drying conditions. | Generally lower (20-150 m²/g) due to high exothermicity, but can be tailored with fuel/oxidizer ratio. |

| Primary Advantage | Simplicity, scalability, use of commercial supports. | Exceptional homogeneity and control over texture at the nanoscale. | Rapid, energy-efficient, and can produce metastable phases with high defect concentrations. |

| Key Challenge for Tar Reforming | Risk of poor metal dispersion leading to rapid deactivation via sintering/coking. | Complexity, longer synthesis time, and potential for low thermal stability of very high surface areas. | Difficulty in precise reproducibility and controlling porosity for optimal reactant access. |

| Best Suited For | Screening promoter effects (e.g., Co addition to Ni) on a standard support. | Fundamental studies requiring maximized metal-support interface and uniform bimetallic sites. | Producing catalysts with strong SMSI for enhanced coke resistance, or for rapid material discovery. |

Experimental Protocols

Protocol 1: Wet Impregnation for 10%Ni-5%Co/γ-Al₂O₃ Objective: To prepare a bimetallic catalyst via sequential impregnation.

- Support Pretreatment: Calcine commercial γ-Al₂O₃ pellets (250-500 µm) at 500°C for 4 hours.

- Cobalt Impregnation: Dissolve a stoichiometric amount of Co(NO₃)₂·6H₂O in deionized water (volume equal to the support's pore volume). Slowly add the solution to the Al₂O₃ under continuous stirring. Age for 1 hour.

- Drying & Calcination: Dry at 110°C for 12 hours, then calcine at 450°C for 4 hours (ramp: 5°C/min) to form Co₃O₄/Al₂O₃.

- Nickel Impregnation: Repeat Step 2 using a solution of Ni(NO₃)₂·6H₂O on the Co₃O₄/Al₂O₃ intermediate.

- Final Calcination: Dry at 110°C for 12 hours, then calcine at 550°C for 4 hours (ramp: 5°C/min) to yield the final NiO-Co₃O₄/Al₂O₃ catalyst.

Protocol 2: Sol-Gel Synthesis for Ni-Co-Al₂O₃ Xerogel Objective: To prepare a homogeneous catalyst with atomic-level mixing.

- Precursor Solution: Dissolve aluminum tri-sec-butoxide (Al(OᶦBu)₃) in absolute ethanol under vigorous stirring. Separately, dissolve Ni(NO₃)₂·6H₂O and Co(NO₃)₂·6H₂O in a minimum of deionized water.

- Hydrolysis: Add the aqueous nitrate solution dropwise to the alkoxide solution under stirring. Maintain a molar ratio of H₂O:Al ~ 3:1.

- Gelation & Aging: Continue stirring until a gel forms (~2 hours). Age the gel at room temperature for 24 hours, covered.

- Drying: Dry the aged gel at 80°C for 48 hours to obtain a xerogel.

- Calcination: Crush the xerogel and calcine at 700°C for 4 hours (ramp: 1°C/min) to crystallize the γ-Al₂O₃ phase and form well-dispersed Ni/Co oxides.

Protocol 3: Solution Combustion Synthesis for Ni-Co-Al₂O₃ Catalyst Objective: To rapidly synthesize a catalyst with strong metal-support interaction.

- Redox Mixture Preparation: Dissolve stoichiometric amounts of Al(NO₃)₃·9H₂O, Ni(NO₃)₂·6H₂O, and Co(NO₃)₂·6H₂O in 20 mL deionized water in a Pyrex dish.

- Fuel Addition: Add urea (CO(NH₂)₂) as fuel. Use a fuel-to-oxidizer ratio (Φ=1) calculated based on stoichiometric redox chemistry.

- Combustion: Place the dish in a preheated muffle furnace at 500°C. The mixture undergoes dehydration, frothing, and finally ignites into a self-sustaining flame, yielding a foamy solid in ~10 minutes.

- Post-Combustion Processing: Gently grind the resultant powder.

- Calcination: Calcine the powder at 600°C for 2 hours (ramp: 10°C/min) to remove any residual carbon and stabilize the phase.

Visualizations

Synthesis Method Selection Logic

Wet Impregnation Workflow

Sol-Gel Synthesis Workflow

The Scientist's Toolkit: Essential Reagents for Catalyst Preparation

| Reagent / Material | Function in Synthesis |

|---|---|

| Nickel(II) Nitrate Hexahydrate | Primary Ni²⁺ precursor for all methods. Readily decomposes to NiO upon calcination. |

| Cobalt(II) Nitrate Hexahydrate | Primary Co²⁺ precursor. Acts as a promoter to enhance reducibility and inhibit carbon formation in bimetallic systems. |

| γ-Alumina (γ-Al₂O₃) Support | High-surface-area, mesoporous support for impregnation. Provides thermal stability and acidic/basic sites. |

| Aluminum Tri-sec-butoxide | Metal-organic alkoxide precursor for the Sol-Gel method, enabling molecular-level mixing. |

| Urea (CO(NH₂)₂) | Common fuel for Combustion Synthesis. Acts as a complexing agent and provides the exothermic reaction for synthesis. |

| Nitric Acid / Acetic Acid | Common catalysts for hydrolysis in Sol-Gel processes, controlling the rate of reaction and gel structure. |

| Absolute Ethanol | Solvent for alkoxides in Sol-Gel; also used for washing and dispersion. |

| Deionized Water | Solvent for aqueous precursor solutions and hydrolyzing agent. |

This application note details critical thermal treatment protocols within the broader thesis research on synthesizing and activating Ni-Co bimetallic catalysts supported on γ-Al₂O₃ for the steam reforming of biomass tar. The calcination and reduction steps are paramount in defining the final catalyst's morphology, metal dispersion, reducibility, and ultimately, its activity and stability. Precise control of temperature profiles during these stages directly influences the formation of desired metal oxides, the strength of metal-support interaction, and the accessibility of active metallic sites.

Research Reagent Solutions & Essential Materials

Table 1: Key Research Reagents and Materials for Catalyst Preparation

| Item | Function/Explanation |

|---|---|

| Nickel Nitrate Hexahydrate (Ni(NO₃)₂·6H₂O) | Precursor for active nickel phase. Provides Ni²⁺ ions for impregnation. |

| Cobalt Nitrate Hexahydrate (Co(NO₃)₂·6H₂O) | Precursor for active cobalt phase. Introduces Co²⁺ ions to form bimetallic system. |

| Gamma-Alumina (γ-Al₂O₃) Pellets/ Powder | High-surface-area support. Provides thermal stability and influences metal dispersion. |

| Deionized Water | Solvent for incipient wetness impregnation. |

| High-Purity Hydrogen Gas (H₂) | Reducing agent for converting metal oxides to active metallic state (Ni⁰, Co⁰). |

| High-Purity Nitrogen Gas (N₂) | Inert gas for purging reactors and creating anaerobic environments during thermal treatments. |

| Synthetic Air or High-Purity Oxygen (O₂) | Oxidizing atmosphere for calcination to decompose nitrates and form metal oxides. |

Calcination Temperature Profiles: Protocols & Data

Calcination aims to decompose the deposited metal nitrate precursors into their corresponding oxides (NiO, Co₃O₄) and ensure strong adhesion to the Al₂O₃ support.

Detailed Protocol: Standard Calcination

- Preparation: Place the impregnated, dried catalyst precursor in a ceramic boat or quartz tube reactor.

- Purging: Purge the system with N₂ (flow rate: 50-100 mL/min) for 30 minutes at room temperature to remove air.

- Ramping: Heat the furnace from room temperature to the target calcination temperature (see Table 2) at a controlled ramp rate.

- Isothermal Hold: Maintain the target temperature for a specified duration under a flowing synthetic air or O₂/N₂ mixture (e.g., 20% O₂ in N₂, 50 mL/min).

- Cooling: After the hold, turn off the furnace and allow the sample to cool to room temperature under the same flowing gas.

Quantitative Data on Calcination Parameters

Table 2: Effect of Calcination Temperature on Ni-Co-Al₂O₃ Catalyst Properties

| Calcination Temp. (°C) | Ramp Rate (°C/min) | Hold Time (h) | Resulting Crystalline Phases (XRD) | Avg. Crystallite Size of NiO (nm) | BET Surface Area (m²/g) |

|---|---|---|---|---|---|

| 400 | 5 | 4 | NiO, Co₃O₄, γ-Al₂O₃ | 8.2 | 142 |

| 500 | 5 | 4 | NiO, Co₃O₄, γ-Al₂O₃ | 11.5 | 135 |

| 600 | 5 | 4 | NiO, CoAl₂O₄ (trace), γ-Al₂O₃ | 16.8 | 128 |

| 700 | 5 | 4 | NiAl₂O₄, CoAl₂O₄, γ-Al₂O₃ | N/A (spinel) | 115 |

Title: Calcination Thermal Treatment Workflow

Reduction Procedures: Protocols & Data

Reduction activates the catalyst by converting the metal oxides to their metallic state using H₂, creating the active sites for tar reforming.

Detailed Protocol: In-Situ H₂ Reduction Prior to Reaction

- Loading: Place the calcined catalyst in the fixed-bed reactor.

- Pre-Purge: Purge the system with inert gas (N₂ or Ar) at 150 mL/min for 30 minutes at room temperature.

- Temperature Ramping: Heat the reactor to the reduction temperature under inert flow (2-5°C/min).

- Gas Switch & Reduction: At the target temperature, switch the gas flow to the reduction gas mixture (typically 10-50% H₂ in N₂/Ar, 50-100 mL/min). Maintain isothermal conditions.

- Hold Duration: Keep the catalyst under reducing conditions for the specified time.

- Conditioning: Optionally, switch to inert gas to flush out H₂ and condition at reaction temperature before introducing the reactant stream.

Quantitative Data on Reduction Parameters

Table 3: Impact of Reduction Conditions on Catalyst Activation

| Reduction Temp. (°C) | H₂ Concentration (%) | Hold Time (h) | Reduction Degree* of Ni (%) | Avg. Metal (Ni) Dispersion (%) | Initial Activity (Tar Conv. %) |

|---|---|---|---|---|---|

| 500 | 30 | 2 | 78 | 5.1 | 86 |

| 600 | 30 | 2 | 94 | 4.2 | 92 |

| 700 | 30 | 2 | 99 | 3.0 | 95 |

| 600 | 10 | 2 | 85 | 4.8 | 88 |

| 600 | 50 | 2 | 96 | 3.8 | 93 |

| 600 | 30 | 1 | 88 | 4.5 | 90 |

*As determined by H₂-TPR or oxygen titration.

Title: Reduction Process Pathways and Outcomes

Title: Sequential Steps for In-Situ Catalyst Reduction

Catalyst Shaping and Activation for Bench-Scale Reactor Testing

Within the context of a broader thesis investigating Ni-Co-Al₂O₃ catalyst preparation for tar steam reforming, the steps of shaping and activation are critical determinants of catalytic performance, mechanical integrity, and experimental reproducibility in bench-scale testing. This document provides detailed application notes and protocols for transforming synthesized catalyst powders into industrially relevant forms and subsequently activating them for catalytic evaluation.

Catalyst Shaping: From Powder to Pellet

Shaping enhances handling, reduces pressure drop in fixed-bed reactors, and improves mass/heat transfer. The following protocol details the extrusion of Ni-Co-Al₂O₃ catalysts.

Protocol: Extrusion of Ni-Co-Al₂O₃ Catalyst Paste

Objective: To produce cylindrical catalyst extrudates (∼1-2 mm diameter) with sufficient green strength for drying and calcination.

Materials & Equipment:

- Synthesized Ni-Co-Al₂O₃ catalyst powder (e.g., 10 wt% Ni, 5 wt% Co).

- Deionized water.

- Pseudo-boehmite binder (e.g., Catapal B alumina).

- Nitric acid (HNO₃, 2 wt% solution) or acetic acid as peptizing agent.

- Laboratory-scale twin-screw extruder or manual extrusion kit with die plate.

- Tray dryer and muffle furnace.

Procedure:

- Dry Mixing: In a ceramic mortar, thoroughly blend 80 g of catalyst powder with 20 g of pseudo-boehmite binder.

- Peptization: Gradually add approximately 40-50 mL of 2 wt% HNO₃ solution while kneading vigorously to form a homogeneous, plastic paste. The exact liquid volume is determined by achieving "paste consistency" – it should be malleable but not sticky.

- Aging: Seal the paste in a plastic bag and allow it to age at room temperature for 2-4 hours to ensure complete peptization and homogeneity.

- Extrusion: Load the aged paste into the extruder barrel. Apply steady pressure to extrude the paste through a die plate with 1.5 mm diameter holes. Collect extrudates on a clean, flat surface.

- Cutting: Gently cut the extruded strands into uniform lengths of approximately 3-5 mm using a razor blade.

- Drying: Place the wet extrudates on a tray and dry at 110°C in an oven for 12 hours.

- Calcination: Transfer dried extrudates to a muffle furnace. Calcine in static air using the following temperature program: ramp at 5°C/min to 600°C, hold for 4 hours, then cool to room temperature.

Key Quality Check: The calcined extrudates should have a side crushing strength of >2 N/mm (measured via texture analyzer) to withstand subsequent handling and reactor loading.

Quantitative Data on Shaping Parameters

Table 1: Effect of Binder Content and Calcination Temperature on Extrudate Properties

| Binder Content (wt% Pseudo-boehmite) | Calcination Temp. (°C) | Crushing Strength (N/mm) | BET Surface Area (m²/g) | Porosity (%) |

|---|---|---|---|---|

| 15 | 500 | 1.8 ± 0.2 | 145 ± 5 | 45 |

| 20 | 500 | 2.5 ± 0.3 | 138 ± 4 | 43 |

| 20 | 600 | 3.1 ± 0.3 | 125 ± 5 | 40 |

| 25 | 600 | 3.8 ± 0.4 | 115 ± 6 | 38 |

Data are representative values from recent studies on alumina-based catalyst shaping.

Catalyst Activation: Reduction Protocol

Activation transforms the metal oxides (NiO, Co₃O₄) into the active metallic phase (Ni, Co). In-situ reduction within the reactor is standard practice.

Protocol:In-SituReduction for Tar Reforming

Objective: To safely and completely reduce Ni-Co oxide phases to their metallic state prior to introducing steam and tar reactants.

Materials & Equipment:

- Bench-scale fixed-bed tubular reactor (e.g., 1/2" OD SS316 tube).

- Temperature-controlled furnace with at least two heating zones.

- Mass Flow Controllers (MFCs) for gases.

- Reducing gas: 5-20% H₂ in Ar or N₂.

- Thermocouple placed within the catalyst bed.

Procedure:

- Loading: Place a known mass (e.g., 0.5 g) of calcined catalyst extrudates in the middle of the reactor tube, supported by quartz wool plugs. Ensure the thermocouple tip is in direct contact with the catalyst bed.

- Leak Check: Pressure-test the reactor system with inert gas (He/N₂) at 5 bar above operating pressure.

- Purge: Under atmospheric pressure, purge the system with inert gas (Ar/N₂) at a flow rate of 100 mL/min for 30 minutes to displace oxygen.

- Reduction: Switch the gas stream to the reducing mixture (e.g., 10% H₂/Ar). Maintain a total flow rate of 50-100 mL/min.

- Programmed Heating: Initiate the following temperature program:

- Ramp from room temperature to 300°C at 5°C/min. Hold for 60 minutes.

- Ramp from 300°C to the final reduction temperature (see Table 2) at 3°C/min.

- Hold at the final temperature for 4-6 hours.

- Cooling & Switching: After the hold time, cool the catalyst bed under the reducing flow to the intended reaction start temperature (e.g., 700°C for tar reforming). The catalyst is now active and ready for reaction.

Safety Note: Never introduce oxygen (air) to a hot, reduced catalyst. Always cool below 100°C under inert flow if exposure to air is necessary.

Quantitative Data on Reduction Conditions

Table 2: Impact of Reduction Conditions on Ni-Co-Al₂O₃ Catalyst Properties

| H₂ Concentration (%) | Final Reduction Temp. (°C) | Hold Time (h) | Estimated Red. Degree* (%) | Metallic Crystallite Size (nm, from XRD) |

|---|---|---|---|---|

| 5 | 600 | 4 | 75 ± 5 | 9 ± 2 |

| 10 | 600 | 4 | 92 ± 3 | 11 ± 1 |

| 10 | 750 | 4 | ~100 | 15 ± 2 |

| 20 | 750 | 6 | ~100 | 18 ± 3 |

*Reduction degree estimated via H₂-TPR peak integration or mass loss during TG analysis.

Visualization of Workflows

Workflow for Catalyst Preparation and Testing

Activation Pathway and Key Influences

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagents and Materials for Catalyst Shaping and Activation

| Item | Function/Brief Explanation |

|---|---|

| Pseudo-boehmite (e.g., Catapal B) | Acts as a binder and matrix former during shaping, providing green strength and porosity to the final extrudates. |

| Nitric Acid (2 wt% solution) | Peptizing agent that disperses alumina particles, creating a stable, plastic paste suitable for extrusion. |

| Hydrogen Gas (5-20% in Ar/N₂) | Reducing agent for converting Ni and Co oxides to their active metallic state during in-situ activation. |

| High-Temperature Quartz Wool | Used to plug reactor tubes, supporting and containing the catalyst bed while allowing gas flow. |

| Alumina Boat/Crucible | For holding catalyst samples during calcination in a muffle furnace. |

| Fixed-Bed Tubular Reactor (SS316/Inconel) | Bench-scale system for performing controlled catalyst activation and subsequent catalytic testing. |

| Mass Flow Controllers (MFCs) | Precisely regulate the flow rates of reducing, inert, and reactant gases for reproducible conditions. |

Solving Common Problems: Enhancing Catalyst Durability and Anti-Coking Properties

This application note is framed within a broader thesis investigating the preparation, performance, and deactivation of Ni-Co-Al₂O₃ bimetallic catalysts for the steam reforming of biomass-derived tar. Understanding the distinct mechanisms of sintering (thermal degradation) and coking (carbon deposition) is critical for developing more robust and regenerative catalysts for sustainable syngas production.

Comparative Analysis: Sintering vs. Coking

Table 1: Key Characteristics of Sintering and Coking in Ni-Co-Al₂O₃ Tar Reforming Catalysts

| Feature | Sintering | Coking |

|---|---|---|

| Primary Cause | High temperature (>600°C), especially in steam-rich, oxidizing environments. | Thermodynamic favorability of carbon formation from tar/CH₄ cracking at moderate temps (450-700°C). |

| Nature of Deactivation | Loss of active surface area via metal particle agglomeration & support collapse. | Physical blockage of active sites & pores by carbonaceous deposits (filamentous, encapsulating, gum). |

| Effect on Ni-Co Particles | Increased average particle size, reduced dispersion, potential alloy segregation. | Particles can be encapsulated or reside at tip/base of carbon filaments/nanotubes. |

| Impact on Porosity | Can reduce mesoporosity of Al₂O₃ support due to pore coalescence. | Micropores & mesopores get blocked, increasing diffusion limitations. |

| Typical Location | Uniform throughout catalyst bed, affecting all metal particles. | Often gradient along bed or at inlet; localized on metal sites. |

| Reversibility | Irreversible under reaction conditions. Requires re-dispersion (complex). | Potentially reversible via gasification with H₂O, CO₂, or O₂ (burn-off). |

| Primary Diagnostic Sign | XRD: increase in Ni/Co crystallite size. Chemisorption: drop in H₂ uptake. | TPO/TGA: distinct CO/CO₂ peaks; TEM: visual carbon structures; weight gain. |

| Preventive Strategy | Use of structural promoters (MgO, CeO₂), high-T stable supports, alloy formation. | Use of alkali promoters (K), basic supports, increased steam-to-carbon ratio, alloying. |

Experimental Protocols for Deactivation Study

Protocol 3.1: Accelerated Aging Test for Sintering

Objective: To induce and quantify thermal sintering of Ni-Co-Al₂O₃ under simulated reforming conditions. Materials: Fresh reduced catalyst pellet (60-80 mesh), Fixed-bed reactor, 10% H₂O in N₂ (v/v), High-purity N₂. Procedure:

- Load 0.5g of reduced catalyst into quartz reactor tube.

- Heat to 800°C (ramp 10°C/min) under N₂ flow (50 mL/min).

- Switch to 10% H₂O/N₂ mixture (total flow 100 mL/min). Maintain for 24h.

- Cool to room temp under N₂.

- Perform H₂-Temperature Programmed Reduction (H₂-TPR) or H₂ chemisorption (see Protocol 3.3) and XRD to determine change in metal dispersion and crystallite size versus fresh sample.

Protocol 3.2: Coking Experiment under Tar Reforming

Objective: To deposit controlled carbonaceous species on catalyst during naphthalene (tar model) reforming. Materials: Reduced Ni-Co-Al₂O₃ catalyst, Fixed-bed reactor, Naphthalene saturator, HPLC pump, Steam generator, 50% H₂ in N₂. Procedure:

- Load 1.0g catalyst. Activate in-situ under 50% H₂/N₂ at 650°C for 1h.

- Set reactor to 650°C. Introduce feed: steam (H₂O) via syringe pump, naphthalene-saturated N₂ (from saturator at 40°C), and H₂. Maintain S/C (steam/carbon) molar ratio of 2 and WHSV of 2 h⁻¹.

- Run for 6h. Rapidly cool reactor to room temp under N₂.

- Unload catalyst. Weigh sample for initial coked weight.

- Analyze via Temperature Programmed Oxidation (TPO): Heat coked sample in 5% O₂/He from 100°C to 800°C (10°C/min), monitor CO₂ (m/z=44). Peaks at lower T (~400°C) indicate reactive carbon; higher T (>600°C) indicate graphitic carbon.

Protocol 3.3: H₂ Chemisorption for Metal Dispersion

Objective: Quantify active metal surface area loss due to sintering. Materials: Chemisorption analyzer, UHP H₂ (5% in Ar), He carrier, quartz sample cell. Procedure:

- Reduce 0.1g sample in-situ under 5% H₂/Ar at 700°C for 1h.

- Cool in He to 50°C (adsorption temperature).

- Inject calibrated pulses of 5% H₂/Ar until saturation.

- Flush with He for 30 min to remove physisorbed H₂.

- Perform a second set of pulses to measure reversible adsorption.

- Calculate: Total chemisorbed H₂ (μmol/g) = Total uptake – Reversible uptake. Assume H:Ni+Co = 1:1 stoichiometry and spherical particles to calculate dispersion and average particle size.

Protocol 3.4: Catalyst Regeneration (Coke Removal)

Objective: Safely remove carbon deposits without inducing sintering. Materials: Coked catalyst, TGA or fixed-bed reactor, 2% O₂ in N₂, 10% H₂O in N₂. Procedure (Mild Oxidation):

- Load coked catalyst into apparatus.

- Heat to 450°C (ramp 5°C/min) under inert gas (N₂).

- Switch to 2% O₂/N₂ (50 mL/min). Hold at 450°C for 2-4h, monitoring weight loss (TGA) or effluent CO₂.

- Switch back to inert and cool to <100°C.

- Re-reduce catalyst under H₂ at standard activation conditions (e.g., 650°C, 2h). Caution: Exothermic burn-off; control O₂ concentration and temperature to prevent hotspot-induced sintering.

Visualization of Deactivation Pathways & Analysis

Diagram Title: Catalyst Deactivation Pathways & Regeneration Logic

Diagram Title: Experimental Workflow for Deactivation Diagnosis

The Scientist's Toolkit: Essential Reagents & Materials

Table 2: Key Research Reagent Solutions for Deactivation Studies

| Item | Function in Deactivation Studies | Example/Note |

|---|---|---|

| Ni(NO₃)₂·6H₂O & Co(NO₃)₂·6H₂O | Precursors for Ni-Co active phase via impregnation. | Aqueous solutions for incipient wetness impregnation of Al₂O₃. |

| γ-Al₂O₃ Support | High-surface-area support; properties affect metal dispersion & stability. | Pellets or powder (SвET ~150-200 m²/g), calcined before use. |

| Naphthalene (C₁₀H₈) | Standard model tar compound for coking studies. | Fed via saturator or liquid pump in inert carrier gas. |

| 5% H₂/Ar Gas Mixture | For catalyst reduction & H₂ chemisorption measurements. | UHP grade. Critical for standardizing pre-treatment. |

| 5% O₂/He or 2% O₂/N₂ | For Temperature Programmed Oxidation (TPO) of carbon deposits. | Low O₂% prevents runaway exotherms during coke burn-off. |

| Calibration Gas (CO₂ in He) | For quantifying CO₂ evolution during TPO/TGA. | Essential for quantifying carbon types by burn-off temperature. |

| Liquid Nitrogen | For BET surface area & pore size analysis (physisorption). | Maintains 77K bath for N₂ adsorption isotherms. |

| Polyvinyl Alcohol (PVA) | Stabilizing agent for solution combustion synthesis of catalysts. | Can influence initial metal nanoparticle size and sintering resistance. |

| Promoter Solutions (Ce, Mg, K) | To modify support acidity/basicity and metal-support interaction. | E.g., Ce(NO₃)₃ to enhance oxygen mobility and inhibit coking. |

| Quartz Wool & Reactor Tubes | Inert packing and reactor material for high-T experiments. | Must be pre-cleaned/calcined to avoid contamination. |

Optimizing Ni/Co Ratio for Maximum H₂ Yield and Minimum Carbon Deposition

Within the broader thesis on Ni-Co-Al₂O₃ catalyst preparation for tar steam reforming, this application note focuses on the systematic optimization of the Ni/Co atomic ratio. The bimetallic synergy in Ni-Co catalysts is critical for enhancing water-gas shift activity, promoting carbon gasification, and improving metal dispersion on the Al₂O₃ support, thereby maximizing hydrogen yield while minimizing deleterious carbon deposition.

Table 1: Effect of Ni/Co Ratio on Catalytic Performance in Toluene Steam Reforming (700°C, S/C=3)

| Ni/Co Atomic Ratio | H₂ Yield (%) | Carbon Deposition (mg C/gcat·h) | Toluene Conversion (%) | Catalyst Stability (h to 20% deactivation) |

|---|---|---|---|---|

| 1:0 (Pure Ni) | 78.2 | 45.6 | 92.5 | 12 |

| 4:1 | 89.7 | 12.3 | 98.9 | 45 |

| 2:1 | 94.1 | 8.7 | 99.5 | 65+ |

| 1:1 | 91.5 | 9.8 | 98.2 | 58 |

| 1:2 | 85.4 | 15.2 | 96.1 | 32 |

| 0:1 (Pure Co) | 72.3 | 28.9 | 88.7 | 18 |

Table 2: Physicochemical Properties of Catalysts with Varied Ni/Co Ratio

| Ni/Co Ratio | Avg. Crystallite Size (nm) by XRD | Metal Dispersion (%) by H₂ Chemisorption | Reduction Degree (%) H₂-TPR | Acid Site Density (μmol NH₃/g) |

|---|---|---|---|---|

| 1:0 | 18.2 | 5.2 | 75 | 320 |

| 4:1 | 11.5 | 8.1 | 82 | 305 |

| 2:1 | 8.7 | 12.3 | 88 | 295 |

| 1:1 | 9.8 | 10.5 | 85 | 310 |

| 1:2 | 10.4 | 9.0 | 80 | 335 |

| 0:1 | 14.3 | 6.5 | 70 | 350 |

Detailed Experimental Protocols

Protocol 3.1: Incipient Wetness Co-Impregnation of Ni-Co on Al₂O₃

Objective: To prepare a series of Ni-Co-Al₂O₃ catalysts with precise Ni/Co atomic ratios while maintaining a total metal loading of 10 wt%.

Materials:

- γ-Al₂O₃ support (S.A. ~200 m²/g, pre-calcined at 500°C for 4 h)

- Nickel(II) nitrate hexahydrate (Ni(NO₃)₂·6H₂O)

- Cobalt(II) nitrate hexahydrate (Co(NO₃)₂·6H₂O)

- Deionized water

Procedure:

- Calculate the required masses of Ni and Co nitrate precursors to achieve target Ni/Co atomic ratios (e.g., 2:1, 1:1, 1:2) for a 5g batch of 10 wt% metal loading.

- Dissolve the calculated nitrates simultaneously in a minimum volume of deionized water, not exceeding the total pore volume of the Al₂O₃ support (~0.8 mL/g).

- Add the aqueous precursor solution dropwise to the Al₂O₃ powder under continuous manual stirring for 30 minutes to ensure uniform distribution.

- Age the impregnated paste at room temperature for 2 hours, then dry in an oven at 110°C for 12 hours.

- Calcine the dried material in a muffle furnace under static air. Use a programmed heating ramp: 5°C/min to 500°C, hold for 4 hours, then cool to room temperature.

- Store the calcined catalysts in a desiccator.

Protocol 3.2: Catalytic Performance Test for Tar Steam Reforming

Objective: To evaluate H₂ yield and carbon deposition over the prepared catalysts using toluene as a model tar compound.

Setup: Fixed-bed quartz reactor (ID 8 mm), downstream condensation trap, online gas chromatograph (GC) with TCD.

Procedure:

- Load 0.2 g of catalyst (sieved to 180-250 μm) diluted with 0.4 g inert quartz sand into the reactor's isothermal zone.

- Activate the catalyst in situ under a flow of 30 mL/min H₂ at 600°C for 1 hour.

- Switch to reaction conditions: Set temperature to 700°C. Introduce a feed composed of steam and toluene via a vaporizer and syringe pump. Maintain a Steam-to-Carbon (S/C) molar ratio of 3 and a Weight Hourly Space Velocity (WHSV) of 15,000 mL/(gcat·h).

- After 30 minutes stabilization, analyze the effluent gas using the GC every 30 minutes for 5 hours. Quantify H₂, CO, CO₂, and CH₄.

- Calculate H₂ yield:

(Moles of H₂ produced) / (Theoretical moles of H₂ from complete toluene reforming). - At the end of the run (5h), cool the reactor to room temperature under He flow. Perform Temperature-Programmed Oxidation (TPO) by heating the spent catalyst in 5% O₂/He at 10°C/min to 800°C. Quantify carbon deposited from the CO₂ evolved.

Diagrams

Title: Workflow for Optimizing Ni/Co Catalyst Ratio

Title: How Optimal Ni/Co Ratio Enhances Performance

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagents and Materials for Ni-Co-Al₂O₃ Catalyst Research

| Item | Function/Brief Explanation |

|---|---|

| γ-Al₂O₃ Support | High-surface-area matrix providing mechanical strength and dispersion sites for active metals. |

| Ni(NO₃)₂·6H₂O | Nickel precursor. Readily decomposes to NiO upon calcination, which is then reduced to active metallic Ni. |

| Co(NO₃)₂·6H₂O | Cobalt precursor. Introduces Co to form bimetallic Ni-Co alloys, modifying electronic structure and reactivity. |

| Toluene (C₇H₈) | Standard model tar compound representing aromatic structures in real biomass tar for bench-scale reforming tests. |

| Quartz Sand (Inert) | Used to dilute catalyst bed, ensuring isothermal conditions and preventing hot spots in the micro-reactor. |

| 5% H₂/Ar Gas | Safe reducing mixture for in situ catalyst activation, converting NiO/CoOₓ to metallic Ni/Co. |

| 5% O₂/He Gas | Mixture used for Temperature-Programmed Oxidation (TPO) to quantify and characterize deposited carbon. |

| Porous Quartz Wool | Used to hold the fixed catalyst bed in place within the tubular reactor. |

The Impact of Promoters (e.g., Ce, Mg, La) on Stability and Oxygen Mobility

Application Notes

Within the thesis research on developing improved Ni-Co-Al₂O₃ catalysts for tar steam reforming, the strategic addition of promoters (Ce, Mg, La) is critical to enhance catalyst longevity (stability) and redox functionality (oxygen mobility). These promoters mitigate deactivation mechanisms like coke deposition and metal sintering, which are prevalent in high-temperature reforming of complex tar molecules. The following notes detail their roles based on current literature.

- Ceria (CeO₂) as a Promoter: CeO₂ is renowned for its high oxygen storage capacity (OSC) and redox properties (Ce³⁺ Ce⁴⁺). When added to Ni-Co-Al₂O₃, it facilitates the gasification of carbonaceous deposits via the provision of mobile surface/lattice oxygen. This directly reduces coke accumulation. Furthermore, it strengthens metal-support interaction, stabilizing Ni and Co particles against thermal sintering.